Академический Документы

Профессиональный Документы

Культура Документы

W G ® An Revolution in Knit PR and Distribution: Hole Arment

Загружено:

Awais ImranОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

W G ® An Revolution in Knit PR and Distribution: Hole Arment

Загружено:

Awais ImranАвторское право:

Доступные форматы

Solutions

WholeGarment ® an ・ Product planning must begin early

due to time spent on sample-

・ Time, cost and material are

required for repeated production

・ Production volume is based

on best guess, with constant

・ Knitted parts require time and

cost for sewing.

・ Conservative inventory

management fearing

・ Aggressive inventory

management may lead to leftover

Revolution in Knit Pr

making. of actual samples. inventory risk. inventory risk, may lead inventory and reduced profits

・ Sewing is based on individual to lost opportunity due to due to discounting.

and Distribution

skill levels, and therefore depleted stock.

quality is inconsistent.

Profit simulation

WholeGarment ® is not just knitwear

without seams. It is a completely new Conventional knit production

category of knitwear, based on a re- Manufacturing

think of all stages of the knit supply chain

from planning and design, production,

distribution, marketing and retail sales.

AW SS

Retail

Bringing Knit Production Back to AW SS

the Consumer Market

The textile industry has shifted its production

base offshore in search of cheaper wages

and a steady workforce, but WholeGarment ® AW SS

has been the focus of attention concerning

Production with SS

the recent trend in returning knit production AW

WholeGarment ®and APEX3

back to markets in which knitted goods Manufacturing

are consumed. With high productivity and

efficiency as well as reduced reliance on

labor, the re-shoring of knit manufacturing AW SS

by means of WholeGarment ® production

becomes a viable alternative to overseas AW SS

production. Combined with the capabilities of Retail

SHIMA SEIKIʼs SDS®-ONE APEX3 design system,

WholeGarment ® production will surely bring

about a revolutionary change in the global AW SS

knitting industry in the 21st Century.

AW SS

・ APEX3 supports product planning, ・ Realistic virtual samples can be used ・ Minimal sewing allows significant ・ Optimized inventory prevents leftover stock,

design and presentation. in presale events. reduction in leadtime. Consistent avoiding bargain sales. Consumption at retail Time saved through

quality and reduced dependence prices maximizes profits. shortened leadtimes

・ Virtual sampling minimizes time and ・ Presale events provide forecasting on labor allow production in

cost spent on actual sample-making.

can be used to increase

of demand, allowing optimized consumer markets. ・ Even if an item goes out of stock, on-demand

production volume. Customer production capability allows for mid-season the number of product

・ Reduced leadtime allows plenty of feedback can be used to perform releases in a single

production for replenishing inventory.

time for product planning without

2 near-season design changes. season.

compromise due to lack of time.

Вам также может понравиться

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- 5S StartДокумент2 страницы5S StartAwais ImranОценок пока нет

- Nifaz e Shariat PDFДокумент275 страницNifaz e Shariat PDFAwais ImranОценок пока нет

- Finishing DR NoorДокумент4 страницыFinishing DR NoorAwais ImranОценок пока нет

- DystarДокумент3 страницыDystarAwais ImranОценок пока нет

- Lean Manufacturing Practices in Textile IndustriesДокумент21 страницаLean Manufacturing Practices in Textile IndustriesAwais ImranОценок пока нет

- Efficency and ProductivityДокумент33 страницыEfficency and ProductivityAwais ImranОценок пока нет

- OEE in StitchingДокумент7 страницOEE in StitchingAwais ImranОценок пока нет

- List of Textile JournalsДокумент3 страницыList of Textile JournalsAwais ImranОценок пока нет

- Imran 2016Документ7 страницImran 2016Awais ImranОценок пока нет

- Research & Development Alkaram Textile MillsДокумент9 страницResearch & Development Alkaram Textile MillsAwais ImranОценок пока нет

- Practical Hints Productivity Measurement of Spinning Mills: 1. Ounces/spindle Shift (OPS)Документ3 страницыPractical Hints Productivity Measurement of Spinning Mills: 1. Ounces/spindle Shift (OPS)Awais ImranОценок пока нет

- Cotton Nanotex DRY INSIDEДокумент2 страницыCotton Nanotex DRY INSIDEAwais ImranОценок пока нет

- Types of Garment WashingsДокумент1 страницаTypes of Garment WashingsAwais ImranОценок пока нет

- Jigger Dyeing ProblemsДокумент6 страницJigger Dyeing ProblemsAwais Imran0% (1)

- ZDHC AchitexMinerva - Marzo 20161Документ7 страницZDHC AchitexMinerva - Marzo 20161Awais ImranОценок пока нет

- Writing A Literature ReviewДокумент13 страницWriting A Literature ReviewAwais Imran100% (1)

- Study On Protein FiberДокумент36 страницStudy On Protein FiberAwais ImranОценок пока нет

- Why The Subatomic World Is Important To Everything in The QuranДокумент76 страницWhy The Subatomic World Is Important To Everything in The QuranAwais Imran100% (2)

