Академический Документы

Профессиональный Документы

Культура Документы

Sigmacover 410

Загружено:

panji akbarАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Sigmacover 410

Загружено:

panji akbarАвторское право:

Доступные форматы

PRODUCT DATA SHEET December 12, 2014 (Revision of March 1, 2014)

SIGMACOVER™ 410 / AMERCOAT® 410

DESCRIPTION

Two-component, high solids, high-build, polyamide cured epoxy coating

PRINCIPAL CHARACTERISTICS

• General-purpose epoxy buildcoat in protective coating systems, for steel and concrete structures exposed to atmospheric

land or marine conditions

• Excellent durability

• Can be recoated with various two-component and conventional coatings, even after long weathering periods

• Easy application by airless spray

• Available in MIO or conventional pigmented grade

COLOR AND GLOSS LEVEL

• MIO and a selected range of colors

• Flat

BASIC DATA AT 20°C (68°F)

Data for mixed product

Number of components Two

Mass density 1.5 kg/l (12.5 lb/US gal), depending on color

MIO: 1.9 kg/l (15.9 lb/US gal)

Volume solids 80 ± 2%

VOC (Supplied) Directive 1999/13/EC, SED: max. 126.0 g/kg

UK PG 6/23(92) Appendix 3: max. 240.0 g/l (approx. 2.0 lb/US gal)

Recommended dry film thickness 75 - 200 µm (3.0 - 8.0 mils) depending on system

Theoretical spreading rate 10.7 m²/l for 75 µm (428 ft²/US gal for 3.0 mils)

Dry to touch 3 hours

Overcoating Interval Minimum: 8 hours

Maximum: Extended

Full cure after 7 days

Shelf life Base: at least 24 months when stored cool and dry

Hardener: at least 24 months when stored cool and dry

Notes:

- See ADDITIONAL DATA – Spreading rate and film thickness

- See ADDITIONAL DATA – Overcoating intervals

- See ADDITIONAL DATA – Curing time

Ref. 6823 Page 1/5

PRODUCT DATA SHEET December 12, 2014 (Revision of March 1, 2014)

SIGMACOVER™ 410 / AMERCOAT® 410

RECOMMENDED SUBSTRATE CONDITIONS AND TEMPERATURES

Substrate conditions

• Suitable primer must be dry and free from any contamination

• When applied to zinc silicate, a mist coat and full coat technique is required

Substrate temperature

• Substrate temperature during application and curing should be above 5°C (41°F)

• Substrate temperature during application and curing should be at least 3°C (5°F) above dew point

INSTRUCTIONS FOR USE

Mixing ratio by volume: base to hardener 80:20 (4:1)

• The temperature of the paint should preferably be above 15°C (59°F), otherwise extra thinner may be required to obtain

application viscosity

• Adding too much thinner results in reduced sag resistance and slower cure

• Thinner should be added after mixing the components

Induction time

None

Pot life

6 hours at 20°C (68°F)

Note: See ADDITIONAL DATA – Pot life

Airless spray

Recommended thinner

THINNER 91-92

Volume of thinner

0 - 10%, 30 - 40% when mist coat applied

Nozzle orifice

Approx. 0.46 – 0.53 mm (0.018 – 0.021 in)

Nozzle pressure

20.0 - 25.0 MPa (approx. 200 - 250 bar; 2901 - 3626 p.s.i.)

Ref. 6823 Page 2/5

PRODUCT DATA SHEET December 12, 2014 (Revision of March 1, 2014)

SIGMACOVER™ 410 / AMERCOAT® 410

Brush/roller

• Application by brush may show brush marking, due to the thixatropic nature of the paint and is most suitable to small areas,

tight angle areas or for stripe coating or touch-up

• Application by roller will leave roller marking and is suitable for minimum DFT requirements only

• A roller suitable for epoxy application must be used

Recommended thinner

THINNER 91-92

Volume of thinner

0 – 5%

Cleaning solvent

THINNER 90-53

ADDITIONAL DATA

Spreading rate and film thickness

DFT Theoretical spreading rate

75 µm (3.0 mils) 10.7 m²/l (428 ft²/US gal)

