Академический Документы

Профессиональный Документы

Культура Документы

ITP (Inspection Test Prosedur) Pipe Steel Inspeksi

Загружено:

Hadiwinata DjakariaАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

ITP (Inspection Test Prosedur) Pipe Steel Inspeksi

Загружено:

Hadiwinata DjakariaАвторское право:

Доступные форматы

PT.

PLN Proyek Pembangunan Coal Unloading Jetty Kapasitas 12000 DWT PLTU Pangkalan Susu Unit 3-4 (2x200 MW).

(P E R S E R O)

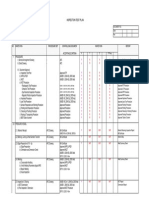

INSPECTION TEST PROSEDUR (ITP)

Constomer : PT. WIJAYA KARYA (persero)

Fabricator : PT. FARIKA STEEL Date of Inspection :

Client : PT. PLN (Persero)

Final Inspector Will inpection each pipe,as follows : Specification : API 5L, ASTM A53, ASTM A252

TABLE FINAL INSPECTION

RESULT

ITEM OF INSPECTION METHOD OF INSPECTION ACCEPTANCE LIMIT FS CONTRACTOR OWNER REF

TEST

Surface Defect Surface defect in weld and Pipe Body Max depth 25% of the nominal

are Inspection while rotating pipe under WT shall be permitted. (may be

adequate illumination explored by grinding or milling)

Depth exceed 25% WT shall be ASTM A.252 para

repaired Repair by welding shall 14.2 & 14.3

be permitted when the depth of

defect does not exceed 33 ½ %

WT

NDT Manual Ultrasonic AWS D1.1

Dimensional

Outside Diameter Tape measurement ± 1 % from the diameter

specified ASTM A.252 para 12.2

Wall Thickness Micrometer or thickness gage The minimum WT at any point

shall not be more than 5% under

the nominal wall thicknees ASTM A.252 para 12.3

specified

Length Tape measurement ± 1 % inch

ASTM A.252 para 13.1

Weight Using calculation -5%

+ 15 % ASTM A.252 para 12.1

Straightness Taut string is held along the pipe surface, measure the max deviation with

steel ruler Reasonably Straight or 0.1% of length

ASTM A.252 para 14.1

Testing Product 1/50 Pipe (12 M)

ASTM A.252 para 9.1 &

9.2

Вам также может понравиться

- Contoh ITP Dan ChecklistДокумент21 страницаContoh ITP Dan Checklistandy100% (5)

- 201485-25000-QP-01-B Inspection Test Plan (ITP) For FRP Tank R0Документ1 страница201485-25000-QP-01-B Inspection Test Plan (ITP) For FRP Tank R0muchamad yasin100% (1)

- DSM - YME - AL - GL00X - G - AL - ITP - 0XXX - 0X Inspection PlanДокумент1 страницаDSM - YME - AL - GL00X - G - AL - ITP - 0XXX - 0X Inspection Plankadir tanzania100% (2)

- SMS-602-RT-003 Radiographic API 1104 - B31.8 - Rev 3Документ27 страницSMS-602-RT-003 Radiographic API 1104 - B31.8 - Rev 3Cak Nhass100% (1)

- INSPECTION AND TEST PLAN OVERVIEWДокумент4 страницыINSPECTION AND TEST PLAN OVERVIEWalex_scribd_rpi100% (1)

- Cover MDR, MDR Index Dan Pembatas (Rev)Документ19 страницCover MDR, MDR Index Dan Pembatas (Rev)Richard Adolf100% (1)

- Bolt Tightening ReportДокумент2 страницыBolt Tightening Reportrimshadtp67% (3)

- ITP Pembangunan Tanki BaruДокумент5 страницITP Pembangunan Tanki Baruwahyu hutama67% (3)

- Check List Pre-CommissioningДокумент1 страницаCheck List Pre-CommissioningAdy Putro100% (1)

- Mobile Crane InspectionДокумент14 страницMobile Crane InspectionMOST PASON100% (1)

- Bolt Tightening ReportДокумент1 страницаBolt Tightening ReporttreyОценок пока нет

- PT WOKATUBA INDONESIA HOIST CRANE INSPECTION REPORTДокумент1 страницаPT WOKATUBA INDONESIA HOIST CRANE INSPECTION REPORTM AzharОценок пока нет

- GRE Pipes Inspection Test PlanДокумент6 страницGRE Pipes Inspection Test PlanMat RidhanОценок пока нет

