Академический Документы

Профессиональный Документы

Культура Документы

Langkah Pekerjaan: Job Step

Загружено:

elvandi0 оценок0% нашли этот документ полезным (0 голосов)

49 просмотров4 страницыThe document outlines potential job hazards and recommended prevention actions for various job steps. It identifies hazards such as miscommunication, equipment failure, defective PPE, slips and falls, exposure to chemicals and dust, electric shock, pinch points, and loose tools. Recommended prevention actions include conducting clear pre-job meetings, inspecting and preparing tools, assessing and checking PPE, maintaining a clean and hazard-free work area, using fall protection for working at heights, and following chemical handling procedures. Responsible parties are identified for planning, reviewing and approving the work.

Исходное описание:

Q

Оригинальное название

JSA CL

Авторское право

© © All Rights Reserved

Доступные форматы

XLSX, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документThe document outlines potential job hazards and recommended prevention actions for various job steps. It identifies hazards such as miscommunication, equipment failure, defective PPE, slips and falls, exposure to chemicals and dust, electric shock, pinch points, and loose tools. Recommended prevention actions include conducting clear pre-job meetings, inspecting and preparing tools, assessing and checking PPE, maintaining a clean and hazard-free work area, using fall protection for working at heights, and following chemical handling procedures. Responsible parties are identified for planning, reviewing and approving the work.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате XLSX, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

49 просмотров4 страницыLangkah Pekerjaan: Job Step

Загружено:

elvandiThe document outlines potential job hazards and recommended prevention actions for various job steps. It identifies hazards such as miscommunication, equipment failure, defective PPE, slips and falls, exposure to chemicals and dust, electric shock, pinch points, and loose tools. Recommended prevention actions include conducting clear pre-job meetings, inspecting and preparing tools, assessing and checking PPE, maintaining a clean and hazard-free work area, using fall protection for working at heights, and following chemical handling procedures. Responsible parties are identified for planning, reviewing and approving the work.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате XLSX, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 4

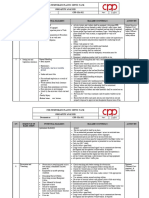

Job Step Potensial Hazard / Environmental Aspect Recommended and Prevention Action Used

Tindakan Pencegahan dan Rekomendasi Yang

Langkah Pekerjaan Potensi Bahaya / Aspek Lingkungan Digunakan

Conducted Pre job safety Loud & clear during submit all job plan & risk

Unclear voice, Miscommunication,

meeting assesment

Prepare all neceseary tools / equipment as per

Equipment failure, pared cable, dan required on the job, Check & inspect

Prepare all tool & equipment personnal injuries (spraining) tools/equipment will be use, ensure the condition

needed of tools, modification tools not allowed to be use

and follow right way of manual handling practices

Review minimum PPE requirement consider: (Safe

halmet, glasses, handgloves,shoes, coverall,

additonal PPE i.e body harness, masker, face shield

Defective of PPE, unstandard PPE and etc

Asses PPE requirements Check condition of PPE), and checks the condition

improper PPE for the job

(ensure all PPE have good condition)

Ensure work site is safe for conducted the job, & n

conflicting activities with other during job in

progress. avoid laying object on walk way or leavin

Prepare work location Slip, trip, and fall equipment where they may present a trip hazard

Observation work area ensured in a safe condition

Working at height Slip, stumble Every worker who will working at height must to

wear and use safety body harness

Removing Paint using brushing Wire brusing and dust rust, Use hand glove, face shield, googles, mask, from

and chemical removing paint iritations/ chemical exposure injured.

