Академический Документы

Профессиональный Документы

Культура Документы

Optic Fiber Protection Overhead Ground Wire: Other Aluminium Products

Загружено:

burvanovОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Optic Fiber Protection Overhead Ground Wire: Other Aluminium Products

Загружено:

burvanovАвторское право:

Доступные форматы

OPGW

Optic fiber Protection Overhead Ground Wire

Other Aluminium products:

AAC (All aluminium conductor) Aluminium strip

AAAC (All aluminium alloy conductor) Aluminium wire

AACSR (All aluminium alloy conductor steel reinforced) Aluminium alloy wire

ACSR (All aluminium alloy conductor steel reinforced)

Solid sector shaped aluminium conductor

www.m-tec.co.ca / Marketing@m-tec.co.za / +2716 450 8200 Page 1 of 7

OPGW

Centre SUS tube single layer

Application:

OPGW conductor is strung on poles or structures in air, supporting its own weight.

Grounding via Aluminium cladded steel and Aluminium alloy conductor,

communication is done via optic fibres in stainless steel SUS tube.

Construction:

Centre wire: SUS tube or Al cladded SUS

1st layer: Aluminium cladded steel wires; Aluminium alloy wires; or combination of ACS & AA Wires

Illustration sketches is for reference only and may not always represent the exact conductor construction.

Specification:

NRS 061-1, IEC793, 794, ITU-T G 650,

IEEE P1138, IEC 61089

Construction

OPGW Size: short circuit rating kA, 1sec 3.2 5 5 7 12.00 12.50 12.22

Tensile rating, RTS kN 65 36 60 60 60 62 107

Fibres per SUS tube number 12, 24 or 48 fibres per SUS tube.

Number of SUS tubes number 1 1 1 1 1 1 1

Fibre SUS tube outer diameter mm 3.1 3.4 4.00 6.3 7.4 9.1 7.9

Aluminium in Al cladded SUS tube

mm² 0.0 0.0 0.0 18.0 29.8 51.8 35.8

(where applicable).

Aluminium Clad Steel

Number of wires # 6 6 6 9 5 5 8

Wire diameter 3.1 3.5 4.0 3.15 3.3 3.4 3.5

Wire area mm² 7.5 9.6 12.6 7.8 8.6 9.1 9.6

Total wire area nominal mm² 45.3 57.7 75.4 70.1 42.8 45.4 77.0

Aluminium in ACS mm² 19.5 32.4 32.4 30.2 18.4 13.2 33.1

Conductivity of wire @ 20°C % 30 40 30 30 30 20.3 30

Aluminium Alloy

Number of wires # - - - - 5 6 2

Wire diameter mm - - - - 3.3 3.4 3.5

Aluminium alloy area nom. mm² - - - - 43 54 19

Conductor physical properties

Diameter 1st layer mm 9.3 10.4 12.0 12.6 14.0 15.9 14.9

Diameter 2nd layer mm - - - - - - -

Total weight nominal kg/km 322 461 461 523 517 630 697

Total OPGW area (conductive components) mm² 45 58 75 88 73 97 113

Final layer stranding direction S/Z S Z Z Z Z Z Z

* RTS (rated tensile strength) kN 54 60 60 60 71.2 72.2 72.2

kgf/mm² 16,519 14,378 13,500 13,500 10,095 12,339 12,339

** Modulus of elasticity Initial

Mpa 162,000 141,000 132,390 132,390 99,000 121,000 121,000

kgf/mm² 15,693 13,659 12,825 12,825 9,590 11,722 11,722

** Modulus of elasticity Final

Mpa 153,900 133,950 125,770 125,770 94,050 114,950 114,950

** Coefficient of linear expansion nom. 10-6/°C 13.0 14.5 13.8 14.7 17.2 17.4 15.2

Maximum allowable temperature °C 200

Conductor electrical properties

* DC Resistance @ 20°C Ω/km 1.90 0.75 0.74 0.55 0.35 0.27 0.38

* Short Circuit 1.0 second kA 3.2 5 5 7 12 12.5 12.22

* Short circuit current capacity

- Initial temperature 20°C kA².s 10 25 25 31 144 156 149

- Final temperature maximum 200°C

Continues current rating A

Lightning Class: 0, 1, 2 or 3

Class 3 3 3 3 3 3 3

Ransfer rate (0:50C, 1:100C, 2:150C, 3:200C)

Lightning maximum durtation 0.5 seconds

Fibre identification: In all groups 1. Blue 2. Orange 3. Green 4. Brown 5. Slate/Grey 6. White 7. Red 8. Black 9. Yellow 10. Violet 11. Pink 12. Aqua

Fiber group identification: Binder colour:

1 x 12 fiber SUS tube: 12 fiber cable 12 fiber: group: no binder

1 x 24 fiber SUS tube: 24 fiber cable 12 fiber: groups: 1st group (Blue), 2nd group (Yellow)

1 x 48 fiber SUS tube: 12 fiber cable 1st tube 12 fiber: groups: 1st group (Blue), 2nd group (Yellow), 3rdgroup (Green), 4th group (Red),

Shipping length m 4000 4000 4000 4000 4000 4000 4000

Grease filling if applicable (IEC61089) Case 4 Case 4 Case 4 Case 4 Case 4 Case 4 Case 4

* Grease weight calculated: Nominal kg/km 4.4 5.6 7.4 4.6 5.0 5.3 5.6

Note: * calculated value, **data for information only

In addition to the sizes above, any other construction can be designed and manufactured on customer request.

