Академический Документы

Профессиональный Документы

Культура Документы

BHEL PIPING Standard-Quality-Plan-1439553413 PDF

Загружено:

Anonymous gr5Pr9AV0 оценок0% нашли этот документ полезным (0 голосов)

31 просмотров10 страницОригинальное название

BHEL PIPING standard-quality-plan-1439553413.pdf

Авторское право

© © All Rights Reserved

Доступные форматы

PDF или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

31 просмотров10 страницBHEL PIPING Standard-Quality-Plan-1439553413 PDF

Загружено:

Anonymous gr5Pr9AVАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

Вы находитесь на странице: 1из 10

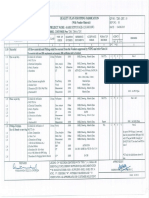

STP UARAT HEAVY ELECTRICALSETD ‘QUALITY PLAN FOR PIPING FABRICATION [QP NO : 7285: QPC:19

PING CENTRE, CHENNAI 17 (With Vendor Material) IREV.NO: 00

‘OcALITY DEPARTMENT. |PROJECT NAME : -BARH STPP STAGE-I (3X 660 MW) DATE : 08.08.2015

[BHEL CUSTOMER Nos: 7285, 7286 & 7287

COMPONENT & z ‘Tyre OF | QUANTUM] REFERENCE | ACCEPTANCE | ForwaTor | [AGENCY]

SNo | “OPERATIONS cuanactmismics | CLASS] Cusce | orcaeck | pocument# | __ NORMS RECORDS -—— ae

T z H z 5 z z z a i

1.00 [Material ‘All Raw material and Fittings shall be sourced from the Vendors approved by NTPC and refer Note:14

[he atari shall met IBR requirements and ncesary TBR cetiates shal be urised

THO [Pbe ase as [Coreation & vreon ‘CialVercaion 1008 ‘BHEL Dawag Maal Spo mare pV] PTV] Nast

le wi TCs or

1 3) Crema Composition lcm sass | et BHEL Drawing Material Spec. Te-Tet Coifcue

2 J sexs. Popes IMech test | utiewsie | BHEL Dranng Maer Spe

3 = soundness ur 100% | ASTMEDIS with 5% Notch, $AS30,5A

99

(in, 3: Mas men)

16 Hea Teeatnent as pple [rinetemp. | 1c Mazel Spee.

1s sacs isn isnt 10% Matta Spee

16 Ip Dimension (OD 1D & Wall Ta) Meare | 1c BHEL Drang, Matcil Spex:

a py Hace e IMesssrment | C0 Mais Spe. 00: forPO1 Pipes

Pats aspera [Conaton Becton itl [eraion ae HEL Drawing Maral Se MATS FLv pv Nestea

Jot Mi Ts for

a | i Creal Composon. loom amis | eae HEL Dring, Mate Sper

x2 | batch. Papers IMac Tee tex. BHEL Drang, Maca Spee.

rs |e) Sounds, lor 100% SASTS

| Je) Dimension & Crane IMeaewerne | 100m HEL Drosng, Meal Sper

fish evi

12s | Jp Hose Measurement | 100% SHEL Drang, Mater Spee. Rest 0: tO Pases

13 Fiings Foreaas, [Costin &vecaon of Cae Verty 1008 SHEL Deswng. Maca Spe Te | vpP|v]v Nose

[Bars & Rounds as per drg|6ilTCs for

131 a Chem. Conpositon lcremAnaais | ea HEL Drewag Maal Spec. incase o SW figs.) a9 matt

132 lb) Mec. Test Mech Test | eat HEL Drowag Maral Spe. shal be prociredrm(BR spp

