Академический Документы

Профессиональный Документы

Культура Документы

jecet.V4I1.C 10

Загружено:

Anonymous kqgdxmYvRОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

jecet.V4I1.C 10

Загружено:

Anonymous kqgdxmYvRАвторское право:

Доступные форматы

JECET; Dec. 2014-Feb. 2015; Sec. C Vol.4.No.1, 0087-0099.

E-ISSN: 2278–179X

Journal of Environmental Science, Computer Science and

Engineering & Technology

An International Peer Review E-3 Journal of Sciences and Technology

Available online atwww.jecet.org

Section C: Engineering & Technology

Research Article

Effect of Tip Clearance on the Casing over the Impeller on

a Low Speed Centrifugal Compressor

S. M. Swamy1* , V.Pandurangadu2

1

Department of Mechanical Engineering, GNITS, Hyderabad. India.

2

Department of Mechanical Engineering, JNTUCE, Anantapur. India.

Received: 29 December 2014; Revised: 18 January 2015; Accepted: 28 January 2015

Abstract: The centrifugal compressor is to study the effect of tip clearance on the

performance characteristics and the wall static pressure for a different flow co-

efficient. The tip clearance is varied by using spacers. The volume flow rate is varied

with the help of throttling device to conduct the performance test. Obtaining the

performance characteristics showing the variation of discharge pressure with volume

flow rate for different tip clearance, viz. τ =2.2%, 4%, 6.1% and 7.9%. Measurement

of periodic pressure at various tip clearance viz. τ =2.2%, 4%, 6.1% and 7.9%. For

each tip clearance pressure measured in radial location of impeller at 6 positions for

five flow coefficients viz., ф =0.40, =0.34 (both the above design flow), =0.28 (near

design flow), =0.21=0.18 (both below design flow) and four values of non

dimensional tip clearance viz., τ =2.2%, 4%, 6.1% and 7.9%, are chosen for

experimental work. The objective of the research work is to measure the periodic

variation static pressure on the casing over the rotor at different values of tip

clearance and flow coefficients. The periodic pressure data is acquired employing the

technique called PLEAT. Experiment carried out in a low speed centrifugal

compressor with un-shrouded rotor. Six holes are provided on the casing in which

adapters are attached, where the transducers are inserted. The pressure transducer

measures pressure in terms of voltage. The voltage output is very low. The output

voltage is amplified and converted to digital values for further processing of data.

JECET; December 2014-February 2015; Sec. C, Vol.4.No.1, 0087-0099. 87

Effect... S. M. Swamy & V. Pandurangadu

Sample results are presented and interpreted. From the measured static pressure, tip

clearance flows can be easily identified.

Keywords: Centrifugal compressor, tip clearance, casing static pressure, fast

response pressure transducer compressor, tip clearance, casing, impeller.

INTRODUCTION

The centrifugal compressor is a major type of compressor used in industrial, vehicular and space

applications. It has inherent advantages such as high pressure ratio per stage, reasonable efficiency,

large surge margin and low cost. A centrifugal compressor is a pressure producing machine which

draws fluid into its impeller at a lower radius and due to external work applied to its shaft, discharges

the fluid at a larger radius due to centrifugal effects. It is widely used for many applications, because

of their low cost, high-pressure ratio, large surge margin and reasonable efficiencies. There are many

factors that affect the performance of centrifugal compressor. Some of them are the inlet geometry,

flow angles, clearance between impeller blades and stationary shroud, rotational speed, diffuser type

and shape of the volute casing. Of these, flow in the tip clearance region is an important factor. A

good knowledge of flow pattern along the shroud and in the tip clearance region is necessary for the

better design of compressor. One of the means of studying the flow pattern is by measuring the

pressure distribution in this region. However pressure at any point on the shroud is not constant. It

varies periodically. This periodic variation of pressure can be measured by using proper

instrumentation. Tip clearance deteriorates the performance of a turbomachine. Because of tip

clearance, the efficiency of the machine decreases and the pressure losses increases. It also alters the

flow pattern in the machine. So it is necessary to understand the physics of the phenomena, and use it

in the design, to improve the performance of a turbomachine. Although there are many studies on the

effect of tip clearance on the performance of centrifugal compressor, the effects are not clearly

understood, because of lack of detailed flow information. Hence the present investigation is

undertaken. Precisely the physics of the pressure loss due to tip clearance is not well understood.

Objectives: The objective of the paper is to measure the periodic of variation static pressure on the

casing over the impeller at different values of tip clearance and flow coefficients. With the availability

of these data, it is possible to improve our understanding of tip clearance flow in centrifugal

compressor, with the ultimate aim of minimizing losses.