Revision: R03 14/06/2017

The information contained within this document must not be copied, reprinted or reproduced in any form, either wholly or in part, without the written consent of M-TEC, The information is believed to be correct at the time of issue to the best of M-TEC’s knowledge. M-TEC reserves the right to

amend this specification without prior notification. This specification is not contractually valid unless specifically authorised by M-TEC. M-TEC shall not be liable for any damages whatsoever (including indirect, incidental, special, punitive or consequential damages and loss of profits, opportunities

or information) arising from or result from the use of or reliance on information contained in this document, and/or any inaccuracy or omission in such information contained in this document.

www.m-tec.co.ca / Marketing@m-tec.co.za / +2716 450 8200 Page 2 of 7

OPGW

Multi layer, inner layer SUS tube

Application:

OPGW conductor is strung on poles or structures in air, supporting its own weight.

Grounding via Aluminium cladded steel and Aluminium alloy conductor,

communication is done via optic fibres in stainless steel SUS tube.

Construction:

1st layer: Aluminium cladded steel wires with integrated SUS tube filled with thixotropic gel

protecting the optical fibres.

2nd Layer: Aluminium alloy wires.

Illustration sketches is for reference only and may not always represent the exact conductor construction.

Specification:

NRS 061-1, IEC793, 794, ITU-T G 650,

IEEE P1138, IEC 61089

Construction

OPGW Size: short circuit rating kA, 1sec 10 11 12 13 13 16 18 21

Tensile rating, RTS kN 58 58 60 72 75 60 70 95

Fibres per SUS tube number 12 or 24 per SUS tube under 4.00mm diameter or 48 fibres per SUS tube per SUS tube over 4.00mm diameter

Number of SUS tubes number 1/2 1/2 1/2 1/2 1/2 1/2 1/2 1/2

Fibre SUS tube outer diameter mm 2.70 3.00 3.10 3.10 3.10 3.40 3.75 4.00

Aluminium Clad Steel

Number of wires # 5 6/5 6/5 6/5 10 / 9 5/4 5/4 5/4

Wire diameter

Centre 2.8 3.0 3.2 3.2 3.2 3.5 3.80 4.1

1st layer mm 2.8 3.0 3.2 3.2 3.0 3.5 3.80 4.1

2nd layer 2.8 3.0 3.2 3.2 3.4 3.5 3.80 4.1

3.2mm: 8.05 9.6 11.3 13.2

Wire area mm² 6.2 7.1 8.0 8.0 3.0mm: 7.07

3.4mm: 9.08

Total wire area nominal mm² 30.8 42.4 / 35.3 48.2 / 40.2 48.2 / 40.2 79.7 / 72.6 81.2 / 76.3 92 / 84.9 101.3 / 94.2

Aluminium in ACS mm² 13.2 12.7 / 10.6 20.8 / 17.3 14 / 11.7 34.3 / 31.2 34.9 / 32.8 39.6 / 36.5 39.2 / 36.4

Conductivity of wire @ 20°C % 30 30 30 20.3 30 30 30 27

Aluminium Alloy

Number of wires # 12 15 12 12 7 12 12 12

Wire diameter mm 2.8 2.36 3.2 3.2 3.4 3.5 3.80 4.1

Aluminium alloy area nom. mm² 74 66 97 97 64 115 136 158

Conductor physical properties

Diameter 1st layer mm 8.4 9.0 9.6 9.6 9.2 10.5 11.4 12.3

Diameter 2nd layer mm 14.0 13.7 16.4 16.0 16.0 17.5 19.0 20.5

Total weight nominal kg/km 424 457 551 560 646 656 771 914

Total OPGW area (conductive components) mm² 105 149 / 142 145 / 137 188 / 180 145 / 137 412188 485878 565623

Final layer stranding direction S/Z Z Z Z Z Z Z Z Z

* RTS (rated tensile strength) kN 58 58 60 72 75 70 70 95

kgf/mm² 8,900 9,900 8,800 9,280 10,500 8,800 8,800 9,000

** Modulus of elasticity Initial

Mpa 87,279 97,086 86,299 91,000 102,970 86,299 86,299 88,260

kgf/mm² 8,455 9,405 8,360 8,816 9,975 8,360 8,360 8,550

** Modulus of elasticity Final

Mpa 82,915 92,232 81,984 86,455 97,821 81,984 81,984 83,847

** Coefficient of linear expansion nom. 10.6 18.3 17.0 18.3 17.8 16.3 18.3 18.4 18.1

Maximum allowable temperature °C 200

Conductor electrical properties

* DC Resistance @ 20°C Ω/km 0.40 0.37 0.27 0.29 0.35 0.23 0.19 0.17

* Short Circuit 1.0 second kA 10 11 12 13 13 16 18 20

* Short circuit current capacity

- Initial temperature 20°C kA².s 100 121 144 174 169 256 324 441

- Final temperature maximum 200°C

Continues current rating A

Lightning Class: 0, 1, 2 or 3

Class 1 1 1 1 1 1 1 1

Ransfer rate (0:50C, 1:100C, 2:150C, 3:200C)

Lightning maximum durtation 0.5 seconds

Fibre identification: In all groups 1. Blue 2. Orange 3. Green 4. Brown 5. Slate/Grey 6. White 7. Red 8. Black 9. Yellow 10. Violet 11. Pink 12. Aqua

Fiber group identification: Binder colour:

1 x 12 fiber SUS tube: 12 fiber cable 12 fiber: group: no binder

1 x 24 fiber SUS tube: 24 fiber cable 12 fiber: groups: 1st group (Blue), 2nd group (Yellow)

1st tube12 fiber: groups: 1st group (Blue), 2nd group (Yellow),

2 x 24 fiber SUS tubes: 48 fiber cable

2nd tube12 fiber: groups: 1st group (Green), 2nd group (Red)

1st tube 12 fiber: groups: 1st group (Blue), 2nd group (Yellow), 3rdgroup (Green), 4th group (Red),