150 µm (6.0 mils) 5.3 m²/l (214 ft²/US gal)

200 µm (8.0 mils) 4.0 m²/l (160 ft²/US gal)

Overcoating interval for DFT up to 200 µm (8.0 mils)

Overcoating with... Interval 5°C (41°F) 10°C (50°F) 20°C (68°F) 30°C (86°F) 40°C (104°F)

various two-pack epoxy Minimum 36 hours 24 hours 8 hours 6 hours 4 hours

and polyurethane coatings Maximum Extended Extended Extended Extended Extended

Notes:

- This product has an unlimited overcoating interval provided the surface is free from chalking and other contaminations

- The optimum intercoat adhesion is obtained when the subsequent coating is applied before the full cure time of the previous coating has

elapsed

- In cases of exposure to direct sunlight or when the surface is contaminated it is recommended that the surface be cleaned and

roughened to ensure good adhesion of the subsequent coating.

Ref. 6823 Page 3/5

PRODUCT DATA SHEET December 12, 2014 (Revision of March 1, 2014)

SIGMACOVER™ 410 / AMERCOAT® 410

Curing time for DFT up to 200 µm (8.0 mils)

Substrate temperature Dry to touch Dry to handle Full cure

5°C (41°F) 12 hours 30 hours 20 days

10°C (50°F) 6 hours 24 hours 14 days

15°C (59°F) 4 hours 10 hours 10 days

20°C (68°F) 3 hours 8 hours 7 days

30°C (86°F) 2 hours 6 hours 5 days

40°C (104°F) 1.5 hours 4 hours 3 days

Note: Adequate ventilation must be maintained during application and curing (please refer to INFORMATION SHEETS 1433 and

1434)

Pot life (at application viscosity)

Mixed product temperature Pot life

10°C (50°F) 12 hours

15°C (59°F) 10 hours

20°C (68°F) 6 hours

25°C (77°F) 4 hours

30°C (86°F) 3 hours

40°C (104°F) 2 hours

SAFETY PRECAUTIONS

• For paint and recommended thinners see INFORMATION SHEETS 1430, 1431 and relevant Material Safety Data Sheets

• This is a solvent-borne paint and care should be taken to avoid inhalation of spray mist or vapor, as well as contact between

the wet paint and exposed skin or eyes

WORLDWIDE AVAILABILITY

It is always the aim of PPG Protective and Marine Coatings to supply the same product on a worldwide basis. However, slight

modification of the product is sometimes necessary to comply with local or national rules/circumstances. Under these

circumstances an alternative product data sheet is used.

Ref. 6823 Page 4/5

PRODUCT DATA SHEET December 12, 2014 (Revision of March 1, 2014)

SIGMACOVER™ 410 / AMERCOAT® 410

REFERENCES

• EXPLANATION TO PRODUCT DATA SHEETS INFORMATION SHEET 1411

• SAFETY INDICATIONS INFORMATION SHEET 1430

• SAFETY IN CONFINED SPACES AND HEALTH SAFETY, EXPLOSION HAZARD – INFORMATION SHEET 1431

TOXIC HAZARD

• SAFE WORKING IN CONFINED SPACES INFORMATION SHEET 1433

• DIRECTIVES FOR VENTILATION PRACTICE INFORMATION SHEET 1434

• CONVERSION TABLES INFORMATION SHEET 1410

• RELATIVE HUMIDITY – SUBSTRATE TEMPERATURE – AIR TEMPERATURE INFORMATION SHEET 1650

WARRANTY

PPG warrants (i) its title to the product, (ii) that the quality of the product conforms to PPG’s specifications for such product in effect at the time of manufacture and (iii) that the product shall be delivered free of the rightful claim of any

third person for infringement of any U.S. patent covering the product. THESE ARE THE ONLY WARRANTIES THAT PPG MAKES AND ALL OTHER EXPRESS OR IMPLIED WARRANTIES, UNDER STATUTE OR ARISING OTHERWISE IN

LAW, FROM A COURSE OF DEALING OR USAGE OF TRADE, INCLUDING WITHOUT LIMITATION, ANY OTHER WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE OR USE, ARE DISCLAIMED BY PPG. Any claim under this

warranty must be made by Buyer to PPG in writing within five (5) days of Buyer’s discovery of the claimed defect, but in no event later than the expiration of the applicable shelf life of the product, or one year from the date of the

delivery of the product to the Buyer, whichever is earlier. Buyer’s failure to notify PPG of such non-conformance as required herein shall bar Buyer from recovery under this warranty.

