Академический Документы

Профессиональный Документы

Культура Документы

Plano Hidraulico RH-90

Загружено:

Eduardo ZamoraАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Plano Hidraulico RH-90

Загружено:

Eduardo ZamoraАвторское право:

Доступные форматы

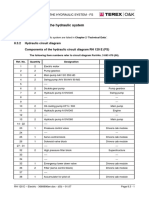

8.

3 DESCRIPTION OF THE HYDRAULIC SYSTEM - FS

8.3 Description of the hydraulic system

8.3.1 Technical data

The technical data of the hydraulic system are listed in Chapter 2 ‘Technical Data’.

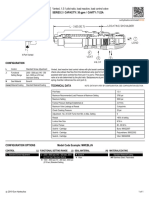

8.3.2 Components of the circuit diagram

The position nos. refer to circuit diagram No. 3 677 219 (00) in chapter 8.3.4.

Position Quantity Designation Location

1 2 Diesel engine Superstructure

2 2 Pump gearbox Superstructure

3 4 Main pump A4V SO 250 HD Pump gearbox

4 2 Swing pump A 4 V 125 MS Pump gearbox

5 ----

6 2 Servo pump Pump gearbox

7-9 ----

10 2 Oil cooling pump KP 5 / 250 Pump gearbox

11 - 15 ----

16 4 Check valve Main pumps

17 - 22 ----

23 2 Proportional valve Hydraulic tank (60)

24 ----

25 1 Proportional valve plate Operator module

26 2 Solenoid valve bank Operator module

27 ----

28 ----

29 1 Pump distributor plate Hydraulic tank (60)

30 2 Pressure relief valve, 330 bar Pump distributor plate (29)

31 ----

32 2 High pressure filter Pump distributor plate (29)

33 2 Filter for servo oil Valve block (40)

34 ----

35 1 Emergency lowering unit

36 1 Filter for proportional valve plate Operator module

37 1 Check valve Operator module

RH 90 C Diesel - 3657775e.doc - (00) – 11.03 Page 8.3 - 1

8.3 DESCRIPTION OF THE HYDRAULIC SYSTEM - FS

Position Quantity Designation Location

38 ----

39 ----

40 1 Servo oil valve block

41 1 Pressure reducing valve Servo oil valve block (40)

42 1 Pressure relief valve Servo oil valve block (40)

43 ----

44 2 Check valve RHZ 12 Hydraulic tank (60)

45 - 59 ----

60 1 Hydraulic tank Superstructure

61 2 Gate valve Hydraulic tank (60)

62 4 Return filter Hydraulic tank (60)

63 2 Bypass valve Hydraulic tank (60)

64 2 Tank line pre-charging valve Hydraulic tank (60)

65 - 79 ----

80 2 Hydraulic oil cooler Oil cooler module

81 2 Fan motor KM 5 / 250

82 ----

83 ----

84 2 Fan Fan motor

85 1 Distributor plate (hydraulic oil cooling) Oil cooler module

86 2 Pressure relief valve Oil cooler module

87 2 Expansion element (40° C) Oil cooler module

88 ----

89 ----

90 1 Travel block compl. Superstructure

91 1 Rotor Travel block (90)

92 1 Travel valve block (RH) Travel block (90)

93 1 Travel valve block (LH) Travel block (90)

94 ----

95 1 Travel retarder valve (RH) Travel block (90)

96 1 Travel retarder valve (LH) Travel block (90)

97 4 Anti-cavitation valve Travel block (90)

98 ----

99 ----

100 2 Swing gearbox S – 2P – 30 Superstructure

Page 8.3 - 2 RH 90 C Diesel - 3657775e.doc - (00) – 11.03

8.3 DESCRIPTION OF THE HYDRAULIC SYSTEM - FS

Position Quantity Designation Location

101 2 Shuttle valve Superstructure

102 2 Swing motor A2F 125 / 6 Swing gearbox (100)

103 4 Blocking valve

104 ---

105 1 Pressure control valve (MS control) Hydraulic tank (60)

106 1 Flushing valve Hydraulic tank (60)

107 ----

108 ----

109 1 Pressure relief valve, 31 bar

110 ----

111 1 Fitting with orifice Flushing valve (106)

112 - 119 ----

120 2 Travel gearbox Undercarriage

121 2 Travel motor A 2 FE 355 Travel gearbox (120)

122 2 Travel parking brake Travel gearbox (120)