2 x 48 fiber SUS tubes: 96 fiber cable

2nd tube 12 fiber: groups: 1st group (Blue), 2nd group (Yellow), 3rdgroup (Green), 4th group (Brown),

1st tube 12 fiber: groups: 1st group (Blue), 2nd group (Yellow), 3rdgroup (Green), 4th group (Red),

3 x 48 fiber SUS tubes: 144 fiber cable 2nd tube 12 fiber: groups: 1st group (Blue), 2nd group (Yellow), 3rdgroup (Green), 4th group (Brown),

3rd tube 12 fiber: groups: 1st group (Blue), 2nd group (Yellow), 3rdgroup (Green), 4th group (Grey),

Shipping length m 4000 4000 4000 4000 4000 4000 4000 4000

Grease filling if applicable (IEC61089) Case 2 Case 2 Case 2 Case 2 Case 2 Case 2 Case 2 Case 2

* Grease weight calculated: Nominal kg/km 13 13 16 16 18 19 23 26

Note: * calculated value, **data for information only

In addition to the sizes above, any other construction can

be designed and manufactured on customer request.

Revision: R03 14/06/2017

The information contained within this document must not be copied, reprinted or reproduced in any form, either wholly or in part, without the written consent of M-TEC, The information is believed to be correct at the time of issue to the best of M-TEC’s knowledge. M-TEC reserves the right to

amend this specification without prior notification. This specification is not contractually valid unless specifically authorised by M-TEC. M-TEC shall not be liable for any damages whatsoever (including indirect, incidental, special, punitive or consequential damages and loss of profits, opportunities

or information) arising from or result from the use of or reliance on information contained in this document, and/or any inaccuracy or omission in such information contained in this document.

www.m-tec.co.ca / Marketing@m-tec.co.za / +2716 450 8200 Page 3 of 7

OPGW

Multi layer, Centre SUS tube

Application:

OPGW conductor is strung on poles or structures in air, supporting its own weight.

Grounding via Aluminium cladded steel and Aluminium alloy conductor,

communication is done via optic fibres in stainless steel SUS tube.

Construction:

Centre wire: SUS tube filled with thixotropic gel

Specification: 1st layer: Aluminium cladded steel wires; Aluminium alloy wires; or combination of ACS & AA Wires

NRS 061-1, IEC793, 794, ITU-T G 650, 2nd Layer: Aluminium alloy wires.

IEEE P1138, IEC 61089

Construction

OPGW Size: short circuit rating kA, 1sec 10 12

Tensile rating, RTS kN 65 62

Fibres per SUS tube number 48 per SUS tube

Number of SUS tubes number 1 1

Fibre SUS tube outer diameter mm 3.60 3.80

Aluminium Clad Steel

Number of wires # 7 4

Wire diameter

Centre

1st layer mm 2.70 2.85

2nd layer

Wire area mm² 5.7 7.1

Total wire area nominal mm² 40.1 25.5

Aluminium in ACS mm² 8.1 3.6

Conductivity of wire @ 20°C % 20.3 14

Aluminium Alloy

Number of wires # 14 16

Wire diameter mm 2.5 2.85

Aluminium alloy area nom. mm² 69 102

Conductor physical properties

Diameter 1st layer mm 9.0 9.5

Diameter 2nd layer mm 14.0 15.2

Total weight nominal kg/km 476 473

Total OPGW area (conductive components) mm² 109 128

Final layer stranding direction S/Z Z Z

* RTS (rated tensile strength) kN 65 62

kgf/mm² 9,891 8,667

** Modulus of elasticity Initial

Mpa 97,000 85,000

kgf/mm² 9,396 8,234

** Modulus of elasticity Final

Mpa 92,148 80,745

** Coefficient of linear expansion nom. 10-6/°C 16.9 18.6

Maximum allowable temperature °C 200

Conductor electrical properties

* DC Resistance @ 20°C Ω/km 0.39 0.30

* Short Circuit 1.0 second kA 10 12

* Short circuit current capacity

- Initial temperature 20°C kA².s 100 144

- Final temperature maximum 200°C

Continues current rating A

Lightning Class: 0, 1, 2 or 3

Class 1 1

Ransfer rate (0:50C, 1:100C, 2:150C, 3:200C)

Lightning maximum durtation 0.5 seconds

Fibre identification: In all groups 1. Blue 2. Orange 3. Green 4. Brown 5. Slate/Grey 6. White 7. Red 8. Black 9. Yellow 10. Violet 11. Pink 12. Aqua

Fiber group identification: Binder colour:

1 x 12 fiber SUS tube: 12 fiber cable 12 fiber: group: no binder

1 x 24 fiber SUS tube: 24 fiber cable 12 fiber: groups: 1st group (Blue), 2nd group (Yellow)

1st tube12 fiber: groups: 1st group (Blue), 2nd group (Yellow),

2 x 24 fiber SUS tubes: 48 fiber cable

2nd tube12 fiber: groups: 1st group (Green), 2nd group (Red)

1st tube 12 fiber: groups: 1st group (Blue), 2nd group (Yellow), 3rdgroup (Green), 4th group (Red),

2 x 48 fiber SUS tubes: 96 fiber cable

2nd tube 12 fiber: groups: 1st group (Blue), 2nd group (Yellow), 3rdgroup (Green), 4th group (Brown),

1st tube 12 fiber: groups: 1st group (Blue), 2nd group (Yellow), 3rdgroup (Green), 4th group (Red),

3 x 48 fiber SUS tubes: 144 fiber cable 2nd tube 12 fiber: groups: 1st group (Blue), 2nd group (Yellow), 3rdgroup (Green), 4th group (Brown),

3rd tube 12 fiber: groups: 1st group (Blue), 2nd group (Yellow), 3rdgroup (Green), 4th group (Grey),

Shipping length m 4000 4000

Grease filling if applicable (IEC61089) Case 2 Case 2

* Grease weight calculated: Nominal kg/km 10 13

Note: * calculated value, **data for information only

In addition to the sizes above, any other construction can

be designed and manufactured on customer request.

