Академический Документы

Профессиональный Документы

Культура Документы

Safety Critical Systems and International Standard IEC 61508

Загружено:

kfathi55Исходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Safety Critical Systems and International Standard IEC 61508

Загружено:

kfathi55Авторское право:

Доступные форматы

Join us on telegram.

me/iComm

The ABB Guide to

Safety Critical Systems and International Standard IEC 61508

1 Concept

IEC 61508 Safety Lifecycle Overview of

ABB provides a total life cycle safety capability aligned to the IEC 61508 Safety 2 Overall Scope Definition Lifecycle Phases

Lifecycle. We are the best-placed leading international company to be able to advise

you on all phases from Concept (1) to Decommissioning (16), including the Hazard and Pre-Design Phases 1-5

Risk Analysis which is necessary to determine the overall safety requirements of any 3 Hazard Risk Analysis

plant or process. In addition, ABB offers a comprehensive selection of instrumentation End User / Operator

and other equipment required to implement fully safety compliant plant, whether as

4 Overall Safety Requirements Set the SIL target

stand alone products or in fully integrated packages. These are supported by our

installation, commissioning, operation, maintenance and other services.

5 Safety Requirements Allocation Design and Installation

Phases 6-13

(Engineering /

Overall Planning 9 Safety Related 10 Safety Related 11 External Risk Equipment Supplier)

Systems: Systems: Reduction

6 Overall Operation 7 Overall 8 Overall Installation E / E / PES Other Facilities

& Maintenance Validation & Commissioning Technology Design the architecture /

Planning Planning Planning Provide the integrity

Realisation Realisation Realisation

information

Overall Installation

12 & Commissioning Operation Phases 14-16

(End User / Operator)

13 Overall Safety Validation

Operate & Test to

14 Overall Operation & Maintenance 15 Overall Modification & Retrofit Verify Target SIL

= Design SIL = Operation.

Manage maintenance

16 Decommissioning Lifecycle repeats and modifications

Pre-Design Phases 1 – 5 (End User / Operator)

Setting the SIL Target

Safety Integrity Levels Typical Methodology

Safety Average Probability of % Reliability • Hazard studies and HAZOPs • Build event chain

Integrity Level Failure on Demand (PFDavg)

1 0.1 to 0.01 90% to 99% Hazard & Risk Analysis • Evaluate possible

consequences

• Estimate demand rates

• Define protection required

2 0.01 to 0.001 99% to 99.9% • Establish tolerable • Specify required Safety

3 0.001 to 0.0001 99.9% to 99.99% frequencies vs ALARP Integrity Level

4 0.0001 to 0.00001 99.99% to 99.999%

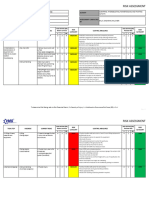

SIL Determination Methodologies Introducing Risk Reduction and Risk Targets

Identify

Risk W3 W2 W1 Potential Residual Residual Process

CA X1

Graphs a --- --- Hazardous risk risk risk

Starting point X2 Operations Events Assess

for risk reduction PA 1 a --- On-going Risk

PB

Review

CB

estimation FA X3

FB PA 2 1 a

CC PB X4

FA

FB PA

3 2 1

X5

CD FA

PB Necessary risk reduction

Generalized arrangement

FB PA

4 3 2

(in practical implementations

the arrangement is specific PB X6

to the applications to be b 4 3 Actual risk reduction

Design Compare

covered by the risk graph)