123 - 129 ----

130 2 Track tensioning cylinder Undercarriage

131 2 Diaphragm accumulator Undercarriage

132 ----

133 1 Track tensioning assembly Undercarriage

134 2 Pressure relief valve Undercarriage

135 2 Check valve RHD 12 Undercarriage

136 - 145 ----

146 1 Service station Superstructure

147 - 159 ----

160 1 3-spool control valve (RH) Boom

161 1 3-spool control valve (LH) Boom

162 ----

163 ----

164 1 Float valve (boom) Boom

165 1 Float valve (arm) Boom

166 1 1-spool control valve Boom

167 - 181 ----

182 2 Boom cylinder Boom

183 2 Arm cylinder Boom/Arm

RH 90 C Diesel - 3657775e.doc - (00) – 11.03 Page 8.3 - 3

8.3 DESCRIPTION OF THE HYDRAULIC SYSTEM - FS

Position Quantity Designation Location

184 2 Bucket crowd cylinder Boom

185 ----

186 2 Clam cylinder Backwall

187 ----

188 1 Distributor block Boom

Page 8.3 - 4 RH 90 C Diesel - 3657775e.doc - (00) – 11.03

8.3 DESCRIPTION OF THE HYDRAULIC SYSTEM - FS

8.3.3 Components of the hydraulic

system RH 90 C (FS) - control pressure

- operating pressure

- torque magnitude and direction

Attention!

Each swing pump has 2 pressure relief-

Position nos. are referred to circuit diagram anticavitation valves.

Part-No. 3 677 219 (00) in chapter 8.3.4

Duty:

Some items are numbered on the schematic

but not mentioned here. They are not important 1. As relief valves they limit the swing circuit on

for the hydraulic functioning. the high-pressure side to 420 bars.

2. As anti-cavitation valves they prevent the oil

column in the swing circuit from being cut off.

Drive unit Pos. 1

Swinging of the superstructure is decelerated via

servo-valve adjustment. the maximum brake pres-

The drive units are water-cooled and turbocharged sure equals the maximum swing pressure (approx.

6-cylinder in-line diesel engines. 370 bar).

A geared pump has been flanged to each swing

pump. It serves as charge pump for the closed oil

Pump gearbox Pos. 2 circuit. This charge pressure is limited by a relief

valve (appr. 25 bar) integrated into the pump.

The pump transfer gearbox is a 2-stage spur gear-

box driven by the engine via a flexible coupling, it The swing pumps are also equipped with a con-

powers the flanged-on hydraulic pumps. tamination switch and a temperature switch. In

case of metallic contamination of the oil or an ex-

cessive oil temperature, a warning is displayed on

the panel in the driver's cab.

Main pump Pos. 3

free Pos. 5

The 4 main pumps for equipment and travel are

axial-piston variable displacement pumps of swash

plate design. Servo pump Pos. 6

Each pump has a contamination switch. In the

event of metal contamination a warning indication The fixed-displacement gear pumps are directly

lights up in the cab. driven (through drive) from main pump (3/P1&P3).

The pumps supply oil to the entire servo-, auxiliary-

and track tensioning circuits.

Swing pump Pos. 4

free Pos. 7 - 9

The swing pumps for the closed swing circuit of the

superstructure are of axial-piston variable-

displacement swashplate design. The flow rate is Hydraulic pump – oil cooling Pos. 10

steplessly variable and increases from zero to

maximum flow with the swivelling angle increasing. The fixed-displacement gear pumps are directly

If the swash plate is tilted through the zero posi- driven (through-drive) from main pumps (3/P2 and

tion, the flow is smoothly reversed. P4). The pumps take oil from the hydraulic tank,

drive the fan motor and circulate the oil through the

The pumps have been fitted with a torque control oil cooler.

system that enables the swing motors (30) to be

steplessly controlled depending on the pre-

selected

RH 90 C Diesel - 3657775e.doc - (00) – 11.03 Page 8.3 - 5

8.3 DESCRIPTION OF THE HYDRAULIC SYSTEM - FS

free Pos. 11 - 15 free Pos. 28

Check valve Pos. 16 Distributor plate for main pumps

Pos. 29

Through the check valves the auxiliary pressure is

fed into the main pump regulator. The check An assembly group comprising 2 primary pressure

valves protect the servo circuit against high pres- relief valves (30), 2 high - pressure filters (32) and

sure produced by the main pumps. 4 check valves.

free Pos. 17 -22

Primary pressure-relief valve Pos. 30

Proportional valve Pos. 23

The primary relief valves are set to 330 bar. They

protect the hydraulic system against pressure

The proportional valve controls the regulators of

peaks occurring as a consequence of pressure

the main pumps (3). It converts electrical signals.

cut-off valve inertia under certain high pressure

The valve receives signals from the load limit

and fluid flow conditions.

regulator (110) of the PMS system and produces

relevant hydraulic pressure to control the flow rate

of the main pumps.

