Академический Документы

Профессиональный Документы

Культура Документы

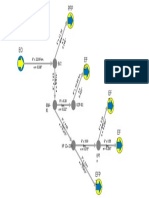

DR Lngo HP System Infographic

Загружено:

rebolledojfОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

DR Lngo HP System Infographic

Загружено:

rebolledojfАвторское право:

Доступные форматы

Micro scale LNG liquefaction system

backed by trusted technology

Providing a modular LNG liquefaction solution for the core of the LNG value chain

with proven technology from the Dresser-Rand business and Siemens

The LNGo™ HP System

Produces approximately 30,000 GPD of LNG

Primary Compressor Feed/Flash Booster Power Module(s)

Module • Proven Dresser-Rand (Optional)

MOS™/HOS™ reciprocating • High-tech, low emission

• Proven Dresser-Rand

compressor lean burn engine with

MOS™/HOS™ reciprocating

compressor • Elevates pressure non-selective catalytic

of feed gas reduction (NSCR)

• Non-lubricated cylinders

and packing (no process • Returns flash to the optimal • Siemens gas engine

contamination) liquefaction pressure power systems

• Prefabricated wiring and piping • Purge flow from gas

for ease of installation conditioning is blended

into the fuel supply to

power module

Process/ Gas Conditioning Controls and MCC

Chiller Module Module • Remote capable control logic

• Cooling and product phase • Cleans and separates gas into: • Wireless instrumentation and

change from gas to liquid transmitters

- Product stream for the

• Mechanical chiller with air- liquefaction process • Network I/O for rapid

cooled condenser interconnection

- Purge stream used for

• Turbo-expander and power generation (if required) • Siemens control and

Joule-Thompson valve monitoring system

What’s in it for you?

Modular and flexible

Modularity • Future expansion

for system build out • Tailored solutions based on site requirements

Efficient and reliable

20 Years

• Reliable, field-proven Dresser-Rand business

and Siemens components

• High-energy efficiency

design life of system

• Highly integrated modules

with pre-engineered interfaces

Flexible and sustainable

Self-powered • No flaring, less environmental impact

• Capture valuable hydrocarbons

option and easy to permit • Allows flexibility for remote sites

What is the equivalent

of 30,000 gallons (48 tons) of LNG?

22,662

average American homes powered daily

117

Class 8 trucks fueled

17,647

gallons (66,801 liters) of diesel

(twin 150 gallon (567 liter) tanks) displaced per day; enough to

fuel 18 heavy-duty mining trucks

14,850

30

cars fueled daily

tug boats fueled with

reduced particulate emissions

30,000

gallons (48 tons) LNG per day

Where will you benefit most

from the LNGo system?

Optimal in areas Wherever flaring is not an option

with no natural gas for regulatory or environmental

infrastructure reasons

Where tight emission Wherever low value processed

§§

standards do not allow gas can be monetized close

burning diesel on marine to the well (e.g. for fueling high

vessels in harbors and horsepower E&P equipment)

intercoastal zones

Wherever diesel for

electric power generation

and vehicles is more

expensive (e.g. in remote

regions)

LNGo.dresser-rand.com

Вам также может понравиться

- Hypm Rack Telecom and DataДокумент4 страницыHypm Rack Telecom and Datac108Оценок пока нет

- br20160822 - PV Skid BrochureДокумент12 страницbr20160822 - PV Skid BrochureAmit KhuranaОценок пока нет

- Lci BrochureДокумент20 страницLci BrochureSergey PavlovОценок пока нет

- Powerbox 20X en PDFДокумент12 страницPowerbox 20X en PDFENG.YONIS HUSSAINОценок пока нет

- 2.DER and RESДокумент62 страницы2.DER and RESNamiraОценок пока нет

- SGT600Документ2 страницыSGT600fabyanoОценок пока нет

- Browsur 1Документ8 страницBrowsur 1wulanОценок пока нет

- Brochure Gas Turbine SGT-400 For Power Generation PDFДокумент4 страницыBrochure Gas Turbine SGT-400 For Power Generation PDFfrdnОценок пока нет

