Академический Документы

Профессиональный Документы

Культура Документы

Molybdenum Disulfide As Solid Lubricant

Загружено:

ChandaKundaОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Molybdenum Disulfide As Solid Lubricant

Загружено:

ChandaKundaАвторское право:

Доступные форматы

Molybdenum disulfide as solid lubricant

Dr. Dmitri Kopeliovich

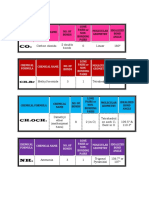

Molybdenum disulfide (MoS2) is a crystalline lamellar structure material contained in the

natural mineral Molybdenite.

Molybdenum disulfide is a solid lubricant relating to the class of Inorganic lubricants with lamellar

structure, which also includes molybdenum Graphite, boron nitride (BN) and some other

sulphides, selenides and tellurides (chalcogenides) of molybdenum, tungsten, niobium, tantalum

and titanium.

The crystal lattice of molybdenum disulfide is similar to that of Graphite. It consists of hexagonal

molybdenum planes sandwiched between two hexagonal sulphur planes. The atoms in the planes

are strongly covalently bonded to each other.

The planes are bonded by weak Van der Waals forces.

The layered structure allows sliding movement of the parallel plates. Weak bonding between the

planes provides low shear strength in the direction of the sliding movement but high

compression strength in the direction perpendicular to the sliding movement.

Friction forces cause the particles of molybdenum disulfide to orient in the direction, in which the

hexagonal layers are parallel to the sliding movement. The anisotropy of the mechanical

properties imparts the combination of low coefficient of friction and high carrying load capacity to

molybdenum disulfide.

The sulfur layers of molybdenum disulfide have an affinity for tenacious adherence to the metal

substrate atoms therefore a strong lubrication film is formed on the substrate surface. The

lubrication film provides good wear resistance and seizure resistance (compatibility).

In contrast to graphie moist atmosphere is not required for lubrication by molybdenum disulfide.

Therefore it demonstrates low friction in dry atmosphere and in vacuum where its coefficient of

friction is even lower than in the presence of water vapor.

Coefficient of friction of molybdenum disulfide is lower than that of graphite and it decreases with

increasing load.

At high loads in vacuum it may be as low as 0.03.

Application of molybdenum disulfide in open air at elevated temperatures is limited to 700°F

(371°C). Higher temperatures cause oxidation of MoS2 into the molybdenum trioxide MoO3 and

sulfur dioxide SO2. The oxides attract moisture resulting in increase of the coefficient of friction.

In non-ixidizing environment and in vacuum molybdenum disulfide is stable up to 2100°F

(1150°C).

Some applications of molybdenum disulfide :

Additives in lubricating oils

Components of polymer based composite anti-friction coatings

Second phase particles of metal based composite anti-friction coatings

Solid lubricant in metal forming

Release coatings and non-sticking refractory linings in foundry

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Manual Caterpillar 5130b Hydraulic Excavators Hydraulic System Components Diagrams Schematics Parts PDFДокумент37 страницManual Caterpillar 5130b Hydraulic Excavators Hydraulic System Components Diagrams Schematics Parts PDFBruno Cecatto92% (12)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- Annex A Step by Step Guide For ISO 9001 2015 NG FG AGДокумент39 страницAnnex A Step by Step Guide For ISO 9001 2015 NG FG AGRt Saragih100% (1)

- Module 1 Property Relationship PDFДокумент32 страницыModule 1 Property Relationship PDFManideep DuggiОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Chess For All-Book PDFДокумент268 страницChess For All-Book PDFChandaKundaОценок пока нет

- (Advances in industrial and hazardous wastes treatment) Chen, Jiaping Paul_ Hung, Yung-Tse_ Shammas, Nazih K._ Wang, Lawrence K._ Wang, Mu Hao Sung-Remediation of heavy metals in the environment-CRC P.pdfДокумент541 страница(Advances in industrial and hazardous wastes treatment) Chen, Jiaping Paul_ Hung, Yung-Tse_ Shammas, Nazih K._ Wang, Lawrence K._ Wang, Mu Hao Sung-Remediation of heavy metals in the environment-CRC P.pdfHuỳnh Tấn NhựtОценок пока нет