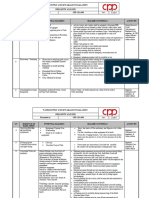

Wearing proper & correct PPE during perform a jo

hand & body placement in right position, and

Visual dan Dimensional Checks Fall from a high position, and pinch point. Maintain communication among crews involved in

the job

Load will be lifted by OHC, make sure the area is

safe and use the command codes understood by

workers, The unit will be picked according to

Struck by object, Threat of material

Proof Lifting Test (Tare mass manufacturers recommendations, The weight of t

measurement and Lifting Test) dropping on to roof, Swinging load over unit and rigging will be approximately half of the

crew and other personnel overall capacity, and the crew will not work under

suspended load & tag lines will be used to position

load

Hand & body placement in right position, ensure

there are MSDS/ certificate of chemical list and th

MPI / PTI Test before and after Electric shocked, Chemical Exposure, and crew understand about content of MSDS (risk,

load test Pinch point potential hazard, etc), knowledge the scope of wo

to be done, and precaution during install &

Hand & body placement in right position, ensure

there are MSDS/ certificate of chemical list and th

MPI / PTI Test before and after Electric shocked, Chemical Exposure, and crew understand about content of MSDS (risk,

load test Pinch point potential hazard, etc), knowledge the scope of wo

to be done, and precaution during install &

disconnect lifting gears.

Bad house keeping, Ensure all tools and equipments are return the

Housekeeping Loosing tools and equipments proper place

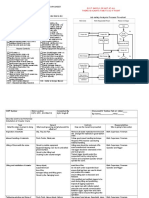

CONTRACTOR Owner / PT. Cikarang Listrin

Kontraktor Pemilik / PT. Cikarang Listrind

Prepared by; Know by; Check and Approved by;

Disiapkan oleh; Diketahui Oleh; Diperiksa & Disetujui Oleh;

HSE Contractor Coordinator Contractor HSE Owner / PT. CL

and Prevention Action Used PIC

gahan dan Rekomendasi Yang

Digunakan PIC

submit all job plan & risk HSE / FS

ry tools / equipment as per

Check & inspect

l be use, ensure the condition FS

n tools not allowed to be use

of manual handling practices.

PE requirement consider: (Safety

dgloves,shoes, coverall,

dy harness, masker, face shield

PPE), and checks the condition HSE / FS

good condition)

afe for conducted the job, & no

with other during job in

ng object on walk way or leaving

hey may present a trip hazard FS

rea ensured in a safe condition.

ill working at height must to FS

body harness

e shield, googles, mask, from FS

orrect PPE during perform a job,

ment in right position, and FS

ation among crews involved in

y OHC, make sure the area is

mmand codes understood by

ll be picked according to

mmendations, The weight of the FS

be approximately half of the

d the crew will not work under

ag lines will be used to position

ment in right position, ensure

rtificate of chemical list and the

out content of MSDS (risk, FS/HSE

c), knowledge the scope of work

caution during install &

FS/HSE

equipments are return the FS

Owner / PT. Cikarang Listrindo

Pemilik / PT. Cikarang Listrindo

Approved by; Know by;

Disetujui Oleh; Diketahui Oleh;

ner / PT. CL User

Вам также может понравиться

- Jsa For Concreate and CivilworksДокумент7 страницJsa For Concreate and CivilworksAnna JisabaОценок пока нет

- Jsa For Concreate and CivilworksДокумент7 страницJsa For Concreate and CivilworksAnna JisabaОценок пока нет

- 5.19 JSP Electrical Power InstallationДокумент4 страницы5.19 JSP Electrical Power InstallationDarius DsouzaОценок пока нет

- Jsa For Modification of HoppersДокумент5 страницJsa For Modification of HoppersEdmy RiveraОценок пока нет

- JSA Elevator MaintenancДокумент6 страницJSA Elevator MaintenancHSE fahadОценок пока нет

- JHSA For Temporary Plastic Septic TankДокумент4 страницыJHSA For Temporary Plastic Septic TankAnna JisabaОценок пока нет

- JSA - Field Instruments InstallationДокумент4 страницыJSA - Field Instruments InstallationSagar PadhiyarОценок пока нет

- 5.19 JSP Self Levelling Epoxy Painting ActivityДокумент8 страниц5.19 JSP Self Levelling Epoxy Painting Activitymuhammad.younisОценок пока нет

