Академический Документы

Профессиональный Документы

Культура Документы

Fat Ds Report

Загружено:

lapet busukАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Fat Ds Report

Загружено:

lapet busukАвторское право:

Доступные форматы

FACTORY ACCEPTANCE TEST (FAT) REPORT FOR

TNP DISCONNECTING SWITCH

1. Location:

Takaoka Toko, Co. Ltd. Oyama Factory, Tochigi Perfecture, Japan.

2. Date and Time: July 20 to 21, 2018 ; 09.00 Am to 17.00 Pm

3. Attendance:

PT Inalum (Persero) : Mr. Nando Purba (PTE) and Mr. Denny Panjaitan (PMN)

PT CKD : Mr. Henry Tantono, Mr. Tandiyono and Mr. Achiruddin

Chiyoda Corporation : Mr. Hiroyuki Iway

Mr. Washin Kusakabe

Takaoka Co., Ltd. : Mr. Hiromitsu Takeda

Mr. Tomoaki Saito

Yuriko Fudota

Yasuko Masubuchi

4. General

The Factory Acceptance Test refers to the functional test that is perform by manufacture

upon completion of the manufacturing process to prove the equipment has the same

specification and functionality that indicated in the datasheet, specification and purchase

order.Inalum purchased Disconnecting Swith for TNP totaly 8 sets, consist : 4 sets for

Bus A and Bus B T-S T/L ; 2 sets for T-S T/L with earthing switch ; 2 sets for Bus Tie.

All 8 sets disconnecting switch have been manufactured and tested by Takaoka itself. In

this moment Inalum only tested 1 set Disconnecting Switch with Earthing switch due to

limited time.

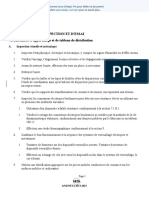

5. Testing Criteria

5.1 Mechanical operating test

Mechanically operating test performed with 40 cycles operating for DS and ES.

Operating voltage (%) Control Voltage (%) Cycles

75%*110V : 82,5V 75%*110V : 82,5V 10

110%*110V : 121V 125%*110V : 137,5V 10

100%*110V : 110V 100%*110V : 110V 20

Test Result : - Control voltage can operated at less than 75% of rated Voltage.

- Operating voltage can operated at less than 75% of rated Voltage.

5.2 Measurement of contact resistance of DS ( Close position)

The resistance contact check performed with DC current injected.

R phase S phase T phase

129 µΩ with 50.1 A test 129 µΩ with 52.8 A test 126.7 µΩ with 51.3 A

current current test current

Test Result : Good. (Less than 205 µΩ)

5.3 Dielectric test

Dielectric test performed; (1) between live parts and ground by AC 330kV within 1

minute; (2) between auxiliary circuit and ground by AC 2kV within 1 minute. This test

conformed no flashover occurred when testing performed.

Test Result : Good. (No flashover)

5.4 Meggering Test

Megger test performed at DC voltage 1000 volts for DS and ground, and DC voltage

500 volts for Motor Operating circuits and ground. Meggering test conducted with

condition before and after dielectric test.

Result

Testing

Before After

Disconnector >2000 MΩ >2000 MΩ

Motor Opearating 100 MΩ >100 MΩ

Test Result : Good ( More than 2000 MΩ for Disconnector and more than 100 MΩ

for Motor operating circuit).

5.5 Visual Inspection

Prior to electrical testing, we verify the following :

a. The equipment complies with contract document and approved drawing.

b. The equipment dimension same with approval drawing.

c. Equipment labels have been installed, etc.

All items above was checked and meet the criteria.

5.6 Manual operation

After mechanical operating test, we verify the following :

a. Mechanical components operate smoothly and freely.

b. Manual operation easy to operated by hand.

Test Result : Manual operating by handle for DS and ES (open and close) is easy

to operated by hand; approximetly 155 Newton.

6. Final Meeting

Discussion between Inalum, CKD, Chiyoda and Takaoka was conducted after test with

results:

6.1. Delivery time

Delivery time for the equipments middle of August 2018.

6.2. Inalum inform that the schedule of installation conducted between February to

April 2019.