See also THB "PMS - Pump Managing System". High - pressure filter Pos. 32

The high - pressure filters in the high - pressure

free Pos. 24 lines from the main pumps protect the downline

units (e. g. control blocks and cylinders) against

metal chips and particles from the pumps (3). The

Proportional valve plate Pos. 25 filter elements are differential pressure resistant

and do not have a bypass valve. The oil flows

The valve plate contains the proportional valves through the HP filters from outside to inside.

and the 3/2 way valves for operation of cylinders,

swing and travel function.

Filter for servo oil Pos. 33

Valve bank, compl. Pos. 26 These filters are mounted to clean the oil flow of

the servo pumps (6).

An assembly group comprising four solenoid

valves and a housing with following functions:

free Pos. 34

• Port A1 is not used.

• Port A2 is not used.

Valve for emergency lowering Pos. 35

• Port A3 is used for operation of the swing The assembly consists of a solenoid valve, a

parking brake. check valve and an accumulator. The solenoid

valve is operated with a button in the joy stick. It

• Port A4 is used for operation of the travel allows lowering of the attachment in case of a sud-

parking brake. den engine shut-down.

free Pos. 27

Page 8.3 - 6 RH 90 C Diesel - 3657775e.doc - (00) – 11.03

8.3 DESCRIPTION OF THE HYDRAULIC SYSTEM - FS

Filter Pos. 36 Check valve Pos. 44

This filter is filtering the oil which is feeding the Check valves prevent oil from being supplied to a

proportional valve plate (25). stationary motor.

free Pos. 45 - 59

Check valve Pos. 37

Hydraulic tank Pos. 60

The check valve prevents pressure loss when the

engines are shut off and the emergency lowering

system (35) is activated. The hydraulic oil storage tank comprises the fol-

lowing components:

free Pos. 38 - 4 return-flow filter elements (62)

- 2 bypass valves (63)

- 1 magnetic rod

free Pos. 39 - 2 tank-line pre-charging valves (64)

- 2 high-pressure filters (32)

- 2 primary relief valves (30)

Servo oil valve block Pos. 40 - 2 shut-off gate valves (61)

- 2 breather filters

The complete assembly group comprises two fil-

ters, two pressure relief valves, two check valves

and a housing.

Gate valve for intake line Pos. 61

The hydraulic tank can be separated from the suc-

Pressure reducing valve Pos. 41 tion lines of the hydraulic pumps by means of the

shut-off gate valves. This enables the oil to be left

in the hydraulic tank when, for example, a pump is

With this valve the auxiliary pressure of 60 bar is to be removed.

set. The pressure level is related to the pressure

setting of the servo pressure relief valve (42). All-

ways when the servo pressure has been adjusted

at the relief valve (42) also the setting of the pres-

sure reducing valve (41) is to be checked. Return flow filter Pos. 62

The return-flow filters serve to clean the oil return-

ing from the consumers. The oil passes through

Pressure relief valve Pos. 42 the filter elements from the inside to the outside.

Metallic contamination collects on the magnetic rod

located above the filter elements.

With this valve the servo pressure of 35 bar is set.

The pressure level of the servo system is also

influencing the pressure of the auxiliary system.

Therefore always the setting of the pressure re-

ducing valve (41) is to be checked. Bypass valve Pos. 63

The bypass valves prevent bursting of the return-

free Pos. 43 flow filter elements (62). The opening pressure is

1.5 bars. In this case, the oil flows back unfiltered

into the tank.

RH 90 C Diesel - 3657775e.doc - (00) – 11.03 Page 8.3 - 7

8.3 DESCRIPTION OF THE HYDRAULIC SYSTEM - FS

Tank line pressurizing valve Pos. 64 Thermostat Pos. 87

These two valves have fixed settings of approx. 12 The four thermostats are fully open at oil tem-

bar. They are arranged in the return lines and keep peratures under 40°C. The majority of the oil then

a constant level of pressure in the hydraulic sys- flows directly back into the tank. As the tempera-

tem. ture rises, the thermostats begin to close so that

an increasing amount of oil flows through the fan

motors and the coolers. At 52°C the thermostats

free Pos. 65 - 79 are fully closed and the full oil flow passes through

the fan motors to the coolers.

Hydraulic oil cooler Pos. 80

free Pos. 88

The hydraulic oil coolers pass the heat generated

in the hydraulic system on to the atmosphere using free Pos. 89

the air flows created by the fans.

Travel block Pos. 90

Fan motor Pos. 81

A complete group comprising rotor (91), the

„Travel“ spools (92 & 93), the travel retarder valves

two fixed - displacement gear - type motors are (95 & 96), anti - cavitation valves (97) and cover

used to drive the fans on the oil coolers. plates.

free Pos. 82

Rotor Pos. 91

free Pos. 83

Conducts hydraulic oil flows between superstruc-

ture and undercarriage. The seven ring channels

Fan Pos. 84 are for:

• Travel (4 channels)

The cooler fans produce the air flow needed to

cool the hydraulic oil.