- Jsa For Electrical Installation.Документ2 страницыJsa For Electrical Installation.Anna JisabaОценок пока нет

- JSA For Road BarrierДокумент3 страницыJSA For Road BarrierMohammed MinhajОценок пока нет

- 06 Scaffold Erection and Dismantling (JHA-JSA)Документ4 страницы06 Scaffold Erection and Dismantling (JHA-JSA)AmanОценок пока нет

- GOSP-5 (60) Placing Red Tile &caution Tape Inside The TrenchДокумент6 страницGOSP-5 (60) Placing Red Tile &caution Tape Inside The TrenchShahid BhattiОценок пока нет

- JSA Blasting and Coating KP 69.4Документ5 страницJSA Blasting and Coating KP 69.4shinto Lawrence100% (6)

- Ninl JhaДокумент21 страницаNinl JhaHari NairОценок пока нет

- Jsa For Erection of Pipes Welding Cutting Grinding-Imtiaz SBДокумент6 страницJsa For Erection of Pipes Welding Cutting Grinding-Imtiaz SBMohammed MinhajОценок пока нет

- 1 SurveyДокумент5 страниц1 Survey王志伟0% (1)

- JHA HondaДокумент2 страницыJHA HondaJaycee QuinОценок пока нет

- Jsa For Excavation and BackfillingДокумент5 страницJsa For Excavation and Backfillingshaibaz chafekarОценок пока нет

- 03-F07 Job Safe Procedure Template - DAMMAM - NO. 01Документ1 страница03-F07 Job Safe Procedure Template - DAMMAM - NO. 01jawad khanОценок пока нет

- 5.19 JSP ScaffoldДокумент4 страницы5.19 JSP Scaffoldpoorm879Оценок пока нет

- PT-03 JSA Dismantling of Slip Form (22-05-09)Документ10 страницPT-03 JSA Dismantling of Slip Form (22-05-09)M Waqas HabibОценок пока нет

- JSA For Lifting of RebarsДокумент5 страницJSA For Lifting of RebarsNiraОценок пока нет

- Excavation Trenching Shoring JsaДокумент10 страницExcavation Trenching Shoring JsaShannon MooreОценок пока нет

- JSA For Scaffolding Erection and Dismentling Inside The Building Room at Accommodation Block CДокумент5 страницJSA For Scaffolding Erection and Dismentling Inside The Building Room at Accommodation Block Cnoahlungu96Оценок пока нет

- JSA SK Erection DismantlingДокумент1 страницаJSA SK Erection DismantlingSamuel Hugos100% (4)

- Job Safety AnalysisДокумент3 страницыJob Safety AnalysisMuhammad KaleemОценок пока нет

- JHA (85T Crawler Crane & Drill Rig Machine Assembling and Inspection)Документ2 страницыJHA (85T Crawler Crane & Drill Rig Machine Assembling and Inspection)Armando AballeОценок пока нет

- Jsa For Pilling WorkДокумент12 страницJsa For Pilling WorkLakhan kumar100% (1)

- Jsa For Tile FixingДокумент4 страницыJsa For Tile FixingMohammed Minhaj100% (1)

- Hot Work Gift Gift / Near Gis SEPCOO III Early Comb: Job Hazard Analysis (Jha) WorksheetДокумент4 страницыHot Work Gift Gift / Near Gis SEPCOO III Early Comb: Job Hazard Analysis (Jha) Worksheet王志伟Оценок пока нет

- Jsa For Drilling WellДокумент5 страницJsa For Drilling WellAnna JisabaОценок пока нет

- JSA Erection StructureДокумент11 страницJSA Erection StructureJAYESH JOSHIОценок пока нет

- JSA For Pipe Line DemolitionДокумент7 страницJSA For Pipe Line DemolitionSiraj Mohamed Ikbal80% (5)

- Scaffolding, Bolting Work & Working at Height at Security Building Area For Vehicle Parking ShedДокумент3 страницыScaffolding, Bolting Work & Working at Height at Security Building Area For Vehicle Parking ShedkrishnakumarОценок пока нет