EXPERIMENTAL INVESTIGATIONS

The experimental set up consisted of centrifugal compressor set-up; driven by 5KW motor. The main

components of the compressor are the nozzle at the inlet, the suction duct, the impeller, the vane less

diffuser formed by the front and the rear walls of the casing and volute casing of circular cross section

and a delivery duct with a throttle at its outlet. The D. C. Motor is directly coupled to the shaft

carrying the impeller. A brief description of each of the component of the experimental set-up is given

below. Numbers in the brackets refers to Figure.1. An inlet nozzle and a suction duct were provided

at the inlet of the compressor. The purpose of the nozzle [1] at the inlet of the suction duct [2] is to

provide uniform flow to the impeller by accelerating it. Besides, the inlet nozzle is used to measure

the volume flow through the impeller. An inlet duct of 300 mm diameter and 1300 mm long is

provided at the inlet to the centrifugal compressor. Since the inlet duct is long, the flow will settle by

the time it approaches the impeller inlet. The front cover of the casing was designed such a way that

its inner surface was similar to the shape of impeller blade shroud contour for its extension formed the

JECET; December 2014-February 2014; Sec. C, Vol.4.No.1, 0087-0099. 88

Effect... S. M. Swamy & V. Pandurangadu

front wall of the vaneless diffuser at the exit of the impeller.Six static pressure holes were made along

the meriodional plane on the inner contour surface of the shroud from the inlet end to the exit end of

the diffuser to measure the static pressures. All the tapping was normal to the inner contour of the

shroud. An impeller of a centrifugal compressor is the most delicate part to be designed. It is to be

ensured that the flow is ideally oriented in the channel passages. The energy transfer from the shaft to

the fluid takes place in the rotating impeller. The existing impeller [6] (Sankaran, 1986) is a special

kind, designed to consider the effect of the outlet edges of the vanes of a centrifugal impeller on its

performance and flow characteristics. The impeller was designed on the power and speed of the

available drive motor. The shape number was chosen was 0.1. The impeller is unshrouded one, with

an inducer at the entry. The inducer is provided to give a smooth guidance to the flow turning from

axial to radial direction inside the inlet region of the impeller. The ratio of the inducer tip diameter to

the impeller outer diameter, d1t /d2t, is 0.6 to minimize the frictional losses. The blade inlet angle β 2 at

the impeller tip is 350 . The meridional component of velocity is uniform at the inlet of the impeller. It

is nearly constant from the inlet to the exit of the impeller. The number of blades used in the impeller

is 16. The selection of the number of blades is based on Pfleiderer’s equation, which gives the

required number corresponding to the impeller geometry. If an excessive number of blades are used,

lesser frictional and blockage would be high reducing the efficiency. Also, if lesser number of blades

were used there would not have been proper guidance of the fluid in the impeller resulting in high slip

and lowering of the work addition to the fluid. With the lesser number of blades, the blade loading

would also be higher. The impeller has twisted blades at the exit region. The impeller blade edges

have a maximum twist angle of 150 at the hub and shroud ends. This makes the blade angles at the

exit of the impeller to uniformly vary from 750 from the hub end to 900 at the mid span and then to

1050 at the shroud end. All angles are measured with respect to the tangential direction.

The major geometrical details of the impeller are given below.

Total pressure rise, ∆P: 300 mm WG

Speed of rotation, N: 2000 rpm

Impeller inlet diameter at inducer tip, d1t ; 300 mm

Impeller inlet diameter at inducer hub, d1h ; 160 mm

Impeller outer diameter, d2 : 500 mm

Blade angle at exit

(a) At hub: 75o

(b) At mean section: 90o

(c) At shroud: 105o

Blade angle at inlet inducer hub, β 1h : 53o

Blade angle at inducer tip, β 1t : 35o

Blade width at the exit, b: 34.7 mm

No. of blades of the impeller, Z: 16

All the angles are with respect to the tangential direction.

The rear cover of the casing called as back [11] shroud forms the hub wall and is attached to the

volute casing [10] by means of studs. A minimum clearance between the impeller and the rear cover

is provided to minimize the leakage. The cover of the casing is extended to form the back wall of the

vane less diffuser. The vaneless diffuser is a simple device consisting of an annulus in which the

radial velocity component is reduced by an increase in the area and the tangential velocity by the

requirement of constant fluid angular momentum (free vortex) .The extended part of the parallel walls

of front cover and the rear cover formed vaneless diffuser. The width of vaneless diffuser was kept

JECET; December 2014-February 2015; Sec. C, Vol.4.No.1, 0087-0099. 89

Effect... S. M. Swamy & V. Pandurangadu

same to direct the flow from, impeller to the annular passage without lateral expansion. The function

of the volute casing is to collect the air from the vane less diffuser and discharges it to the delivery

duct. The volute casing was of circular cross section. The width at entry to the volute casing is also

kept the same as that of the vane less diffuser exit width, so that the surfaces at the two sides of the

volute at entry forms a continuous portion of the vaneless diffuser. It is firmly fixed to the foundation.

