Академический Документы

Профессиональный Документы

Культура Документы

Conversion Cycle

Загружено:

Zara Jane DinhayanАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Conversion Cycle

Загружено:

Zara Jane DinhayanАвторское право:

Доступные форматы

The Conversion Cycle maintain inventory control, and perform cost

accounting.

The Traditional Manufacturing

Environment Documents in the Batch Processing

System

The context-level data flow diagram (DFD) in A manufacturing process such as that in Figure

Figure 7-1 illustrates the central role of the 7-2 could be triggered by either individual

conversion cycle and its interactions with other sales orders from the revenue cycle or by a

business cycles. Production is triggered by sales forecast the marketing system

customer orders from the revenue cycle and/or provides. For discussion purposes, we will

by sales forecasts from marketing. These assume the latter. The sales forecast shows

inputs are used to set a production target and the expected demand for a firm’s finished

prepare a production plan, which drives goods for a given period.

production activities. Purchase requisitions for

the raw materials needed to meet production The production schedule is the

objectives are sent to the purchases formal plan and authorization to begin

procedures (expenditure cycle), which prepares production. This document describes

purchase orders for vendors. Labor used in the specific products to be made, the

production is transmitted to the payroll system quantities to be produced in each

(expenditure cycle) for payroll processing. batch, and the manufacturing

Manufacturing costs associated with timetable for starting and completing

intermediate work-in-process and finished production

goods are sent to the general ledger and

financial reporting system. The bill of materials (BOM), an

example of which is illustrated in

Depending on the type of product being Figure 7-4, specifies the types and

manufactured, a company will employ one quantities of the raw material (RM) and

of the following production methods: subassemblies used in producing a

single unit of finished product.

1. Continuous processing creates a A route sheet, illustrated in Figure 7-

homogeneous product through a continuous 5, shows the production path that a

series of standard procedures. Cement and particular batch of product follows

petrochemicals are produced by this during manufacturing. It is similar

manufacturing method. Typically, under this conceptually to a BOM. Whereas the

approach firms attempt to maintain finished- BOM specifies material requirements,

goods inventory at levels needed to meet the route sheet specifies the sequence

expected sales demand. The sales forecast in of operations (machining or assembly)

conjunction with information on current and the standard time allocated to

inventory levels triggers this process. each task.

2. Make-to-order processing involves the

fabrication of discrete products in accordance

The work order (or production order)

with customer specifications. This process is

draws from BOMs and route sheets to

initiated by sales orders rather than depleted

specify the materials and production

inventory levels.

(machining, assembly, and so on) for

each batch.

3. Batch processing produces discrete groups

(batches) of product. Each item in the batch is

A move ticket, shown in Figure 7-7,

similar and requires the same raw materials

records work done in each work center

and operations. To justify the cost of setting up

and authorizes the movement of the

and retooling for each batch run, the number

job or batch from one work center to

of items in the batch tends to be large. This is

the next.

the most common method of production and is

used to manufacture products such as

A materials requisition authorizes

automobiles, household appliances, canned

the storekeeper to release materials

goods, automotive tires, and textbooks. The

(and subassemblies) to individuals or

discussion in this chapter is based on a batch

work centres in the production process.

processing environment.

This document usually specifies only

Batch Processing System standard quantities. Materials needed

in excess of standard amounts require

Four basic processes: plan and control separate requisitions that may be

production, perform production operations,

identified explicitly as excess materials To evidence that a stage of production has

requisitions. been completed, a copy of the move ticket is

sent back to production planning and control to

This allows for closer control over the update the open work order file. Upon receipt

production process by highlighting of the last move ticket, the open work order

excess material usage. In some cases, file is closed.

less than the standard amount of

material is used in production. When The finished product along with a copy of the

this happens, the work centres return work order is sent to the finished goods (FG)

the unused materials to the storeroom warehouse. Also, a copy of the work order is

accompanied by a materials return sent to inventory control to update the FG

ticket. Figure 7-8 presents a format inventory records. Work centers also fulfill an

that could serve all three purposes. important role in recording labor time costs.