C = Consequence parameter

---= No safety requirements

a = No special safety requirements Safety Overall with

F = Exposure time parameter Risk reduction

P = Probability of avoiding the hazardous event

W = In the absence of the SIF under consideration

b = A single SIF is not sufficient

1, 2, 3, 4 = Safety integrity level

Instrumented

Function

Lifecycle Criteria

Risk reduction

from other

Risk reduction

from other

non-SIS

from SIS layer protection

prevention /

Layer of Protection Analysis layers

mitigation layers

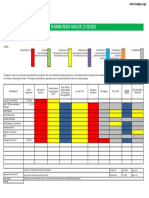

# 1 2 3 4 5 6 7 8 9 10 11

PROTECTION LAYERS

Impact Severity Initiating Initiation General BPCS Alarms, Additional IPL Inter- SIF Mitigated Notes Risk reduction achieved by all protection layers

event level cause likelihood process F.14.5 etc. mitigation, additional mediate integrity event

description

F.3

F.4

F.14.1

F.5

F.14.2

F.6

F.14.3

design

F.14.4

F.14.6 restricted mitigation

access F.8 dikes,

event

likelihood

level

F.11

likelihood

F.12

Assess SIL Assess

F.14.1 F.14.7 pressure

relief

F.10

F.14.9

F.14.10 F.14.10 for Instrumented Required

F.9

F.14.8 Risk Reduction Risk Reduction

1 Fire from S Loss of 0,1 0,1 0,1 0,1 0,1 PRV 01 10-7 10-2 10-9 High Allocate

distillation

column

cooling

water

pressure

causes Risk For Safety Lifecycle and Hazard Analysis

rupture column

rupture Reduction to

2 Fire from

distillation

S Steam

control

0,1 0,1 0,1 0,1 PRV 01 10-6 10-2 10-8 Same

as

Technologies advice, please call 01642 372000.

column loop above

rupture failure

N

For details of relevant ABB

Instrumentation, Systems and Equipment,

Fault Tree OVERPRESSURIZATION

0.1/year please call 0870 600 6122.

Analysis

EXTERNAL EVENTS BPCS FUNCTION

(fire) FAILS

BPCS SENSOR VALVE

Legend

OR

Demand more from your instrumentation.

FAILS FAILS STUCK

Basic event

Transfer gate

Demand more from your source.

www.abb.co.uk/instrumentation ABB Limited, Howard Road, St Neots, Cambridgeshire, PE19 8EU, UK. Tel: 0870 600 6122 WP/SIL Issue 1 (09.03)

Вам также может понравиться

- HIMA - Safety BasicsДокумент37 страницHIMA - Safety BasicsLisdan100% (1)

- Isa 62443-3-3-2013Документ84 страницыIsa 62443-3-3-2013kfathi55100% (1)

- Emergency Response PlanДокумент355 страницEmergency Response Plankfathi5586% (7)

- A Embedded Software Testing Process ModelДокумент5 страницA Embedded Software Testing Process ModelNV Raman PrasadОценок пока нет

- Wagoappjson: Release 1.1.0.11Документ32 страницыWagoappjson: Release 1.1.0.11MarcioWatanabeОценок пока нет

- Edwards+Radial+5+ +A06.DesbloqueadoДокумент39 страницEdwards+Radial+5+ +A06.DesbloqueadoalfomapperОценок пока нет

- 4 - SIL TrainingДокумент23 страницы4 - SIL TrainingNGUYEN HUU TUANОценок пока нет

- Characteristics of LPGasДокумент8 страницCharacteristics of LPGasAnkita KulshreshthaОценок пока нет

- Life Saving Rules: Safety by Choice, Not by ChanceДокумент32 страницыLife Saving Rules: Safety by Choice, Not by ChanceAnonymous wPVGEORpjHОценок пока нет

- NCCEH Extreme Heat Event - Health Checklist WEB - 0Документ5 страницNCCEH Extreme Heat Event - Health Checklist WEB - 0WL TribuneОценок пока нет

- Green Chemistry ProjectДокумент4 страницыGreen Chemistry Projectapi-320290632Оценок пока нет

- 3 SOP - Emergency Procedure - Final Sent To Zones Without PhotДокумент20 страниц3 SOP - Emergency Procedure - Final Sent To Zones Without PhotVijayОценок пока нет

