Академический Документы

Профессиональный Документы

Культура Документы

Cefotaxime Injection 1 GM

Загружено:

iloveit52252Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Cefotaxime Injection 1 GM

Загружено:

iloveit52252Авторское право:

Доступные форматы

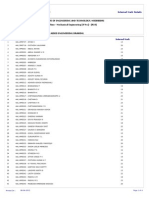

BEXIMCO PHARMACEUTICALS LTD.

PRODUCT DEVELOPMENT DEPARTMENT

Lab Scale / Pilot Batch Evaluation Sheet

Dosage Form : Tablet

Batch formula

Sl. Name of Materials Quantity Remarks

No B/N: B/N: B/N: B/N: B/N: B/N:

Active Ingredients R-No.

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

17

18

19

20

SOP Ref.: PDD-009 From No.: PD-18

Page 1 of 10

Batch formula

Sl. Name of Materials Quantity Remarks

No B/N: B/N: B/N: B/N: B/N: B/N:

Excipients R-No.

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

SOP Ref.: PDD-009 From No.: PD-18

Page 2 of 10

Batch formula

Sl. Name of Materials Quantity Remarks

No B/N: B/N: B/N: B/N: B/N: B/N:

Coating Materials R-No.

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

SOP Ref.: PDD-009 From No.: PD-18

Page 3 of 10

Process Parameters Observations Remarks

Steps Dt.: Dt.: Dt.: Dt.: Dt.: Dt.:

B/N: B/N: B/N: B/N: B/N: B/N:

Granulation In-process parameters

& Blending

Qty of water for paste

Dry mixing time

Wet mixing time

a) Dry milling

Sieve______RPM_____

b) Wet milling

Sieve______RPM_____

c) Milling after drying

Sieve______RPM_____

d) Final milling

Sieve______RPM_____

Milling time

Drying temp. & time

Blending rpm & time

Appearance

SOP Ref.: PDD-009 From No.: PD-18

Page 4 of 10

Process Parameters Observations Remarks

Steps Dt.: Dt.: Dt.: Dt.: Dt.: Dt.:

B/N: B/N: B/N: B/N: B/N: B/N:

Granulation Loss on drying (LOD)

& Blending

(continued) Tap density

Bulk density

Sieve analysis

a) __________mesh

b) __________mesh

c) __________mesh

Compressibility

Assay

Compression In-process parameters

Machine name

Pre-compression force

Machine speed

Description

Diameter

Thickness

Hardness

SOP Ref.: PDD-009 From No.: PD-18

Page 5 of 10

Process Parameters Observations Remarks

Steps Dt.: Dt.: Dt.: Dt.: Dt.: Dt.:

B/N: B/N: B/N: B/N: B/N: B/N:

Un-coated / Friability

Core Tablet

Disintegration

Description

Diameter

Thickness

Hardness

Friability

Disintegration

Dissolution

Assay

Coating In-process parameters

Machine name

Inlet temperature

Bed temperature

Exhaust temperature

SOP Ref.: PDD-009 From No.: PD-18

Page 6 of 10

Process Parameters Observations Remarks

Steps Dt.: Dt.: Dt.: Dt.: Dt.: Dt.:

B/N: B/N: B/N: B/N: B/N: B/N:

Coating In-process parameters

(continued)

Air Seal Coating

pressure

Drug Coating

Color Coating

Enteric Coating

Sub-coating

Smoothing

Coloring

Pan rpm Seal Coating

Drug Coating

Color Coating

Enteric Coating

Sub-coating

Smoothing

Coloring

Pump rpm Seal Coating

Drug Coating

Color Coating

Enteric Coating

Sub-coating

Smoothing

Coloring

SOP Ref.: PDD-009 From No.: PD-18

Page 7 of 10

Process Parameters Observations Remarks

Steps Dt.: Dt.: Dt.: Dt.: Dt.: Dt.:

B/N: B/N: B/N: B/N: B/N: B/N:

Spray rate Seal Coating

Drug Coating

Color Coating

Enteric Coating

Sub-coating

Smoothing

Coloring

Distance of Seal Coating

gun to tab

bed Drug Coating

Color Coating

Enteric Coating

Sub-coating

Smoothing

Coloring

Number of Seal Coating

guns

Drug Coating

Color Coating

Enteric Coating

Sub-coating

Smoothing

Coloring

SOP Ref.: PDD-009 From No.: PD-18

Page 8 of 10

Process Parameters Observations Remarks

Steps Dt.: Dt.: Dt.: Dt.: Dt.: Dt.:

