Академический Документы

Профессиональный Документы

Культура Документы

Aadsorption Capacities Greater Than 1.docx Page Number 29

Загружено:

rizwanОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Aadsorption Capacities Greater Than 1.docx Page Number 29

Загружено:

rizwanАвторское право:

Доступные форматы

adsorption capacities greater than 1.

0 mg/g were obtained for all the metal ions studied by

a s

Ali et al. (2010)[106].

Many industrial wastes are high in carbon content and offer significant potential for conversion

d f g

into carbonaceous chars which may then be further activated to yield porous adsorbents. Like g

gricultural waste, industrial by-products such as fly ash ,used tyres, waste iron, metallic iron,

ha j

hydrous titanium oxide, and blast furnace slag are inexpensive and abundantly available (Mohan

j k l z

et al., 2006)[107]. These materials can be c hemically modified to enhance their removal

x cc v

performance. However, unlike those from agricultural waste, adsorbents from this source can be

b

obtained from industrial processing only. In South Africa, several such wastes currently pose a

n m

variety of disposal problems due to bulk volume, auto reactivity or physical nature like oily

m q

wastes and scrap tyres. Thus, the controlled epyrolysis of these wastes combined with the reuse

w r

of porous products contributes to a minimization of handling difficulties (Pollard et al.,

t y

1992)[108]. Some of these industrial by-products combine good adsorption capacities and

y u y

buffering effect, which assure almost complete removal of heavy metal ions without preliminary

y y u

correction of the initial pH being necessary. Fly ash, an industrial solid waste of thermal power

i o

plants is one of the cheapest adsorbents having excellent removal capabilities for different

p z w r

wastes. South Africa produces approximately 28 million tons of coal fly ash per annum q

(Reynolds et al., 2002)[108]. Only 5% of the fly ash is used as a construction material while the e

rest is stored in ash damps, which in turn have to be rehabilitated increasing the cost of ash

t q

handling (Woolardet al., 2000)[109]. Sen and De (1987) carried out a study on the adsorption of z

mercury using coal fly ash and it was reported that the maximum adsorption capacity of 2.82 mg

v b

Hg2+/g took place at a pH range of 3.5–4.5 and that adsorption followed the Freundlich n m

model[110]. In another work, a comparative adsorption study was carried out by Jain et al.

l p r

(2001) using carbon slurry waste obtained from a fertilizer plant and blast furnace sludge, dust,

a s

and slag from steel plant wastes as adsorbents for the removal of dyes[111]. It was found that

f

carbonaceous adsorbent prepared from the fertilizer plant waste exhibited a good potential for

h n t

the removal of dyes as compared to the other three adsorbents prepared. Adsorption is

s w a

influenced by the nature of solution in which the contaminant is dispersed, molecular size and

t e

polarity of the contaminant and the type of adsorbent. Food processing wastewater often

i c

contains multiple types of contaminants that are generally biodegradable. There are various

y r

types of wastewater discharged from the food processing industry due to the fact that the number

e t s

of raw materials

f

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Final Year Project Report 2018Документ29 страницFinal Year Project Report 2018rizwan100% (1)

- Assignment of Irrigation 1111Документ5 страницAssignment of Irrigation 1111rizwan100% (1)

- University of Engineering and Technology: Fluid MechanicsДокумент1 страницаUniversity of Engineering and Technology: Fluid MechanicsrizwanОценок пока нет

- Dani 3Документ1 страницаDani 3rizwanОценок пока нет

- University of Engineering and Technology: Fluid MechanicsДокумент1 страницаUniversity of Engineering and Technology: Fluid MechanicsrizwanОценок пока нет

- AimДокумент7 страницAimrizwanОценок пока нет

- BucklingДокумент5 страницBucklingrizwanОценок пока нет

- Aim 2Документ3 страницыAim 2rizwanОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- 3512TA - 1000kVA - LV - Spec Sheet PDFДокумент5 страниц3512TA - 1000kVA - LV - Spec Sheet PDFavinash_1229Оценок пока нет

- WM2077CW Service ManualДокумент44 страницыWM2077CW Service ManualMichael David SharkeyОценок пока нет