- Activity 3.2.1 Training Needs Analysis (Документ1 страницаActivity 3.2.1 Training Needs Analysis (Mahnoor MasroorОценок пока нет

- Heat StressДокумент2 страницыHeat StressChad WhiteheadОценок пока нет

- Diabetes and RamadanДокумент4 страницыDiabetes and Ramadan80082583Оценок пока нет

- Toolbox Meeting Guide Near MissesДокумент1 страницаToolbox Meeting Guide Near MissesIwan MsОценок пока нет

- Training Package: Life Saving RulesДокумент28 страницTraining Package: Life Saving RulesSomzworld SomzОценок пока нет

- Ipc 15 Valve CharacteristicsДокумент41 страницаIpc 15 Valve CharacteristicsHarsh RavalОценок пока нет

- PSM 22.1 - Element 17 - Incident Investigation - BSCAT (v2)Документ27 страницPSM 22.1 - Element 17 - Incident Investigation - BSCAT (v2)Ahmed AdelОценок пока нет

- Basic Occupational Safety & Health OverviewДокумент22 страницыBasic Occupational Safety & Health OverviewXerxa LinganОценок пока нет

- User-Manual-25262Compressed Gas Cylinders PowerPointДокумент20 страницUser-Manual-25262Compressed Gas Cylinders PowerPointMohammed NaseeruddinОценок пока нет

- Emcy Resp PlanДокумент40 страницEmcy Resp PlanredchaozОценок пока нет

- Technical Report on SIWES at Nigerian BreweriesДокумент18 страницTechnical Report on SIWES at Nigerian BreweriesBenbaroОценок пока нет

- Npe Project Ikpt Hsse Programs 2018: NO. Programmed & CoursesДокумент1 страницаNpe Project Ikpt Hsse Programs 2018: NO. Programmed & CoursesilhamОценок пока нет

- LPG Check ListДокумент39 страницLPG Check ListARUL SANKARANОценок пока нет

- H2S Awareness Training EssentialsДокумент40 страницH2S Awareness Training EssentialsANSHUL HIKERОценок пока нет

- PDO Hse AuditДокумент21 страницаPDO Hse Auditnagul kmtcОценок пока нет

- Safety Moment - Cope With Heat Stress - PpsДокумент8 страницSafety Moment - Cope With Heat Stress - PpsAnthony BarnesОценок пока нет

- DBBVДокумент29 страницDBBVsanchay2503Оценок пока нет

- Bulk LPG TT - Safety in Design & OperationДокумент35 страницBulk LPG TT - Safety in Design & OperationNilambar Bariha100% (1)

- Confined Space Entry: Safety Manual: 5.2.1Документ19 страницConfined Space Entry: Safety Manual: 5.2.1mangesh.narkar638Оценок пока нет

- LNG Handbook Provides Guidance for Establishing SupplyДокумент60 страницLNG Handbook Provides Guidance for Establishing SupplyAbhishek LeveОценок пока нет

- LPG Bottling Plant Operation ProcessesДокумент15 страницLPG Bottling Plant Operation ProcessesmdashrafalamОценок пока нет

- Name: SignДокумент1 страницаName: SignAdel AlKhedawyОценок пока нет

- Shift Handover HF KilДокумент119 страницShift Handover HF KilmashanghОценок пока нет

- Tyco Qatar Company ProfileДокумент14 страницTyco Qatar Company ProfileMohammad Areyan RaajОценок пока нет

- LPG Safety Data SheetДокумент8 страницLPG Safety Data Sheetbungi888Оценок пока нет

- RA-0021 Eastern Perumai at Fujairah Port (Drydock Area) BLASTING & PAINTINGДокумент6 страницRA-0021 Eastern Perumai at Fujairah Port (Drydock Area) BLASTING & PAINTINGJustine Christian DimaculanganОценок пока нет