• Track parking brakes/Track motor adjustment

• Track tensioning

Distributor plate for oil cooling Pos. 85 • Leakage oil

The plate contains two thermostats (87), two pres-

sure relief valves (86) and two check valves. The

check valves function as anti - cavitation valves Travel valve block RH Pos. 92

while the engines are being shut down.

A servo - controlled single - spool block that actu-

ates the right - hand track.

Pressure relief valve Pos. 86

The two pilot controlled, variable setting pressure Travel valve block LH Pos. 93

relief valves protect the cooler circuit against over-

pressure, e. g. in case of a line blockage.

A servo - controlled single - spool block that actu-

ates the left - hand track.

Page 8.3 - 8 RH 90 C Diesel - 3657775e.doc - (00) – 11.03

8.3 DESCRIPTION OF THE HYDRAULIC SYSTEM - FS

free Pos. 94 Swing motor Pos. 102

Travel retarder valve RH Pos. 95 The swing motors are 40°, fixed - displacement

axial piston pumps whose output speed is propor-

tional to the flow of oil. The output torque increases

Prevents the excavator from „running away“ down- with the pressure drop over the motor.

hill and keeps the track motors full of oil (to avoid

cavitation). The speed of the track motors is then Shut-off valve Pos. 103

always determined by the working pressure of the

pumps (3).

The shut-off valves are flanged-mounted on the

swing pumps.

The valves are opened by means of servo oil after

Travel retarder valve LH Pos. 96 the relevant engine has been started. The valves

shall rule out that the swing system acts on the

stationary engine when the machine is powered by

See travel retarder valve (95). one engine only.

Anti - cavitation valve Pos. 97 Pressure governing valve Pos. 105

The four valves mounted on the „Travel“ spools Governs the torque in the closed - loop swing cir-

(92 & 93) keep a constant column of oil in the track cuit.

motors. They crack open at the slightest pressure

so that oil can be drawn in from the tank line. The valve governs the pressure and direction of oil

flow (and therefore extent and direction of the

swing motors` output ) depending upon the se-

free Pos. 98 lected control pressure

The radio between control pressure and working

free Pos. 99 pressure is approx. 1 : 12, i. e. 10 bar control pres-

sure on ports (Y 1 or Y 2) corresponds to 120 bar

operating pressure in the swing circuit.

Swing gearbox Pos. 100

The gearbox are 2 - stage planetary reducers.

Flushing valve Pos. 106

The spring applied multi disc brakes on the swing

gearboxes serve to hold the superstructure sta-

tionary (parking brakes). They are actuated by a The flushing valve serves to flush the closed swing

toggle switch in the cab. circuit. During each swing operation the valve

The brake must only be actuated when the super- flushes a small oil volume from the low-pressure

structure has stopped swinging. side of the swing circuit. The charge pump flange-

mounted to the swing pump replaces this oil vol-

ume by cooled oil from the hydraulic tank.

Shuttle valve Pos. 101

free Pos. 107

One of the two shuttle valves is connecting the

swing charge pressure of the swing charge pumps

to the pressure port P of the pressure governing free Pos. 108

valve.

The other shuttle valve is connecting the control

pressure lines Y1 and Y 2 to the pressure relief

valve ((109).

RH 90 C Diesel - 3657775e.doc - (00) – 11.03 Page 8.3 - 9

8.3 DESCRIPTION OF THE HYDRAULIC SYSTEM - FS

Pressure relief valve Pos. 109 A single-acting hydraulic cylinder tensions each

track.

Diaphragm accumulator Pos. 131

The valve limits the pressure that controls the

pressure governing valve (105) to max. 31 bar.

The valve is direct acting and has a variable set- Impacts produced by external influences acting on

ting. the tracks are compensated by the diaphragm

accumulators.

free Pos. 110

Track tensioning assembly Pos. 133

Orifice Pos. 111

The hydraulic track-tensioning assembly com-

prises pressure-relief valves (134) and non-return

The fitting with orifice is limiting the oil flow which is valves (135) in the undercarriage.

flushed out of the system by the flushing valve

(106).

Pressure relief valve Pos. 134

free Pos. 112 - 119

The pressure relief valves protect the hydraulic

Travel gearbox Pos. 120 tensioning system against overload resulting from

external forces at the idler.

The travel gearboxes with an integrated multi-disk

brake (parking brake) are of 3-stage planetary

design.

Check valve Pos. 135

The check valves protect the hydraulic tensioning

Travel motor Pos. 121 system in the superstructure against overload re-

sulting from external forces at the idler.

The 2 travel motors are 40° fixed-displacement

axial-piston units.

The output speed is proportional to the oil flow. free Pos. 136 – 145

The produced torque increases as a function of the

pressure difference encountered between the Service station Pos: 146

high- and low-pressure side.