- Jsa Civil Work (00000002)Документ6 страницJsa Civil Work (00000002)Ali AlahmaОценок пока нет

- Fill-Up This Card Before Commencement of Critical WorksДокумент4 страницыFill-Up This Card Before Commencement of Critical WorksSiddhant choudharyОценок пока нет

- JSA For SURGE VESSEL WorkДокумент6 страницJSA For SURGE VESSEL Workathul subashОценок пока нет

- Excavation (Company Name) : Safe Work Plan (SWP) /phase Hazard Analysis (Pha)Документ11 страницExcavation (Company Name) : Safe Work Plan (SWP) /phase Hazard Analysis (Pha)PABITRA PANDAОценок пока нет

- JSA For EXCAVATION AND BACKFILLING ARAMCO PROJECTДокумент6 страницJSA For EXCAVATION AND BACKFILLING ARAMCO PROJECTshaibaz chafekarОценок пока нет

- Hazard Identification, Risk Assessment & Control Measures: NCC/BMRCL/PH-2B/P2/69 (B) /MS-012Документ1 страницаHazard Identification, Risk Assessment & Control Measures: NCC/BMRCL/PH-2B/P2/69 (B) /MS-012somashekhar. ncclОценок пока нет

- Copy (2) of JSA For Welding, Cutting and Grinding (Alam Engineering)Документ5 страницCopy (2) of JSA For Welding, Cutting and Grinding (Alam Engineering)Viron BaxhiaОценок пока нет

- Risk AssessmentДокумент33 страницыRisk AssessmentMadelo, Allysa Mae, M.Оценок пока нет

- JSA For Crawler Crane Installation FormДокумент3 страницыJSA For Crawler Crane Installation FormDaniel Prakoso0% (1)

- How Chin Engineering: Job Safety AnalysisДокумент5 страницHow Chin Engineering: Job Safety AnalysisHow Chin Engineering Sdn BhdОценок пока нет

- JHSA Water Supply and Sewer InstallationДокумент4 страницыJHSA Water Supply and Sewer InstallationAnna JisabaОценок пока нет

- Jsa Installing BracketДокумент3 страницыJsa Installing BracketHow Chin Engineering Sdn Bhd100% (1)

- JSA 001 - UG Pipe Fabrication & ErectionДокумент14 страницJSA 001 - UG Pipe Fabrication & ErectionNitish SinghОценок пока нет

- Gas Cutting JsaДокумент4 страницыGas Cutting JsaMohammed Minhaj100% (1)

- Fabrication Work Risk AssessmentДокумент11 страницFabrication Work Risk Assessmentstansilous100% (1)

- JSA For EXCAVATION AND BACKFILLING ARAMCO PROJECTДокумент6 страницJSA For EXCAVATION AND BACKFILLING ARAMCO PROJECTshaibaz chafekarОценок пока нет

- Jsa For Installation of Pipe Railing On SkidДокумент6 страницJsa For Installation of Pipe Railing On SkidLokesh Aravindan100% (1)

- JSA For Scaffolding Erection and Dismentling at Ko DrumДокумент5 страницJSA For Scaffolding Erection and Dismentling at Ko DrumViron BaxhiaОценок пока нет

- 004 Piling JSAДокумент5 страниц004 Piling JSAmidozotyОценок пока нет

- 1st Aid Training Siemens ContractorДокумент11 страниц1st Aid Training Siemens ContractorTigor GurningОценок пока нет

- Risk Assessment For External Façade & Canopies CleaningДокумент6 страницRisk Assessment For External Façade & Canopies Cleaningjulius0% (1)

- 004 Piling JSAДокумент4 страницы004 Piling JSAIdada EzekielОценок пока нет

- Job Safety Analysis: Shaybah NGL Recovery Plant DepartmentДокумент4 страницыJob Safety Analysis: Shaybah NGL Recovery Plant DepartmentMadhan KannanОценок пока нет