LIMITATIONS OF LIABILITY

IN NO EVENT WILL PPG BE LIABLE UNDER ANY THEORY OF RECOVERY (WHETHER BASED ON NEGLIGENCE OF ANY KIND, STRICT LIABILITY OR TORT) FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES IN ANY WAY RELATED TO, ARISING FROM, OR RESULTING FROM ANY USE MADE OF THE PRODUCT. The information in this sheet is intended for guidance only and is based upon laboratory tests that PPG believes to

be reliable. PPG may modify the information contained herein at any time as a result of practical experience and continuous product development. All recommendations or suggestions relating to the use of the PPG product, whether in

technical documentation, or in response to a specific inquiry, or otherwise, are based on data, which to the best of PPG’s knowledge, is reliable. The product and related information is designed for users having the requisite knowledge

and industrial skills in the industry and it is the end-user’s responsibility to determine the suitability of the product for its own particular use and it shall be deemed that Buyer has done so, as its sole discretion and risk. PPG has no

control over either the quality or condition of the substrate, or the many factors affecting the use and application of the product. Therefore, PPG does not accept any liability arising from any loss, injury or damage resulting from such

use or the contents of this information (unless there are written agreements stating otherwise). Variations in the application environment, changes in procedures of use, or extrapolation of data may cause unsatisfactory results. This

sheet supersedes all previous versions and it is the Buyer’s responsibility to ensure that this information is current prior to using the product. Current sheets for all PPG Protective & Marine Coatings Products are maintained at

www.ppgpmc.com. The English text of this sheet shall prevail over any translation thereof.

The PPG Logo, Bringing innovation to the surface., and all other trademarks herein are property of the PPG group of companies.

Ref. 6823 Page 5/5

Вам также может понравиться

- Pop Art: Summer Flip FlopsДокумент12 страницPop Art: Summer Flip FlopssgsoniasgОценок пока нет

- CIR vs RUEDA Estate Tax Exemption for Spanish NationalДокумент1 страницаCIR vs RUEDA Estate Tax Exemption for Spanish NationalAdriel MagpileОценок пока нет

- Both Sides NowДокумент3 страницыBoth Sides Nowd-railОценок пока нет

- Marraige and CompatabilityДокумент3 страницыMarraige and CompatabilityRamesh Menon100% (1)

- Kiln PDFДокумент134 страницыKiln PDFpanji akbarОценок пока нет

- Toles Higher SampleДокумент13 страницToles Higher SampleKarl Fazekas50% (2)

- Sigmacover™ 620: Product Data SheetДокумент5 страницSigmacover™ 620: Product Data SheetAnonymous fvO1W3100% (1)

- Counteracting Ring Formation in Rotary Kilns: Research Open AccessДокумент19 страницCounteracting Ring Formation in Rotary Kilns: Research Open Accesspanji akbarОценок пока нет

- Sigmacover 410Документ6 страницSigmacover 410Armanda SiryogiawanОценок пока нет

- en-US 6823MEДокумент5 страницen-US 6823MEbaseet gazaliОценок пока нет

- PPG PDS Phenguard 935Документ5 страницPPG PDS Phenguard 935sanguripОценок пока нет

- PPG PDS Phenguard 930Документ5 страницPPG PDS Phenguard 930sanguripОценок пока нет

- Phenguard™ 935: Product Data SheetДокумент5 страницPhenguard™ 935: Product Data SheetMahmoud TahaОценок пока нет

- SigmaCover 400 Product Data SheetДокумент4 страницыSigmaCover 400 Product Data SheetSomak DuariОценок пока нет

- Sigmazinc™ 109 HS: Product Data SheetДокумент5 страницSigmazinc™ 109 HS: Product Data SheetinnovativekarthiОценок пока нет