6.3. Inalum asked to Takaoka to supply cable flange with galvanized steel material.

6.4. Balancing spring for ES modified to balancing weight. Mostly function for those

items was same.

6.5. Only installation for Disconnector with ES will be supervised by Takaoka

engineer.

7. Attachment

7.1. Minutes of Meeting for Acceptance Testing

7.2.Witness Test Report for Disconnector

Reported by:

(F.Z Nando Purba) (Denny Panjaitan)

Manager Ast.Superintendent

Engineering Section Maintenance Section

Вам также может понравиться

- EXP MN SM110 FR R0 Pompes MaintenanceДокумент90 страницEXP MN SM110 FR R0 Pompes MaintenancePrince Rushdie Mongo100% (2)

- Methode AgileДокумент40 страницMethode AgilesebtarrisОценок пока нет

- CH06 Mise en Service D'un Ouvrage Final2Документ9 страницCH06 Mise en Service D'un Ouvrage Final2NabilBouabana100% (1)

- Guide NF c15-100 0Документ20 страницGuide NF c15-100 0Lotfi ElaoudОценок пока нет

- Devoirs Surveilles Et ExamensДокумент36 страницDevoirs Surveilles Et ExamensHØu ÇîNe100% (1)

- CH06 Mise en Service D'un Ouvrage Final2Документ9 страницCH06 Mise en Service D'un Ouvrage Final2NabilBouabanaОценок пока нет

- Diagnostic TransformateurДокумент45 страницDiagnostic TransformateurChaouki AbdallahОценок пока нет

- Cours410 Document Synthã SeДокумент148 страницCours410 Document Synthã Seferiel aissiОценок пока нет

- Synchronisation Disjoncteurs HT PDFДокумент33 страницыSynchronisation Disjoncteurs HT PDFABELWALID0% (1)

- PMB 714 - 0Документ15 страницPMB 714 - 0fayssal salvadorОценок пока нет

- Manuel 06 12 F800GS 2016Документ166 страницManuel 06 12 F800GS 2016Alexandros Gi100% (2)

- Projet Catia Support de L'appareilДокумент6 страницProjet Catia Support de L'appareilSara EcheradiОценок пока нет

- TD2 Corrigé (Rég GTE 1A)Документ7 страницTD2 Corrigé (Rég GTE 1A)mohamed creatorОценок пока нет

- Ds InfoДокумент2 страницыDs Infoⵀⴰⵊⴰⵔ ⴰⴱОценок пока нет

- Merlin Gerin Breaker Test Kit 34547Документ28 страницMerlin Gerin Breaker Test Kit 34547vjОценок пока нет

- Eddy Current Manual Volume 1 V CECCO PDFДокумент208 страницEddy Current Manual Volume 1 V CECCO PDFP BОценок пока нет

- DTS 48VDCДокумент49 страницDTS 48VDCelsayed abdemagiedОценок пока нет

- Abdelkrim Ben CheikhДокумент1 страницаAbdelkrim Ben Cheikhachraf.sotumeОценок пока нет

- Travaux Effectues Aucours de StageДокумент11 страницTravaux Effectues Aucours de StageRotimi Réné ElgbdОценок пока нет

- Presentation Sae s2 EtudiantsДокумент8 страницPresentation Sae s2 Etudiantsbor652799Оценок пока нет

- Rapport D'essaiДокумент1 страницаRapport D'essaiHaifa MabroukОценок пока нет

- Iec 116Документ17 страницIec 116adanОценок пока нет

- BK601 ManualДокумент11 страницBK601 ManualTatatiti TataОценок пока нет

- Hitachi Manual j100 FRДокумент54 страницыHitachi Manual j100 FRGraphica EuroОценок пока нет

- UG FrenchДокумент21 страницаUG FrenchhamzaОценок пока нет

- Epreuve U32 Sujet Bts Fed 2021 GCFДокумент12 страницEpreuve U32 Sujet Bts Fed 2021 GCFjimzd7215Оценок пока нет

- Arrêt Du Moteur Par IntermittenceДокумент4 страницыArrêt Du Moteur Par IntermittenceMahaman kabirouОценок пока нет

- Sectionneur RotatifsДокумент7 страницSectionneur RotatifshichosenОценок пока нет