- Sample WorkpackДокумент9 страницSample WorkpackKhairun Mohamad IshakОценок пока нет

- 2.5 - FAT - C1574 - FAT Procedure PDFДокумент7 страниц2.5 - FAT - C1574 - FAT Procedure PDFGeorge Jhonson100% (2)

- PENETRANT TEST REPORT - ContohДокумент2 страницыPENETRANT TEST REPORT - ContohSmksore Pas100% (1)

- 5-Mooring Buoy KEMENANGAN BrosurДокумент2 страницы5-Mooring Buoy KEMENANGAN Brosurdody andiОценок пока нет

- Itp PipingДокумент12 страницItp PipingCak Nhass100% (1)

- Inspection of Test Plan: Rotating EquipmentДокумент7 страницInspection of Test Plan: Rotating Equipmentzvlcar nainОценок пока нет

- Hydrostatic Pressure Test Process for ValvesДокумент31 страницаHydrostatic Pressure Test Process for ValvesIksan Mustofa50% (2)

- Rsae-Frm-227 Inspection Check List For Motor Solo RunДокумент1 страницаRsae-Frm-227 Inspection Check List For Motor Solo RunkamilОценок пока нет

- Inspection Test PlanДокумент3 страницыInspection Test PlanMohd Shafuaaz Kassim100% (2)

- Undangan Inspeksi MaterialДокумент1 страницаUndangan Inspeksi MaterialwahyuОценок пока нет

- Fabrication Prosedure: Continuous Improvement & Sustainbility ProjectДокумент12 страницFabrication Prosedure: Continuous Improvement & Sustainbility Projectmoddys100% (1)

- Organization Chart For Pipe Line Project 01Документ1 страницаOrganization Chart For Pipe Line Project 01MaherОценок пока нет

- WSA Line 5 Anchor Bolt Tightening Inspection ReportДокумент1 страницаWSA Line 5 Anchor Bolt Tightening Inspection ReportMahfudRido'iRonggomaniaОценок пока нет

- Prosedur Plumbness MJKДокумент9 страницProsedur Plumbness MJKAnonymous xdBQM5VkYОценок пока нет

- Check List For DI Pipe InstallationДокумент1 страницаCheck List For DI Pipe InstallationSaifur Rahman0% (1)

- Galvanized and Black Malleable Iron Pipe Fittings SpecificationsДокумент24 страницыGalvanized and Black Malleable Iron Pipe Fittings Specificationshse vje100% (1)

- Check List After HydrotestДокумент1 страницаCheck List After Hydrotestரமேஷ் பாலக்காடு91% (11)

- Itp and Test Plan Rubber Fender Rev. 0Документ5 страницItp and Test Plan Rubber Fender Rev. 0Danu Sutanto100% (1)

- FIT UP ReportДокумент2 страницыFIT UP Reportsiva8000Оценок пока нет

- WMS Pekerjaan Catodic ProtectionДокумент35 страницWMS Pekerjaan Catodic ProtectionHeru IndrianurОценок пока нет

- Potongan A - A Oil Catcher Gambar Tampak Atas Oil Catcher: OilcatcherДокумент1 страницаPotongan A - A Oil Catcher Gambar Tampak Atas Oil Catcher: OilcatcherLoekman Akeem100% (1)

- TEMPORARY POWER PROJECT PANEL INSTALLATIONДокумент18 страницTEMPORARY POWER PROJECT PANEL INSTALLATIONNurdin Sudrajat SasrabahuОценок пока нет

- Wrapping Coating ProcedureДокумент5 страницWrapping Coating Procedureshantanu kumar100% (1)

- Contoh Inspection Test PlansДокумент8 страницContoh Inspection Test PlansImam Syafni L100% (2)

- ITP Inspection Test Plan FormatДокумент1 страницаITP Inspection Test Plan FormatArthur50% (6)

- Piping Daily Fit Up Quality Control and Inspection Report FormДокумент4 страницыPiping Daily Fit Up Quality Control and Inspection Report FormnguyenquanghiepОценок пока нет

- Pipe Installation Procedure - IndonesiaДокумент30 страницPipe Installation Procedure - IndonesiaIrvan Maruli67% (3)

- Pipe Line Works Inspection and Test PlanДокумент1 страницаPipe Line Works Inspection and Test PlanCrstnScribidОценок пока нет

- 3.inspection & Testing PlanДокумент24 страницы3.inspection & Testing PlanIrfan Putra100% (4)