- SGT 800 Factsheet 2017Документ2 страницыSGT 800 Factsheet 2017pradeepnair1710% (1)

- AD419254016605en 000101Документ20 страницAD419254016605en 000101Mohamed ElsayedОценок пока нет

- Dozer D37 24 Brochure English en D37 24BR01 1022 V1Документ16 страницDozer D37 24 Brochure English en D37 24BR01 1022 V1linh congОценок пока нет

- D39EX D39PX: Tier 4 Final EngineДокумент16 страницD39EX D39PX: Tier 4 Final EngineJustinОценок пока нет

- Factsheet SGT-700 enДокумент2 страницыFactsheet SGT-700 enAzril DahariОценок пока нет

- R922Документ24 страницыR922equipment9278Оценок пока нет

- Liebherr RMG Technical DescriptionДокумент4 страницыLiebherr RMG Technical DescriptionHua Hidari YangОценок пока нет

- H2 PACE Plugpower 1Документ6 страницH2 PACE Plugpower 1Deepak GehlotОценок пока нет

- 151105c2 MVG2 E Low 1106Документ16 страниц151105c2 MVG2 E Low 1106stoneminerОценок пока нет

- Servoantriebe-Kleinspannungen en WebДокумент32 страницыServoantriebe-Kleinspannungen en WebServomotores SimairОценок пока нет

- Powerbox: C1000 D2R and C1250 D2RДокумент12 страницPowerbox: C1000 D2R and C1250 D2RMohamedJaberKutkutMjk100% (1)

- Magnomatics BrochureДокумент4 страницыMagnomatics BrochureVijay17101972Оценок пока нет

- Siemens Sgt-A45 Mobile Unit Data SheetДокумент2 страницыSiemens Sgt-A45 Mobile Unit Data SheetThanapaet Rittirut100% (1)

- Rexnord Euroflex Disc Couplings: Overview BrochureДокумент8 страницRexnord Euroflex Disc Couplings: Overview BrochureJodans Engineering MAACOОценок пока нет

- SolarTurbine O&G OverviewДокумент12 страницSolarTurbine O&G Overviewkecskemet100% (1)

- Battery: Range SummaryДокумент2 страницыBattery: Range SummaryMEER MUSTAFA ALIОценок пока нет

- Hydran M2: GE Grid SolutionsДокумент2 страницыHydran M2: GE Grid SolutionsLaurentiuОценок пока нет

- Amber Kinetics DataSheetДокумент2 страницыAmber Kinetics DataSheetAdrian NituОценок пока нет

- SGT-600 GT PowerGen EN PDFДокумент4 страницыSGT-600 GT PowerGen EN PDFM BОценок пока нет

- 5 - GrenCo - Company PresentationДокумент34 страницы5 - GrenCo - Company PresentationCluis KeОценок пока нет

- GD Power Generation High Pressure Comp 16224 - 2 - 7 - 15 - 02 - GD - POWER - GENERATION - 2015 - V2 - AWДокумент8 страницGD Power Generation High Pressure Comp 16224 - 2 - 7 - 15 - 02 - GD - POWER - GENERATION - 2015 - V2 - AWgheantikaОценок пока нет

- Modern Small-Scale LNG Plant Solutions: Clean and Stand-AloneДокумент5 страницModern Small-Scale LNG Plant Solutions: Clean and Stand-AloneabsahkahОценок пока нет

- Cryotec Small Scale LNG EngДокумент5 страницCryotec Small Scale LNG EngRamesh NairОценок пока нет

- Industrial GeneratorsДокумент8 страницIndustrial GeneratorsJulio Fernando Antezana HinojosaОценок пока нет

- EN - Lowvoltagedrivesformining - REVAДокумент40 страницEN - Lowvoltagedrivesformining - REVAbakien-canОценок пока нет

- D61EX D61PX: EU Stage IV EngineДокумент16 страницD61EX D61PX: EU Stage IV EngineMarcos DamascenoОценок пока нет