This task is handled by work center supervisors

Batch Production Activities who, at the end of each work week, send

employee time cards and job tickets to the

Production Planning and Control. We first payroll and cost accounting departments,

examine the production planning and control respectively.

function. This consists of two main activities:

(1) specifying materials and operations Inventory Control. The inventory control

requirements and (2) production scheduling. function consists of three main activities. First,

it provides production planning and control

Materials and Operations Requirements. with status reports on finished goods and raw

The raw materials requirement for a batch of materials inventory. Second, the inventory

any given product is the difference between control function is continually involved in

what is needed and what is available in the raw updating the raw material inventory records

material inventory. This information comes from materials requisitions, excess materials

from analysis of inventory on hand, the sales requisitions, and materials return tickets.

forecast, engineering specifications (if any), Finally, upon receipt of the work order from the

and the BOM. A product of this activity is the last work center, inventory control records the

creation of purchase requisitions for additional completed production by updating the finished

raw materials goods inventory records.

Production Scheduling. The second activity An objective of inventory control is to minimize

of the planning and control function is total inventory cost while ensuring that

production scheduling. The master schedule for adequate inventories exist to meet current

a production run coordinates the production of demand. Inventory models used to achieve this

many different batches. The schedule is objective help answer two fundamental

influenced by time constraints, batch size, and questions:

specifications derived from BOMs and route

sheets. The scheduling task also produces work

orders, move tickets, and materials requisitions 1. When should inventory be purchased?

for each batch in the production run. 2. How much inventory should be purchased?

A copy of each work order is sent to cost

accounting to set up a new work-in-process

(WIP) account for the batch. The work orders, A commonly used inventory model is the

move tickets, and materials requisitions enter economic order quantity (EOQ) model.

the production process and flow through the This model, however, is based on simplifying

various work centers in accordance with the assumptions that may not reflect the economic

route sheet. reality. These assumptions are:

1. Demand for the product is constant and

Work Centers and Storekeeping. The actual known with certainty.

production operations begin when workers 2. The lead time—the time between placing an

obtain raw materials from storekeeping in order for inventory and its arrival—is known

exchange for materials requisitions. These and constant.

materials, as well as the machining and the

labor required to manufacture the product, are 3. All inventories in the order arrive at the

applied in compliance with the work order. same time.

When the task is complete at a particular work 4. The total cost per year of placing orders is a

center, the supervisor or other authorized variable that decreases as the quantities

person signs the move ticket, which authorizes ordered increase. Ordering costs include the

the batch to proceed to the next work center. cost of preparing documentation, contacting

vendors, processing inventory receipts,

maintaining vendor accounts, and writing

checks.

5. The total cost per year of holding

inventories (carrying costs) is a variable that

increases as the quantities ordered increase.

These costs include the opportunity cost of

invested funds, storage costs, property taxes,

and insurance.

6. There are no quantity discounts. Therefore,

the total purchase price of inventory for the

year is constant.

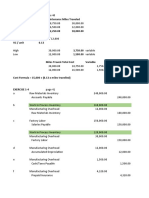

The objective of the EOQ model is to reduce

total inventory costs. The significant

parameters in this model are the carrying costs

and the ordering costs.

(insert figure 7-10)

World-Class Companies and minimizing waste and remaining flexible.

Success depends, in great part, on employees

Lean Manufacturing

understanding and embracing lean

manufacturing principles.

What Is a World-Class Company?

Indeed, the cultural aspects of this philosophy

The following features characterize the world are as important as the machines and

class company: methodologies it employs. The following

principles characterize lean manufacturing.

-World-class companies must maintain

strategic agility and be able to turn on a dime. Pull Processing. Products are pulled from the

Top management must be intimately aware of consumer end (demand), not pushed from

customer needs and not become rigid and the production end (supply). Under the lean

resistant to paradigm change. approach, inventories arrive in small quantities

from vendors several times per day, just in

-World-class companies motivate and treat time to go into production. They are pulled

employees like appreciating assets. To activate into production as capacity downstream

the talents of everyone, decisions are pushed becomes available. Unlike the traditional push

to the lowest level in the organization. The process, lean does not create batches of semi-

result is a flat and responsive organizational finished inventories at bottlenecks.

structure.