133 Je Dimensicas of Sigs IMessiement | 100% HEL Drawing, Maral See sith UT ae per SASH spay of

(OD & wal hiekness Je Vinal [Satee FILK Fiz wclas 2nd 221

at lo Sutice Defers Mer 1008 AST En09 Jeass3

Gs Je Soins or > 6am lor toon | sAses/asMe Sec vin Dive 33.4

lr ia> NB 200m or BW fing

fy Sounnes fo orig, Bas Runes UT 1008 sA3es er otf tices above 50

PREPARED [CEGEND, "D RECORDS IDENTIED WITHT-TICK™(v) SHALL BE ‘APPROVED BY

WO lESSENTIALLY INCLUDED BY SUPPLIER IN QA DOCUMENTATION

"VIVEKANANDA VELLU, Se ENORY QA © M: MANUFACTURER / SUB ~ SUPPLIER B: BHEL / BHEL-TPL. N MADHAV. Ga

INTPC. “P": PERFORM “W": WITNESS "R RANDOM AND" V

|VERIFICATION. AS APPROPRIATE, CHP: CUSTOMER HOLD POINT Fact o1oFt0

(EIGETPUARAT HEAVY ELECTRICALSETD

PIPING CENTRE, CHENNAL-17

CD econo

(QUALITY PLAN FOR PIPING FABRICATION

(With Vendor Material)

[PROJECT NAME : -BARH STPP STAGE-I (3X 660 MW)

|BHEL CUSTOMER Nos: 7285, 7286 & 7287.

JQP NO : 7285: QPC: 19

IREV.NO: 00

DATE. : 04.08.2015

ama See See | ee Dees ee

— OPERATIONS oo CAS | caer ‘OF CHECK | DOCUMENT # ‘NORMS RECORDS MLE Dw aR

& SS TS

toe

— ih | eae

beet ee ee

te | ee | eee

ot backattact

|Personal Major | -do- 100% — |IBR WOR wie) per ee er

mie | ieee et . ees

JT charts [P5A: 695+/-15 dee. C

| ge le

= | ane

Mieco’: teat! (| ae bees ae

quality

— A

ae eee ee

Ramaeted, Pasay wd AT a

eee

|VERIFICATION. AS APPROPRIATE; CHP: CUSTOMER HOLD POINT oe oR

(QUALITY PLAN FOR PIPING FABRICATION

JQP NO : 7285: QPC: 19)

ra PIPING CENTRE, CHENNAL—17 (With Vendor Material) REV.NO: 00

‘QUALITY DEPARTMENT. [PROJECT NAME : -BARH STPP STAGE-1 (3X 660 MW) DATE = 04.08.2015

|BHEL CUSTOMER Nos: 7285, 7286 & 7287.

‘COMPONENT & ‘Tyre oF ] quantum | rererence | accertance | FORMATOF AGENCY |

ae OPERATIONS nae CLASS) cueck | OFcHECK | DOCUMENT # NORMS RECORDS aTELe Ree

z z z a = z 7 z 3 BL mo Tr

225 [Post weld [Time & Temp. control Major [Review of 100% [PI 605+ 15 Des. C ® PY] VY] ¥ (Soaking 25 mavmm

leat treatment (as HT charts Ps: 6ssei- 15 Deg. C lof thickness

spplicable) PSA: 6954-15 Deg. C

226 [Dimensional check lovatity, thickness Major Measurement | 100% R vfelviy

JOD, 1D & Length Drawing & IBR

227 |Produetion west Mechanical Properties Major |Laboratory | As perIBR Material specn, & IBR R piv|y

Plate for LS Welds [Test

23 [Bending

23 [Beating and [Time & Temp. control Major |Review of 100% [Note 12.0 R piy|y

lea weatment HT chartsog

232 [Dimensions [Bend angle, Arm length.Radius of |Major [Measurement | 100% [Drawing & IBR R | P| w | ¥ |rhinning only for R/D <3 forcold

bend. Ovalty. Thinning, Wrinkles |& Visual bends and for all hot bends. FOT

will be done fo: cold Bends of R/D

3

233 [Pot Bends Micro |cvitical |Reptice @ | Meterit speen R P | we] Vv |@3 replicas inone bend per HT

Hardness |Crtical Measurement | 100% [250 BHN max. R P | w] w oatch

| [soundness \Crtical {NOT-MPI 100% ASME Sec V/ ASME B3ILI ct R P | w | w [We Random Witness

