Академический Документы

Профессиональный Документы

Культура Документы

Prestressed Concrete

Загружено:

guian doman0 оценок0% нашли этот документ полезным (0 голосов)

22 просмотров2 страницыasdasd

Авторское право

© © All Rights Reserved

Доступные форматы

DOCX, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документasdasd

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

22 просмотров2 страницыPrestressed Concrete

Загружено:

guian domanasdasd

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 2

CONSOLACION, Emmanuel B

BSCE

CHEMECALLY PRESTRESSSED CONCRETE

During the past 10 years, research with expansive cements and expansive

cement concrete has been conductive at the University of California at

Berkeley reported on the development of a new compound, an anhydrous

calcium sulfoaluminate, which can be used in combination with Portland

cement in concrete to cause an expansion of the concrete to during its early

stage of hydration. The expansive cement concretes are classified into two

general categories-shrinkage compensation and self-stressing.

Shrinkage compensation is accomplished by restraining the expansion of

the concrete by means of reinforcing steel, thus developing during the

curing period aa slight compression in the concrete and a tension in the

steel. On drying, this concrete will shrink similarly to ordinary Portland

cement concrete and it is initially compressive stress will be reduce. It is

desirable to have sufficient initial compression in the concrete to prevent

the development of tensile stresses during the drying period thus

increasing its crack resistance.

Self-stressing or chemical prestressing can be accomplished if the

expansive cement has the potential of producing large expansions and if

the concrete is properly restrained by steel reinforcement so as to

produce high compressive stresses in the concrete and high tensile

stresses in the steel. On drying, as in ordinary restresses concrete, there will

be some loss of prestress due to the residual compressive stress will be

significant from a structural point of view

WORKABILITY.

A practical problem of structural application is proper workability of the

concrete for purpose of placing and compacting. The chemically

prestressed structural elements tested to date had water-cement ratio

between 0.28 to 0.45. such low water cement ratios were used to obtain

high strength, particularly at early ages, and high expansion and prestress.

A low water-cement ratio causes decreased workability, which might be

overcome by use of additives. The possible long-term influence of such

additive needs investigation.

DURABILITY.

Deterioration of concrete subjected to aggressive environments usually

starts at the exposed surface. Unfortunately, in a chemically prestessed

element the exposed surface is not usually restrained in its normal

direction, consequently the material properties off the surface will be

inferior those of the interior concrete.

BASIC CONSIDERATION.

In the design of chemically prestressed elements, it is necessary to keep in

mind the following two, apparently conflicting, fundamental principles of

this type of prestressing

1. Sufficient expansion is required to achieve the desired level of

structural prestress,

2. This expansion should be kept below a certain limit, since the larger

the expansion the lower the quality of the concrete.

A practical solution requires the determination of the optimum expantion

satisfying these two requirements.

CONCLUSION.

Basic considerations of structural chemical prestressing are outlined, along

with applications for which chemical prestressing is more advantageous

than conventional prestressing.

REFERENCES.

Ji_68_october_3.pdf

1.2_advantages_types of Prestressing.pdf

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Code Requirements: Post Weld Heat Treatment: Asme Sec-Iii: Div.-1Документ22 страницыCode Requirements: Post Weld Heat Treatment: Asme Sec-Iii: Div.-1Vinu RaveendranОценок пока нет

- MATH Formulas PDFДокумент33 страницыMATH Formulas PDFAnonymous 0Mduljho100% (3)

- Subcooling Superheating and Liquid Suction Heat ExchangerДокумент4 страницыSubcooling Superheating and Liquid Suction Heat ExchangerDeniell Joyce MarquezОценок пока нет

- Machine Design SpringsДокумент4 страницыMachine Design Springscoc boyОценок пока нет

- Che 3G04 Winter 2004 Mcmaster UniversityДокумент33 страницыChe 3G04 Winter 2004 Mcmaster UniversityAris Koreya100% (2)

- Lecture 4 - Categories of Traffic FlowДокумент27 страницLecture 4 - Categories of Traffic Flowguian domanОценок пока нет