The hydraulic cylinder for lifting and lowering the

service station is activated by manually operated

Travel parking brake Pos. 122 valve.

A check valve prevents pressure loss.

Each travel gearbox is equipped with a mechanical

holding brake (multiple disk brake) which is applied free Pos. 147 - 159

by springs and released by servo pressure when

the travel system is actuated.

3-spool control block (RH) Pos. 160

free Pos. 123 - 129

The servo-controlled 3-spool valve block controls

the working cylinders for boom, arm (stick) and

Track tensioning cylinder Pos. 130 bucket.

For each function a secondary pressure-relief

valve and an anti-cavitation valve is installed.

Page 8.3 - 10 RH 90 C Diesel - 3657775e.doc - (00) – 11.03

8.3 DESCRIPTION OF THE HYDRAULIC SYSTEM - FS

The two double-acting hydraulic cylinders are in-

stalled between superstructure and the TriPower.

3-spool control block (LH) Pos. 161 They are lifting or lowering the boom and thus the

complete working equipment.

See Pos. 160

Stick cylinder Pos. 183

free Pos. 162

The 2 double-acting hydraulic cylinders are in-

free Pos. 163 stalled between boom and arm and serve to ex-

tend and retract the arm.

Float valve – boom Pos. 164

The float valves save time and energy when low- Bucket crowd Pos. 184

ering the boom. The valves connect the piston and

rod sides of the cylinders so that the piston rods The two double-acting hydraulic cylinders are in-

retract only as a result of the attachment`s own stalled between the TriPower and the bucket

dead weight. Only the excess oil (piston - side backwall and are used to turn the bucket.

chamber has a greater volume than the rod - side)

is allowed to escape to the tank. The main pumps

(3) are not activated. If it is required to lower the

boom or the arm with pressure, the „float“ valves free Pos. 185

can be switched off using solenoid valve (Y 10).

Clamshell cylinder Pos. 186

Float valve – arm Pos. 165 The two double-acting hydraulic cylinders are in-

stalled between backwall and frontlip and are used

to open and close the bucket.

The float valves save time and energy when low-

ering the arm. The valves connect the piston and

rod sides of the cylinders so that the piston rods

retract only as a result of the attachment`s own

dead weight. Only the excess oil (piston - side

chamber has a greater volume than the rod - side)

is allowed to escape to the tank. The main pumps

(3) are not activated. If it is required to lower the

boom or the arm with pressure, the „float“ valves

can be switched off using solenoid valve (Y 8.1).

1-spool control block Pos. 166

The servo-controlled 1-spool valve block controls

the clam cylinders of the bucket.

For each function a secondary pressure-relief

valve and an anti-cavitation valve is installed.

free Pos. 167 - 181

Boom cylinder Pos. 182

RH 90 C Diesel - 3657775e.doc - (00) – 11.03 Page 8.3 - 11

8.3 DESCRIPTION OF THE HYDRAULIC SYSTEM - FS

Page 8.3 - 12 RH 90 C Diesel - 3657775e.doc - (00) – 11.03

8.3 DESCRIPTION OF THE HYDRAULIC SYSTEM - FS

8.3.4 Hydraulic circuit diagram

The position nos. in the circuit diagram Part-

No. 3 677 219 are referred to chapter 8.3.2.

RH 90 C Diesel - 3657775e.doc - (00) – 11.03 Page 8.3 - 13

8.3 DESCRIPTION OF THE HYDRAULIC SYSTEM - FS

Page 8.3 - 14 RH 90 C Diesel - 3657775e.doc - (00) – 11.03

Вам также может понравиться

- Fuel SystemДокумент60 страницFuel SystemAntonio Gaspar100% (2)

- Zx330 Series (Ttla0481) Performance Check-TroubleshootingДокумент277 страницZx330 Series (Ttla0481) Performance Check-TroubleshootingUn'galluОценок пока нет

- 008 - Cat-6060 - Attachment Functions FSДокумент38 страниц008 - Cat-6060 - Attachment Functions FSJorby CuadrosОценок пока нет

- Track Roller Frames D&AДокумент62 страницыTrack Roller Frames D&Anelson troncoso galdamesОценок пока нет

- Ex1200 7 - Ko 582 00 - Weekly+visualДокумент12 страницEx1200 7 - Ko 582 00 - Weekly+visualJardel Fernandes de MoraesОценок пока нет

- Steel Pipes Pipe Schedule ChartДокумент1 страницаSteel Pipes Pipe Schedule Chartbadesharamk100% (4)

- RH-170 FS Legend H-Schematic 3668520Документ15 страницRH-170 FS Legend H-Schematic 3668520KJDNKJZEFОценок пока нет

- 03 - C9 Serv1814 - D6R IiiДокумент37 страниц03 - C9 Serv1814 - D6R Iiieder50% (2)