- Pro Hse 024 Eni Iraq r00 - Working in Confined Space - Annex IДокумент3 страницыPro Hse 024 Eni Iraq r00 - Working in Confined Space - Annex IMohammed Hamza100% (1)

- 04 Incident InvestigationsДокумент26 страниц04 Incident InvestigationsRoman SydorovОценок пока нет

- Osha Niosh Heat Illness InfosheetДокумент3 страницыOsha Niosh Heat Illness InfosheetUsman RajputОценок пока нет

- Cossh Risk Assessment - Austren GarnetДокумент3 страницыCossh Risk Assessment - Austren GarnetKishor KoshyОценок пока нет

- Cardinal Rules January 2013Документ31 страницаCardinal Rules January 2013MUKAОценок пока нет

- Hse MS SlidesДокумент32 страницыHse MS SlidesEneyo Victor100% (1)

- Qatar Operations Org Chart 2016Документ1 страницаQatar Operations Org Chart 2016Mohamed ShehataОценок пока нет

- KPI Definitions Visualizations v1 0bДокумент15 страницKPI Definitions Visualizations v1 0bMakhrus ShofiОценок пока нет

- System Safety Engineering An Overview For Engineers and ManagersДокумент42 страницыSystem Safety Engineering An Overview For Engineers and Managersmadonnite3781Оценок пока нет

- 1 45Документ3 страницы1 45nsadnan0% (1)

- Fire and Gas Mapping SolutionДокумент3 страницыFire and Gas Mapping SolutionGustavo AgudeloОценок пока нет

- HSE MS Training Feb 2019Документ17 страницHSE MS Training Feb 2019Tatak Bay AhmedОценок пока нет

- Basics of Functional Safety in Process Industry (SIL ClassificationДокумент33 страницыBasics of Functional Safety in Process Industry (SIL Classification최재호Оценок пока нет

- 08PR301C - Storage and Handling of Gas CylindersДокумент7 страниц08PR301C - Storage and Handling of Gas Cylinderskenoly123Оценок пока нет

- Positioning of Sensors GuidelinesДокумент3 страницыPositioning of Sensors GuidelinesMátyás DalnokiОценок пока нет

- 17 Subcon RequirementsДокумент38 страниц17 Subcon RequirementsMohammed MinhajОценок пока нет

- Air Receiver Tank Hazard ChecklistДокумент2 страницыAir Receiver Tank Hazard ChecklistJade JavierОценок пока нет

- Industry LPG Transport DisciplineДокумент18 страницIndustry LPG Transport DisciplineLittle PtshОценок пока нет

- PGT005 Control Valves TrainingДокумент12 страницPGT005 Control Valves TrainingJom BonhayagОценок пока нет

- Diference Between HAZID and HAZOPДокумент2 страницыDiference Between HAZID and HAZOPQueziaОценок пока нет

- HSEQ - Calibration KitdddeeДокумент4 страницыHSEQ - Calibration KitdddeeSalim MuftahОценок пока нет

- HSE RegulationsДокумент60 страницHSE RegulationsChandrasekhar SonarОценок пока нет

- Fire HydrantsДокумент22 страницыFire HydrantsRaduОценок пока нет

- 134 A - Flexible Hose SafetyДокумент1 страница134 A - Flexible Hose SafetyNibha100% (1)

- ABB 2003 The ABB Guide To Safety Critical Systems and International Standard IEC 61508Документ1 страницаABB 2003 The ABB Guide To Safety Critical Systems and International Standard IEC 61508NICOОценок пока нет

- ABB +SIL+Presentation PDFДокумент41 страницаABB +SIL+Presentation PDFsatishkumar0085Оценок пока нет

- Assurance Technologies Principles and Practices: A Product, Process, and System Safety PerspectiveОт EverandAssurance Technologies Principles and Practices: A Product, Process, and System Safety PerspectiveОценок пока нет