24 [Post weld [Time & Temp, control Major |Review of 100% [Note 13.0 R piwiy

Heat treatment HT charts

75__[NDE after PWHT: (NDE shal be carved out by qualified aerator as per SNT TT TA)

Tt [Soundness [erieal RT IERCUT [ASME Sec V/ASME SILI cl ® TT? | W | w [cL-xdesign emp > 218 deg or

I<102, 10% |136.4.5 [steam Pr >17.06 Ks/Sq. cm o

I>102, l:WerPr> 24.6. Ke/Sq.cm

100% ICL: Not exceeding above values

fe-tt- 10% |+Review of filns

Buse joins (P91) {soundness |cetical MP 100% _ |ASME Sec V// ASME BSI. I ct R vp P| wlwe

13643 lt UT on accessible areas based on

ur 100R# |ASME See V/ ASME B3ILt cl R P | w | w [easbiity of scanning in nozzle

13645 land branch wells.

Hardness 100% [300 HVI0 (Mex) R PB} wlwe

253 |Full penetration nozzle —_|Soundness Ciel [RTF UTSS 100% | ASME See V/ ASME B31.1 cl 1364.5/ repor | V| P| w | we|ss:in teu or RTT, ime satze

lioits (OD > 114.3) [213546 IMP canbe done for every 10mm weld

laos

PREPARED JCEGEND: “D*" RECORDS IDENTIFIED WITH “TICK = (v) SHALL BE ‘APPROVED BY

| ©. IESSENTIALLY INCLUDED BY SUPPLIER IN QA DOCUMENTATION RS

‘VIVERANANDA YELLU, Se ENGR QA f= M: MANUFACTURER / SUB — SUPPLIER B: BHEL / BHEL-TPI. N: Me AP.AGMIC

INTRC. “P": PERFORM “W": WITNESS°R'RANDOM AND " V":

L |VERIFICATION. AS APPROPRIATE: CHP: CUSTOMER HOLD POINT PAGE 03 OF 10

(Sage MARAT HEAVY ELECTRICALS LTD QUALITY PLAN FOR PIPING FABRICATION ]QP NO : 7285 : QPC: 19

rr PIPING CENTRE, CHENNAI~ 17 (With Vendor Material) |REV.NO: 00

(QUALITY DEPARTMENT. |PROJECT NAME : -BARH STPP STAGE-I (3X 660 MW) [DATE : 04.08.2015

lBHEL. CUSTOMER Nos: 7285, 7286 & 7287

| COMPONENT & Tye oF ] quanTum | REFERENCE | accerrance | Fonwavor | [AGeNcY

| ss cra cuss

es OPERATIONS oe — S| CHECK OF CHECK | DOCUMENT # ‘NORMS RECORDS we te cee

7 z z wef res 7 z n a mn

TS rach Blond Cnyng [Souter vais ILL Tom [ASME SoC VTASWEBIT a ® PTV] ¥

| ashen: wes 36a. 13644

255 [seal wet ofsrewsand | souines Majer Jortaeiet | 100% [ASM SocV/ ASME Bac R piviv

fad fe plats 1368.31 1364.4

25 [oimensocalinpesion eng cago Fes 3°, Weti Major [Measemen | 100% _forawing TBR R ef wlw

End cick, Loca OF

suOrienmtion

0 [mat inspection

| owe ines wer os wits of SL, RH

tin Revew of Pvioe io bo o | w [oveefeceet

Sa ajo [veatrenet | 1098 BHEL Drawing we vf e {wf

ow diese

one Mas jr |speeonenay | con | AsperRequieanal aso) spem | repot |v] P| wv

deitcaton fray Set oars

compen (on Weld

bar ma,

ic icy Cd

| J suctcpepacion 8 nr [inal & soos eter Note:8 wee | vf ef | y foe tomt Rae

| Panne essen

|

| neon Making & sj: visu 10% SHEL Davine.?0 rl v| v [ims

coke coting

|

| Je) IBR Certification Major |Review 100% [BR a) Pbviw

|

| practin 8 Et proecin jr Ji 10% HEL Daving 70 P]v| v [rset

40 [pocumenranton

41, faperion cere possnrtin erst |verieon | 1008 [atrepons asses inthis QP IB rly] -

42 ep Cees pupa Comm esis vesceon | 098 woce e |v low Note?