Perfect Quality. Success of the pull

-A world-class company profitably meets the processing model requires zero defects in raw

needs of its customers. Its goal is not simply to material, work-in-process, and finished goods

satisfy customers, but to positively delight inventory. Poor quality is very expensive to a

them. This is not something that can be done firm. Consider the cost of scrap, reworking,

once and then forgotten. With competitors scheduling delays, and extra inventories

aggressively seeking new ways to increase to compensate for defective parts, warranty

market share, a world-class firm must continue claims, and field service. In the traditional

to delight its customers. manufacturing environment, these costs can

represent between 25 and 35 % of total

-The philosophy of customer satisfaction product cost. Also, quality is a basis on which

permeates the world-class firm. All of its world-class manufacturers compete. Quality

activities, from the acquisition of raw materials has ceased to be a trade-off against price.

to selling the finished product, form a Consumers demand quality and seek the

chain of customers. Each activity is dedicated lowest-priced quality product.

to serving its customer, which is the next

activity in the process. The final paying Waste Minimization. All activities that do not

customer is the last in the chain. add value and maximize the use of scarce

resources must be eliminated. Waste involves

-Finally, manufacturing firms that achieve financial, human, inventory, and fixed

world-class status do so by following a assets. The following are examples of waste in

philosophy of lean manufacturing. This traditional environments, which lean

involves doing more with less, eliminating manufacturing seeks to minimize.

waste, and reducing production cycle time.

-Overproduction of products, which includes

Principles of Lean Manufacturing making more than needed and/or producing

earlier than needed.

Lean manufacturing evolved from the Toyota

Production System (TPS), which is based -Transportation of products farther than is

on the just-in-time (JIT) production model. minimally necessary.

This manufacturing approach is in direct

opposition to traditional manufacturing, which -Bottlenecks of products waiting to move to

is typified by high inventory levels, large the next production step.

production lot sizes, process inefficiencies, and

waste. The goal of lean production is improved -Idle workers waiting for work to do as

efficiency and effectiveness in every area, production bottlenecks clear.

including product design, supplier interaction,

factory operations, employee management, -Inefficient motion of workers who must walk

and customer relations. Lean involves getting more than necessary in the completion

the right products to the right place, at the of their assigned tasks.

right time, in the right quantity while

-Islands of technology created by stand-alone

processes that are not linked to upstream or shipping— everyone. Each employee must be

downstream processes. vigilant of problems that threaten the

continuous flow operation of the production

-Production defects that require unnecessary line. Lean requires a constant state of quality

effort to inspect and/or correct. control along with the authority to take

immediate action.

-Safety hazards that cause injuries and lost

work hours and associated expenses. Techniques and Technologies that

Promote Lean Manufacturing

Inventory Reduction. The hallmark of lean

manufacturing firms is their success in

Modern consumers want quality products, they

inventory reduction. ies, lean firms have only a

want them quickly, and they want variety of

few days or sometimes even a few hours of

choice. This demand profile imposes a

inventory on hand.

fundamental conflict for traditional

manufacturers, whose structured and inflexible

The three common problems outlined below

orientation renders them ineffective in this

explain why inventory reduction is important.

environment. In contrast, lean companies meet

the challenges of modern consumerism by

1. Inventories cost money. They are an

achieving manufacturing flexibility.

investment in materials, labor, and overhead

that cannot be realized until sold. Inventories

A.Physical Reorganization of the

also contain hidden costs. They must be

transported throughout the factory. They must Production Facilities

be handled, stored, and counted. In addition, A much simplified facility, which supports

Inventories lose value through obsolescence. flexible manufacturing, is presented in Figure