- QUALITY ASSURANCE PROTOCOLДокумент2 страницыQUALITY ASSURANCE PROTOCOLShah Newaz KabirОценок пока нет

- Itp GeneratorДокумент4 страницыItp Generatormuhammad afrizalОценок пока нет

- SOP - 06 - Visual and Dimensional ProcedureДокумент22 страницыSOP - 06 - Visual and Dimensional ProcedureSuci YatiningtiyasОценок пока нет

- QAQC Form - ArchitechtureДокумент42 страницыQAQC Form - ArchitechtureMohammad Hadoumi SaldanОценок пока нет

- Welding Inspection Report for Pertamina PadalarangДокумент1 страницаWelding Inspection Report for Pertamina PadalarangabdiОценок пока нет

- ITP - Erection of Static EquipmentДокумент4 страницыITP - Erection of Static Equipmentbhct1987Оценок пока нет

- Piping NDT Request Quality Control and Inspection FormДокумент1 страницаPiping NDT Request Quality Control and Inspection FormEdison WalitОценок пока нет

- Qaqc Format - Sandblasting y PinturaДокумент2 страницыQaqc Format - Sandblasting y Pinturaosdavid0490100% (1)

- ITP For Piping WorksДокумент3 страницыITP For Piping WorksOrlando1949100% (3)

- PT Perdana Karya Perkasa sandblasting and painting procedureДокумент10 страницPT Perdana Karya Perkasa sandblasting and painting procedureNauval Labiby N M100% (1)

- Rab Sand BlastingДокумент1 страницаRab Sand BlastingIrnaldi Yoza Wijaya100% (1)

- ITP-01 - BackfillingДокумент1 страницаITP-01 - BackfillingMaddala Srinivasa Rao50% (2)

- Itp For Pipeline at SiteДокумент3 страницыItp For Pipeline at Siteanang_pri100% (2)

- Wrb-Air Barrier - Parex Usa Weatherseal Trowel OnДокумент2 страницыWrb-Air Barrier - Parex Usa Weatherseal Trowel Onsaffronbuilders9Оценок пока нет

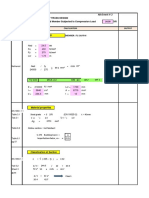

- SS Stub End Thickness CalculationДокумент1 страницаSS Stub End Thickness CalculationSrinivas KadivetiОценок пока нет

- B76-90 (2013) Standard Test Method For Accelerated Life of Nickel-Chromium and Nickel-Chromium-Iron Alloys For Electrical HeatingДокумент6 страницB76-90 (2013) Standard Test Method For Accelerated Life of Nickel-Chromium and Nickel-Chromium-Iron Alloys For Electrical HeatingEhab HarbОценок пока нет

- mechanical-metigurical-dimensionalДокумент4 страницыmechanical-metigurical-dimensionalPaviter SinghОценок пока нет

- Technical Brief Galal Make SleevesДокумент1 страницаTechnical Brief Galal Make SleevesSELVAGANAPATHIОценок пока нет

- SPP - Description Test PDFДокумент18 страницSPP - Description Test PDFHadiwinata DjakariaОценок пока нет

- Precastinstallation PDFДокумент9 страницPrecastinstallation PDFEcoPrasinosОценок пока нет

- Robert Fox PresentationДокумент27 страницRobert Fox PresentationKapil SharmaОценок пока нет

- Form Work 1 PDFДокумент36 страницForm Work 1 PDFsanjeev2812Оценок пока нет

- CIVL 392 - Chapter 6 - FormworkДокумент69 страницCIVL 392 - Chapter 6 - FormworkGerold MolinaОценок пока нет

- Kapasitas Crane 25 TonДокумент3 страницыKapasitas Crane 25 TonHadiwinata DjakariaОценок пока нет

- Soil Nailing - Where When and WhyДокумент27 страницSoil Nailing - Where When and WhyarshashajiОценок пока нет

- Spec Crane 30 TonДокумент8 страницSpec Crane 30 TonHadiwinata DjakariaОценок пока нет

- UNirap SystemДокумент2 страницыUNirap SystemHadiwinata DjakariaОценок пока нет

- English ModulДокумент66 страницEnglish ModulErwin Hari Kurniawan100% (2)

- Dry EtchingДокумент12 страницDry EtchingMosaddekОценок пока нет

- Summary Bill of Quantities: Project Identifying InformationДокумент15 страницSummary Bill of Quantities: Project Identifying InformationRussel Renz de MesaОценок пока нет