- GEA31911 ProCraneMC Brochure - ENДокумент4 страницыGEA31911 ProCraneMC Brochure - ENJonathanОценок пока нет

- Product Brochure LR 636 LitronicДокумент22 страницыProduct Brochure LR 636 LitroniczliangОценок пока нет

- AnsaldoEnergia SYNCHRONOUSCONDENSERS 20220622Документ6 страницAnsaldoEnergia SYNCHRONOUSCONDENSERS 20220622rotimi olalekan fataiОценок пока нет

- EU Stage IV Engine: Crawler DozerДокумент16 страницEU Stage IV Engine: Crawler DozerEko PrasetyoОценок пока нет

- 22hd Hybrid LoaderДокумент5 страниц22hd Hybrid LoaderAnonymous AaWiU0tJkОценок пока нет

- Electrical Design of High-Speed Induction Motors of Up To 15 MW and 20000 RPMДокумент7 страницElectrical Design of High-Speed Induction Motors of Up To 15 MW and 20000 RPMzachxie100% (1)

- Series Compensation Systems: Grid SolutionsДокумент12 страницSeries Compensation Systems: Grid SolutionsasrinkaramanОценок пока нет

- Lehe8967 00Документ6 страницLehe8967 00AM76Оценок пока нет

- Industrial Cooling Systems EMDC. HY10 6000 UK LR - EUДокумент4 страницыIndustrial Cooling Systems EMDC. HY10 6000 UK LR - EUMiguel Angel LopezОценок пока нет

- SGT-500 Industrial Gas Turbine: Answers For EnergyДокумент4 страницыSGT-500 Industrial Gas Turbine: Answers For EnergySalim BenlahceneОценок пока нет

- RLC PRC020G en - 08252015Документ48 страницRLC PRC020G en - 08252015sehonoОценок пока нет

- Dry-Type Transformers For Railways Brochure A4 - vFINALДокумент18 страницDry-Type Transformers For Railways Brochure A4 - vFINALYusuke Okudaira100% (1)

- Sauer Danfoss Orbital Motors PDFДокумент5 страницSauer Danfoss Orbital Motors PDFSoledad Navarro LazoОценок пока нет

- Lean Burn Product BrochureДокумент8 страницLean Burn Product BrochurepradeeepgargОценок пока нет

- 1LAB000297 Cast Coil Dry-Type Transformers-20180705Документ24 страницы1LAB000297 Cast Coil Dry-Type Transformers-20180705Martin E. Rosales GonzalezОценок пока нет

- Copeland Scroll Variable Speed Compressors For Commercial Applications Brochure en Us 1570792Документ6 страницCopeland Scroll Variable Speed Compressors For Commercial Applications Brochure en Us 1570792Youssef BoulaghlaОценок пока нет

- Modulos Hibridos Siemens PDFДокумент12 страницModulos Hibridos Siemens PDFgueilor perezОценок пока нет

- Elegance-Ducted-19 11 19Документ2 страницыElegance-Ducted-19 11 19Tee Shi FengОценок пока нет

- Synchronous Condenser en FR DataДокумент12 страницSynchronous Condenser en FR DataGustavo SouzaОценок пока нет

- Natural Gas ContinuousДокумент7 страницNatural Gas ContinuousIbrar HussainОценок пока нет

- Heavy Duty Rectifier Broschuere Chlor 020 FINALДокумент6 страницHeavy Duty Rectifier Broschuere Chlor 020 FINALdwijanuarpribadiОценок пока нет

- RTHD Catalog RLC Prc020 enДокумент32 страницыRTHD Catalog RLC Prc020 enCharles Lee50% (2)

- Borri Oil Gas Appl en PDFДокумент8 страницBorri Oil Gas Appl en PDFTerry wei shengОценок пока нет

- 566 180083 Factsheet SGT A45 Online PDFДокумент2 страницы566 180083 Factsheet SGT A45 Online PDFIwan AbdurahmanОценок пока нет