- 4 5895258014406934730Документ80 страниц4 5895258014406934730kfathi55Оценок пока нет

- Hart ProtocolДокумент80 страницHart ProtocolPatil Mohan100% (1)

- Urea ChehutДокумент36 страницUrea Chehutkfathi55Оценок пока нет

- 5352 Full Document PDFДокумент72 страницы5352 Full Document PDFkfathi55Оценок пока нет

- Unix Haters HandbookДокумент360 страницUnix Haters Handbookfredx10Оценок пока нет

- WP01062F24EN0117-Frequency and Antenna Selection Effects On Accuracy of Free Space Radar-V002Документ6 страницWP01062F24EN0117-Frequency and Antenna Selection Effects On Accuracy of Free Space Radar-V002kfathi55Оценок пока нет

- S-RSBD Technical InfoДокумент60 страницS-RSBD Technical Infokfathi55Оценок пока нет

- 3bus094075r0301 Advant OcsДокумент400 страниц3bus094075r0301 Advant Ocsmotoro123444Оценок пока нет

- 5352 Full Document PDFДокумент72 страницы5352 Full Document PDFkfathi55Оценок пока нет

- 2CDC120068M0202 PDFДокумент654 страницы2CDC120068M0202 PDFkfathi55Оценок пока нет

- ACS501 Installation Startup PDFДокумент81 страницаACS501 Installation Startup PDFkfathi55Оценок пока нет

- Ips M in 120Документ45 страницIps M in 120kfathi55Оценок пока нет

- Unix Haters HandbookДокумент360 страницUnix Haters Handbookfredx10Оценок пока нет

- ANSI-IsA 5.4 Standard For Loop DiagramsДокумент22 страницыANSI-IsA 5.4 Standard For Loop DiagramsharishtokiОценок пока нет

- IEC 62439 SummaryДокумент51 страницаIEC 62439 Summarykfathi55Оценок пока нет

- Taylor Solutions Rockwell 2012Документ2 страницыTaylor Solutions Rockwell 2012kfathi55Оценок пока нет

- M in 110Документ33 страницыM in 110kfathi55Оценок пока нет

- 6AV21240MC010AX0 Datasheet en PDFДокумент10 страниц6AV21240MC010AX0 Datasheet en PDFkfathi55Оценок пока нет

- Flow Calibration Procedure PDFДокумент32 страницыFlow Calibration Procedure PDFkfathi55100% (1)

- IEC 62439 SummaryДокумент51 страницаIEC 62439 Summarykfathi55Оценок пока нет

- Compliance Checklist PSMДокумент7 страницCompliance Checklist PSMTomas Gaviria MartinezОценок пока нет

- SolidsNotes4 3Документ14 страницSolidsNotes4 3Prasit MeeboonОценок пока нет

- ANSI-IsA 5.4 Standard For Loop DiagramsДокумент22 страницыANSI-IsA 5.4 Standard For Loop DiagramsharishtokiОценок пока нет

- Steam TracingДокумент18 страницSteam TracingSyed Mujtaba Ali Bukhari100% (2)

- Risk AnalysisДокумент8 страницRisk Analysiskfathi55100% (1)

- Fluidized Bed Modeling Applied To The Analysis of Processes: Review and State of The ArtДокумент9 страницFluidized Bed Modeling Applied To The Analysis of Processes: Review and State of The Artkfathi55Оценок пока нет

- 1 s2.0 S187704281500614X Main PDFДокумент6 страниц1 s2.0 S187704281500614X Main PDFkfathi55Оценок пока нет

- 2002 KX250 Race TuningДокумент4 страницы2002 KX250 Race TuningKidKawie100% (1)

- L12 Tech BenchesДокумент7 страницL12 Tech BenchesIndira KarimovaОценок пока нет

- Zscaler Internet Access - 2022Документ7 страницZscaler Internet Access - 2022Mossasi ChunОценок пока нет