PREPARED, ILEGEND: "D" RECORDS IDENTIFIED WITH “TICK (v) SHALL BE EFROVED

| oO: lessENTIALLY INCLUDED BY SUPPLIER IN QA DOCUMENTATION

VIVERONANOA EDU SV ENGRTO eM: MANUFACTURER /SUB ~ SUPPLIER B: BHEL /BHEL-T N MGiiaid

lsrec. “P PERFORM. "W": WITNESS RANDOM AND *V"

|VERIFICATION. AS APPROPRIA1 HP: CUSTOMER HOLD POINT aare

(SUgSTMMARAT HEAVY ELECTRICALS LTD QUALITY PLAN FOR PIPING FABRICATION [QP NO : 728:

PIPING CENTRE, CHENNAI - 17 (With Vendor Material) |REV.NO: 00

aa chin sencibe PROJECT NAME: -BARH STEP STAGEGX 650 MW) Bie lasrors

aera strata nasnee ar

ae) | eee canes | [eae] ee on | ene | eee | es (See ae rants

|NOTES

1) (@) E the raw materials are received directly from RM Manufacturer's work, the material shall be accepted based on (correlation of Heat number on material with TC and (jiverification of TCs.

() Ifthe materials are received from Dealers place, check test ( Chemical and Mechanical tests on one sample per Heat/ size) shall be done in addition to the above for accepting the material

BHEL shall identify and witness the sample for check test.

Special requirements like supplementary test, restriction of Raw material Vendors, NDT requirements and if any indicated shall be taken care.

2) GrS1 Fittings shall be procured only from NTPC approved vendors & Refer Note:13. All the requirements covered in para 1.30 to 1.40 shall be taken care by the Sub-vendor while ordering,

fttngs on the manufacturer.

3) Plates used for attachements shall be of BHEL approved make.

4) Heat number transfer to cut piece (raw material) shall be done by Sub- Vendor inthe presence of BHEL/BHEL's TPI & IBR/IBR approved Agency.

5) The items shall be manufactured as per BHEL drawing .

6) Welding Elecrodes used shall be of BHEL approved make.

7) Al items shall be inspected end cleared by BHEL/BHEL's TPI and IBR/IBR approved Agency and NTPC as indicated in the above QP Witness/Hold points. The Vendor shall get despatch clearance

from the NTPC before despatch of finished materialitems.

8) Surface Preparation & Painting :

4) Indigenous Vendor :- Surface Preparation : Power Tool Cleaning: Primer Coat : 2 coats of 2Smicrons of each coat of Red Oxide Zine Phosphate Primer to 1812744.

Finish coat : Une coat ot 29 microns of Synthetic enamel paint (Jong Cil alkyd) 10 18 2932

‘Total DFT : 75 microns minimum, Shade : Smoke Grey Shade No 692 of IS 5

b) Foreign Vendor :- Surface Preparation : Blast Cleaning(SSPC-SP10 / SA2 1/2); Primer Coat : One coat of 60 microns of In-Organic Ethyl Zine Silicate primer:

Finish coat : Two coats of 20 microns each of Heat Resistance Aluminium paint to IS13183 Gr-1

‘Total DFT : 100 microns minimum. Shade : Aluminium

9) All IBR requirements shall be taken care and IBR documents shall be furnished.

10) The finished components shall be punched with DU code (14 digit work order du details) Heat number, material specification, maker's emblem, Inspectors seal and Statutory authorities seal

In edition, the DU code, Heat no. and Material specification shall also be paint stencilled.

Colour coding : Red for SA106 Gr B : Blue for SA106 GrC ; Green & White for SA335PI1 ; Black & Red for SA335 P12 ; Bluc & Red for SA335 P22: Brown & Red for SA335 P91

11) Machined enes shall be well protected using end caps and fittings shall be suitably packed_in box / crate to avoid transit & other damages.