The volute casing is designed for a constant angular momentum for the air stream. The cross-section

of the volute is circular. It has a base circle of 630 mm diameter, a volute angle of 13 o and cut-off

angle of 23o . The passage width at the entry to the volute cross-section at the exit is

Figure-1: Meridional view of impeller showing static pressure measurement

positions and Schematic diagram of centrifugal compressor setup

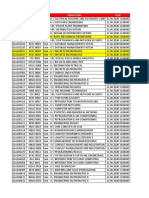

S.NO. 1 2 3 4 5 6

m

-0.13 0.00 0.40 0.67 1.00 1.25

mo

200 mm in diameter and is directly connected to a delivery duct of the same diameter through a 90o

bend. The delivery duct is 200 mm in diameter and 5 m in length. The throttle cone is fitted at the end

of the delivery duct to regulate the volume flow through the impeller. The average delivery pressure is

measured through the static pressure tapping provided on delivery duct wall at a distance of about 1 m

from the 90o bend following the volute casing. The throttle cone could be moved forward or backward

manually inside the delivery duct to regulate the volume flow through the compressor. On the shroud

adapters, for the pressure sensor, are provided at twelve different radial locations from inlet, just

behind the leading edge, to exit, after the trailing edge of the impeller. The sensor is passed inside a

brass holder of 2 mm internal diameter and with external threading (M4). The sensor is glued to this

brass holder using Fevikwik. The brass holder is screwed into these adapters at different locations for

JECET; December 2014-February 2014; Sec. C, Vol.4.No.1, 0087-0099. 90

Effect... S. M. Swamy & V. Pandurangadu

pressure measurement. Spacers were used to maintain the tip clearance accurately. Tip clearance is

varied by moving the front shroud axially. Thereby the distance between the front and rear cover

would alter. Provisions are made on front cover to fix the spacers in position. Four spacers were used

for each tip clearance were fixed at 90 degrees. The experimental investigations involve study for four

tip clearance .so hence four set of spacers were made. To measure the suction, delivery and wall static

pressures along the shroud and scanning box (Furnace Control Model no. FCO 91-3) with a micro

manometer (Model FCO12) manufactured by M/s Furness Control Ltd., Bexhill, UK is used. The

micro manometer has a sensitive differential pressure measuring device capable of reading air

pressures up to ± 1999 mm WG. It would respond to pressure inputs up to 5 kHz. But the time

constant potentiometer could be used to dampen response the fluctuating signal. It is useful in

damping flow fluctuations. The pressure can be measured to an accuracy of ± 0.1mmWG. The

scanning box contains 20 valves so we can measure up to 20 pressures. The speed of the centrifugal

compressor is measured using a non-contact digital type tachometer. The speed measurement is based

upon the evaluation of reflecting pulses from the rotating shaft. It has a range of 0-9999 and its

accuracy is ± 1 rpm. Tip clearance is varied by moving the shroud axially. Thereby the distance

between the hub and shroud would alter.

Instrumentation for Periodic Pressure Measurement:

Piezoresistive Analog to Personal

pressure Amplifier Digital Compute r

transducer converter

Figure-1(1): Schematic layout of the pressure measurement instrumentation

Amplifier as discussed already, the voltage from the transducer is very small so it has to be amplified

by using an amplifier. I used Ectron Amplifier (563 H). This 563H transducer conditioning amplifier

is a wideband, differential dc instrumentation amplifier with built-in transducer conditioning

functions. The compact design features good linearity, gain stability for input impedance. The output

of the basic amplifier is 10V at 10mA. The amplifier has 2 channels. The first channel is used to

amplify the signals from sensor. The second channel is used to attenuate the signals from the

tachometer. On the front panel of the amplifier, rotary gain switch, venire gain control, RTI-zero,

RTO-zero, bridge balance potentiometer are provided. On the back panel are TS101, TS102 each

consisting ten terminals. The zero detector switch provided on the back panel is moved to off position.

The signal generator is used generate a signal of known frequency and amplitude. This is connected to

the analogue-to-digital converter. The signal is sampled at known frequency and then converted to

digital value. It is stored in a memory location of a personnel computer, from which are signal is

plotted. This is compared with original signal.

RESULTS AND DISCUSSION:

The results of experiments conducted on the centrifugal impeller at four values of tip clearances i.e.,

=2.2%, 4%, 6.1% and 7.9% for four different flow coefficients i.e., = 0.18, 0.21, 0.28, 0.34 and 0.40

are presented and discussed in this chapter. The performance characteristics of the impeller are

presented first and then results of wall static pressure measured from the front shroud to impeller exit

JECET; December 2014-February 2015; Sec. C, Vol.4.No.1, 0087-0099. 91

Effect... S. M. Swamy & V. Pandurangadu

are presented.

The result of the experimental investigations revealed that, as the tip clearance is increased, there is a

reduction in energy coefficient. The decrease in energy coefficient is more for higher flow coefficient.

The operating range also slightly decreases with the increase in the tip clearance (Figure-2). The

decrease in energy coefficient is higher flow coefficient. The operating range also slightly decreases

with the increase in the tip clearance. Using the micro manometer the static pressure difference

between the entry and exit of the compressor is measured, at a particular tip clearance. The figure

depicts a negligible difference in efficiency for flow coefficients up to 0.30, for all tip clearances. At

flow rates higher than this, the difference in efficiency is appreciable, the peak efficiency being lower

for higher tip clearance and vice versa. This can be attributed to the increase in tip losses with the

increase in the clearance. The reduction in efficiency is due to the reduction in energy transfer for

higher tip clearances, since the input power remains more or less the same.

Figure-2: Performance characteristics

The pressure initially decreases due to suction and then uniformly increases, indicating that there are

no dead zones or eddies near the shroud region inside the impeller and energy transfer occurs

smoothly to the fluid near the shroud (Figure-3).