- Dimensionnement Partie1Документ42 страницыDimensionnement Partie1Imane SAHDAOUIОценок пока нет

- Spécifications Techniques IM Manuelle 16kaДокумент5 страницSpécifications Techniques IM Manuelle 16kaISGEОценок пока нет

- Session 2006: 1 H 30 Page 1/5Документ9 страницSession 2006: 1 H 30 Page 1/5fabОценок пока нет

- ELM Leblanc AxeliaДокумент12 страницELM Leblanc AxeliaWalid Aouini80% (5)

- Inspection and Test Procedure1 FRДокумент11 страницInspection and Test Procedure1 FRanselme djarsidamОценок пока нет

- TP 2 Matériaux Introduction A La HTДокумент5 страницTP 2 Matériaux Introduction A La HTSabri LoucifОценок пока нет

- Theme4 MalaxeurДокумент9 страницTheme4 MalaxeurgirardОценок пока нет

- TtttttttttrfffssssДокумент5 страницTtttttttttrfffssssKouokam mbobda pascalОценок пока нет

- BA WNB Francais D10330Документ20 страницBA WNB Francais D10330Hamed KoneОценок пока нет

- Eaton 243132 PLS6 C6 2 DC MW FR - FRДокумент2 страницыEaton 243132 PLS6 C6 2 DC MW FR - FRZineb HakimiОценок пока нет

- COPREC Services GénérauxДокумент2 страницыCOPREC Services GénérauxGaétanОценок пока нет

- 6AG40210AB120CA0 Datasheet FRДокумент2 страницы6AG40210AB120CA0 Datasheet FRsqdqsdОценок пока нет

- Manuale Trasformatore FraДокумент24 страницыManuale Trasformatore FraMekkov MekkovvОценок пока нет

- Mise en Service de LA STATION DE POMPAGEДокумент12 страницMise en Service de LA STATION DE POMPAGEkedhanhaОценок пока нет

- DT ENV RBS6150 - AC Avec Batterie Ericsson Outdoor AV n5 Au Contrat 20510091494.19.IR - Ir ReduiteДокумент6 страницDT ENV RBS6150 - AC Avec Batterie Ericsson Outdoor AV n5 Au Contrat 20510091494.19.IR - Ir ReduiteNabil MaataouiОценок пока нет

- Bancs de Maintenance Du Tramway Du Mans: Dossier QuestionnementДокумент10 страницBancs de Maintenance Du Tramway Du Mans: Dossier QuestionnementMohamed Yasser AdamОценок пока нет

- TP9.4 - Niveau DebitДокумент10 страницTP9.4 - Niveau DebitZied OmarОценок пока нет

- Coprec & Auto ControleДокумент8 страницCoprec & Auto ControletravauxОценок пока нет

- TDChapitre1 2Документ6 страницTDChapitre1 2ABDELALI SASSIOUIОценок пока нет

- PDF Bowa Ifu mn030 423 Testing Device For Electrode Handles and Cables MultilingualДокумент70 страницPDF Bowa Ifu mn030 423 Testing Device For Electrode Handles and Cables MultilingualWillemОценок пока нет

- Rapport Projet Aida FayeДокумент19 страницRapport Projet Aida FayeAïda FayeОценок пока нет

- Specification Technique: Résistances de Neutre MTДокумент7 страницSpecification Technique: Résistances de Neutre MTMahmoud ChihebОценок пока нет

- Catalogue FinderДокумент123 страницыCatalogue FinderDida DadalОценок пока нет

- 9090 Corrige E2 Metropole Bac Pro Eleec 2017Документ24 страницы9090 Corrige E2 Metropole Bac Pro Eleec 2017loicОценок пока нет

- 9091 Corrige E2 Polynesie Bac Pro Eleec 2017Документ26 страниц9091 Corrige E2 Polynesie Bac Pro Eleec 2017Bationo Antoine De padoueОценок пока нет

- Cellule MT Étanche: Cellule Rmu Compact À Fusibles Uring-24 LLFДокумент9 страницCellule MT Étanche: Cellule Rmu Compact À Fusibles Uring-24 LLFFati FatineОценок пока нет