7-15. The flexible production system is

2. Inventories camouflage production organized into a smooth-flowing stream of

problems. Bottlenecks and capacity imbalances activities. Computer-controlled machines,

in the manufacturing process cause WIP robots, and manual tasks that comprise the

inventory to build up at the choke points. stream are grouped together physically into

Inventories also build up when customer factory units called cells. This arrangement

orders and production are out of sync. shortens the physical distances between the

activities, which reduces setup and processing

3. Willingness to maintain inventories can time, handling costs, and inventories flowing

precipitate overproduction. Because of setup through the facility.

cost constraints, firms tend to overproduce

inventories in large batches to absorb the

allocated costs and create the image of

improved efficiency. The true cost of this

dysfunctional activity is hidden in the excess

inventories.

Production Flexibility. Long machine setup

procedures cause delays in production and

encourage overproduction. Lean companies

strive to reduce setup time to a minimum,

which allows them to produce a greater

diversity of products quickly, without sacrificing

efficiency at lower volumes of production.

Established Supplier Relations. A lean

manufacturing firm must have established and

cooperative relationships with vendors. Late

deliveries, defective raw materials, or incorrect

orders will shut down production immediately

since this production model allows no

inventory reserves to draw upon.

Team Attitude. Lean manufacturing relies

heavily on the team attitude of all employees

involved in the process. This includes those in

purchasing, receiving, manufacturing,

B.Automation of the Manufacturing materials from stores to the shop floor and

Process finished products to the warehouse.

Automation is at the heart of the lean

manufacturing philosophy. By replacing labor *Robotics. Manufacturing robots are

with automation, a firm can reduce waste, programmed to perform specific actions over

improve efficiency, increase quality, and and over with a high degree of precision and

improve flexibility. are widely used in factories to perform jobs

such as welding and riveting. They are also

useful in hazardous environments or for

performing dangerous and monotonous tasks

that are prone to causing accidents.

*Computer-Aided Design (CAD). Engineers

use computer-aided design (CAD) to design

better products faster. CAD systems increase

engineers’ productivity, improve accuracy

by automating repetitive design tasks, and

allow firms to be more responsive to market

demands.

B.1.Traditional Manufacturing

*Computer-Aided Manufacturing (CAM).

The traditional manufacturing environment

Computer-aided manufacturing (CAM) is

consists of a range of different types of

the use of computers to assist the

machines, each controlled by a single operator.

manufacturing process. CAM focuses on the

Because these machines require a great deal of

shop floor and the control of the physical

setup time, the cost of setup must be absorbed

manufacturing process. The output of the CAD

by large production runs.

system (see Figure 7-17) is fed to the CAM

system. The CAD design is thus converted by

B.2.Islands of Technology

CAM into a sequence of processes such as

Islands of technology describes an

drilling, turning, or milling by CNC machines.

environment where modern automation exists

The CAM system monitors and controls the

in the form of islands that stand alone within

production process and routing of products

the traditional setting. The islands employ

through the cell. (insert figure)

computer numerical controlled (CNC)

machines that can perform multiple operations

Value Stream Mapping

with little human involvement. CNC machines

A company’s value stream includes all the

contain computer programs for all the parts

steps in the process that are essential to

that are manufactured by the machine. Under

producing a product. These are the steps for

a CNC configuration, humans still set up

which the customer is willing to pay.

the machines. A particularly important benefit

For example, balancing the wheels of each car

of CNC technology is, however, that little

off the production line is essential because the

setup time (and cost) is needed to change

customer demands a car that rides smoothly

from one operation to another.

and is willing to pay the price of the balancing.

B.3.Computer-Integrated Manufacturing

Companies pursuing lean manufacturing often

Computer-integrated manufacturing

use a tool called a value stream map (VSM)

(CIM) is a completely automated environment

to graphically represent their business

with the objective of eliminating non-value-

processes to identify aspects of it that are

added activities. A CIM facility makes use of

wasteful and should be removed. A VSM

group technology cells comprised of various

identifies all of the actions required to

types of CNC machines to produce an entire

complete processing on a product (batch or

part from start to finish in one location. In

single item), along with key information about

addition to CNC machines, the process employs

each action item.

automated storage and retrieval systems and

robotics.