- Air Cooler LeafletДокумент2 страницыAir Cooler LeafletSaad zubayr MОценок пока нет

- Orient Price List NewДокумент3 страницыOrient Price List Newrohan12345670% (1)

- Omax Annual ReprtДокумент78 страницOmax Annual ReprtSalini RajamohanОценок пока нет

- EB Welding of SS405 To GR70Документ5 страницEB Welding of SS405 To GR70s_m_taheriОценок пока нет

- Proposed Rule: Airworthiness Directives: Cubcrafters, Inc., Model PC18&ndash 160Документ2 страницыProposed Rule: Airworthiness Directives: Cubcrafters, Inc., Model PC18&ndash 160Justia.comОценок пока нет

- Spe 21970 MSДокумент13 страницSpe 21970 MSasu jaranОценок пока нет

- Mantrac Egypt ProfileДокумент9 страницMantrac Egypt ProfilenabilredascribdОценок пока нет

- Inspection, Test, Marking and RecordsДокумент10 страницInspection, Test, Marking and RecordssuryaОценок пока нет

- DPDC MaintenanceДокумент5 страницDPDC MaintenanceArfana Akter BanogirОценок пока нет

- Edexcel - IAS - Group 2 and Group 7 - 1Документ21 страницаEdexcel - IAS - Group 2 and Group 7 - 1mostafa barakatОценок пока нет

- GS-37 LcaДокумент22 страницыGS-37 LcaGeny KucherОценок пока нет

- EnergySRP Forms MatchingДокумент2 страницыEnergySRP Forms Matchingeiad-mahmoudОценок пока нет

- CV - Alok Singh - Tech HSE & Loss Prevention Engineer (May-2018)Документ5 страницCV - Alok Singh - Tech HSE & Loss Prevention Engineer (May-2018)toalok4723Оценок пока нет

- Aviation Tinning and SolderingДокумент16 страницAviation Tinning and SolderingRebecca RiversОценок пока нет

- Teco s310 User ManualДокумент10 страницTeco s310 User ManualEhsan GhanbarzadehОценок пока нет

- Master Plan 2021Документ172 страницыMaster Plan 2021Rajnish MishraОценок пока нет

- Operator's Manual-TT55-TT65-TT75-English PDFДокумент129 страницOperator's Manual-TT55-TT65-TT75-English PDFvalgorunescu@hotmail.com88% (16)

- QT-002!02!50 HZ Lister Peter - Aksa - Mitsubishi - John Deere - Perkins Engine-Alternator Couple Table 2015.02.16Документ1 страницаQT-002!02!50 HZ Lister Peter - Aksa - Mitsubishi - John Deere - Perkins Engine-Alternator Couple Table 2015.02.16Cris_eu09Оценок пока нет

- IGBTДокумент22 страницыIGBTumeshgangwar100% (1)

- Test 48Документ9 страницTest 48Thị VyОценок пока нет

- Sany HBT8018C-5S (T3) Trailer Pump - 004118Документ2 страницыSany HBT8018C-5S (T3) Trailer Pump - 004118اهى عيشه وبن عشها just a lifeОценок пока нет

- Short and Open Circuit Test On TransformerДокумент1 страницаShort and Open Circuit Test On TransformerRyan DagsilОценок пока нет

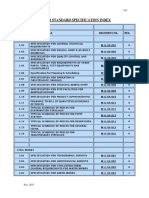

- Water Standard Specification Index As On Dec 2015Документ10 страницWater Standard Specification Index As On Dec 2015afp15060% (1)

- Amcor 2016Документ69 страницAmcor 2016Romulo AlvesОценок пока нет

- Cylinder Cutout Cylinder CutoutДокумент12 страницCylinder Cutout Cylinder CutoutIsrael Miranda ZamarcaОценок пока нет

- Mechatronics Handbook - 02 - Mechatronic Design Approach PDFДокумент16 страницMechatronics Handbook - 02 - Mechatronic Design Approach PDFJosé Fernando TerronesОценок пока нет

- Question Paper Code:: Reg. No.Документ2 страницыQuestion Paper Code:: Reg. No.tamilarasi87thulasiОценок пока нет