- Phenguard 930 (2018) PDFДокумент5 страницPhenguard 930 (2018) PDFkaleshОценок пока нет

- Phenguard™ 935: Product Data SheetДокумент6 страницPhenguard™ 935: Product Data SheetMuthuKumarОценок пока нет

- Amercoat® 68 G: Product Data SheetДокумент5 страницAmercoat® 68 G: Product Data SheetNizar BouchaalaОценок пока нет

- Sigmadur 580Документ6 страницSigmadur 580CRISTIAN SILVIU IANUCОценок пока нет

- Sigmacover™ 410/sigmacover™ 410 LT: Product Data SheetДокумент5 страницSigmacover™ 410/sigmacover™ 410 LT: Product Data SheetNaveedMalikОценок пока нет

- Sigmacover™ 410/sigmacover™ 410 LT: Product Data SheetДокумент5 страницSigmacover™ 410/sigmacover™ 410 LT: Product Data SheetNaveedMalikОценок пока нет

- Sigmashield 460Документ6 страницSigmashield 460Armanda SiryogiawanОценок пока нет

- Nova Guard 260 - InternalДокумент6 страницNova Guard 260 - InternalfaisalfaiОценок пока нет

- Sigma Cover 256Документ5 страницSigma Cover 256Trịnh Minh KhoaОценок пока нет

- Sigmaguard™ 730: Product Data SheetДокумент5 страницSigmaguard™ 730: Product Data SheetLjubomirSinđelićОценок пока нет

- Phenguard 965 (Finish)Документ5 страницPhenguard 965 (Finish)Rauf AliyevОценок пока нет

- Sigmaguard™ 730: Product Data SheetДокумент5 страницSigmaguard™ 730: Product Data SheetMahmoud TahaОценок пока нет

- Sigmaguard 730Документ5 страницSigmaguard 730Vijay KumarОценок пока нет

- Sigma Zinc 102en-US - 7702 PDFДокумент5 страницSigma Zinc 102en-US - 7702 PDFaselabollegalaОценок пока нет

- Sigma Zinc 102en-US - 7702Документ5 страницSigma Zinc 102en-US - 7702aselabollegalaОценок пока нет

- Sigmashield 2 GF (Mid Coat)Документ5 страницSigmashield 2 GF (Mid Coat)Rauf AliyevОценок пока нет

- New Guard Group: CoatingsДокумент6 страницNew Guard Group: CoatingsAryo WicaksonoОценок пока нет

- Sigmatherm™ 230 / PPG Hi-Temp™ 230: Product Data SheetДокумент5 страницSigmatherm™ 230 / PPG Hi-Temp™ 230: Product Data SheetAnonymous n4bJbeLAqОценок пока нет

- Sigmadur™ 550: Product Data SheetДокумент5 страницSigmadur™ 550: Product Data SheetAneesh Lie A YoungОценок пока нет

- Sigmadur™ 188: Product Data SheetДокумент5 страницSigmadur™ 188: Product Data SheetkaleshОценок пока нет

- Sigmatherm™ 230: Product Data SheetДокумент5 страницSigmatherm™ 230: Product Data SheetRanier FesarilloОценок пока нет

- en-US 7466Документ5 страницen-US 7466RizckyAdhiprasetyoОценок пока нет

- Sigmashield 905Документ5 страницSigmashield 905Vijay KumarОценок пока нет

- Sigmacover 620Документ5 страницSigmacover 620praveenpatel.pp7143Оценок пока нет

- en-US 7537Документ5 страницen-US 7537pradnyeyОценок пока нет

- en-US 7749Документ5 страницen-US 7749Movie LoverОценок пока нет

- SIGMALINE™ 2000: Product Data SheetДокумент5 страницSIGMALINE™ 2000: Product Data SheetAbhishek KaliaОценок пока нет

- Sigmaline™ 780 / Phenguard™ Subsea 780: Product Data SheetДокумент4 страницыSigmaline™ 780 / Phenguard™ Subsea 780: Product Data SheetscottОценок пока нет

- Sigmarine-28 Technical Data SheetДокумент4 страницыSigmarine-28 Technical Data SheetGurdeep Sungh AroraОценок пока нет