*Automated Storage and Retrieval

Systems (AS/RS). Many firms have increased

productivity and profitability by replacing

traditional forklifts and their human operators

with automated storage and retrieval

systems (AS/RS). AS/RS are computer-

controlled conveyor systems that carry raw

Вам также может понравиться

- Chapter 7 The Conversion Cycle: Batch Processing SystemДокумент6 страницChapter 7 The Conversion Cycle: Batch Processing SystemAnne Rose EncinaОценок пока нет

- 05 Conversion CycleДокумент24 страницы05 Conversion CycleDillon Murphy100% (1)

- James Hall CH 1Документ21 страницаJames Hall CH 1ANNE PAMELA TIUОценок пока нет

- A New Systems Development Project Is Being Planned For Reindeer Christmas Supplies CompanyДокумент1 страницаA New Systems Development Project Is Being Planned For Reindeer Christmas Supplies CompanyAshleigh DelicacyОценок пока нет

- Ias 41 AgricultureДокумент33 страницыIas 41 AgriculturePrudence MagaragadaОценок пока нет

- Lesson Plan 02 - Cost Terminology and Cost BehaviorsДокумент3 страницыLesson Plan 02 - Cost Terminology and Cost BehaviorsIda TakahashiОценок пока нет

- Topic 4 Provisions, Contingent Liabilities and Contingent AssetsДокумент34 страницыTopic 4 Provisions, Contingent Liabilities and Contingent AssetsRavinesh PrasadОценок пока нет

- Quiz SIA - SolvedДокумент5 страницQuiz SIA - SolvedShinta AyuОценок пока нет

- M4 Budgeting For Profit and ControlДокумент8 страницM4 Budgeting For Profit and Controlwingsenigma 00Оценок пока нет

- MS 3407 Balanced Scorecard and Responsibility AccountingДокумент7 страницMS 3407 Balanced Scorecard and Responsibility AccountingMonica GarciaОценок пока нет

- Chapter 1Документ5 страницChapter 1Kyla CamilleОценок пока нет

- P2 Process CostingДокумент9 страницP2 Process CostingGanessa RolandОценок пока нет

- CompExam D AcceptedДокумент10 страницCompExam D Acceptedrahul shahОценок пока нет

- Philippine Interpretations Committee (Pic) Questions and Answers (Q&As)Документ6 страницPhilippine Interpretations Committee (Pic) Questions and Answers (Q&As)verycooling100% (1)

- Week 8Документ3 страницыWeek 8Anonymous J0pEMcy5vY100% (1)

- Far Qualifying ExaminationДокумент30 страницFar Qualifying ExaminationAlvin BaternaОценок пока нет

- Financial Reporting in Hyperinflationary EconomiesДокумент8 страницFinancial Reporting in Hyperinflationary EconomiesLakshminarasimman V RaoОценок пока нет

- Job Costing CAДокумент13 страницJob Costing CAmiranti dОценок пока нет

- PSBA - GAAS and System of Quality ControlДокумент10 страницPSBA - GAAS and System of Quality ControlephraimОценок пока нет

- TM 7 AklДокумент6 страницTM 7 AklSyam NrОценок пока нет

- 7Документ101 страница7Navindra JaggernauthОценок пока нет

- LCCM Class Activity Audit Program - Nov 16 2020-StudentДокумент4 страницыLCCM Class Activity Audit Program - Nov 16 2020-StudentLeane MarcoletaОценок пока нет

- CHAPTER 5 - Assignment SolutionДокумент16 страницCHAPTER 5 - Assignment SolutionCoci KhouryОценок пока нет

- Cost Concepts and ClassificationsДокумент15 страницCost Concepts and ClassificationsMae Ann KongОценок пока нет

- Accounting For Labor 3Документ13 страницAccounting For Labor 3Charles Reginald K. HwangОценок пока нет