PREPARED ILEGEND: -D*" RECORDS IDENTIFIED WITH “TICK = (v) SHALL BE APPROVED BY

0, lESSENTIALLY INCLUDED BY SUPPLIER IN QA DOCUMENTATION RN 2

\VIVERANANDA VELLU, Sr ENGRTQA le i: MANUPACTURER / SUB ~ SUPPLIER B: BHEL / BHEL-TPI.N: MADMAVANKUTTY AP. AGM/Q

INTPC. “P": PERFORM “W"; WITNESS °R'RANDOM AND ° V"

| VERIFICATION. AS APPROPRIATE; CHP: CUSTOMER HOLD POINT.

PAGE O50 10

IHARAT HEAVY ELECTRICALSLTD

NG CENTRE, CHENNAI~17

(QUALITY DEPARTMENT

QUALITY PLAN FOR PIPING FABRICATION

(With Vendor Material)

PROJECT NAME : -BARH STPP STAGE-I (3X 660 MW)

[BHEL CUSTOMER Nos: 7285, 7286 & 7287.

[QP NO : 7285: QPC: 19

IREV.NO: 00

DATE: 04.08.2015

cxo | COMPONENT & ‘Type oF | QUANTUM | REFERENCE | ACCEPTANCE | FoRMATOF | [AGENCY

SNe | OPERATIONS CHaracTaisrics —|CLASS| “cueck’ | oFCHECK | DOCUMENT# | NORMS RECORDS Tete es

I z z z 5 = 7 z 7 —Tep 0 7

Note 12:0 Post forming Heat treatment [Cold and Hot bending of pipes (OD > = 1143 mm) ‘Temp. in degC

Material Cold bending Hot bending Theremental Bending®™

(emp. < 590)

Fr ‘When > 19 ma eating: 900-1070 Heating 90OTOTO

SRat 595-635 Bending ot below 670 ¢<=40 mm, NoSR

se 610 /- 15 1Ft> 40 mm, SR 8595-635

[No SR bending is

m1

Tae is eating 920-1010, Heating: 920-1010

Bending nat below 720 Normals a 920-960

Normals at 920-960, Temper at 655+. 15,

Lrener at 6554-15

Pe Rass eating: 920-1010, Ie eatin 1 Post forming A

Bending not below 750 |uD>2 Normals a 923960,

Normalize at 920-960, Tension side: 70-780 ‘Temper at 695 +115,

[reaper a 6954-15, \compresson side: 830-850

RD <=2

| frension side: 770-780 Normatise st 920960

compression sie: 920-1010 Temper at 695 +15

FEGapT Nou Applicable ating: 1050-1100 eating: 1000-1100

| en ening nox below 1000 Nexis at 1040-1070

| INormalise at 1040-1060, ‘Temper at 760-780

| [renges at 760-780

[ ‘Cold and Hot bending of pipes (OD < 1143 mm) Temp. in deze

Vista ‘Cold bending (Temp. <590) Hor bending

Fr Wen > 19 mam, SRALSOS- OBS [Hot Bend a STO.5O, SRN

[ Fe [Wien RID <2 ort 1S mm SRATOSSA TS lot bend a 70.500: RID <2 SR a SSIS

| Pa [Wien RID <2 or (> 15 mm, SRat OSHS [Hor bend at 870-900; SR 695 +15

PEG [) For Design Temp. 340°C a) RD 25, SRat 6OH/10°C. ) RD>=25, NORT [Hot bead a 10501100

| co) i) Foc Design Temp. 540°C & ,=600°C:~ 3) RID 25, Normale at [040-1070 & Temper at 7604/-10%C__]Normalse at 1040-1060

| ') RDo/s2 & 600°C:~ 2) RID <2.5, Normalise at 1040-1070 & Tempera 760¥-10°C

') RDo/s2 & 10, No HT

7 For Incremental bonding, the parameters shal be suitably slated to ensure uniform eating of the entre thioess, Tempering and SR may be

jd except for PO.