- EsquemaДокумент1 страницаEsquemarebolledojfОценок пока нет

- Ejemplo Tabla Contactos GMail para Importación AutomáticaДокумент7 страницEjemplo Tabla Contactos GMail para Importación AutomáticaXaviera UgarrizaОценок пока нет

- Sistema de Distribucion Jusepin Criogenico San Joaquin PDFДокумент1 страницаSistema de Distribucion Jusepin Criogenico San Joaquin PDFrebolledojfОценок пока нет

- Sistema de Distribucion Jusepin Criogenico San Joaquin PDFДокумент1 страницаSistema de Distribucion Jusepin Criogenico San Joaquin PDFrebolledojfОценок пока нет

- ReciprocatingCompressorPower-US Field UnitsДокумент4 страницыReciprocatingCompressorPower-US Field UnitsrebolledojfОценок пока нет

- EsquemaДокумент1 страницаEsquemarebolledojfОценок пока нет

- 4290 19496 1 PB PDFДокумент22 страницы4290 19496 1 PB PDFrebolledojfОценок пока нет

- Comparative AnalysisДокумент17 страницComparative AnalysisrebolledojfОценок пока нет

- Warranty Notification - Installation List Data and Start Up Check Lists For Reciprocating Compressors JG:A:M:N:P:Q:R:J:H:E:K:T:C:D:FДокумент9 страницWarranty Notification - Installation List Data and Start Up Check Lists For Reciprocating Compressors JG:A:M:N:P:Q:R:J:H:E:K:T:C:D:FMandava Subrahmanya Sivarama PrasadОценок пока нет

- Peru Look Attractive To Invest in New LNG ProjectsДокумент1 страницаPeru Look Attractive To Invest in New LNG ProjectsrebolledojfОценок пока нет

- Crisis Migracion VenezuelaДокумент2 страницыCrisis Migracion VenezuelarebolledojfОценок пока нет

- GLD.031 Major Capital Projects (Minerals)Документ35 страницGLD.031 Major Capital Projects (Minerals)rebolledojf100% (3)

- Formato Proyecta UNI 2014Документ4 страницыFormato Proyecta UNI 2014rebolledojfОценок пока нет

- Dart LNG BusДокумент8 страницDart LNG BusrebolledojfОценок пока нет

- Cell Cycle Regulation and Neural DifferentiationДокумент12 страницCell Cycle Regulation and Neural DifferentiationrebolledojfОценок пока нет

- 2016 World LNG ReportДокумент92 страницы2016 World LNG ReportrebolledojfОценок пока нет

- Cpi Spending Outlook 2020Документ20 страницCpi Spending Outlook 2020NguyễnMinhQuânОценок пока нет

- 5 Generation NGL / LPG Recovery Technologies For RetrofitsДокумент14 страниц5 Generation NGL / LPG Recovery Technologies For RetrofitsrebolledojfОценок пока нет

- Cpi Spending Outlook 2020Документ20 страницCpi Spending Outlook 2020NguyễnMinhQuânОценок пока нет

- Validation PDRI PDFДокумент95 страницValidation PDRI PDFrebolledojfОценок пока нет

- WBS Project Management PDFДокумент85 страницWBS Project Management PDFGilmer Patricio100% (1)

- Derichebourg - Universal Registration Document 2020-2021Документ256 страницDerichebourg - Universal Registration Document 2020-2021Abhijeet ShindeОценок пока нет

- Federal Ombudsman of Pakistan Complaints Resolution Mechanism For Overseas PakistanisДокумент41 страницаFederal Ombudsman of Pakistan Complaints Resolution Mechanism For Overseas PakistanisWaseem KhanОценок пока нет

- MoMA Learning Design OverviewДокумент28 страницMoMA Learning Design OverviewPenka VasilevaОценок пока нет

- 11-03-25 PRESS RELEASE: The Riddle of Citizens United V Federal Election Commission... The Missing February 22, 2010 Judgment...Документ2 страницы11-03-25 PRESS RELEASE: The Riddle of Citizens United V Federal Election Commission... The Missing February 22, 2010 Judgment...Human Rights Alert - NGO (RA)Оценок пока нет