Figure-3: Variation of time averaged static pressure along the casing

JECET; December 2014-February 2014; Sec. C, Vol.4.No.1, 0087-0099. 92

Effect... S. M. Swamy & V. Pandurangadu

The performance of the compressor in terms of energy coefficient vs. flow coefficient is presented in

Figure-2. The range of flow coefficient for which the compressor operates stably is =0.08 to

=0.48.The result of the experimental investigations revealed that, energy coefficient across the

compressor is reduced as the tip clearance is increased. The flow coefficient, where the energy

coefficient is maximum decreases with the increase in tip clearance. However the operating range of

the compressor is decreased slightly as the maximum volume flow passing through the compressor is

reduced with tip clearance. The performance curves shown include losses not only the in the impeller,

but also in the following vaneless diffuser, volute casing and delivery duct.

The static pressure distribution measured at the casing static pressure holes, at 2.2% tip clearance for

different flow coefficients. On the shroud, static pressure taps were provided from the inducer leading

edge to the impeller exit. The shroud has its inner shape contoured to match the impeller blade tip

profile from the inlet to the exit. The static pressure measurements on the shroud indicate variation in

the static pressure coefficient, which matches with the blade passage clearly. From the figure it is seen

that the distribution is high for ф= 0.28, as it is nearer to design point operation. The pressure initially

decreases due to suction and then uniformly increases,

The local distribution of the casing static pressure is used to draw contours. Such contours at ф= 0.34

are shown in Figure-5 (11) for four values of tip clearance. Gradual increases of pressure are

observed from this meridional distance 0.40 to 0.53. After this meridional distance there is increase in

curvature of the casing. Because of thid flow accelerates due to which velocity increases and pressure

decreases. This decrease in pressure can be clearly observed.

After the meridional distance of 67 percent is reached the curvature straightens up. There is a increase

in pressure. This effect can be seen from the figure. The constant pressure lines are sloping towards

the suction side of the blade up to meridional distance of 120 percent. After meridional distance of

120 percent which falls in the vane less diffuser section, the slope of the constant pressure lines is

almost zero, i.e., the static pressure remains nearly constant in circumferential direction.

UNSTEADY WALL STATIC PRESSURE DISTRIBUTION

The variations of pressure at the location 1, the pressure is below atmospheric, which is due to

suction. The signals showed a more negative static pressure, compared to that with a flow coefficient

of 0.21. But the trend observed in the static pressure between the different tip clearances is the sa me,

for all the above flow coefficients. The suction pressure increases from 0.28 to 0.34 and the effect of

tip clearance is predominant as compared to the previous low flow coefficients. For a flow coefficient

of 0.40, the suction pressure here also reduces more predominant when tip clearance is increased from

2.2 to 7.9%. The variation of pressure at location 2, for a flow coefficient of 0.18.The suction side

pressure is below atmospheric, while on the pressure side it is above atmospheric pressure. Though

irregularity of pressure variation is present, blade crossing can be observed. Fluid pressure rise is still

below atmospheric. The pressure difference between the suction side and pressure side is about

18mmWG. This is because there is not much blade loading at this location. When the tip clearance is

increased from 2.2% to 7.9% the maximum pressure is reduced, even the variation is small i.e.

maximum of 4mmWG.The variation of pressure at location 2, for a flow coefficient of 0.21.The

pressure variation for the other flow coefficients was observed. The difference of peak pressures at

2.2% and at 7.9% tip clearance is more when compared to that of at a flow coefficient of 0.18. This

pressure difference increases with increased flow coefficient. The pressure fluctuations at location 3,

for a flow coefficient of 0.18. Periodicity in pressure fluctuations can be seen clearly. Tip clearance

effect, i.e. sharp rise and fall in pressure can be seen clearly at minimum pressure position. Similar

JECET; December 2014-February 2015; Sec. C, Vol.4.No.1, 0087-0099. 93

Effect... S. M. Swamy & V. Pandurangadu

trend is observed for the other flow coefficients. The pressure fluctuations at location 4 for a flow

coefficient of 0.18. Clear smooth periodicity of pressure fluctuations is observed on the shroud. Blade

positions can be seen clearly. Pressure difference between the suction side and the pressure side of the

blade is increased to 80mmWG. Here when the tip clearance is increase the maximum pressure

reduces. Maximum pressure difference between 2.2% tip clearance and 7.9% tip clearance is around

25 mm WG only. Similar trend is observed for flow coefficients from 0.21 to 0.40.The average

instantaneous pressure values at 5th location for a flow coefficient of 0.18. It is situated at the exit of

the impeller. Similar trend is observed for this location also what we discussed earlier locations. The

pressure fluctuations at 6th location for a flow coefficient of 0.18. Uniformity in pressure can be seen

to certain extent. The pressure difference got diffused due to mixing. Reduction in the intensity of

wake is observed. The average pressure is about 160 mm WG for 2.2% tip clearance. It reduces to 150

mm WG when tip clearance increases to 7.9%. The similar trend observed for other flow coefficients

0.21 to 0.40.