‘PREPARED

VIVERANANDA YELLD, Se bell

JLEGEND: "D*" RECORDS IDENTIFIED WITH “TICK "(v) SHALL BE,

[ESSENTIALLY INCLUDED BY SUPPLIER IN QA DOCUMENTATION

+ M: MANUBACTURER / SUB ~ SUPPLIER B: BHEL / BHEL-TPI. N:

‘APPROVED BY

wid ON Scat

lwrpc. “P"; PERFORM “W": WITNESS "R'RANDOM AND " V"

| VERIFICATION. AS APPROPRIATE: CHP: CUSTOMER HOLD POINT,

PAGE 06 0F10

NHARAT HEAVY ELECTRICALS LTD QUALITY PLAN FOR PIPING FABRICATION |QP.NO : 7285: QPC : 19

PIPING CENTRE, CHENNAI ~17 (With Vendor Material) [REV.NO: 00.

QUALITY DEPARTMENT. |PROJECT NAME : -BARH STPP STAGE-I (3X 660 MW) IDATE : 04.08.2015

BIEL CUSTOMER Nos: 7285, 7286 8 727

Ne] conronent Tree oF | quawruw | sererence | Accarmaice | romwaror | [acencr ;

sans OPERATIONS ae oS) cece OFCHECK | DOCUMENT # NORMS, RECORDS WETS =

7 3 maf as z T 7 po S

Note 130; PRE HEAT, POST HEAT © POST WELD BEAT TREATMENT TEMPERATURE Dex O FOR PING

post WELD HEAT TREATWENT TEMP.

Dima Ee Sab and AaSnea Was

Peta joe Basemaal jn Pe acetate

| = reosn9/mm Troe 19 mm

| oor Pt 2 (Gr ©): These kas eto be een 150g. ©

. oe ak ie i. in Potcaes ah weet Sars Ce tn

eto’ Joos ww fu ovis fr rows erichancyecemt sng 8g 20 og. Costna

sts 10 fyi Joos laws formas

So ca sox mcSekingin an atig eto sng Sal ben

oonl3 Nit Nit ae 655-15 jas

tb ce 2s Pee

laters: eee Hi) Soaking: 2.5 minutes per mm of “1”

a sso jv ses lesewis ——_fesuas (por mint fr P2 wt >= (27 mm an

Some pecbaTe lesen thikner>= 3mm, hermit fr PO ad

wy Lo yaungaectnnnssinan te)

Ped j=. essveis Tacecset | Maxirumrateof Heating

roy boxe 10 fee lesws seis foswas — ee

| jopeiaae 130 [Ni loons free © [oasis Upto 25 mm ‘m0 Cir

ee Owe2sS0mm IOC

ie js esse i Ovrst73mm 73H

| eee ‘Over 75 mm ‘55 Ciltr

| loonie aro fso.2m fosswis — fosuas —fssuas

}P22+POL [Alle 720 [280-2 brs [760-1088 | 760+/-108% [7601-1088 |## : Preheat shall be maintained for P1SE Gr-1 (P91) urtil the welding

: f : L cons comple. ners temp saben 35085. Aer

ea = BI PD-BiaPRFLOREDIOR ODIO ts of PSE real bey cold down rom ey

then Kp aha emp fora asin of 72s oe PWT

|

FREEARED TEENS 'D™ RECORDS DENTIRED WHITTIER") SHALL BE PROVES EY

0 ESSENTIALLY INCLUDED BY SUPPLIER I Qa DOCUMENTATION

eer ae ro = tc MANUFACTURER / SUB SUPPLIER B: BHEL / BEL TPL S AN iG score

IN1PC. “P": PERFORM “W": WITNESS *R' RANDOM AND " V":

VERIFICATION. AS APPROPRIATE; CHP: CUSTOMER HOLD POINT.