- Sigmadur™ 520: Product Data SheetДокумент5 страницSigmadur™ 520: Product Data SheetMANUEL LOPEZ MOLINAОценок пока нет

- Sigmacover 380 Data SheetДокумент5 страницSigmacover 380 Data SheetcloudОценок пока нет

- Sigmacover™ 620: Product Data SheetДокумент5 страницSigmacover™ 620: Product Data SheetMahmoud TahaОценок пока нет

- Sigmaline 2000Документ5 страницSigmaline 2000mahotkatОценок пока нет

- Sigmashield™ 880 / Amerlock® 880: Product Data SheetДокумент5 страницSigmashield™ 880 / Amerlock® 880: Product Data SheetIchsan RosidinОценок пока нет

- Sigmazinc 109hs PDFДокумент5 страницSigmazinc 109hs PDFAneesh Lie A YoungОценок пока нет

- SIGMALINE™ 2500: Product Data SheetДокумент5 страницSIGMALINE™ 2500: Product Data SheetEduardoОценок пока нет

- Sigmaline 2000Документ6 страницSigmaline 2000Prasad PalanichamyОценок пока нет

- Sigmacover™ 380: Product Data SheetДокумент5 страницSigmacover™ 380: Product Data SheetGibbs PerОценок пока нет

- en-US 7743Документ5 страницen-US 7743Jose Manuel Guizado SolisОценок пока нет

- Sigmazinc™ 68 SP: Product Data SheetДокумент5 страницSigmazinc™ 68 SP: Product Data SheetStuart LemonОценок пока нет

- en-US 7490Документ5 страницen-US 7490Movie LoverОценок пока нет

- Amerlock® 400 GF / Sigmashield™ 400: Product Data SheetДокумент5 страницAmerlock® 400 GF / Sigmashield™ 400: Product Data SheetscottОценок пока нет

- Pitt-Char XP - TdsДокумент4 страницыPitt-Char XP - TdsMohamed NouzerОценок пока нет

- Sigmafast 155YДокумент5 страницSigmafast 155YStephen Francis BothelloОценок пока нет

- Sigmacover 850 Sigmashield 880 HSДокумент6 страницSigmacover 850 Sigmashield 880 HSshahrimanОценок пока нет

- en-US 7605Документ5 страницen-US 7605Ha SonОценок пока нет

- Sigmacover™ 456: Product Data SheetДокумент6 страницSigmacover™ 456: Product Data SheetscottОценок пока нет

- Sigmashield™ 880 / Amerlock® 880: Product Data SheetДокумент5 страницSigmashield™ 880 / Amerlock® 880: Product Data Sheetjaime San Martin PulgarОценок пока нет

- Sigmacover-456 Technical Data SheetДокумент6 страницSigmacover-456 Technical Data SheetGurdeep Sungh AroraОценок пока нет

- Amer Coat 383 Sigma Fast TdsДокумент5 страницAmer Coat 383 Sigma Fast TdsVINAY SARDAОценок пока нет

- Sigmarine 48 1Документ5 страницSigmarine 48 1Sail 'O' RiderОценок пока нет

- Zinc Silicate Primer Product Data SheetДокумент6 страницZinc Silicate Primer Product Data Sheetgst ajahОценок пока нет

- HARDNESS TEST METHODSДокумент13 страницHARDNESS TEST METHODShaizum_adamОценок пока нет

- INSPECTION of Galvanize Product PDFДокумент24 страницыINSPECTION of Galvanize Product PDFNasikhatul AmanahОценок пока нет

- JIS Z2331, 2003 SS Covered ElectrodesДокумент18 страницJIS Z2331, 2003 SS Covered Electrodespanji akbarОценок пока нет

- Overview of Steel Surface Preparation: H. William HitzrotДокумент5 страницOverview of Steel Surface Preparation: H. William Hitzrotpanji akbarОценок пока нет

- Manual For Cyclic Triaxial TestДокумент49 страницManual For Cyclic Triaxial Testpanji akbarОценок пока нет

- Malaysia Standart IncomingДокумент21 страницаMalaysia Standart Incomingpanji akbarОценок пока нет