- Moyen de Controle de SoudureДокумент17 страницMoyen de Controle de SoudureFilaliAbderrahimОценок пока нет

- Etude Et Amélioration D'une Découpeuse Des Plaques de JointДокумент31 страницаEtude Et Amélioration D'une Découpeuse Des Plaques de JointMoudi BouhlelОценок пока нет

- Equipement de La RouteДокумент87 страницEquipement de La RouteRémi LelièvreОценок пока нет

- Examen CI 2021Документ5 страницExamen CI 2021Thierry IlboudoОценок пока нет

- Transfo Sec 1250kva B568-F1e03-2aДокумент7 страницTransfo Sec 1250kva B568-F1e03-2abahous mokhtarОценок пока нет

- Présentation1 - Copie - CopieДокумент37 страницPrésentation1 - Copie - CopieJesuis ContentОценок пока нет

- Zelio Time - RE9RA11MW7Документ8 страницZelio Time - RE9RA11MW7Dominique KomeyОценок пока нет

- Compair Luchard 4000 ElДокумент56 страницCompair Luchard 4000 ElfamilysegardОценок пока нет

- Cours Mise en Service Pages-1-6Документ6 страницCours Mise en Service Pages-1-6Ced RicОценок пока нет

- Variateur de Vitesse de La Série AC10 Series: IP20 0-180kWДокумент183 страницыVariateur de Vitesse de La Série AC10 Series: IP20 0-180kWLotfi AmmarОценок пока нет

- TD7 Corr PDFДокумент7 страницTD7 Corr PDFKhaled MasoudiОценок пока нет

- Bulletin de Geotechnique Au SenegalДокумент7 страницBulletin de Geotechnique Au SenegalAnonymous 7OG1zAОценок пока нет

- Synthèse Bibliographique Des Outils D'évaluation Du Ruissellement - Sept2010 - 2Документ22 страницыSynthèse Bibliographique Des Outils D'évaluation Du Ruissellement - Sept2010 - 2YASSINОценок пока нет

- Equipements - CentralesДокумент37 страницEquipements - CentralessamsoumalekingОценок пока нет

- SVS 800Документ2 страницыSVS 800Shouzab AbbasОценок пока нет

- Cluster E.noutaryДокумент10 страницCluster E.noutaryL'Usine Nouvelle100% (3)

- Catalogue de Prix AuДокумент13 страницCatalogue de Prix AuNarindra Tatiana AnjaОценок пока нет

- Barrage en TerredefДокумент39 страницBarrage en TerredefMed ElouartiОценок пока нет

- Régulation CompresseurДокумент8 страницRégulation CompresseurtasnimОценок пока нет

- Suite Chapitre2 Synthèse FiltrageДокумент13 страницSuite Chapitre2 Synthèse Filtrageikram mbrОценок пока нет

- ERERERДокумент4 страницыERERERmadmajОценок пока нет

- Les Radiers GenerauxДокумент5 страницLes Radiers GenerauxMyriam KhouryОценок пока нет

- MPLSДокумент35 страницMPLSAziz AbdouОценок пока нет

- L31法文筆記Документ8 страницL31法文筆記YU-WEN WANGОценок пока нет

- Série D'exercices N°2 - Sciences Physiques LA BOBINE ET LE DIPOLE RL - Bac Sciences Exp (2015-2016) MR Daghsni Sahbi PDFДокумент5 страницSérie D'exercices N°2 - Sciences Physiques LA BOBINE ET LE DIPOLE RL - Bac Sciences Exp (2015-2016) MR Daghsni Sahbi PDFMahmoud Essahbi Sahbi DaghsniОценок пока нет

- Dtu 37-1Документ2 страницыDtu 37-1moil69Оценок пока нет

- Curriculum Vitae MakamboДокумент2 страницыCurriculum Vitae Makambosalomonmakambo01Оценок пока нет

- Les Entreprises Franc Aises en Chine - Quels EnjeuxДокумент4 страницыLes Entreprises Franc Aises en Chine - Quels EnjeuxIslam El OusroutiОценок пока нет

- NF en 10020Документ14 страницNF en 10020HALINОценок пока нет

- TCP UdpДокумент5 страницTCP UdpOmar AhОценок пока нет