- AFAR Test BankДокумент57 страницAFAR Test BankandengОценок пока нет

- Cost2 - Finals SY 2020 21 PDFДокумент10 страницCost2 - Finals SY 2020 21 PDFshengОценок пока нет

- Session 6 - Process Costing: Multiple ChoiceДокумент10 страницSession 6 - Process Costing: Multiple Choiceatty lesОценок пока нет

- Tutorial Questions Week 6Документ7 страницTutorial Questions Week 6julia chengОценок пока нет

- Blocher8e EOC SM Ch15 Final StudentДокумент53 страницыBlocher8e EOC SM Ch15 Final StudentKatelynОценок пока нет

- Fear and Risk in Audit Process PDFДокумент25 страницFear and Risk in Audit Process PDFElena DobreОценок пока нет

- Modul P&P - FAR320 Nov 2014-Yusnaliza Vs NorlianaДокумент21 страницаModul P&P - FAR320 Nov 2014-Yusnaliza Vs NorlianaAiman Abdul BaserОценок пока нет

- AFAR ProblemДокумент14 страницAFAR ProblemGil Enriquez100% (1)

- Chapter 1 - Strategic Cost Management: MidtermДокумент19 страницChapter 1 - Strategic Cost Management: MidtermAndrea Nicole De LeonОценок пока нет

- BUSINESS COMBINATION-lesson 1Документ10 страницBUSINESS COMBINATION-lesson 1Rhea Mae CarantoОценок пока нет

- Sample Exam 2Документ16 страницSample Exam 2Zenni T XinОценок пока нет

- Capital BudgetingДокумент4 страницыCapital Budgetingrachmmm0% (3)

- Chap 13 Statement of Cash FlowsPractice QuestionsДокумент7 страницChap 13 Statement of Cash FlowsPractice QuestionshatanoloveОценок пока нет

- THEORY26PROBLEMSДокумент10 страницTHEORY26PROBLEMSIryne Kim PalatanОценок пока нет

- Audit & Assurance ICMAP SyllabusДокумент5 страницAudit & Assurance ICMAP SyllabusEhtisham BukhariОценок пока нет

- Module IV: MUS Sampling - Factory Equipment Additions: RequirementsДокумент2 страницыModule IV: MUS Sampling - Factory Equipment Additions: RequirementsMukh UbaidillahОценок пока нет

- Redesigning Cost Systems: Is Standard Costing Obsolete?Документ10 страницRedesigning Cost Systems: Is Standard Costing Obsolete?SillyBee1205Оценок пока нет

- Scanner CAP II Financial ManagementДокумент195 страницScanner CAP II Financial ManagementEdtech NepalОценок пока нет

- Acco 20073 Discussion Sy2122 (Bsma 2-4)Документ81 страницаAcco 20073 Discussion Sy2122 (Bsma 2-4)Paul BandolaОценок пока нет

- The Dilemma at Day 21Документ4 страницыThe Dilemma at Day 21Christian AndreОценок пока нет

- Cost Concepts and ClassificationsДокумент5 страницCost Concepts and ClassificationsAbdulrahman M. MacacuaОценок пока нет

- Intermediate AccountingДокумент60 страницIntermediate AccountingResky Andika YuswantoОценок пока нет

- 2 Presentation of Financial Statements - Lecture Notes PDFДокумент14 страниц2 Presentation of Financial Statements - Lecture Notes PDFCatherine RiveraОценок пока нет

- Kuis Perbaikan UTS AKbi 2016-2017Документ6 страницKuis Perbaikan UTS AKbi 2016-2017Rizal Sukma PОценок пока нет

- Question Bank - Practical QuestionsДокумент10 страницQuestion Bank - Practical QuestionsNeel KapoorОценок пока нет

- AT-05 (Quality Management)Документ7 страницAT-05 (Quality Management)Soremn Potatohead100% (1)

- Long Term Construction ContractsДокумент2 страницыLong Term Construction ContractsJM BalanoОценок пока нет