- Excellent French Pronouns and Prepositions-BookДокумент31 страницаExcellent French Pronouns and Prepositions-BookChandaKundaОценок пока нет

- Bubble Column ReactorsДокумент34 страницыBubble Column ReactorsGhaya Bani Rushaid100% (2)

- Axial Thrust in Centrifugal PumpsДокумент14 страницAxial Thrust in Centrifugal PumpsAndré Da Cunha SilveiraОценок пока нет

- KSB Know-How, Volume 0 - Selecting-Centrifugal-Pumps-data PDFДокумент92 страницыKSB Know-How, Volume 0 - Selecting-Centrifugal-Pumps-data PDFRodrigo Astudillo AedoОценок пока нет

- Sprinkler DesignДокумент63 страницыSprinkler DesignChandaKundaОценок пока нет

- Sprinkler DesignДокумент63 страницыSprinkler DesignChandaKundaОценок пока нет

- Sprinkler DesignДокумент63 страницыSprinkler DesignChandaKundaОценок пока нет

- Iso 9001 Quality ManagementДокумент1 страницаIso 9001 Quality ManagementChandaKundaОценок пока нет

- Efficiency and EffectivenessДокумент1 страницаEfficiency and EffectivenessChandaKundaОценок пока нет

- Iso 9001 Supply ChainДокумент20 страницIso 9001 Supply ChainRichard More LeonОценок пока нет

- Control of Production and Service ProvisionДокумент1 страницаControl of Production and Service ProvisionChandaKundaОценок пока нет

- Sprinkler Technology:: James Golinveaux Senior Fellow - Tyco Fire Protection ProductsДокумент74 страницыSprinkler Technology:: James Golinveaux Senior Fellow - Tyco Fire Protection ProductsChandaKundaОценок пока нет

- Benefits of ISO 9001Документ4 страницыBenefits of ISO 9001ChandaKundaОценок пока нет

- ISO Design and DevelopmentДокумент5 страницISO Design and DevelopmentChandaKundaОценок пока нет

- NFPA 13 Sprinkler System Design Density Curves - Where Did They Come From?Документ7 страницNFPA 13 Sprinkler System Design Density Curves - Where Did They Come From?ChandaKundaОценок пока нет

- Seventh Edition - December 2015Документ67 страницSeventh Edition - December 2015Oanh NguyenОценок пока нет

- Automatic Fire SprinklerДокумент3 страницыAutomatic Fire SprinklerChandaKundaОценок пока нет

- An Introduction To SprinklersДокумент97 страницAn Introduction To SprinklersShayan IrevaniОценок пока нет

- Calculation Examples FIREДокумент21 страницаCalculation Examples FIREChandaKundaОценок пока нет

- Design Consideration PumpsДокумент18 страницDesign Consideration PumpsChandaKundaОценок пока нет

- Types of Electrical LoadsДокумент2 страницыTypes of Electrical LoadsChandaKunda100% (1)

- EdasdДокумент3 страницыEdasdmayukhguha1988Оценок пока нет

- 15-Hydraulic Pumps (Compatibility Mode) PDFДокумент60 страниц15-Hydraulic Pumps (Compatibility Mode) PDFmechanddoniОценок пока нет

- Spec Speed PrimerДокумент11 страницSpec Speed PrimerEbby OnyekweОценок пока нет

- Designing an ultra-low specific speed centrifugal pumpДокумент6 страницDesigning an ultra-low specific speed centrifugal pumpChandaKundaОценок пока нет

- A Review of Major Centrifugal Pump Failure Modes - Water Supply and Sewage IndustriesДокумент12 страницA Review of Major Centrifugal Pump Failure Modes - Water Supply and Sewage IndustriesNang TruongОценок пока нет

- Centrifugal Pump DesignДокумент7 страницCentrifugal Pump DesignChandaKundaОценок пока нет

- Centrifugal Pumps 8 B PDFДокумент14 страницCentrifugal Pumps 8 B PDFGeorge OparОценок пока нет

- Molecular Geometry ChartДокумент3 страницыMolecular Geometry ChartJoyci CauilanОценок пока нет