- Hydraulic Mining Excavator: Operating WeightДокумент8 страницHydraulic Mining Excavator: Operating Weighthenry sarmientoОценок пока нет

- Viktor Schauberger Vortex EngineДокумент4 страницыViktor Schauberger Vortex EngineRed Phoenix100% (1)

- 8.3 Description of The Hydraulic System: 8.3.1 Technical DataДокумент15 страниц8.3 Description of The Hydraulic System: 8.3.1 Technical DataOsvaldo UrbanoОценок пока нет

- 004 - CAT-6015 - Engine Pump DriveДокумент26 страниц004 - CAT-6015 - Engine Pump DriveGracia SediОценок пока нет

- ROC L Hydr Valve Blocks - V2Документ11 страницROC L Hydr Valve Blocks - V2ApeksОценок пока нет

- Cat Product LineДокумент16 страницCat Product LineSandro Cuti TaipeОценок пока нет

- DM30 II Instruction Manual (English) 005 035033Документ520 страницDM30 II Instruction Manual (English) 005 035033icatandhika77Оценок пока нет

- 015 - Legend For 3748761 - #170112 - 08 - 03-3746450enДокумент15 страниц015 - Legend For 3748761 - #170112 - 08 - 03-3746450enhectorОценок пока нет

- Operational PrincipleДокумент257 страницOperational PrinciplemahmudiОценок пока нет

- TRAB PC1250-8 Sales Presentation AEPB422 00Документ62 страницыTRAB PC1250-8 Sales Presentation AEPB422 00joao maria100% (1)

- Report P2u XCMG 800D #Exxc051 - PT - Kai-Tabang - HM3076Документ9 страницReport P2u XCMG 800D #Exxc051 - PT - Kai-Tabang - HM3076Dedy DarmansyahОценок пока нет

- 365B L Config Options (AEDC0625)Документ5 страниц365B L Config Options (AEDC0625)suwarjitechnic100% (2)

- M4-2 Final Nov-2012Документ40 страницM4-2 Final Nov-2012Jose luis ConsuegraОценок пока нет

- Assy Propel Trans 7495HRДокумент2 страницыAssy Propel Trans 7495HRFrancisco GonzalezОценок пока нет

- Hydrotest Blind Thickness CalculatorДокумент2 страницыHydrotest Blind Thickness CalculatorVishwanath PrasadОценок пока нет

- R984C XXXX 15116 10-2008 enДокумент262 страницыR984C XXXX 15116 10-2008 enАлександрОценок пока нет

- CameronДокумент4 страницыCameronhermon_agustio0% (1)

- UntitledДокумент326 страницUntitledANGELA ARACELLY PAREDES PEREZОценок пока нет

- Hydraulic Mining Shovels Cat 6060/6060FS: 12.0 Central Greasing System - AttachmentДокумент50 страницHydraulic Mining Shovels Cat 6060/6060FS: 12.0 Central Greasing System - Attachmentdarwin100% (1)

- Visual Inspection: Backhoe FrontДокумент41 страницаVisual Inspection: Backhoe FrontJardel Fernandes de MoraesОценок пока нет

- Control ValvesДокумент127 страницControl ValvesMarcus Barber100% (1)

- 6060HydMiningShvl M08 SwingSys enДокумент20 страниц6060HydMiningShvl M08 SwingSys enJonathan José Alvis GonzalesОценок пока нет

- Stick Cylinder - Pala Hidraulica 6040FSДокумент9 страницStick Cylinder - Pala Hidraulica 6040FSAbel Jairo Santos CabelloОценок пока нет

- Hydraulic Mining Shovel: (E-Drive) With CAMP/SIL and BCS4Документ2 страницыHydraulic Mining Shovel: (E-Drive) With CAMP/SIL and BCS4hectorОценок пока нет

- Sistema Pilotoserv7107 - V05N01 - SLD2Документ19 страницSistema Pilotoserv7107 - V05N01 - SLD2jorge william ramirezОценок пока нет

- 8.3 Description of The Hydraulic System: 8.3.1 Technical DataДокумент14 страниц8.3 Description of The Hydraulic System: 8.3.1 Technical DatahectorОценок пока нет

- Air Receiver SizingДокумент4 страницыAir Receiver SizingAnonymous a4Jwz14WОценок пока нет

- Turbine & AuxilariesДокумент64 страницыTurbine & Auxilariesulhatolkargmailcom100% (1)

- SE Zorya-Mashproekt - Gas Turbine Engines For Gas Pipelines PDFДокумент12 страницSE Zorya-Mashproekt - Gas Turbine Engines For Gas Pipelines PDFMohammad Bahreini100% (1)

- 009.2 CAT-6040 FS-AttachmentДокумент27 страниц009.2 CAT-6040 FS-AttachmentWillian Ticlia Ruiz100% (1)