- New and Old Conceptual Framework, Accounting Principles, Accounting Process, PAS 18 - RevenueДокумент13 страницNew and Old Conceptual Framework, Accounting Principles, Accounting Process, PAS 18 - RevenueDennis VelasquezОценок пока нет

- Course Outline Audit & TaxДокумент5 страницCourse Outline Audit & TaxMuhammad RizwanОценок пока нет

- Proposed Strategic Position: Porter's Generic StrategyДокумент3 страницыProposed Strategic Position: Porter's Generic StrategyAyunda Utari100% (1)

- Standard Cost and Components and Variance AnalysisДокумент7 страницStandard Cost and Components and Variance AnalysisNaveen RajputОценок пока нет

- Flexible Budgets, Variances, and Management Control: I: Learning ObjectivesДокумент14 страницFlexible Budgets, Variances, and Management Control: I: Learning ObjectivesKelvin John RamosОценок пока нет

- Process Costing Wave HWДокумент6 страницProcess Costing Wave HWReynard GomezОценок пока нет

- Chapter 7the Conversion Cycle SummaryДокумент13 страницChapter 7the Conversion Cycle Summary0nionringsОценок пока нет

- Chapter 7 Detailed ReportДокумент32 страницыChapter 7 Detailed ReportHarvey AguilarОценок пока нет

- Booking and Approval of Cafeteria Cycle MenuДокумент1 страницаBooking and Approval of Cafeteria Cycle MenuZara Jane DinhayanОценок пока нет

- Robotics Process Automation (RPA) OpportunitiesДокумент4 страницыRobotics Process Automation (RPA) OpportunitiesZara Jane DinhayanОценок пока нет

- White PaperДокумент5 страницWhite PaperZara Jane DinhayanОценок пока нет

- White PaperДокумент5 страницWhite PaperZara Jane DinhayanОценок пока нет

- Conversion Cycle WordsДокумент2 страницыConversion Cycle WordsZara Jane DinhayanОценок пока нет

- Chapter 13 Management of People RelationshipsДокумент3 страницыChapter 13 Management of People RelationshipsZara Jane DinhayanОценок пока нет

- Audit Software ReportДокумент2 страницыAudit Software ReportZara Jane DinhayanОценок пока нет

- Intercompany BondsДокумент6 страницIntercompany BondsZara Jane DinhayanОценок пока нет

- Robotics Process Automation (RPA) OpportunitiesДокумент4 страницыRobotics Process Automation (RPA) OpportunitiesZara Jane DinhayanОценок пока нет

- Global Technology Audit GuideДокумент3 страницыGlobal Technology Audit GuideZara Jane DinhayanОценок пока нет

- TAX3 Study On Cryptocurrencies and BlockchainДокумент103 страницыTAX3 Study On Cryptocurrencies and BlockchainWessel SimonsОценок пока нет

- Cryptocurrencies and BlockchainДокумент7 страницCryptocurrencies and BlockchainZara Jane DinhayanОценок пока нет

- Special Concerns OnBlockchain and Big DataДокумент17 страницSpecial Concerns OnBlockchain and Big DataZara Jane DinhayanОценок пока нет

- Cornell Dubilier and Its Robotics Combany BackgroundДокумент3 страницыCornell Dubilier and Its Robotics Combany BackgroundZara Jane DinhayanОценок пока нет

- The Expenditure Cycle Part IIДокумент1 страницаThe Expenditure Cycle Part IIZara Jane DinhayanОценок пока нет

- Expenditure Cycle NoteДокумент2 страницыExpenditure Cycle NoteZara Jane DinhayanОценок пока нет

- Cloud ComputingДокумент2 страницыCloud ComputingZara Jane DinhayanОценок пока нет

- DPW HistoryДокумент4 страницыDPW Historydundarave print workshopОценок пока нет

- Multi Level MarketingДокумент74 страницыMulti Level Marketingsandeep_dhuriОценок пока нет