Figure-4: Compressor characteristic curve

The static pressure is high for lower tip clearance when compared with that for the higher tip

clearance for all flow coefficients. For high flow coefficient, reduction in static pressure is more near

the inducer when compared to low flow coefficient, which indicates more deceleration of flow at high

flow coefficients (Figure-5 (1) to 5 (10)).

Figure-5 (1): Pressure distribution for 1st hole for ф =0.18

JECET; December 2014-February 2014; Sec. C, Vol.4.No.1, 0087-0099. 94

Effect... S. M. Swamy & V. Pandurangadu

Figure-5 (2) Pressure distribution for 3rd hole for ф =0.21

Figure-5 (3): Pressure distribution for 3rd hole for ф =0.28

Figure-5(4): Pressure distribution for 5th hole for ф =0.21

JECET; December 2014-February 2015; Sec. C, Vol.4.No.1, 0087-0099. 95

Effect... S. M. Swamy & V. Pandurangadu

Figure-5 (5): Pressure distribution for 5th hole for ф =0.28

Figure-5 (6): Pressure distribution for 5th hole for ф =0.34

Figure-5 (7): Pressure distribution for 5th hole for ф =0.40

JECET; December 2014-February 2014; Sec. C, Vol.4.No.1, 0087-0099. 96

Effect... S. M. Swamy & V. Pandurangadu

Figure-5 (8): Pressure distribution for 6th hole for ф=0.28

Figure-5 (9): Pressure distribution for 6th hole for ф=0.34

Figure-5 (10): Pressure distribution for 6th hole for ф=0.40

JECET; December 2014-February 2015; Sec. C, Vol.4.No.1, 0087-0099. 97

Effect... S. M. Swamy & V. Pandurangadu

Figure-5 (11): Contours of static pressure on casing over the impeller.

JECET; December 2014-February 2014; Sec. C, Vol.4.No.1, 0087-0099. 98

Effect... S. M. Swamy & V. Pandurangadu

CONCLUSIONS

The present experimental investigations were conducted to study the effect of tip clearance on the

performance and wall static pressure in a centrifugal compressor. Performance tests were conducted at

five flow coefficient with four different tip clearances for each flow coefficient. Based on the

experimental investigations, following conclusions are drawn

1 As the tip clearance is increased, there is a reduction in static pressure rise across the

compressor, which causes reduction in energy coefficient.

2 The decrease in energy coefficient is more at higher value of flow coefficient.

3 The operating range slightly decreases with the increase in tip clearance.

The wall static pressure is high for lower tip clearance for all the flow coefficients. For high flow

coefficient, reduction in static pressure is more near the inducer, which indicates more deceleration of

flow at higher flow coefficient. The tip clearance is more pronounced at higher flow coefficients.

From these graphs it shows that the maximum pressure is achieved for 2.2% tip clearance, as

compared to other tip clearance, for all flow coefficients. Similarly for a flow coefficient of 0.28, the

static pressure observed is higher than other flow coefficients for all tip clearances.

REFERENCES

1 A. Engeda and M. Rautenberg. Comparisons of the Relative effect of TipClearance on

centrifugal impellers, ASME paper, 1987, 87-GT-11.

2 C.H. Sieverding, T. Arts, R. Denos and J.F. Brouckaert, Measurement techniques for

unsteady flows in turbomachines, Experiments in Fluids, 2000, Vol. 28, pp. 285-321.

3 T.N. Sridhara, Experimental Investigation on Tip Clearance Effects in aCentrifugal

Compressor, Ph. D. thesis, IIT Madras.1998.

4 M. Ishida, H. Ueki and Y. Senoo. Effect of blade tip configuration ontip clearance loss of

a centrifugal impeller, ASME Jl. of Turbomachinery, 1990, Vol. 112, No. 1, 14-18.

5 P. Kupferschmied, K. Pascal, O. Gizzi, C. Roduner, G. Gyarmathy, Time-resolved flow

measurements with fast-response aerodynamic probes in turbomachines, Measurement

Science and Technology, 2000, Vol. 11, 1036–1054.

6 Y. Senoo and Ishida, “Deterioration of Compressor Performance due to Tip Clearance of

Centrifugal Impellers”, ASME J. of Turbo, 1987, 109 (1), 55-61.

7 N. Sitaram and B. Pandey, “Tip Clearance Effects on a Centrifugal Compressor”, J. of

the Aero. Society of India, 1990, 42 (2) 309-315.

8 N. Sitaram and S.M. Swamy, “Performance Improvement of a Centrifugal Compressor by

Passive Means”, paper accepted for presentation at the 38th NCFMFP and publication in the

proceedings.2011.

9 A.L. Treaster and A.M. Yocum, “The calibration and application of five-hole probes”,

Trans. of ISA, 1979, 18(3), 23-34.

Corresponding Author: S. M. Swamy

Department of Mechanical Engineering, GNITS, Hyderabad. India.