- Greenberg's Model: (Ce 425) Transportation EngineeringДокумент5 страницGreenberg's Model: (Ce 425) Transportation Engineeringguian domanОценок пока нет

- Steam Condensers and Cooling Towers ExplainedДокумент43 страницыSteam Condensers and Cooling Towers ExplainedrrhoshackОценок пока нет

- 000000000001001849Документ544 страницы000000000001001849Dante Filho100% (1)

- DWDM PPT Industrial SeminarДокумент29 страницDWDM PPT Industrial SeminarRajat Goel100% (1)

- Nuclear Engineering Homework Solutions Due 16 February 2006Документ8 страницNuclear Engineering Homework Solutions Due 16 February 2006Snakefistx100% (1)

- Economy SolutionДокумент2 страницыEconomy Solutionguian domanОценок пока нет

- Theoretical Framework for Suyo 2 Mini-Hydro ResearchДокумент9 страницTheoretical Framework for Suyo 2 Mini-Hydro Researchguian domanОценок пока нет

- TRANSPORTATION ENGINEERING TERMS AND DEFINITIONSДокумент12 страницTRANSPORTATION ENGINEERING TERMS AND DEFINITIONSguian domanОценок пока нет

- Kinetic Molecular Theory Explains States of MatterДокумент4 страницыKinetic Molecular Theory Explains States of Matterguian domanОценок пока нет

- Media and Information Literacy Assignment 1 InstructionsДокумент2 страницыMedia and Information Literacy Assignment 1 Instructionsguian domanОценок пока нет

- Definition of TermsДокумент1 страницаDefinition of Termsguian domanОценок пока нет

- Freshman Engineering Student Weekly ScheduleДокумент1 страницаFreshman Engineering Student Weekly Scheduleguian domanОценок пока нет

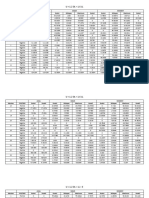

- Reinforced Concrete Design 2: Frame Analysis Ultimate Load CombinationДокумент1 страницаReinforced Concrete Design 2: Frame Analysis Ultimate Load Combinationguian domanОценок пока нет

- Phenomenolgy of LoveДокумент2 страницыPhenomenolgy of Loveguian domanОценок пока нет

- Proposal Student 1Документ6 страницProposal Student 1Joshua Ellie Gerona GabionОценок пока нет

- U Frame AДокумент8 страницU Frame Aguian domanОценок пока нет

- Erich Fromm Mentions Love in The Present As "Falling in Love"Документ4 страницыErich Fromm Mentions Love in The Present As "Falling in Love"guian domanОценок пока нет

- Certification of Good Moral Character: Batangas State UniversityДокумент1 страницаCertification of Good Moral Character: Batangas State Universityguian domanОценок пока нет

- Erich Fromm Mentions Love in The Present As "Falling in Love"Документ4 страницыErich Fromm Mentions Love in The Present As "Falling in Love"guian domanОценок пока нет

- DRRRДокумент1 страницаDRRRguian domanОценок пока нет

- Theoretical Framework Mini Hydro Research ProjectДокумент4 страницыTheoretical Framework Mini Hydro Research Projectguian domanОценок пока нет

- OJT JournalДокумент23 страницыOJT Journalguian domanОценок пока нет

- Task #1: A. Compute The Mean of Grade 11 STEM I's Average Grade in Basic CalculusДокумент3 страницыTask #1: A. Compute The Mean of Grade 11 STEM I's Average Grade in Basic Calculusguian domanОценок пока нет

- Summary of Cost EstimateДокумент1 страницаSummary of Cost Estimateguian domanОценок пока нет

- Introduction (Lec 1)Документ23 страницыIntroduction (Lec 1)guian domanОценок пока нет

- DRRRДокумент1 страницаDRRRguian domanОценок пока нет

- Strength Bracelet: Doman, Brian Clark D. Stem IДокумент1 страницаStrength Bracelet: Doman, Brian Clark D. Stem Iguian domanОценок пока нет