- General5 PDFДокумент18 страницGeneral5 PDFrifqimaterialОценок пока нет

- 05 RecrystallizationsДокумент26 страниц05 Recrystallizationspanji akbarОценок пока нет

- Property Law-FDДокумент9 страницProperty Law-FDNavjit SinghОценок пока нет

- Napoleon Edwards Amended Complaint - RedactedДокумент13 страницNapoleon Edwards Amended Complaint - Redactedthe kingfishОценок пока нет

- Trilogy Monthly Income Trust PDS 22 July 2015 WEBДокумент56 страницTrilogy Monthly Income Trust PDS 22 July 2015 WEBRoger AllanОценок пока нет

- Clem Amended ComplaintДокумент26 страницClem Amended ComplaintstprepsОценок пока нет

- Chapter 14 Exercises - Investments - BodieДокумент2 страницыChapter 14 Exercises - Investments - BodieNguyệtt HươnggОценок пока нет

- 해커스토익 김진태선생님 2020년 7월 적중예상문제Документ7 страниц해커스토익 김진태선생님 2020년 7월 적중예상문제포도쨈오뚜기Оценок пока нет

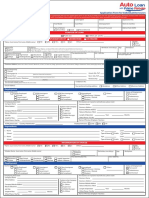

- Psbank Auto Loan With Prime Rebate Application Form 2019Документ2 страницыPsbank Auto Loan With Prime Rebate Application Form 2019jim poblete0% (1)

- Co-Operative Act (No. 14 of 2005)Документ45 страницCo-Operative Act (No. 14 of 2005)MozitomОценок пока нет

- MC No. 005.22Документ5 страницMC No. 005.22raymund pabilarioОценок пока нет

- Maam CoryДокумент3 страницыMaam CoryCHERIE ANN APRIL SULITОценок пока нет

- Test 1. Answer SheetДокумент3 страницыTest 1. Answer SheetAdi AlshtiwiОценок пока нет

- Austerity Doesn't Work - Vote For A Real Alternative: YoungerДокумент1 страницаAusterity Doesn't Work - Vote For A Real Alternative: YoungerpastetableОценок пока нет

- Denatured Fuel Ethanol For Blending With Gasolines For Use As Automotive Spark-Ignition Engine FuelДокумент9 страницDenatured Fuel Ethanol For Blending With Gasolines For Use As Automotive Spark-Ignition Engine FuelAchintya SamantaОценок пока нет

- TAXATION LAW EXPLAINEDДокумент41 страницаTAXATION LAW EXPLAINEDSarika MauryaОценок пока нет

- Ds Tata Power Solar Systems Limited 1: Outline AgreementДокумент8 страницDs Tata Power Solar Systems Limited 1: Outline AgreementM Q ASLAMОценок пока нет

- Carrier Liability for Passenger DeathДокумент256 страницCarrier Liability for Passenger DeathLouie EllaОценок пока нет

- Pappu Kumar Yadaw's CAT Exam Admit CardДокумент2 страницыPappu Kumar Yadaw's CAT Exam Admit Cardrajivr227Оценок пока нет

- Script FiestaДокумент5 страницScript FiestaLourdes Bacay-DatinguinooОценок пока нет

- Partnership Liability for Debts IncurredДокумент12 страницPartnership Liability for Debts IncurredDennis VelasquezОценок пока нет

- School EOEДокумент1 страницаSchool EOEMark James S. SaliringОценок пока нет

- DocsssДокумент4 страницыDocsssAnne DesalОценок пока нет

- Etm 2011 7 24 8Документ1 страницаEtm 2011 7 24 8Varun GuptaОценок пока нет

- JIRA Issue-Bug March OnwardsДокумент10 страницJIRA Issue-Bug March OnwardsMoses RashidОценок пока нет

- Muzaffarnagar Riots Report - The Jat PerspectiveДокумент11 страницMuzaffarnagar Riots Report - The Jat Perspectivedharma nextОценок пока нет

- Education in The Face of Caste: The Indian CaseДокумент13 страницEducation in The Face of Caste: The Indian CaseParnasha Sankalpita BhowmickОценок пока нет