- 000 Cat 6040ac Camp Sil Bcs4 ContentsДокумент2 страницы000 Cat 6040ac Camp Sil Bcs4 ContentsMiguel Rodriguez100% (2)

- CHW Pipe Straight Pressure DropДокумент2 страницыCHW Pipe Straight Pressure DropDesigner ForeverОценок пока нет

- Mini Hydraulic ExcavatorДокумент8 страницMini Hydraulic ExcavatorYaroslava YatsukОценок пока нет

- Plano Hidraulico Camion 777F PDFДокумент15 страницPlano Hidraulico Camion 777F PDFheberОценок пока нет

- Plano Hidraulico 992gДокумент2 страницыPlano Hidraulico 992gEduardo Zamora100% (2)

- Plano Hidraulico 992gДокумент2 страницыPlano Hidraulico 992gEduardo Zamora100% (2)

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Документ11 страницInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Roberto Antonio Chihuaihuan Araya100% (1)

- QRF HB205+HB215Документ2 страницыQRF HB205+HB215Ralf MaurerОценок пока нет

- 970E IIIA 20 PG A4 Broch - 03 - 2020Документ11 страниц970E IIIA 20 PG A4 Broch - 03 - 2020Sandeep Kumar100% (1)

- NO Brand Description Part No QTY 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30Документ6 страницNO Brand Description Part No QTY 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30BARIŞОценок пока нет

- Boom Cylinder Remove and InstallДокумент8 страницBoom Cylinder Remove and InstallEDSON JONATHAN SALINAS AYALAОценок пока нет

- Terex Rh340 Maintenance TrainingДокумент17 страницTerex Rh340 Maintenance Trainingjicrgz7998100% (2)

- Hce - hx210hd & Hx220hdДокумент11 страницHce - hx210hd & Hx220hdRivandho AnangОценок пока нет

- 2 PDFДокумент9 страниц2 PDFRicardo OjedaОценок пока нет

- 002 RH120E UndercarriageДокумент28 страниц002 RH120E UndercarriageOsvaldo UrbanoОценок пока нет

- Information ExДокумент39 страницInformation Exlove anaОценок пока нет

- 02 RH40E UndercarriageДокумент16 страниц02 RH40E UndercarriageBladimir PadillaОценок пока нет

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Документ10 страницInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768MAdhie WaraОценок пока нет

- 016 Cat-6040AC FS 3758531 CAMP-SIL BCS Colour Sheet2 Dec 10 2013 PreliminaryДокумент1 страница016 Cat-6040AC FS 3758531 CAMP-SIL BCS Colour Sheet2 Dec 10 2013 PreliminaryJorby Cuadros100% (1)

- HO 02 01 KTPK Components OverviewДокумент39 страницHO 02 01 KTPK Components OverviewMARIO DEL PINO MUÑOZОценок пока нет

- VOLVO EC700B HR EC700BHR EXCAVATOR Service Repair Manual PDFДокумент17 страницVOLVO EC700B HR EC700BHR EXCAVATOR Service Repair Manual PDFfjjsjekdmmeОценок пока нет

- Hydraulic Mining Shovel 6040AC: 08. Attachment Functions - FSДокумент20 страницHydraulic Mining Shovel 6040AC: 08. Attachment Functions - FShector50% (2)

- Folding Ladder: Manual For Cat D9RdozerДокумент27 страницFolding Ladder: Manual For Cat D9Rdozer9879136501Оценок пока нет

- Electric Mining Shovel - DC Drive Product OverviewДокумент5 страницElectric Mining Shovel - DC Drive Product OverviewmohanОценок пока нет

- Catallogo Pala Cable 7495 HFДокумент4 страницыCatallogo Pala Cable 7495 HFmarceloОценок пока нет

- Bucyrus 495BII vs. Bucryus 495HR Super 2 (Caterpillar 7495) : Bucyrus 495HR - Side Profile Bucyrus 495HR - Side ProfileДокумент4 страницыBucyrus 495BII vs. Bucryus 495HR Super 2 (Caterpillar 7495) : Bucyrus 495HR - Side Profile Bucyrus 495HR - Side ProfileManuel VargasОценок пока нет

- Pm-Clinic: Hydraulic Mining ExcavatorДокумент34 страницыPm-Clinic: Hydraulic Mining ExcavatorGustavoSilvaОценок пока нет

- 336d L Excavators M4t00001-Up (Machine) Powered by c9 Engine (Sebp5387 - 33) - DocumentationДокумент11 страниц336d L Excavators M4t00001-Up (Machine) Powered by c9 Engine (Sebp5387 - 33) - DocumentationluishvanegasОценок пока нет

- BD 50Документ4 страницыBD 50amit_sharma333Оценок пока нет

- 001 6060 RH340B Introduction CATДокумент13 страниц001 6060 RH340B Introduction CAThectorОценок пока нет