- Joy MoviereviewДокумент4 страницыJoy MoviereviewToni Nih ToningОценок пока нет

- Whitney Sullivan Debree: SummaryДокумент2 страницыWhitney Sullivan Debree: SummaryWhitney Sullivan DeBreeОценок пока нет

- Market ResearchДокумент54 страницыMarket ResearchAli SaifyОценок пока нет

- Treacy and Wiersema 1995 How Market Leaders Keep Their EdgeДокумент9 страницTreacy and Wiersema 1995 How Market Leaders Keep Their EdgeEdwards TranОценок пока нет

- Packaging and LabellingДокумент5 страницPackaging and LabellingTaruna NirankariОценок пока нет

- Mapro Food Private LimitedДокумент41 страницаMapro Food Private Limitedlaxmiprasad gudaОценок пока нет

- Bsbinm601 Copy 2Документ12 страницBsbinm601 Copy 2sayan goswamiОценок пока нет

- A Case Study in Perfect CompetitionДокумент6 страницA Case Study in Perfect Competitionshahid ahmed laskar33% (3)

- Bergerac Systems: The Challenge of Backward IntegrationДокумент3 страницыBergerac Systems: The Challenge of Backward IntegrationPulkit Aggarwal100% (1)

- Press Release: IAGTO Annual Report Shows 9% Growth in Golf Tourism WorldwideДокумент2 страницыPress Release: IAGTO Annual Report Shows 9% Growth in Golf Tourism WorldwidePantazis PastrasОценок пока нет

- Accounting Cycle: 4. Preparation of The Trial BalanceДокумент8 страницAccounting Cycle: 4. Preparation of The Trial BalanceAda Janelle Manzano0% (1)

- Operation Management Final Exam Assignment RealДокумент5 страницOperation Management Final Exam Assignment RealArafatОценок пока нет

- Emerging Market Strategy of ToyotaДокумент12 страницEmerging Market Strategy of ToyotaAbhimanyu Singh RathoreОценок пока нет

- PNB V DE JESUSДокумент1 страницаPNB V DE JESUSTricia Sibal100% (1)

- The Recruitment, Selection and Training of People at Arcadia An Arcadia Case StudyДокумент12 страницThe Recruitment, Selection and Training of People at Arcadia An Arcadia Case StudyVinodNKumarОценок пока нет

- PatagoniaДокумент12 страницPatagoniaAkshay D NicatorОценок пока нет

- GST Module 1Документ7 страницGST Module 1mohanraokp2279Оценок пока нет

- Consumer Behaviour For Online Shopping"Документ12 страницConsumer Behaviour For Online Shopping"Nishpakash Lakhanpal0% (1)

- Financial Accounting I Final Practice Exam 1Документ14 страницFinancial Accounting I Final Practice Exam 1misterwaterr100% (1)

- Cebu vs. CA (Digest) 1Документ2 страницыCebu vs. CA (Digest) 1Alfred LacandulaОценок пока нет

- Vat Collection Problems in Case of Revenue Authority of Dilla TownДокумент36 страницVat Collection Problems in Case of Revenue Authority of Dilla TownRha100% (4)

- Deregulated Power System: Presented byДокумент21 страницаDeregulated Power System: Presented bySurya TejaОценок пока нет

- Roast ArticleIndex2017Документ4 страницыRoast ArticleIndex2017Mu'ammarKhadafiMalahatОценок пока нет

- 34703bos24444 Finalp5 cp2 PDFДокумент108 страниц34703bos24444 Finalp5 cp2 PDFMilan OndhiyaОценок пока нет

- Route DeterminationДокумент6 страницRoute DeterminationRajan S PrasadОценок пока нет

- Brand Management Module 1 Question BankДокумент4 страницыBrand Management Module 1 Question BankVishnuKoduvathОценок пока нет

- Inventory Template Annex AДокумент4 страницыInventory Template Annex AMarfin M. Ramos62% (13)

- Channel Incentive Policy 20-21Документ5 страницChannel Incentive Policy 20-21kushrohitОценок пока нет