Revision: R03 14/06/2017

The information contained within this document must not be copied, reprinted or reproduced in any form, either wholly or in part, without the written consent of M-TEC, The information is believed to be correct at the time of issue to the best of M-TEC’s knowledge. M-TEC reserves the right to

amend this specification without prior notification. This specification is not contractually valid unless specifically authorised by M-TEC. M-TEC shall not be liable for any damages whatsoever (including indirect, incidental, special, punitive or consequential damages and loss of profits, opportunities

or information) arising from or result from the use of or reliance on information contained in this document, and/or any inaccuracy or omission in such information contained in this document.

www.m-tec.co.ca / Marketing@m-tec.co.za / +2716 450 8200 Page 4 of 7

OPGW LT

ACS / Central AA Loose tube

Application:

OPGW conductor is strung on poles or structures in air, supporting its own weight.

Grounding via Aluminium cladded steel conductor, communication is done via optic fibres in PBT Loos

tubes encased in an Aluminium extruded tube.

Construction:

1st layer: Aluminium cladded steel wires with integrated SUS tube filled with thixotropic gel

Specification: protecting the optical fibres.

NRS 061-1, IEC793, 794, ITU-T G 650,

IEEE P1138, IEC 61089

Construction

OPGW Size: short circuit rating kA, 1sec 10

Tensile rating, RTS kN 58

Fibres per PBT / AA loose tube number 48

Fibre AA loose tube outer diameter mm 2.70

Aluminium Clad Steel

Number of wires # 5

Wire diameter

Centre

mm 2.8

1st layer

Wire area mm² 6.2

Total wire area nominal mm² 30.8

Aluminium in ACS mm² 13.2

Conductivity of wire @ 20°C % 30

Conductor physical properties

Diameter 1st layer mm 8.4

Diameter 2nd layer mm 15.2

Total weight nominal kg/km 424

Total OPGW area (conductive components) mm² 31

Final layer stranding direction S/Z Z

* RTS (rated tensile strength) kN 58

kgf/mm² 8,900

** Modulus of elasticity

Mpa 87,279

** Coefficient of linear expansion nom. 10-6/°C 18.3

Maximum allowable temperature °C 200

Conductor electrical properties

* DC Resistance @ 20°C Ω/km 0.40

* Short Circuit 1.0 second kA 10

* Short circuit current capacity

- Initial temperature 20°C kA².s 100

- Final temperature maximum 200°C

Continues current rating A

Lightning Class: 0, 1, 2 or 3

Class 1

Ransfer rate (0:50C, 1:100C, 2:150C, 3:200C)

Lightning maximum durtation 0.5 seconds

Fibre identification: In all tubes. 1. Blue 2. Orange 3. Green 4. Brown 5. Slate/Grey 6. White 7. Red 8. Black 9. Yellow 10. Violet 11. Pink 12. Aqua

Loose Tube identification: 1. Blue 2. Orange 3. Green 4. Brown

Shipping length m 4000

Grease filling if applicable (IEC61089) Case 2

* Grease weight calculated: Nominal kg/km 13

Note: * calculated value, **data for information only

In addition to the sizes above, any other construction can

be designed and manufactured on customer request.

Revision: R03 14/06/2017

The information contained within this document must not be copied, reprinted or reproduced in any form, either wholly or in part, without the written consent of M-TEC, The information is believed to be correct at the time of issue to the best of M-TEC’s knowledge. M-TEC reserves the right to

amend this specification without prior notification. This specification is not contractually valid unless specifically authorised by M-TEC. M-TEC shall not be liable for any damages whatsoever (including indirect, incidental, special, punitive or consequential damages and loss of profits, opportunities

or information) arising from or result from the use of or reliance on information contained in this document, and/or any inaccuracy or omission in such information contained in this document.

www.m-tec.co.ca / Marketing@m-tec.co.za / +2716 450 8200 Page 5 of 7

1. GENERAL

This specification covers the design requirements and performance standard for OPGW in overhead transmission line.

1.1 Conductor Description

Loose tube conductor is a design that has high tensile strength and flexibility in a compact cable size.

The stainless steel loose tube cable provides excellent optical transmission and physical performance.

1.2 Quality

Level of quality in our cable products is ensured through several quality control program including ISO 9001.

1.3 Reliability

Product reliability is ensured through rigorous qualification testing of each product family.

Both initial and periodic qualification testing are performed to assure the cable's performance and durability in the field environments.

2. OPTICAL FIBER

2.1 Single Mode Fiber, G652D

Single mode fiber manufactured by the vapour axial deposition (VAD) process to produce the highest quality glass with excellent geometry, high strength

characteristics, and attenuation that approaches theoretical minimum. The single mode fiber is fully compatible with other commercially available single mode fibres and

has the zero dispersion wavelength around 1310nm. The main operating wavelength region of the fiber is around 1310 nm and 1550 nm.

2.2 General Design

Its optical properties are achieved through a germanium doped silica based core with a pure silica cladding.

An acrylate protective coating is applied over glass cladding to provide the necessary maximum fiber lifetime.