- 173544avaya Aura AES 7-0 JTAPI Programmers GuideДокумент88 страниц173544avaya Aura AES 7-0 JTAPI Programmers GuideAhmed SakrОценок пока нет

- THM07 Module 2 The Tourist Market and SegmentationДокумент14 страницTHM07 Module 2 The Tourist Market and Segmentationjennifer mirandaОценок пока нет

- MigrationДокумент6 страницMigrationMaria Isabel PerezHernandezОценок пока нет

- What's More: Quarter 2 - Module 7: Deferred AnnuityДокумент4 страницыWhat's More: Quarter 2 - Module 7: Deferred AnnuityChelsea NicoleОценок пока нет

- Correlation SecretДокумент23 страницыCorrelation SecretDavid100% (1)

- In Practice Blood Transfusion in Dogs and Cats1Документ7 страницIn Practice Blood Transfusion in Dogs and Cats1何元Оценок пока нет

- 215 Final Exam Formula SheetДокумент2 страницы215 Final Exam Formula SheetH.C. Z.Оценок пока нет

- McEwan Pacific Student Scholarship 1374 RegulationsДокумент2 страницыMcEwan Pacific Student Scholarship 1374 RegulationsHaitelenisia Hei'ululua KAMAОценок пока нет

- Bed BathДокумент6 страницBed BathKristil ChavezОценок пока нет

- Ingrid Gross ResumeДокумент3 страницыIngrid Gross Resumeapi-438486704Оценок пока нет

- Pr1 m4 Identifying The Inquiry and Stating The ProblemДокумент61 страницаPr1 m4 Identifying The Inquiry and Stating The ProblemaachecheutautautaОценок пока нет

- Faculty of Computer Science and Information TechnologyДокумент4 страницыFaculty of Computer Science and Information TechnologyNurafiqah Sherly Binti ZainiОценок пока нет

- Bacanie 2400 Articole Cu Cod de BareДокумент12 страницBacanie 2400 Articole Cu Cod de BareGina ManolacheОценок пока нет

- Promises From The BibleДокумент16 страницPromises From The BiblePaul Barksdale100% (1)

- OatДокумент46 страницOatHari BabuОценок пока нет

- Comparative Study of The Prison System in India, UK and USAДокумент12 страницComparative Study of The Prison System in India, UK and USAHarneet Kaur100% (1)

- Right To Information: National Law University AND Judicial Academy, AssamДокумент20 страницRight To Information: National Law University AND Judicial Academy, Assamsonu peterОценок пока нет

- Discuss The Following Questions With Your Family Members Casually and Write The AnswersДокумент2 страницыDiscuss The Following Questions With Your Family Members Casually and Write The AnswersVincent Stephen AmalrajОценок пока нет

- The Gift of ADHDДокумент233 страницыThe Gift of ADHDGerman Rosales Vargas100% (3)

- MMWModule1 - 2023 - 2024Документ76 страницMMWModule1 - 2023 - 2024Rhemoly MaageОценок пока нет

- The Confederation or Fraternity of Initiates (1941)Документ82 страницыThe Confederation or Fraternity of Initiates (1941)Clymer777100% (1)

- WILDLIFEДокумент35 страницWILDLIFEnayab gulОценок пока нет

- WWW - Nswkendo IaidoДокумент1 страницаWWW - Nswkendo IaidoAshley AndersonОценок пока нет

- 47 Vocabulary Worksheets, Answers at End - Higher GradesДокумент51 страница47 Vocabulary Worksheets, Answers at End - Higher GradesAya Osman 7KОценок пока нет

- The Role of Religion in The Causation of Global Conflict & Peace and Other Related Issues Regarding Conflict ResolutionДокумент11 страницThe Role of Religion in The Causation of Global Conflict & Peace and Other Related Issues Regarding Conflict ResolutionlorenОценок пока нет

- New Microsoft Office Word DocumentДокумент6 страницNew Microsoft Office Word DocumentJasmine KumariОценок пока нет