- Exercise - Current ElectricityДокумент21 страницаExercise - Current ElectricitythefutureОценок пока нет

- Mole Concept Q.P.Документ5 страницMole Concept Q.P.Leap Up JEE NEET100% (1)

- Dubai Municipality Lists Approved B2B BiocidesДокумент14 страницDubai Municipality Lists Approved B2B BiocidesAhmed FathyОценок пока нет

- Chapter 5: Solid State Chemistry and Crystal StructuresДокумент43 страницыChapter 5: Solid State Chemistry and Crystal StructuresABDU EL RAHОценок пока нет

- Determination of Total Lipids As Fatty Acid Methyl Esters (FAME) by in Situ TransesterificationДокумент16 страницDetermination of Total Lipids As Fatty Acid Methyl Esters (FAME) by in Situ TransesterificationpeterОценок пока нет

- Types of MicroscopeДокумент3 страницыTypes of MicroscopeRommel Paz AlbertoОценок пока нет

- Membrane Proc GuideДокумент10 страницMembrane Proc GuideXiaoying ZhuОценок пока нет

- Subject Catagories ETDE PDFДокумент67 страницSubject Catagories ETDE PDFmartinimartiiniОценок пока нет

- Experimental Analysis of Shot Peening On Carburized or CarbonitridedДокумент5 страницExperimental Analysis of Shot Peening On Carburized or CarbonitridedkarimОценок пока нет

- Defects in Liquid Crystals - Maurice KlemanДокумент101 страницаDefects in Liquid Crystals - Maurice KlemanAlexCooksОценок пока нет

- Flame Light RelightДокумент3 страницыFlame Light RelightChrono AeonОценок пока нет

- GCE Chemistry A2C2Документ6 страницGCE Chemistry A2C2cafffy100% (1)

- Catalysts: Hydrogen Production From Semiconductor-Based Photocatalysis Via Water SplittingДокумент27 страницCatalysts: Hydrogen Production From Semiconductor-Based Photocatalysis Via Water SplittingMurariu OvidiuОценок пока нет

- Chandrasekhar's Book An Introduction To The Study: of Stellar StructureДокумент9 страницChandrasekhar's Book An Introduction To The Study: of Stellar StructureSouvik DasОценок пока нет

- Chapter - 3 ShortДокумент4 страницыChapter - 3 ShortNadeem ArainОценок пока нет

- Test 1 September 2020 SemesterДокумент3 страницыTest 1 September 2020 SemesterAhmed AlwaqediОценок пока нет

- MCQ in General Chemistry Part 3 - AnswersДокумент3 страницыMCQ in General Chemistry Part 3 - Answerssam labineОценок пока нет

- домофонДокумент12 страницдомофонСтоян МитевОценок пока нет

- Using Waste Coffee Grounds in ElectrodesДокумент6 страницUsing Waste Coffee Grounds in ElectrodesHuynh Nghiep ThanhОценок пока нет

- 1.4 Assessed Homework Mark Scheme: 10.4 Periodicity HW MSДокумент2 страницы1.4 Assessed Homework Mark Scheme: 10.4 Periodicity HW MSSumathi GanasenОценок пока нет

- Thermodynamics Chapter 1 ReviewДокумент20 страницThermodynamics Chapter 1 ReviewReinzo GallegoОценок пока нет

- Atp and Coupled ReactionДокумент3 страницыAtp and Coupled ReactionBhea Mariel CaipangОценок пока нет

- Chapter 21 Cutting Tools: MET 33800 Manufacturing ProcessesДокумент25 страницChapter 21 Cutting Tools: MET 33800 Manufacturing ProcessesAlissa Saphira PutriОценок пока нет

- Materials Challenges in Hydrogen-Fuelled Gas TurbinesДокумент27 страницMaterials Challenges in Hydrogen-Fuelled Gas TurbinesSaiful ShokriОценок пока нет

- Bber Compounding LPE 4th Year 2022Документ20 страницBber Compounding LPE 4th Year 2022afia rahmanОценок пока нет

- 2013Документ11 страниц2013Nguyễn Bá LâmОценок пока нет