2.3 Construction

Mode field diameter at 1310nm 9.2㎛ ± 0.4㎛

Mode field diameter at 1550nm 10.4㎛ ± 0.5㎛

Mode field concentricity error < 0.5㎛

Cladding diameter 125 ± 0.7㎛

Cladding non-circularity ≤ 0.7%

Primary coating material UV curable acrylate

Fibre diameter 250 ± 10㎛

2.4 Optical characteristics

Attenuation at 1310 nm ≤ 0.36 dB/km

Attenuation at 1550 nm ≤ 0.25 dB/km

Dispersion at 1285 ~ 1330nm ≤ 3.5ps/(nm.km)

Dispersion at 1550nm ≤ 18ps/(nm.km)

Zero dispersion wavelength 1300 ~ 1322nm

Zero dispersion slope < 0.093 ps/(nm².km)

Cable cut off wavelength (λccf) < 1260nm

2.5 Mechanical characteristics

Fiber proof test level ≥ 1% x 1sec

Bending test (75 mm diameter mandrel 100 turns) ≤ 0.05 dB at 1550nm

2.6 Removal of primary coating

For jointing, removal of primary coating is achieved without the use of any chemicals. A simple mechanical operation is sufficient to prepare the fiber for jointing.

3. Test and Inspection

All tests and inspection shall be made in accordance with above mentioned standard specification.

4. Packing and Marking

4.1 Finished cable shall be delivered on wooden drum or metal drum.

4.2 Each dead-end of cable shall have effectively sealed with heat shrinkable cap.

4.3 On side of the cable drum, required marking shall be printed.

4.4 The barrel diameter shall not be less than 40 times of the diameter of the cable.

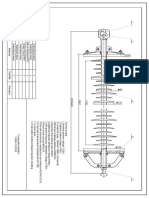

Dimension of Wooden Drum

[Unit: mm]

Drum details (Nominal)

Spindle

Reel

Barrel Flange Inner Flange Outer

hole

number width width

diameter diameter diameter diameter

AS 1900 1900 960 90 1088 1240

TB 2000 2000 1200 90 908 1060

SB 1700 1700 830 90 908 1060

SC 1600 1600 830 90 900 1052

CB 1300 1300 700 90 900 1052

DB 1000 1000 500 90 800 952

- We apply ISO, BS and DEF standard for drum construction, bolt size and etc.

- The dimension of drum is nominal value and so, if necessary, it will be possible to change applicable dimensions if needed.

Revision: R03 14/06/2017

The information contained within this document must not be copied, reprinted or reproduced in any form, either wholly or in part, without the written consent of M-TEC, The information is believed to be correct at the time of issue to the best of M-TEC’s knowledge. M-TEC reserves the right to

amend this specification without prior notification. This specification is not contractually valid unless specifically authorised by M-TEC. M-TEC shall not be liable for any damages whatsoever (including indirect, incidental, special, punitive or consequential damages and loss of profits, opportunities

or information) arising from or result from the use of or reliance on information contained in this document, and/or any inaccuracy or omission in such information contained in this document.

www.m-tec.co.ca / Marketing@m-tec.co.za / +2716 450 8200 Page 6 of 7

Wooden Drum Construction

The information contained within this document must not be copied, reprinted or reproduced in any form, either wholly or in part, without the written consent of M-TEC, The information is believed to be correct at the time of issue to the best of M-TEC’s knowledge. M-TEC reserves the right to

amend this specification without prior notification. This specification is not contractually valid unless specifically authorised by M-TEC. M-TEC shall not be liable for any damages whatsoever (including indirect, incidental, special, punitive or consequential damages and loss of profits, opportunities

or information) arising from or result from the use of or reliance on information contained in this document, and/or any inaccuracy or omission in such information contained in this document.

www.m-tec.co.ca / Marketing@m-tec.co.za / +2716 450 8200 Page 7 of 7

Вам также может понравиться

- ACSR Rail ZTTДокумент6 страницACSR Rail ZTTAntony Cesar Caballero IbarraОценок пока нет

- Technical Datasheet for Unolit 48203 K4-5 Wire Rope LubricantДокумент2 страницыTechnical Datasheet for Unolit 48203 K4-5 Wire Rope Lubricanttony mejiaОценок пока нет

- 24 Fiber OPGW ANDES PDFДокумент7 страниц24 Fiber OPGW ANDES PDFMAN TОценок пока нет

- TOPCABLE - RH5Z1-OL Al Eng - Rev7Документ4 страницыTOPCABLE - RH5Z1-OL Al Eng - Rev7apranaguptaОценок пока нет

- 132kV Composite InsulatorДокумент1 страница132kV Composite InsulatorAneelОценок пока нет

- 2B P6 MVCC - RDSS - PGVCL - Infra SBD - Part 2 - TS - Version-2 - 28062022Документ202 страницы2B P6 MVCC - RDSS - PGVCL - Infra SBD - Part 2 - TS - Version-2 - 28062022Mrugesh Samsung.m31sОценок пока нет

- ECO Conductors Low Loss Conductor SolutionДокумент2 страницыECO Conductors Low Loss Conductor SolutionBalaji_Rajaman_2280Оценок пока нет

- Arial Bunch ConductorДокумент10 страницArial Bunch Conductorbbakari2000Оценок пока нет

- Technical Specification for Medium Voltage AAA Covered Conductor & AccessoriesДокумент36 страницTechnical Specification for Medium Voltage AAA Covered Conductor & AccessoriesCabcon India100% (1)

- Types of Materials for Marine and Offshore CablesДокумент55 страницTypes of Materials for Marine and Offshore Cablesandy175Оценок пока нет

- MVCC-Tech SpecДокумент3 страницыMVCC-Tech Specvishnu ojhaОценок пока нет

- Aluminium ConductorsДокумент2 страницыAluminium ConductorsNgô Tiến PhúОценок пока нет

- 2 - Nexans Aerial CablesДокумент28 страниц2 - Nexans Aerial CablesMilan RadojkovicОценок пока нет

- Low Loss Conductor CatalogueДокумент4 страницыLow Loss Conductor Cataloguevishnu ojhaОценок пока нет