- DRRRДокумент1 страницаDRRRguian domanОценок пока нет

- Activity No.4: Csi: And-Orthopedic-Injuries/spinal-ImmobilizationДокумент1 страницаActivity No.4: Csi: And-Orthopedic-Injuries/spinal-Immobilizationguian domanОценок пока нет

- Strength Bracelet: Doman, Brian Clark D. Stem IДокумент1 страницаStrength Bracelet: Doman, Brian Clark D. Stem Iguian domanОценок пока нет

- 1234Документ7 страниц1234guian domanОценок пока нет

- Hurricane Pumps - 4SD2 - 14 Single Phase Borehole Pump 220V 0 PDFДокумент2 страницыHurricane Pumps - 4SD2 - 14 Single Phase Borehole Pump 220V 0 PDFSiziba NhlanhlaОценок пока нет

- Slater's RuleДокумент5 страницSlater's RuleacasОценок пока нет

- Ryton PPS Design GuideДокумент24 страницыRyton PPS Design GuideAnonymous l2sT4aEОценок пока нет

- Solution - Manual - Fundamentals - o 83Документ1 страницаSolution - Manual - Fundamentals - o 83Lit Pao WongОценок пока нет

- Traversable Wormholes: Some Simple Examples: Matt VisserДокумент7 страницTraversable Wormholes: Some Simple Examples: Matt VisserllapeyreОценок пока нет

- Physics - Light: Notes and StuffsДокумент42 страницыPhysics - Light: Notes and StuffsSijabuliso SibandaОценок пока нет

- Sample Admission Test For MS Civil Engineering Degree ProgramДокумент2 страницыSample Admission Test For MS Civil Engineering Degree ProgramDhiraj ShakyaОценок пока нет

- Contact Design of A Solar CellДокумент19 страницContact Design of A Solar CellTahir DialloОценок пока нет

- Introduction To Wellbore Positioning - V01.7.12 PDFДокумент157 страницIntroduction To Wellbore Positioning - V01.7.12 PDFMiguelОценок пока нет

- 9.1 Multiple-Choice and Bimodal QuestionsДокумент18 страниц9.1 Multiple-Choice and Bimodal QuestionsQuốc Thắng NguyễnОценок пока нет

- Corrosion On Stainless SteelДокумент3 страницыCorrosion On Stainless SteelMondayОценок пока нет

- TORING LC Exer4 7LДокумент19 страницTORING LC Exer4 7LLanoline ToringОценок пока нет

- FlowControl Manual PDFДокумент168 страницFlowControl Manual PDFToyinОценок пока нет

- Solar Air Conditioning ThesisДокумент7 страницSolar Air Conditioning Thesisjjvveqvcf100% (2)

- Submittal FCQ24MVJU - RZQ24MVJU 07-06 - DaikinДокумент1 страницаSubmittal FCQ24MVJU - RZQ24MVJU 07-06 - Daikinedward sabedraОценок пока нет

- Determining The Penetration of Chloride Ion Into Concrete by PondingДокумент4 страницыDetermining The Penetration of Chloride Ion Into Concrete by PondingMarco RiveraОценок пока нет

- Chemical SensorsДокумент4 страницыChemical SensorsBianca Clarice DalistanОценок пока нет

- EuleДокумент9 страницEuleAnand Utsav KapoorОценок пока нет

- Factors Affecting Steam Turbine Performance-MergedДокумент26 страницFactors Affecting Steam Turbine Performance-MergedrahulОценок пока нет

- The Specific Static Rotor Work YpДокумент36 страницThe Specific Static Rotor Work YpFiraol DinaolОценок пока нет

- Turbulent Flows and Modelling: S.Vengadesan Department of Applied Mechanics, IIT MadrasДокумент35 страницTurbulent Flows and Modelling: S.Vengadesan Department of Applied Mechanics, IIT MadrasVXОценок пока нет

- Design Procedure For Journal BearingsДокумент4 страницыDesign Procedure For Journal BearingsSwaminathan100% (1)