JECET; December 2014-February 2015; Sec. C, Vol.4.No.1, 0087-0099. 99

Вам также может понравиться

- Analysis of A Centrifugal Pump Impeller Using ANSYS-CFXДокумент6 страницAnalysis of A Centrifugal Pump Impeller Using ANSYS-CFXBilal WaseemОценок пока нет

- An Investigation On The Performance Characteristics of A Centrifugal CompressorДокумент7 страницAn Investigation On The Performance Characteristics of A Centrifugal CompressorIJERDОценок пока нет

- Influence of Blade Outlet Angle On Performance of Low-Specific-Speed Centrifugal PumpДокумент6 страницInfluence of Blade Outlet Angle On Performance of Low-Specific-Speed Centrifugal PumpVignesh KumaranОценок пока нет

- Experimental Analysis On A Low Speed Centrifugal CompressorДокумент15 страницExperimental Analysis On A Low Speed Centrifugal CompressorInternational Journal of Application or Innovation in Engineering & ManagementОценок пока нет

- Pressure Recovery and Loss Coefficient Variations in The Two Different Centrifugal Blower Volute DesignsДокумент9 страницPressure Recovery and Loss Coefficient Variations in The Two Different Centrifugal Blower Volute DesignsJoseph Alexander BorgОценок пока нет

- Numerical Flow Analysis of An Axial Flow PumpДокумент6 страницNumerical Flow Analysis of An Axial Flow Pumpbinho58Оценок пока нет

- Iaetsd-Jaras-Cfd Simulation of Twin Screw Vacuum Pump WithДокумент4 страницыIaetsd-Jaras-Cfd Simulation of Twin Screw Vacuum Pump WithiaetsdiaetsdОценок пока нет

- Wind Turbine Oblique FlowДокумент7 страницWind Turbine Oblique FlowAnonymous gxAd4liОценок пока нет

- Ijri Me 01 003Документ5 страницIjri Me 01 003ijripublishersОценок пока нет

- Effect of Inlet Straighteners On Centrifugal Fan Performance: N.N. Bayomi, A. Abdel Hafiz, A.M. OsmanДокумент12 страницEffect of Inlet Straighteners On Centrifugal Fan Performance: N.N. Bayomi, A. Abdel Hafiz, A.M. OsmanAli HusseiniОценок пока нет

- Usha IJFMTS 2020Документ10 страницUsha IJFMTS 202001988Оценок пока нет

- Analyzing The Effects of Splitter Blade On The Performance Characteristics For A High-Speed Centrifugal PumpДокумент11 страницAnalyzing The Effects of Splitter Blade On The Performance Characteristics For A High-Speed Centrifugal PumpBRENDA VIVIANA ARANDA JURADOОценок пока нет

- Performance Test On Single Stage Axial Flow FanДокумент3 страницыPerformance Test On Single Stage Axial Flow FanAkhil Jaiswal100% (1)

- Diesel Engine Air Swirl Mesurements Using Avl Test RigДокумент13 страницDiesel Engine Air Swirl Mesurements Using Avl Test RigIAEME PublicationОценок пока нет

- Performance Analysis of Backward Curved Centrifugal Fan in Heating Ventilation and Air-ConditioningДокумент3 страницыPerformance Analysis of Backward Curved Centrifugal Fan in Heating Ventilation and Air-ConditioningIjsrnet Editorial100% (1)

- Analysis of Axial Flow Fan Using AnsysДокумент9 страницAnalysis of Axial Flow Fan Using AnsysgarystevensozОценок пока нет

- Pneumatic Sheet Bending Bend Removing MachineДокумент50 страницPneumatic Sheet Bending Bend Removing MachinenaveensagarОценок пока нет

- Inlet Recirculation Influence To The Flow Structure of Centrifugal ImpellerДокумент8 страницInlet Recirculation Influence To The Flow Structure of Centrifugal ImpellerSrinivasОценок пока нет

- 5 2 HergtMiKTeX V5N2Документ11 страниц5 2 HergtMiKTeX V5N2anggacenter_19Оценок пока нет

- Analysis of A Centrifugal Pump Impeller Using Ansys CFX IJERTV1IS3098Документ6 страницAnalysis of A Centrifugal Pump Impeller Using Ansys CFX IJERTV1IS3098Nithin LouisОценок пока нет

- Analytical Investigation of Centrifugal Pump Impeller - Jicr-December-2020Документ7 страницAnalytical Investigation of Centrifugal Pump Impeller - Jicr-December-2020raviОценок пока нет

- Stability Improvement of High-Pressure-Ratio Turbocharger Centrifugal Compressor by Asymmetric Flow Control-Part I Non-Axisymmetrical Flow in Centrifugal CompressorДокумент9 страницStability Improvement of High-Pressure-Ratio Turbocharger Centrifugal Compressor by Asymmetric Flow Control-Part I Non-Axisymmetrical Flow in Centrifugal CompressorjswxieОценок пока нет

- Butter Valve Thickness PDFДокумент10 страницButter Valve Thickness PDFAnand KumarОценок пока нет

- Irjet V4i5292Документ10 страницIrjet V4i5292Srinivas HuraliОценок пока нет

- Design & Analysis of FanДокумент96 страницDesign & Analysis of FanMrudula Chintana91% (11)

- Effects of Impeller Trim On Performance of Two-Stage Self-Priming Centrifugal PumpДокумент11 страницEffects of Impeller Trim On Performance of Two-Stage Self-Priming Centrifugal PumpGunjanОценок пока нет