- DEL - 064 Jsa For Load Test of Davit ArmsДокумент4 страницыDEL - 064 Jsa For Load Test of Davit ArmsMohammed Minhaj100% (1)

- Project of RDMP Balikpapan: PertaminaДокумент10 страницProject of RDMP Balikpapan: PertaminaelvandiОценок пока нет

- Phillips Precision QMS RevCДокумент21 страницаPhillips Precision QMS RevCTarnaveanValeriuDanОценок пока нет

- QESH-13FR-07 Rev.00 Job Safety Analysis - JSAДокумент2 страницыQESH-13FR-07 Rev.00 Job Safety Analysis - JSAelvandiОценок пока нет

- Form Ibpr Haul Road PDFДокумент2 страницыForm Ibpr Haul Road PDFelvandi100% (1)

- Emergency Contact NumberДокумент1 страницаEmergency Contact NumberelvandiОценок пока нет

- Rescue at WAH (Bahasa)Документ3 страницыRescue at WAH (Bahasa)elvandiОценок пока нет

- Akura - Hse Compliance (Tubular Inspection)Документ46 страницAkura - Hse Compliance (Tubular Inspection)elvandiОценок пока нет

- JSA Safety Valve CertivicationДокумент12 страницJSA Safety Valve CertivicationelvandiОценок пока нет

- Safety Induction: School of Plant Biology University of Western AustraliaДокумент61 страницаSafety Induction: School of Plant Biology University of Western AustraliaelvandiОценок пока нет

- 1.6 Safety CultureДокумент59 страниц1.6 Safety CultureAinur Sya Irah100% (4)

- Meja Kerja Ibu Ariani: Before Ringkas Rapi Resik AfterДокумент16 страницMeja Kerja Ibu Ariani: Before Ringkas Rapi Resik AfterelvandiОценок пока нет

- PT Akura Bina Citra Competency RecordДокумент2 страницыPT Akura Bina Citra Competency RecordelvandiОценок пока нет

- Pengoperasian Compressor Ingersoll Rand P90CWIRДокумент24 страницыPengoperasian Compressor Ingersoll Rand P90CWIRelvandiОценок пока нет

- Phillips Precision QMS RevCДокумент21 страницаPhillips Precision QMS RevCTarnaveanValeriuDanОценок пока нет

- Hazard Identification and ObservationДокумент6 страницHazard Identification and ObservationelvandiОценок пока нет

- Cover Dokumen Hse PlanДокумент1 страницаCover Dokumen Hse Planelvandi100% (1)

- ISO 14001 2015 Versi EnglishДокумент12 страницISO 14001 2015 Versi EnglishelvandiОценок пока нет

- Inspection CraneДокумент22 страницыInspection CraneelvandiОценок пока нет

- Safety Induction: School of Plant Biology University of Western AustraliaДокумент61 страницаSafety Induction: School of Plant Biology University of Western AustraliaelvandiОценок пока нет

- Journey ManagementДокумент4 страницыJourney ManagementelvandiОценок пока нет

- ZPT Hsse Report MayДокумент7 страницZPT Hsse Report MayelvandiОценок пока нет

- HIRA Crossing Hauling RoadДокумент2 страницыHIRA Crossing Hauling RoadelvandiОценок пока нет

- SOP HSE 02 Legal ComplianceДокумент4 страницыSOP HSE 02 Legal Complianceelvandi100% (1)

- SHES.F.004 Laporan Kejadian BerbahayaДокумент2 страницыSHES.F.004 Laporan Kejadian BerbahayaelvandiОценок пока нет

- 0.0 EHS Agenda 130418 r1.0Документ2 страницы0.0 EHS Agenda 130418 r1.0elvandiОценок пока нет

- Enerfab JSAДокумент2 страницыEnerfab JSAelvandiОценок пока нет

- Oracle Application Framework (OAF) Training ManualДокумент239 страницOracle Application Framework (OAF) Training ManualIsa Sarreira Mendes100% (1)