- Aaac 1120Документ1 страницаAaac 1120TriSanОценок пока нет

- Aerial Bundled Conductor Solutions: Product CatalogДокумент44 страницыAerial Bundled Conductor Solutions: Product CatalogNimish TaterhОценок пока нет

- TR18.03.05 Damping Study - Transmission Line On Tunrkey Basis 132kV Double Circuit LT - ACCC HAWK PDFДокумент29 страницTR18.03.05 Damping Study - Transmission Line On Tunrkey Basis 132kV Double Circuit LT - ACCC HAWK PDFAsaduzzaman KhanОценок пока нет

- Extra-High-Strength and Ultra-High-Strength Zinc-Coated (Galvanized) Steel Core Wire For Overhead Electrical ConductorsДокумент4 страницыExtra-High-Strength and Ultra-High-Strength Zinc-Coated (Galvanized) Steel Core Wire For Overhead Electrical ConductorsSofia YuliОценок пока нет

- Compact Round Concentric-Lay-Stranded Aluminum 1350 ConductorsДокумент6 страницCompact Round Concentric-Lay-Stranded Aluminum 1350 ConductorsThanh DangОценок пока нет

- OPGW Specification for Transmission LinesДокумент12 страницOPGW Specification for Transmission Linesgiorgis072Оценок пока нет

- ACCC Helsinki Conductor-Bill of QuantitiesДокумент1 страницаACCC Helsinki Conductor-Bill of QuantitiesGopal BhattaraiОценок пока нет

- 11 KV 120 SQMM AAA Covered Conductor TSДокумент7 страниц11 KV 120 SQMM AAA Covered Conductor TSabhishekОценок пока нет

- Iec 61869 - 87 2009Документ16 страницIec 61869 - 87 2009Anonymous UbwGTAcKlsОценок пока нет

- Datasheet Assembly Cable LugsДокумент6 страницDatasheet Assembly Cable LugsGunjanОценок пока нет

- Standard Specification For Copper, Bus Bar, Rod, and Shapes and General Purpose Rod, Bar, and Shapes ASTM B187 - B187M - 11Документ8 страницStandard Specification For Copper, Bus Bar, Rod, and Shapes and General Purpose Rod, Bar, and Shapes ASTM B187 - B187M - 11Mauricio Leyton OtarolaОценок пока нет

- Astm B411B411M-14Документ3 страницыAstm B411B411M-14Gabriel Perez CruzОценок пока нет

- Electrical inspection checklist for equipment suitability and installation safetyДокумент7 страницElectrical inspection checklist for equipment suitability and installation safetyBennyОценок пока нет

- Opgw Fiber Spec Dno 91391Документ5 страницOpgw Fiber Spec Dno 91391carlos diazОценок пока нет

- GTP For DPDC HTДокумент2 страницыGTP For DPDC HTjamilОценок пока нет

- Annexure B HT Aerial Bunched Cable (ABC)Документ1 страницаAnnexure B HT Aerial Bunched Cable (ABC)sunilgvoraОценок пока нет

- Routine Test Reports for DisconnectorsДокумент5 страницRoutine Test Reports for Disconnectorsgrigore mircea100% (1)

- SNOWBIRD ACSS Aluminum ConductorДокумент1 страницаSNOWBIRD ACSS Aluminum ConductorssappanОценок пока нет

- NA2XS (F) 2Y 26-45 KV 1x120Документ2 страницыNA2XS (F) 2Y 26-45 KV 1x120plavi10Оценок пока нет

- Limitei) : BRB Cable IndustriesДокумент10 страницLimitei) : BRB Cable IndustriesShahriar AhmedОценок пока нет

- Specification For PVC Insulated (Heavy Duty) Electric CablesДокумент18 страницSpecification For PVC Insulated (Heavy Duty) Electric CablesPrashant TrivediОценок пока нет

- (Catalogue) OPGW Ver.2Документ16 страниц(Catalogue) OPGW Ver.2scribdgineerОценок пока нет

- Nhxmh-O-J 300-500VДокумент4 страницыNhxmh-O-J 300-500VA. HassanОценок пока нет

- Fictitious Calculation Method For Determination of Dimensions of Protective Layer of HT CableДокумент8 страницFictitious Calculation Method For Determination of Dimensions of Protective Layer of HT CableChocki100% (1)

- Technical Specification For Low-Frequency Cables and Wires - Fo PDFДокумент40 страницTechnical Specification For Low-Frequency Cables and Wires - Fo PDFking_electricalОценок пока нет

- Compact Round Concentric-Lay-Stranded Copper Conductors: Standard Specification ForДокумент3 страницыCompact Round Concentric-Lay-Stranded Copper Conductors: Standard Specification ForCarlos HerreraОценок пока нет

- Resistance and Reactance of Copper and Aluminium CablesДокумент2 страницыResistance and Reactance of Copper and Aluminium CablesTheophilus AmaraОценок пока нет

- LS Catalogue HCCДокумент10 страницLS Catalogue HCCVICTOR JOSE VILORIAОценок пока нет

- Temperature, Low-Sag (HTLS) ConductorsДокумент3 страницыTemperature, Low-Sag (HTLS) ConductorsApoorv TalatiОценок пока нет

- BS6346-MULTICORE-CURRENT-CAPACITYДокумент1 страницаBS6346-MULTICORE-CURRENT-CAPACITYlkt_pestechОценок пока нет

- Drawing AAAC 630 MM PDFДокумент1 страницаDrawing AAAC 630 MM PDFdick rifki wardhanaОценок пока нет

- 600 / 1000v Stranded Copper Conductors PVC Insulated With Steel Wire Amour and PVC Sheathed Overall. (BS 6346: 1997)Документ8 страниц600 / 1000v Stranded Copper Conductors PVC Insulated With Steel Wire Amour and PVC Sheathed Overall. (BS 6346: 1997)Himdad TahirОценок пока нет