PAGE 7OFI0

THARAT HEAVY ELECTRICALS LTD QUALITY PLAN FOR PIPING FABRICATION JQP NO : 7285: QPC:19

are eee ay

(QUALITY DEPARTMENT. [PROJECT NAME : -BARH STPP STAGE-I (3X 660 MW) IDATE : 04.08.2015

pra ante nee a

i Se oe oe ee eee

Ta z z z z z Z z z BL i ir

Mote

|S1.No |Sub Supplier Place |Remarks

|CS, P22 (*Hot finished seamless pipes &

|tubes - OD 38.0 mm to 273.0 mm WT: 3.5

| 3 fwr remaabad/ [rims atimm Cl raed semles

Seca onal

[72 |Wallorec & Mannesamenn France P91, P22, CS

9 _|JFE ( Kawasaki) Uapan P91, P22, CS

a iz eS

14 |Yangzhou Chengde Stee! Pipe Co Ltd [China ere B22 tw yinan Conon eace amp on

ae ee oe=

ane, on a ae oe

pew cae ere ae

| VERIFICATION. AS APPROPRIATE; CHP: CUSTOMER HOLD POINT ee

TURD WARAT HEAVY ELECTRICATSIDD ‘(QUALITY PLAN FOR PIPING FABRICATION [QP NO : 7285: QPC:19

ir PIPING CENTRE, CHENNA=17 (With Vendor Material) JREV.NO: 00

(QUALITY DEPARTMENT. PROJECT NAME : -BARH STPP STAGE-I (3X 660 MW) DATE : 04.08.2015

BHEL CUSTOMER Nos: 7285, 7286 & 7287.

(COMPONENT & Tye OF | QuanTum | REFERENCE ] ACCEPTANCE | FoRMaror | [aceNcY ee

=Y OPERATIONS ee class! “cuscx | orcueck | pocuments | NoRMs RECORDS Teh ene

fa z z z z i z i z Bp 0 7

(CS, P22 (*Hot finished seamniess pipes &

tubes - OD 33.4 mm to 168.3 mm WT :3.5

| 27 hindat saw a Nasik: mm to 21.95 mm * Cold finsihed seamless

| pipes & tubes - OD 6.0 mm to 140.0 mm WT

(0.8 mm to 15.0 mm)

[ia [rennaris Global (Dalmine) italy P91, P22, CS

19. [liangsu Chengde Steel Tube Share [china (CS, P22 (upto 219.0 mm),

| ICS Hot finished seamless pipes - OD 219.1

st i

Pea ee mm to 355.6 mm WT: 6.35 mm to 35.1mm

21_[Arcelor Mittal Romania iS

22,_[Valconvy Trub Chomutov [Czech Rep (CS, Pad, P22

| (CS, P22 (*Hot finished seamless pipes &

| tubes -00 28.6 mm to 177.8 mm WT:3.0

23. |Remi Bharuch imm to 28.0 mm * Cold finsined seamless

pipes & tubes - OD 9.0 mm to 127.0 mm WT

1.6 mm to 20.0 mm)

24 |Ringril Italy Forged CS Pipe (upto OD $14 X WT 102mm)

25 |/BHEL [Trichy |AS upto P22/T22 grade & OD upto 133mm

b) For Gr-91 Fittings :-

[SLNo [Sub Supplier Place [Remarks

[4 [Sunekwang Bend Co Ltd Korea P91 7 F91, Formed, Forged & Welded

2 [IBF SPA. italy P91 /F91, Formed, Forged & Welded

[3 Teast Luigi SPA italy P91 /F8i, Forged & Welded

[4 [mega sea italy P91 / F91, & Welded

PREPARED ICEGEND: "D RECORDS IDENTIFIED WITH “TICK (v7) SHALL BE ‘APPROVED BY

0 S. f [ESSENTIALLY INCLUDED BY SUPPLIER IN QA DOCUMENTATION

| SRANANDA VECUG, Sr ENGR OA = M: MANUFACTURER / SUB - SUPPLIER B: BHEL / BHEL-TPL N anny iAP, AaM/@

INTPC. “P”: PERFORM “W": WITNESS “R’RANDOM AND " V"

[VERIFICATION. AS APPROPRIATE: CHP: CUSTOMER HOLD POINT PAGE opOF IO

FTE WARAT HEAVY ELECTRICALS LTD

PIPING CENTRE, CHENNAI 17

ETA listens,

‘QUALITY PLAN FOR PIPING FABRICATION

(With Vendor Material)

PROJECT NAME : -BARH STPP STAGE-I (3X 660 MW)

[BHEL CUSTOMER Nos: 7285, 7286 & 7287.