B/N: B/N: B/N: B/N: B/N: B/N:

Nozzle Seal Coating

diameter

Drug Coating

Color Coating

Enteric Coating

Sub-coating

Smoothing

Coloring

Loss on Seal Coating

drying

(LOD) Drug Coating

Color Coating

Enteric Coating

Sub-coating

Smoothing

Coloring

% weight Seal Coating

gain

Drug Coating

Color Coating

Enteric Coating

Sub-coating

Smoothing

Coloring

Polishing

SOP Ref.: PDD-009 From No.: PD-18

Page 9 of 10

Process Parameters Observations Remarks

Steps Dt.: Dt.: Dt.: Dt.: Dt.: Dt.:

B/N: B/N: B/N: B/N: B/N: B/N:

Coated Tablet Description

Diameter

Thickness

Hardness

Disintegration

Dissolution

Assay

SOP Ref.: PDD-009 From No.: PD-18

Page 10 of 10

Вам также может понравиться

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Request 123Документ32 страницыRequest 123iloveit52252Оценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- DRAPДокумент2 страницыDRAPiloveit52252Оценок пока нет

- Scan Jan 05, 2022Документ1 страницаScan Jan 05, 2022iloveit52252Оценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Zinc Oxide 40%Документ2 страницыZinc Oxide 40%iloveit52252Оценок пока нет

- JJNKДокумент2 страницыJJNKiloveit52252Оценок пока нет

- TgyhujДокумент9 страницTgyhujiloveit52252Оценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Document Change Log Table: Neutro Pharma Quality Control LaboratoryДокумент8 страницDocument Change Log Table: Neutro Pharma Quality Control Laboratoryiloveit52252Оценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- COA of Prune Extract (Xian)Документ1 страницаCOA of Prune Extract (Xian)iloveit52252Оценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Health Benefits of Boswellia 89549Документ6 страницThe Health Benefits of Boswellia 89549iloveit52252Оценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Pharmaceutical Dispersion Techniques For Dissolution and Bioavailability Enhancement of Poorly Water-Soluble DrugsДокумент33 страницыPharmaceutical Dispersion Techniques For Dissolution and Bioavailability Enhancement of Poorly Water-Soluble Drugsiloveit52252Оценок пока нет

- Certificate PDFДокумент1 страницаCertificate PDFiloveit52252Оценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Control Strategy For Process Development of High Shear Wet Granulation and Roller Compaction To Prepare A Combination Drug Using Integrated Quality by DesignДокумент27 страницControl Strategy For Process Development of High Shear Wet Granulation and Roller Compaction To Prepare A Combination Drug Using Integrated Quality by Designiloveit52252Оценок пока нет

- Certificate of Analysis: Xi'An B-ThrivingДокумент1 страницаCertificate of Analysis: Xi'An B-Thrivingiloveit52252Оценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Abstract:: Extended Release Tablet With Active CoatingДокумент10 страницAbstract:: Extended Release Tablet With Active Coatingiloveit52252Оценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Null PDFДокумент38 страницNull PDFiloveit52252Оценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- "Plop, Plop, Fizz, Fizz, Oh What A Reaction Is ": Effect of Temperature On Rate of ReactionДокумент4 страницы"Plop, Plop, Fizz, Fizz, Oh What A Reaction Is ": Effect of Temperature On Rate of Reactioniloveit52252Оценок пока нет

- The Stability of Ascorbic Acid in Various Liquid Media : or ImpactionДокумент4 страницыThe Stability of Ascorbic Acid in Various Liquid Media : or Impactioniloveit52252Оценок пока нет

- Title:: Release of Polyphenols From Liposomes Loaded With Echinacea PurpureaДокумент1 страницаTitle:: Release of Polyphenols From Liposomes Loaded With Echinacea Purpureailoveit52252Оценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Appendix-V (Log Book)Документ1 страницаAppendix-V (Log Book)iloveit52252Оценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- APPENDIX-I (Request Sheet)Документ2 страницыAPPENDIX-I (Request Sheet)iloveit52252Оценок пока нет

- Xcell 94Документ64 страницыXcell 94Eugen SpiritDivinОценок пока нет

- Biomaterials in Construction IndustryДокумент28 страницBiomaterials in Construction IndustryAntara SablokОценок пока нет