- 5110B Performance Report I (PR00263)Документ5 страниц5110B Performance Report I (PR00263)suwarjitechnicОценок пока нет

- Jurnal Alat BeratДокумент10 страницJurnal Alat BeratFitri AniОценок пока нет

- 14 RH90C BH Legend H-Schematic 08 03-3720173enДокумент15 страниц14 RH90C BH Legend H-Schematic 08 03-3720173enMiguel Angel RodriguezОценок пока нет

- 015 RH200 FS Legend H-Schematic 08 03-3668664enДокумент14 страниц015 RH200 FS Legend H-Schematic 08 03-3668664enMiguel Angel RodriguezОценок пока нет

- 8.3 Description of The Hydraulic System: 8.3.1 Technical DataДокумент12 страниц8.3 Description of The Hydraulic System: 8.3.1 Technical DataFuad JahićОценок пока нет

- PM ClinicДокумент8 страницPM ClinicEduardo ZamoraОценок пока нет

- 012 RH170B CylindersДокумент11 страниц012 RH170B CylindersEduardo Zamora100% (2)

- Plano Hidraulico 992g PDFДокумент15 страницPlano Hidraulico 992g PDFEduardo ZamoraОценок пока нет

- Cat-Tdto-10 30 50 PDFДокумент4 страницыCat-Tdto-10 30 50 PDFEduardo Zamora100% (1)

- Catalogo Caterpillar de LucesДокумент8 страницCatalogo Caterpillar de LucesEduardo ZamoraОценок пока нет

- Catalogo Compact RangeДокумент12 страницCatalogo Compact RangeEduardo ZamoraОценок пока нет

- 08D BubenzerHydraulic Unit PB-3421285-E4Документ20 страниц08D BubenzerHydraulic Unit PB-3421285-E4Edward Erney Salas ValenzuelaОценок пока нет

- APL Series: Propeller FansДокумент6 страницAPL Series: Propeller FansDinh NguyenОценок пока нет

- 2-2 Estructura MCV PDFДокумент29 страниц2-2 Estructura MCV PDFlevinton jose tobias genesОценок пока нет

- Hvac QuestionsДокумент2 страницыHvac QuestionsTariqОценок пока нет

- WellHead PDFДокумент6 страницWellHead PDFsolomonicbdmОценок пока нет

- Soft Seated Gate Valves in Ductile Iron, PN 10 and 16Документ2 страницыSoft Seated Gate Valves in Ductile Iron, PN 10 and 16Mohamed RaafatОценок пока нет

- Sun Hydraulics MWEB-LJN Technical SpecificationsДокумент1 страницаSun Hydraulics MWEB-LJN Technical SpecificationsJustinОценок пока нет

- 67Документ10 страниц67johnnylim456Оценок пока нет

- Assignment ME401 For GATE PreparationДокумент26 страницAssignment ME401 For GATE Preparationhameem mohdОценок пока нет

- The Tata Power Company Limited Bhira 100 MW - Augmentation Scheme Including Mulshi Lake Sub-Storage UtilizationДокумент5 страницThe Tata Power Company Limited Bhira 100 MW - Augmentation Scheme Including Mulshi Lake Sub-Storage Utilizationpavankumar001Оценок пока нет

- Packing List - TRANSPORTДокумент11 страницPacking List - TRANSPORTTerluka DalamОценок пока нет

- Troubleshooting Gas-Liquid Separators - Removal of Liquids From The GasДокумент12 страницTroubleshooting Gas-Liquid Separators - Removal of Liquids From The GaseltonОценок пока нет

- Class 14: Drag Prediction II: Parasite Drag - "Drag Build-Up"Документ8 страницClass 14: Drag Prediction II: Parasite Drag - "Drag Build-Up"Krish ManglaniОценок пока нет

- CUP 04 BOIN USA 02 WebДокумент2 страницыCUP 04 BOIN USA 02 WebMajid abdulОценок пока нет

- COMPR User GuideДокумент12 страницCOMPR User GuideJoaquinBarretoОценок пока нет

- HTG-SEPV - Inquiry Steel PipeДокумент1 страницаHTG-SEPV - Inquiry Steel PipeXuan Thanh NguyenОценок пока нет

- SKU Name & Description Link To Website Price in R (Excl. Vat)Документ29 страницSKU Name & Description Link To Website Price in R (Excl. Vat)icumba6180Оценок пока нет

- NAFRA Guaranteed Technical Perticulars Spherical ValveДокумент8 страницNAFRA Guaranteed Technical Perticulars Spherical Valvepavankumar001Оценок пока нет

- Centrifugal PumpsДокумент4 страницыCentrifugal PumpsKalyani SSECОценок пока нет