- Thermo Exam QuestionsДокумент4 страницыThermo Exam QuestionssiskieoОценок пока нет

- Cti-Std 154 - FRP PipesДокумент12 страницCti-Std 154 - FRP PipesNilesh Kitey100% (2)

- B 36 - B 36M - 13Документ9 страницB 36 - B 36M - 13Ahmed BilalОценок пока нет

- 5 6138727946501751075Документ3 страницы5 6138727946501751075Xkarr RastaОценок пока нет

- Proper Maintenance of InstrumentsДокумент92 страницыProper Maintenance of InstrumentsDimi DimoОценок пока нет

- Carrier Furnace 58UHV, 58UXV WeatherMaker 8000VS 1088653Документ20 страницCarrier Furnace 58UHV, 58UXV WeatherMaker 8000VS 1088653Jerry HanОценок пока нет

- Dissertation CGДокумент147 страницDissertation CGChiheb BaОценок пока нет

- Computational Fluid Dynamics Simulation of The Progress of Fire Smoke in Large Space, Building AtriaДокумент7 страницComputational Fluid Dynamics Simulation of The Progress of Fire Smoke in Large Space, Building AtriaAravind KumarОценок пока нет

- Aroon v. Shenoy (Auth.) - Rheology of Filled Polymer Systems-Springer Netherlands (1999)Документ483 страницыAroon v. Shenoy (Auth.) - Rheology of Filled Polymer Systems-Springer Netherlands (1999)Swetha100% (1)

- Tabla 310.15 (B) (16) - Ampacidades PDFДокумент1 страницаTabla 310.15 (B) (16) - Ampacidades PDFDettagli GuateОценок пока нет

- Chapter 11 Introduction To PolymerДокумент11 страницChapter 11 Introduction To Polymersyed izzuddin alhadyОценок пока нет

- 5.01 Cold Water Plumbing Cold Water Pipe Sizing Testing and Commissioning PDFДокумент4 страницы5.01 Cold Water Plumbing Cold Water Pipe Sizing Testing and Commissioning PDFrhomadonaОценок пока нет

- Rigid Pavement Design As Per IRC 58 2011 BUC and TDC AnalysisДокумент3 страницыRigid Pavement Design As Per IRC 58 2011 BUC and TDC Analysisarvind sharmaОценок пока нет

- Flexural Toughness and Strength of Fiber ConcreteДокумент8 страницFlexural Toughness and Strength of Fiber ConcreteGabriel Cachi Cerna100% (2)

- Scrim FabaricsДокумент10 страницScrim FabaricsGauri PuranikОценок пока нет

- StainlessSteelBraid (SSB)Документ2 страницыStainlessSteelBraid (SSB)phucgenjiОценок пока нет

- 07part AD Asme 8Документ8 страниц07part AD Asme 8ingalejosОценок пока нет

- BS en 10130 2006Документ16 страницBS en 10130 2006Phong TongОценок пока нет

- Stone Masonry (Training Element and Technical Guide For SPWP Workers Booklet 3)Документ86 страницStone Masonry (Training Element and Technical Guide For SPWP Workers Booklet 3)Wubetie MengistОценок пока нет

- Chennai BOQДокумент8 страницChennai BOQDharmendra SharmaОценок пока нет

- Enau Polyla (FDM Filament) : Problem StatementДокумент1 страницаEnau Polyla (FDM Filament) : Problem Statementhakim nasirОценок пока нет

- Rudawska 2016Документ33 страницыRudawska 2016MochammadDzulFiqarОценок пока нет

- Stalargo Stainless Steel I-Beams: For Demanding ApplicationsДокумент4 страницыStalargo Stainless Steel I-Beams: For Demanding ApplicationsTushar PatilОценок пока нет

- The Nature of MaterialsДокумент11 страницThe Nature of MaterialscdymlkОценок пока нет

- Tool SteelsДокумент31 страницаTool SteelsMaheswaran MuthuОценок пока нет

- Piping Material Specification 2010014 00 l0 Gs 001Документ215 страницPiping Material Specification 2010014 00 l0 Gs 001Wilson Xavier Orbea Bracho100% (1)

- ZA DC F 77 Shoring Design Review Checklist PDFДокумент2 страницыZA DC F 77 Shoring Design Review Checklist PDFkareemОценок пока нет

- ENVIRONMENTAL CONTROL SYSTEMS (3681) Lec 2-3Документ73 страницыENVIRONMENTAL CONTROL SYSTEMS (3681) Lec 2-3shariq talatОценок пока нет