- Production Repairs EngineerДокумент3 страницыProduction Repairs Engineerwasco plantОценок пока нет

- lsf9.1.3 Quick Reference PDFДокумент20 страницlsf9.1.3 Quick Reference PDFccchanОценок пока нет

- RPF TemplateДокумент5 страницRPF TemplatecolombiasouОценок пока нет

- AC Machine RobinairДокумент36 страницAC Machine Robinairlightning_mike100% (2)

- IEC Motor ControlДокумент192 страницыIEC Motor ControlFlo MircaОценок пока нет

- Cheat Sheets A To EДокумент49 страницCheat Sheets A To Ebobo1010Оценок пока нет

- Construction ContractДокумент3 страницыConstruction ContractLahiru WijethungaОценок пока нет

- SAP MM Integration With Finance & Controlling (FICO)Документ2 страницыSAP MM Integration With Finance & Controlling (FICO)Vicky KumarОценок пока нет

- LATДокумент12 страницLATRicha SunnyОценок пока нет

- Content Extraction From Marketing Flyers: (Ignazio - Gallo, A.zamberletti, Lucia - Noce) @uninsubria - ItДокумент2 страницыContent Extraction From Marketing Flyers: (Ignazio - Gallo, A.zamberletti, Lucia - Noce) @uninsubria - ItcYbernaTIc enHancEОценок пока нет

- SEC5 (1) WashpipeДокумент22 страницыSEC5 (1) WashpipeCarlos Alberto PerdomoОценок пока нет

- Veeam Backup & Replication Vs Quest VrangerДокумент8 страницVeeam Backup & Replication Vs Quest Vrangerfuct999Оценок пока нет

- ENGG1960 Engineering Drawings Lecture Introduction 2014Документ29 страницENGG1960 Engineering Drawings Lecture Introduction 2014crazzyrajОценок пока нет

- CTFL 2018 Sample Exam A Answers PDFДокумент40 страницCTFL 2018 Sample Exam A Answers PDFAlan SilvaОценок пока нет

- SAP Manufacturing ExecutionДокумент23 страницыSAP Manufacturing ExecutionmayurОценок пока нет

- Black and Yellow Business - PresentationДокумент25 страницBlack and Yellow Business - PresentationKerly VacaОценок пока нет

- Practice PLSQLДокумент52 страницыPractice PLSQLEugenОценок пока нет

- Niagara 42 July IndianДокумент16 страницNiagara 42 July IndianGarry GrahamОценок пока нет

- Radar Product Catalog v2Документ4 страницыRadar Product Catalog v2Eleazar DavidОценок пока нет

- DN Iso 5817Документ13 страницDN Iso 5817Phani Sridhar ChОценок пока нет

- Nce 158087Документ19 страницNce 158087Роман ДяченкоОценок пока нет

- Heta BhavsarДокумент3 страницыHeta Bhavsarmiss_jyoti_kapoorОценок пока нет

- Ejercicios SimulacionДокумент7 страницEjercicios SimulacionVictor CastroОценок пока нет

- Hs-3400 Manual m9252 - r1 - Ms3400 STD XPДокумент109 страницHs-3400 Manual m9252 - r1 - Ms3400 STD XPrlcc1984100% (5)

- TIME VoBB Business - 0Документ6 страницTIME VoBB Business - 0Afiq AsyrafОценок пока нет

- SCM2 Group5 Wills LfestyleДокумент5 страницSCM2 Group5 Wills LfestyleAbhinav MishraОценок пока нет

- Secco Catalogo 1Документ16 страницSecco Catalogo 1emilio_707Оценок пока нет

- U.S. Department of Transportation: Laboratory Test Procedure FOR Fmvss 114 Theft Protection and Rollaway PreventionДокумент43 страницыU.S. Department of Transportation: Laboratory Test Procedure FOR Fmvss 114 Theft Protection and Rollaway PreventionMОценок пока нет

- Mordec-Catalogue 2011 MayДокумент83 страницыMordec-Catalogue 2011 Maykiiru88100% (1)