- OFO Installation Guidelines For ADSS Cables V6 PDFДокумент27 страницOFO Installation Guidelines For ADSS Cables V6 PDFUdriste DanielОценок пока нет

- Zolex - Bi Metalic PDFДокумент6 страницZolex - Bi Metalic PDFHemang M. GajjarОценок пока нет

- 2.3 Cable de Guardia - OPGW SPEC (15-53931)Документ9 страниц2.3 Cable de Guardia - OPGW SPEC (15-53931)xcazor morayОценок пока нет

- Theoretical Model for Assessing Zinc Layer Thickness in Overhead Power Line ConductorsДокумент6 страницTheoretical Model for Assessing Zinc Layer Thickness in Overhead Power Line Conductorsdeathjester1Оценок пока нет

- Aluminium Conductor Composite Core: Specification: ASTM B 857, ASTM B 609 Manufacturer SpecificationДокумент1 страницаAluminium Conductor Composite Core: Specification: ASTM B 857, ASTM B 609 Manufacturer SpecificationFani Dwi PutraОценок пока нет

- Tabla IEC 62219Документ5 страницTabla IEC 62219ManuelОценок пока нет

- FRP Rods For Brittle Fracture ResistantДокумент9 страницFRP Rods For Brittle Fracture Resistantdmsoares1989Оценок пока нет

- Technical Specification AL-59 Conductor 893Документ18 страницTechnical Specification AL-59 Conductor 893pramjitОценок пока нет

- Overhead Conductors Trefinasa 2016webДокумент52 страницыOverhead Conductors Trefinasa 2016weboaktree2010Оценок пока нет

- HVDC Rihand 500KVДокумент6 страницHVDC Rihand 500KVpremredОценок пока нет

- Carta Presentacion FerreteriaДокумент10 страницCarta Presentacion FerreteriaDrakhoОценок пока нет

- SIEMENS MTO ITEM No.: A4 25mm2 600/1000V XLPE power cableДокумент16 страницSIEMENS MTO ITEM No.: A4 25mm2 600/1000V XLPE power cablerhomadonaОценок пока нет

- OPGW Catalogo ZTTДокумент12 страницOPGW Catalogo ZTTlopesfelipe93Оценок пока нет

- Dno-6282-OPGW 12 HILOS PDFДокумент2 страницыDno-6282-OPGW 12 HILOS PDFCristyan Marcelo Rosero ChingalОценок пока нет

- High Voltage Skywrap: Fiber Optic CableДокумент1 страницаHigh Voltage Skywrap: Fiber Optic CableburvanovОценок пока нет

- High Voltage Reactive Power Brochure GBДокумент20 страницHigh Voltage Reactive Power Brochure GBburvanovОценок пока нет

- IT Application Guide Ed4Документ134 страницыIT Application Guide Ed4K Vijay Bhaskar ReddyОценок пока нет

- Service Manual: CDX-4270RДокумент12 страницService Manual: CDX-4270RburvanovОценок пока нет

- Lecture 03Документ18 страницLecture 03burvanovОценок пока нет

- T Rec L.26 201508 I!!pdf eДокумент24 страницыT Rec L.26 201508 I!!pdf eburvanovОценок пока нет

- E907w Wwen PDFДокумент92 страницыE907w Wwen PDFDarshana Herath LankathilakОценок пока нет

- ADSS Fiber Optic Cable Bismon 2018Документ4 страницыADSS Fiber Optic Cable Bismon 2018burvanovОценок пока нет

- High Voltage Skywrap: Fiber Optic CableДокумент1 страницаHigh Voltage Skywrap: Fiber Optic CableburvanovОценок пока нет

- ARB OHL CatalogueДокумент84 страницыARB OHL Catalogueburvanov60% (5)

- T Rec K.33 199610 W!!PDF eДокумент18 страницT Rec K.33 199610 W!!PDF eVatsanОценок пока нет

- Technical Catalogue for ConductorsДокумент150 страницTechnical Catalogue for ConductorsGanesh Veeran100% (1)

- ELEN 7000 - Main Report (Final Submission)Документ242 страницыELEN 7000 - Main Report (Final Submission)burvanovОценок пока нет

- How To Modify Old Qbasic Programs To Run in Visual Basic: Bergmann@rowan - Edu Chandrupatla@rowan - Edu Osler@rowan - EduДокумент7 страницHow To Modify Old Qbasic Programs To Run in Visual Basic: Bergmann@rowan - Edu Chandrupatla@rowan - Edu Osler@rowan - EduJohn K.E. EdumadzeОценок пока нет

- EuroEngineering Catalog 2009Документ23 страницыEuroEngineering Catalog 2009burvanovОценок пока нет

- Alstom Grid - RPC&HF - HV Air-Core ReactorsДокумент8 страницAlstom Grid - RPC&HF - HV Air-Core Reactorsmourinho22Оценок пока нет

- Spec6 01 140Документ13 страницSpec6 01 140burvanovОценок пока нет

- Composite Insulating Cross ArmsДокумент4 страницыComposite Insulating Cross ArmsburvanovОценок пока нет

- Data Sheet Rodurflex Composite Line PostДокумент1 страницаData Sheet Rodurflex Composite Line PostburvanovОценок пока нет

- OH VI 1 Fiber OpticДокумент38 страницOH VI 1 Fiber OpticRochaWillОценок пока нет

- Dynamic Response of The Switch Disconnect orДокумент7 страницDynamic Response of The Switch Disconnect orTran Thai DuongОценок пока нет

- Aislador Sediver CompositeДокумент16 страницAislador Sediver CompositeelatoradoОценок пока нет