- Dyeing Acrylic With Cationic Dyes PDFДокумент6 страницDyeing Acrylic With Cationic Dyes PDFAwais ImranОценок пока нет

- Handbook of TextilesДокумент378 страницHandbook of TextilesAwais ImranОценок пока нет

- Seam Slip 2Документ8 страницSeam Slip 2Awais ImranОценок пока нет

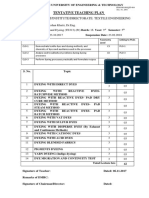

- Tentative Teaching Plan: Department/Institute/Directorate: Textile EngineeringДокумент1 страницаTentative Teaching Plan: Department/Institute/Directorate: Textile EngineeringAwais ImranОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- UNIUYO Past QuestionДокумент23 страницыUNIUYO Past QuestionCharles Udofia100% (1)

- Digital CompaqДокумент8 страницDigital CompaqgauravrewariОценок пока нет

- Fiscal PolicyДокумент13 страницFiscal PolicypriyaОценок пока нет

- Oligopoly ExercisesДокумент18 страницOligopoly Exercisesalekin100% (1)

- REAL 4000 Ch3 HW SolutionsДокумент6 страницREAL 4000 Ch3 HW SolutionsnunyabiznessОценок пока нет

- Pricing Products: Developing Pricing Strategies UnderstandingДокумент9 страницPricing Products: Developing Pricing Strategies UnderstandingsandipgargОценок пока нет

- Product, Services, and ExperiencesДокумент11 страницProduct, Services, and ExperiencesAubrey Joy PlantoОценок пока нет

- Makro 401Документ11 страницMakro 401askerow0073Оценок пока нет

- CV Tarun Das For Monitoring and Evaluation Expert July 2016Документ9 страницCV Tarun Das For Monitoring and Evaluation Expert July 2016Professor Tarun DasОценок пока нет

- Novartis PharmaДокумент11 страницNovartis PharmaDeepak GuptaОценок пока нет

- Shoe Industry in GuatemalaДокумент20 страницShoe Industry in GuatemalaFrancisco Prado BarraganОценок пока нет

- Fox Wave by Ahmed MaherДокумент20 страницFox Wave by Ahmed MaherPranav IweОценок пока нет

- A Comparison of Different Automated Market-Maker StrategiesДокумент14 страницA Comparison of Different Automated Market-Maker StrategiesmeamaОценок пока нет

- Market Failure in SingaporeДокумент5 страницMarket Failure in SingaporeMichael Loh100% (2)

- PEST Analysis On Mutual FundsДокумент17 страницPEST Analysis On Mutual Fundsrishu0075352490% (10)

- ICT London Kill ZoneДокумент3 страницыICT London Kill Zoneazhar500100% (3)

- Discount Rates: III: Relative Risk MeasuresДокумент20 страницDiscount Rates: III: Relative Risk MeasuresElliОценок пока нет

- Malaysia Petrochemical Country Report 2018: Presented ToДокумент49 страницMalaysia Petrochemical Country Report 2018: Presented TorexОценок пока нет

- ASSIGNMENT VII MeДокумент3 страницыASSIGNMENT VII MeRiya SinghОценок пока нет

- Resource-Based Theories of Competitive Advantage: A Tenyear Retrospective On The Resource-Based ViewДокумент9 страницResource-Based Theories of Competitive Advantage: A Tenyear Retrospective On The Resource-Based Viewxaxif8265Оценок пока нет

- Mercantilism - Practice of State Dirigism and ProtectionismДокумент12 страницMercantilism - Practice of State Dirigism and ProtectionismAbraham L ALEMUОценок пока нет

- IGCSE Business Studies Revision IGCSE Business Studies RevisionДокумент27 страницIGCSE Business Studies Revision IGCSE Business Studies RevisionTobek69Оценок пока нет

- Market Indices PDFДокумент3 страницыMarket Indices PDFAshwani Rana100% (1)

- Risk & ReturnДокумент31 страницаRisk & ReturnPramod VasudevОценок пока нет

- Acfn ResearchДокумент44 страницыAcfn ResearchAYNETU TEREFEОценок пока нет

- Pages From Chapter 5 - The Film Marketing Mix - (PDF Library)Документ3 страницыPages From Chapter 5 - The Film Marketing Mix - (PDF Library)nistha2011Оценок пока нет

- Test Bank For Principles of Economics 7th EditionДокумент24 страницыTest Bank For Principles of Economics 7th EditionKevinHarrisonnkrqm100% (38)

- Yoshino and Helble - The Housing Challenge in Emerging Asia PDFДокумент397 страницYoshino and Helble - The Housing Challenge in Emerging Asia PDFSheilaОценок пока нет

- Public Fiscal ManagementДокумент5 страницPublic Fiscal ManagementClarizze DailisanОценок пока нет

- The Importance of Porters Five ForcesДокумент2 страницыThe Importance of Porters Five ForcesDurga 94Оценок пока нет