- Control of BLДокумент13 страницControl of BLابراهيم اسامهОценок пока нет

- Zhao 2017Документ17 страницZhao 2017Muhammad UsamaОценок пока нет

- Ijmet 08 08 073Документ8 страницIjmet 08 08 073ABDULLAH SHAHRIAR PIYAL CHY 1803034Оценок пока нет

- Design and Development of Centrifugal Pump ImpellerДокумент7 страницDesign and Development of Centrifugal Pump ImpellerAmpera marzelaОценок пока нет

- Optimization of Discrete Cavities in A Centrifugal Compressor To Enhance Operating StabilityДокумент12 страницOptimization of Discrete Cavities in A Centrifugal Compressor To Enhance Operating StabilitySinan ÖrmeciОценок пока нет

- Micro BombaДокумент8 страницMicro BombaMilton Flores MendozaОценок пока нет

- CFD Analysis of Flow Through A Conical ExhaustДокумент26 страницCFD Analysis of Flow Through A Conical Exhaustrvnaveen26Оценок пока нет

- Blower Manual PDFДокумент6 страницBlower Manual PDFDatta DoifodeОценок пока нет

- CFD Analysis of The Volute Geometry Effect On The Turbulent Air Flow Through The Turbocharger CompressorДокумент10 страницCFD Analysis of The Volute Geometry Effect On The Turbulent Air Flow Through The Turbocharger CompressorbcshendeОценок пока нет

- CFD Analysis of Centrifugal Pump ImpelleДокумент9 страницCFD Analysis of Centrifugal Pump Impelleبلال بن عميرهОценок пока нет

- Gear Pump PaperДокумент9 страницGear Pump PaperVassoula DarОценок пока нет

- Energies 13 01628 PDFДокумент17 страницEnergies 13 01628 PDFHayderAlSamawiОценок пока нет

- Research Paper1Документ6 страницResearch Paper1Mitul PatelОценок пока нет

- Experiment Study of Vaned Diffuser Effects On Overall Performance and Flow Field of A Centrifugal CompressorДокумент8 страницExperiment Study of Vaned Diffuser Effects On Overall Performance and Flow Field of A Centrifugal CompressorBrahimABDОценок пока нет

- CFD Analysis of Swept and Leaned Transonic Compressor RotorДокумент5 страницCFD Analysis of Swept and Leaned Transonic Compressor RotorseventhsensegroupОценок пока нет

- Research Article: Numerical Investigation On Pressure Fluctuations For Different Configurations of Vaned Diffuser PumpsДокумент10 страницResearch Article: Numerical Investigation On Pressure Fluctuations For Different Configurations of Vaned Diffuser Pumpsbakri10101Оценок пока нет

- Complex Engineering Problem: Group Members: Mudassar Javed BMEF17E027 Hamza Kunwar BMEF17E020Документ10 страницComplex Engineering Problem: Group Members: Mudassar Javed BMEF17E027 Hamza Kunwar BMEF17E020Mudassar JavedОценок пока нет

- 505 - Lec 01 PDFДокумент33 страницы505 - Lec 01 PDFUdara DissanayakeОценок пока нет

- Compressible Flow Across A Varying Area PassageДокумент4 страницыCompressible Flow Across A Varying Area PassageGaurav VaibhavОценок пока нет

- Hydraulic Efficiencies of Impeller and PumpДокумент9 страницHydraulic Efficiencies of Impeller and PumpJohn Archie MendozaОценок пока нет

- Simulation of Drilling Pressure Profile in DirectiДокумент7 страницSimulation of Drilling Pressure Profile in DirectiSivaramanОценок пока нет

- Micro BombaДокумент12 страницMicro BombaMilton Flores MendozaОценок пока нет

- Hydraulic Analysis of Multistage Vertical Turbine Pump: Prof Jvalant Trivedi, Prof Nitinchandra Patel, Jaydeep TrivediДокумент7 страницHydraulic Analysis of Multistage Vertical Turbine Pump: Prof Jvalant Trivedi, Prof Nitinchandra Patel, Jaydeep TrivediJvalant TrivediОценок пока нет

- Design, Development and Testing of An Impeller ofДокумент6 страницDesign, Development and Testing of An Impeller ofbhaveshlibОценок пока нет

- Finite Element Analysis of Pressure Drop in Orifice Meter IJERTV3IS030297Документ4 страницыFinite Element Analysis of Pressure Drop in Orifice Meter IJERTV3IS030297keiko davilaОценок пока нет

- Inhouse Trbfgfaning Report OnДокумент13 страницInhouse Trbfgfaning Report OnmustafahОценок пока нет

- Analysis and Development of Restrictor For Parallel Twin Engine in FSAE CarsДокумент4 страницыAnalysis and Development of Restrictor For Parallel Twin Engine in FSAE Carsbritisha2610Оценок пока нет

- Effects of Probe Support On The Flow Field of A Low-Speed Axial CompressorДокумент7 страницEffects of Probe Support On The Flow Field of A Low-Speed Axial CompressorUmair MunirОценок пока нет