- A185716 175Документ8 страницA185716 175burvanovОценок пока нет

- High Voltage Reactive Power Brochure GBДокумент20 страницHigh Voltage Reactive Power Brochure GBburvanovОценок пока нет

- Littelfuse ProtectionRelays SE 330AU Neutral Earthing Resistor Monitor Manual R3Документ32 страницыLittelfuse ProtectionRelays SE 330AU Neutral Earthing Resistor Monitor Manual R3burvanovОценок пока нет

- 164 - Accurate Simulation of AC Interference Caused by Electrical Power Lines - A Parametric AnalysisДокумент7 страниц164 - Accurate Simulation of AC Interference Caused by Electrical Power Lines - A Parametric AnalysisburvanovОценок пока нет

- Raychem Stripping Tool For Extruded and Bonded Cable ScreensДокумент4 страницыRaychem Stripping Tool For Extruded and Bonded Cable ScreensburvanovОценок пока нет

- CABLE SYSTEMS FOR ENERGY APPLICATIONSДокумент7 страницCABLE SYSTEMS FOR ENERGY APPLICATIONSburvanovОценок пока нет

- 380kV DiagonalConnection Brochure 50hertzДокумент15 страниц380kV DiagonalConnection Brochure 50hertzburvanovОценок пока нет

- API571 Part3Документ326 страницAPI571 Part3Charlie Chong100% (6)

- Construction Materials Technical Data SheetДокумент2 страницыConstruction Materials Technical Data SheetSHAIK ASIMUDDIN100% (1)

- PK29 3 0242Документ6 страницPK29 3 0242김정연Оценок пока нет

- Ceiling PDFДокумент1 страницаCeiling PDFjun vincint geleraОценок пока нет

- M Faisal Riyad@Sample SOPДокумент2 страницыM Faisal Riyad@Sample SOPZayed Khan100% (1)

- 4 Cement TechnologyДокумент43 страницы4 Cement TechnologySomu AdityaОценок пока нет

- Windshield Markings Explained - What To Know About Auto GlassДокумент3 страницыWindshield Markings Explained - What To Know About Auto GlassMiguel BentoОценок пока нет

- Concrete and Composite Poles Construction and Design GuideДокумент18 страницConcrete and Composite Poles Construction and Design GuideJayabalan R KОценок пока нет

- 2014 - 11 - Basic Metallurgy Grey Iron PDFДокумент34 страницы2014 - 11 - Basic Metallurgy Grey Iron PDFfelipeОценок пока нет

- Materials Used in Building ConstructionДокумент31 страницаMaterials Used in Building ConstructionRushaОценок пока нет

- LowCarbonConcrete ConcreteMagazineДокумент4 страницыLowCarbonConcrete ConcreteMagazineRdhn fingerstyleОценок пока нет

- 03.effects of Alloying ElementsДокумент8 страниц03.effects of Alloying Elementsandrian hermanОценок пока нет

- Self Priming Pump "Kpa" - Data Sheet - Data SheetДокумент3 страницыSelf Priming Pump "Kpa" - Data Sheet - Data SheetMohamed RashidОценок пока нет

- NMCE Commodity Report 25-02-2010Документ4 страницыNMCE Commodity Report 25-02-2010National Multi Commodity Exchange of India Ltd.Оценок пока нет

- CE 523 Research Assignment on Bridge Engineering DesignДокумент4 страницыCE 523 Research Assignment on Bridge Engineering DesignRuthОценок пока нет

- MAT 3420 Data SheetДокумент3 страницыMAT 3420 Data SheetDiógenes da Silva PereiraОценок пока нет

- SMR System DataSheetДокумент4 страницыSMR System DataSheetTracyОценок пока нет

- Straw As ReinforcementДокумент4 страницыStraw As ReinforcementANKIT KUMARОценок пока нет

- A Review On Dielectric Elastomer Actuators, Technology, Applications, and ChallengesДокумент11 страницA Review On Dielectric Elastomer Actuators, Technology, Applications, and ChallengesDaniel Garza ReynaОценок пока нет

- Liquid Composite Moulding TДокумент40 страницLiquid Composite Moulding TguillermoОценок пока нет

- ASTM Volume 08.04, January 2018 Plastic Piping SystemsДокумент7 страницASTM Volume 08.04, January 2018 Plastic Piping SystemsJ.CarrascoОценок пока нет

- Control of Chilling Tendency in Grey Cast Iron ReuДокумент6 страницControl of Chilling Tendency in Grey Cast Iron ReuMURSELIM ALIОценок пока нет

- An Overview On TeflonДокумент25 страницAn Overview On TeflonZainab Ali100% (1)

- Thesis Stage1 ME16B20M000005Документ11 страницThesis Stage1 ME16B20M000005bhavarajunba2024Оценок пока нет

- Skirt Board Rubber Sheet: Abrasion & Impact Resistant - Fire & Chemical Resistant - Good Mechanical StrengthДокумент1 страницаSkirt Board Rubber Sheet: Abrasion & Impact Resistant - Fire & Chemical Resistant - Good Mechanical StrengthDwi SetyaoneОценок пока нет

- Aws N-1 WPS-PQR FormДокумент2 страницыAws N-1 WPS-PQR FormEdwin MariacaОценок пока нет

- Ballistic Protective Clothing An Overview PDFДокумент18 страницBallistic Protective Clothing An Overview PDFJuanОценок пока нет

- Chap 3chemistryДокумент34 страницыChap 3chemistryLina AnberОценок пока нет

- Lubrication and Wear in Forging - Gear Solutions Magazine Your Resource To The Gear IndustryДокумент29 страницLubrication and Wear in Forging - Gear Solutions Magazine Your Resource To The Gear Industrynimesh singhОценок пока нет

- Is 875 1 1987Документ43 страницыIs 875 1 1987George SharonОценок пока нет