- L6 Interpreting FlowchartДокумент28 страницL6 Interpreting FlowchartRykkiHigajVEVOОценок пока нет

- IBM Impact 2011 - Five Guidelines To Better Process Modeling For Execution - Stuart and ZahnДокумент32 страницыIBM Impact 2011 - Five Guidelines To Better Process Modeling For Execution - Stuart and ZahnMing ChonlanotrОценок пока нет

- 03 Database Design 1SДокумент36 страниц03 Database Design 1SraymondОценок пока нет

- An Introduction To DockerДокумент15 страницAn Introduction To DockerPratham JaiswalОценок пока нет

- Quality Assurance in Software Project Management: Presented By: Muhammad Imran Malik Muhammad Ouns Qureshi Nasir AnsariДокумент14 страницQuality Assurance in Software Project Management: Presented By: Muhammad Imran Malik Muhammad Ouns Qureshi Nasir AnsariMuhammad Ouns QureshiОценок пока нет

- C++ Multi-Threaded Programming GuideДокумент72 страницыC++ Multi-Threaded Programming GuideNhiОценок пока нет

- Vehicle Parking Management SystemДокумент48 страницVehicle Parking Management SystemKeerthi Vasan L100% (3)

- Unit-2.3 PPT Basic Behavioural ModelingДокумент84 страницыUnit-2.3 PPT Basic Behavioural ModelingSiddharth RajОценок пока нет

- Diesel Engines for Unrestricted Continuous OperationДокумент2 страницыDiesel Engines for Unrestricted Continuous OperationJorge Bellido100% (1)

- Exception HandlingДокумент15 страницException HandlingRoshan ShawОценок пока нет

- Slides 08 PDFДокумент95 страницSlides 08 PDFRobin RohitОценок пока нет

- ReportДокумент23 страницыReportDurvesh PradhanОценок пока нет

- Tie Rod Cylinder 2Документ1 страницаTie Rod Cylinder 2Fernando RíosОценок пока нет

- POSIX THREADS MUTEX VARIABLESДокумент11 страницPOSIX THREADS MUTEX VARIABLESSuman KaurОценок пока нет

- 2011 Online CatalogДокумент198 страниц2011 Online CatalogdmkrouseОценок пока нет

- UK Approves Weichai Engine Family for Emissions ComplianceДокумент46 страницUK Approves Weichai Engine Family for Emissions ComplianceAlberto F. Apablaza Meza100% (1)

- DEF CON Safe Mode - Munoz Mirosh - Room For Escape Scribbling Outside The Lines of Template SecurityДокумент72 страницыDEF CON Safe Mode - Munoz Mirosh - Room For Escape Scribbling Outside The Lines of Template SecurityasdfОценок пока нет

- Knowledge Unit of Science and Technology: Laboratory Manual (CC1021) : (Programming Fundamentals) (Semester Fall-2021)Документ5 страницKnowledge Unit of Science and Technology: Laboratory Manual (CC1021) : (Programming Fundamentals) (Semester Fall-2021)Hassam ShahidОценок пока нет

- Thermodynamics 2Документ29 страницThermodynamics 2S Tunkla EcharojОценок пока нет

- SDLCДокумент74 страницыSDLCtharushikavishka56Оценок пока нет

- Rajesh Kumar's 11.8-year experience as an Automation Test AnalystДокумент5 страницRajesh Kumar's 11.8-year experience as an Automation Test AnalystSendil KumarОценок пока нет

- Apartment Portal System Project DocumentationДокумент155 страницApartment Portal System Project DocumentationShaikh BilalОценок пока нет

- Successful Software Development 2nd Edition Prentice HallДокумент779 страницSuccessful Software Development 2nd Edition Prentice HallWalid Rannoo100% (1)

- AIOU Distributed Computing AssignmentДокумент2 страницыAIOU Distributed Computing AssignmentNazish NaeemОценок пока нет