[QP NO -7285 QC: 19

REV.NO: 00

DATE. : 08.08.2015,

Si eo eee

11 _|BGH Edelstanl Seigen GmBH [Germany |P91, Forged

12_|TKCorp [Korea |P91, Formed

13_|Bokyoung Metal Corp Korea |P91 / F91, Forged

|P91 / F91, Formed & Forged ( size upto 273

14 pesos \vizeg Imm dia and thickness upto 30 mm)

grade upto 2"

c) Other than Gr-91 Fittings :- As per the list attached. Refer annexure-I.

pe ea ea

a enya ——

seeneaeeacunsh/ ss ba

| VERIFICATION. AS APPROPRIATE: CHP: CUSTOMER HOLD POINT PAGE W0FW

Вам также может понравиться

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Pipe Hangers and Supports Materials, Design, Manufacture, Selection, Application, and InstallationДокумент6 страницPipe Hangers and Supports Materials, Design, Manufacture, Selection, Application, and InstallationAnonymous gr5Pr9AV0% (3)

- Combustion Optimization-Technology Developments ExperiencesДокумент60 страницCombustion Optimization-Technology Developments ExperiencesAnonymous gr5Pr9AV100% (1)

- Corrosion Control of Ductile Iron Pipelines - Dipra PDFДокумент10 страницCorrosion Control of Ductile Iron Pipelines - Dipra PDFAnonymous gr5Pr9AVОценок пока нет

- Long Term Test Report-9578-001-132-Pvm-W-030-00Документ35 страницLong Term Test Report-9578-001-132-Pvm-W-030-00Anonymous gr5Pr9AVОценок пока нет

- RAW Material TC For GRP PipesДокумент13 страницRAW Material TC For GRP PipesAnonymous gr5Pr9AVОценок пока нет

- Spring FailureДокумент39 страницSpring FailureAnonymous gr5Pr9AVОценок пока нет

- 14 - Cooling Water Spec - DI PDFДокумент2 страницы14 - Cooling Water Spec - DI PDFAnonymous gr5Pr9AVОценок пока нет

- Comparison Between Light Box Test and Vacuum Chamber TestДокумент2 страницыComparison Between Light Box Test and Vacuum Chamber TestAnonymous gr5Pr9AVОценок пока нет

- BHEL PIPING Standard Quality Plan 1439553413Документ10 страницBHEL PIPING Standard Quality Plan 1439553413Anonymous gr5Pr9AVОценок пока нет

- DENOXДокумент8 страницDENOXAnonymous gr5Pr9AV100% (1)

- History of Thermal Power PlantsДокумент9 страницHistory of Thermal Power PlantsAnonymous gr5Pr9AVОценок пока нет

- Boiler Tube Failure in Natural Circulation High Pressure Drum Boiler of A Power StationДокумент5 страницBoiler Tube Failure in Natural Circulation High Pressure Drum Boiler of A Power StationAnonymous gr5Pr9AVОценок пока нет

- Visual Examination GuideДокумент13 страницVisual Examination GuideAnonymous gr5Pr9AVОценок пока нет

- Welded Pipes For CRH Line-SummaryДокумент1 страницаWelded Pipes For CRH Line-SummaryAnonymous gr5Pr9AVОценок пока нет

- Visual Examination GuideДокумент13 страницVisual Examination GuideAnonymous gr5Pr9AVОценок пока нет

- Casting NDT-Consolidated Acceptance Criteria For CastingДокумент2 страницыCasting NDT-Consolidated Acceptance Criteria For CastingAnonymous gr5Pr9AV100% (1)