- Design of A New Improved Intake Manifold For F-Sae Car: January 2016Документ6 страницDesign of A New Improved Intake Manifold For F-Sae Car: January 2016İlker EnesОценок пока нет

- How to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesОт EverandHow to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesРейтинг: 5 из 5 звезд5/5 (1)

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsОт EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsОценок пока нет

- Brochure ISДокумент4 страницыBrochure ISJAYESH VIKRAM RastogiОценок пока нет

- Methanol Technologies of Tkis: A Brief OverviewДокумент12 страницMethanol Technologies of Tkis: A Brief OverviewMuhammad NaeemОценок пока нет

- E11133 MB Pin Definition v2 Print Vendor Only PDFДокумент18 страницE11133 MB Pin Definition v2 Print Vendor Only PDFLuciano MalancaОценок пока нет

- Notes Ch. 4 - Folk and Popular CultureДокумент7 страницNotes Ch. 4 - Folk and Popular CultureVienna WangОценок пока нет

- CSA Pre-Test QuestionnaireДокумент16 страницCSA Pre-Test Questionnairedaniella balaquitОценок пока нет

- How To Build A GreenhouseДокумент67 страницHow To Build A GreenhouseBolarinwaОценок пока нет

- Time Series - Practical ExercisesДокумент9 страницTime Series - Practical ExercisesJobayer Islam TunanОценок пока нет

- Submittal ReviewДокумент22 страницыSubmittal ReviewuddinnadeemОценок пока нет

- Content For Essay and Paragraph Writing On Maritime HistoryДокумент15 страницContent For Essay and Paragraph Writing On Maritime HistoryRaju KumarОценок пока нет

- A General Strategy For The Synthesis of Reduced Graphene Oxide-Based CompositesДокумент8 страницA General Strategy For The Synthesis of Reduced Graphene Oxide-Based CompositesCristian Gonzáles OlórteguiОценок пока нет

- Staff Code Subject Code Subject Data FromДокумент36 страницStaff Code Subject Code Subject Data FromPooja PathakОценок пока нет

- WEG CTM Dwb400 10004024165 Installation Guide EnglishДокумент1 страницаWEG CTM Dwb400 10004024165 Installation Guide Englishjeffv65Оценок пока нет

- The Lower Parts of The Lock Stitch Sewing MachineДокумент3 страницыThe Lower Parts of The Lock Stitch Sewing MachineHazelAnnCandelarioVitug20% (5)

- Final Project ReportДокумент83 страницыFinal Project ReportMohit SrivastavaОценок пока нет

- Samsung Bd-p4600 SMДокумент101 страницаSamsung Bd-p4600 SMIonel CociasОценок пока нет

- 12.1 ANSYS CompositePrepPostДокумент2 страницы12.1 ANSYS CompositePrepPostLakmal ArandaraОценок пока нет

- Biomaterials in Restorative Dentistry and Endodontics: An OverviewДокумент6 страницBiomaterials in Restorative Dentistry and Endodontics: An Overviewmanzoor ul haq bukhariОценок пока нет

- Stahl - PUDSДокумент29 страницStahl - PUDSsusanasusana_Оценок пока нет

- RestrictedДокумент51 страницаRestrictedsridharpalledaОценок пока нет

- Acute Coronary Syndrome: Diagnosis and Initial Management: Each YearДокумент9 страницAcute Coronary Syndrome: Diagnosis and Initial Management: Each YearGabriela Pacheco0% (1)

- Neoliberalism and Altered State Developmentalism in The Twenty First Century Extractive Regime of IndonesiaДокумент26 страницNeoliberalism and Altered State Developmentalism in The Twenty First Century Extractive Regime of IndonesiaErwin SuryanaОценок пока нет

- Macedonian KavalДокумент1 страницаMacedonian Kavalmikiszekely1362Оценок пока нет

- 020 Basketball CourtДокумент4 страницы020 Basketball CourtMohamad TaufiqОценок пока нет

- Aircraft Structures - Ii (AER18R372)Документ15 страницAircraft Structures - Ii (AER18R372)sarathkumar sebastinОценок пока нет

- (Js-Umum) Daftar Harga 01 Maret '23Документ1 страница(Js-Umum) Daftar Harga 01 Maret '23Kristin NataliaОценок пока нет

- M.E Construction Engineering ManagementДокумент43 страницыM.E Construction Engineering ManagementLeilani JohnsonОценок пока нет

- Origami Undergrad ThesisДокумент63 страницыOrigami Undergrad ThesisEduardo MullerОценок пока нет

- Anish Pandey ResumeДокумент4 страницыAnish Pandey ResumeAnubhav ChaturvediОценок пока нет

- Chemistry - JEE Main 2024 January - Detailed Analysis by MathonGoДокумент3 страницыChemistry - JEE Main 2024 January - Detailed Analysis by MathonGoGulam Naziruddin Makandar (NuTHeaD94)Оценок пока нет

- Lecture 9: Quarter-Wave-Transformer Matching.: R JZ L Z Z Z JR LДокумент13 страницLecture 9: Quarter-Wave-Transformer Matching.: R JZ L Z Z Z JR LRuth EnormeОценок пока нет