- Vijay KumarДокумент4 страницыVijay Kumarkaran bainsОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Amphenol N-Type RF ConnДокумент6 страницAmphenol N-Type RF ConnShaunVermaakОценок пока нет

- Al - Alva 'S Institute of Engineering and Technology, Moodbidri 140120SUF - B.E Full Time - Mechanical Engineering (4 Yrs) - (R14) 2 - Semester 14ced24 - Computer Aided Engineering DrawingДокумент4 страницыAl - Alva 'S Institute of Engineering and Technology, Moodbidri 140120SUF - B.E Full Time - Mechanical Engineering (4 Yrs) - (R14) 2 - Semester 14ced24 - Computer Aided Engineering DrawingenggsantuОценок пока нет

- Injection Well ProblemsДокумент12 страницInjection Well Problemsdriller2250% (2)

- Guia para Expandido de TubosДокумент3 страницыGuia para Expandido de Tubosjafc986Оценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Rov Tooling PDFДокумент136 страницRov Tooling PDFcharles IkeОценок пока нет

- RP 1034Документ116 страницRP 1034naveen_k2004Оценок пока нет

- GTO SampleДокумент24 страницыGTO Samplego25101992Оценок пока нет

- ManДокумент154 страницыManbarun1977Оценок пока нет

- Ir5020i Parts Catalog PDFДокумент52 страницыIr5020i Parts Catalog PDFSuresh KumarОценок пока нет

- Enarayan Elex India (P) LTD: Awards AchievedДокумент8 страницEnarayan Elex India (P) LTD: Awards AchievedSrikanth Reddy SunketaОценок пока нет

- 2SK 2371 - 2372 - NecДокумент8 страниц2SK 2371 - 2372 - NecStevenОценок пока нет

- Tigrip PDFДокумент83 страницыTigrip PDFWolf LordОценок пока нет

- MR Developers Plumbing - ITIДокумент31 страницаMR Developers Plumbing - ITIUmamaheshwarrao Varma100% (1)

- Ruskin Fire DamperДокумент4 страницыRuskin Fire DamperRAGANОценок пока нет

- HJF24R R4 ES - eДокумент3 страницыHJF24R R4 ES - evincatesОценок пока нет

- Hfcats14 011306Документ8 страницHfcats14 011306Enrique Romero SanchezОценок пока нет

- 0231 - 17 Research Assistant Engineer in Electrical and Electronic Engineering Job DescriptionДокумент3 страницы0231 - 17 Research Assistant Engineer in Electrical and Electronic Engineering Job DescriptiondickyОценок пока нет

- Building Structures and TechnologyДокумент98 страницBuilding Structures and TechnologyBandilung Tz100% (1)

- PrefaceДокумент45 страницPrefaceaddy_callsoutОценок пока нет

- Example - Design of A Cold-Formed Steel Lipped Channel Wall Stud in Compression and BendingДокумент10 страницExample - Design of A Cold-Formed Steel Lipped Channel Wall Stud in Compression and BendingChristian ChetcutiОценок пока нет

- Green Bee Smart BuildingДокумент3 страницыGreen Bee Smart BuildingKatama Raju Bandigari100% (2)

- EPS Data SheetДокумент2 страницыEPS Data SheetajoilhamОценок пока нет

- Surendiran Ramani NewДокумент3 страницыSurendiran Ramani NewlogaОценок пока нет

- Basics of Computational Combustion Modeling PDFДокумент30 страницBasics of Computational Combustion Modeling PDFEvelin KochОценок пока нет

- Effect of Rice Husk Ash Mass On Sustainability Pyrolysis Zone of Fixed Bed Downdraft Gasifier With Capacity of 10 KgHour-AIP (2017)Документ9 страницEffect of Rice Husk Ash Mass On Sustainability Pyrolysis Zone of Fixed Bed Downdraft Gasifier With Capacity of 10 KgHour-AIP (2017)Hafif DafiqurrohmanОценок пока нет

- Condensate Tank Trench Calculation: Sheet 5 of 7Документ3 страницыCondensate Tank Trench Calculation: Sheet 5 of 7Agarry EmmanuelОценок пока нет

- ICH Quality Guidelines: An Implementation GuideОт EverandICH Quality Guidelines: An Implementation GuideAndrew TeasdaleОценок пока нет

- The Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsОт EverandThe Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsРейтинг: 5 из 5 звезд5/5 (3)

- The Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactОт EverandThe Nature of Drugs Vol. 1: History, Pharmacology, and Social ImpactРейтинг: 5 из 5 звезд5/5 (5)