Академический Документы

Профессиональный Документы

Культура Документы

BBQ - Behaviour Based Quality Card

Загружено:

ittiphon31Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

BBQ - Behaviour Based Quality Card

Загружено:

ittiphon31Авторское право:

Доступные форматы

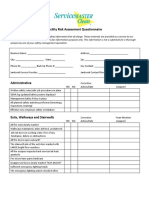

BBQ Observation Card BBQ Observation Card BBQ Observation Card

COMPANY NAME: COMPANY NAME: COMPANY NAME:

Date : Month : Year : Date : Month : Year : Date : Month : Year :

Area Inspected : Area Inspected : Area Inspected :

Employee Name : Employee Name : Employee Name :

Scope of Work : Scope of Work : Scope of Work :

Compliance Non-Compliance Compliance Non-Compliance Compliance Non-Compliance

Observation Observation Observation

BBQ Code Job No. BBQ Code Job No. BBQ Code Job No.

Description : Description : Description :

Root Causes : Root Causes : Root Causes :

4M o Man o Material o Method o Mechine 4M o Man o Material o Method o Mechine 4M o Man o Material o Method o Mechine

Disposition : Disposition : Disposition :

Recommended Solution : Recommended Solution : Recommended Solution :

Yes No Yes No Yes No Yes No Yes No Yes No

Use-as-it Customer Concession Use-as-it Customer Concession Use-as-it Customer Concession

Rework Reject Rework Reject Rework Reject

BBQ Code Job No. BBQ Code Job No. BBQ Code Job No.

Description : Description : Description :

Root Causes : Root Causes : Root Causes :

4M o Man o Material o Method o Mechine 4M o Man o Material o Method o Mechine 4M o Man o Material o Method o Mechine

Disposition : Disposition : Disposition :

Recommended Solution : Recommended Solution : Recommended Solution :

Yes No Yes No Yes No Yes No Yes No Yes No

Use-as-it Customer Concession Use-as-it Customer Concession Use-as-it Customer Concession

Rework Reject Rework Reject Rework Reject

Behaviour based Quality (BBQ) Behaviour based Quality (BBQ) Behaviour based Quality (BBQ)

Not Not Not

Piping and Structure Fabrication Comply

Comply

Piping and Structure Fabrication Comply

Comply

Piping and Structure Fabrication Comply

Comply

1.0 DOCUMENTATION 1.0 DOCUMENTATION 1.0 DOCUMENTATION

1.1 Procedure / Work Instruction 1.1 Procedure / Work Instruction 1.1 Procedure / Work Instruction

1.2 Specification / Code & Standards 1.2 Specification / Code & Standards 1.2 Specification / Code & Standards

1.3 Inspection and Test Plan (ITP) 1.3 Inspection and Test Plan (ITP) 1.3 Inspection and Test Plan (ITP)

2.0 IN PROCESS INSPECTION & TESTING 2.0 IN PROCESS INSPECTION & TESTING 2.0 IN PROCESS INSPECTION & TESTING

2.1 Delay Inspection 2.1 Delay Inspection 2.1 Delay Inspection

2.2 Material Verification 2.2 Material Verification 2.2 Material Verification

2.2.1 Material receiving inspection 2.2.1 Material receiving inspection 2.2.1 Material receiving inspection

2.2.2 Material traceability 2.2.2 Material traceability 2.2.2 Material traceability

2.2.3 Positive Material Identification (PMI) 2.2.3 Positive Material Identification (PMI) 2.2.3 Positive Material Identification (PMI)

2.2.4 Check UTM Inspection 2.2.4 Check UTM Inspection 2.2.4 Check UTM Inspection

2.3 Fit-up Inspection /dimension check 2.3 Fit-up Inspection /dimension check 2.3 Fit-up Inspection /dimension check

2.3.1 Joint preparation /WPS/Dwg. 2.3.1 Joint preparation /WPS/Dwg. 2.3.1 Joint preparation /WPS/Dwg.

2.3.2 Rotation of flanges from the indicate 1/16" (Max) 2.3.2 Rotation of flanges from the indicate 1/16" (Max) 2.3.2 Rotation of flanges from the indicate 1/16" (Max)

2.3.3 Pipe aligment of facing or ends /ISO Dwg. 2.3.3 Pipe aligment of facing or ends /ISO Dwg. 2.3.3 Pipe aligment of facing or ends /ISO Dwg.

2.3.4 Tolerance on dimensions/ISO Dwg./Procedure 2.3.4 Tolerance on dimensions/ISO Dwg./Procedure 2.3.4 Tolerance on dimensions/ISO Dwg./Procedure

2.3.5 Camber level for structure platform 2.3.5 Camber level for structure platform 2.3.5 Camber level for structure platform

2.3.6 Diagonal level for structure platform 2.3.6 Diagonal level for structure platform 2.3.6 Diagonal level for structure platform

3.0 WELDING CONTROL 3.0 WELDING CONTROL 3.0 WELDING CONTROL

3.1 Welding parameter Monotoring and record /WPS/WQT 3.1 Welding parameter Monotoring and record /WPS/WQT 3.1 Welding parameter Monotoring and record /WPS/WQT

3.2 Weld Visual Inspection 3.2 Weld Visual Inspection 3.2 Weld Visual Inspection

3.2.1 Crack 3.2.1 Crack 3.2.1 Crack

3.2.2 Lack of fusion 3.2.2 Lack of fusion 3.2.2 Lack of fusion

3.2.3 Lack of penetration 3.2.3 Lack of penetration 3.2.3 Lack of penetration

3.2.4 Underfill 3.2.4 Underfill 3.2.4 Underfill

3.2.5 Undercut 3.2.5 Undercut 3.2.5 Undercut

3.2.6 Overlap 3.2.6 Overlap 3.2.6 Overlap

3.2.7 Porosity 3.2.7 Porosity 3.2.7 Porosity

3.2.8 Excess Reinforcement 3.2.8 Excess Reinforcement 3.2.8 Excess Reinforcement

3.2.9 Excess root penetration 3.2.9 Excess root penetration 3.2.9 Excess root penetration

3.2.10 Concave root (suck back) 3.2.10 Concave root (suck back) 3.2.10 Concave root (suck back)

3.2.11 Burn through 3.2.11 Burn through 3.2.11 Burn through

3.2.12 Oxidation root (Root coking) 3.2.12 Oxidation root (Root coking) 3.2.12 Oxidation root (Root coking)

3.2.13 Linear misalignment 3.2.13 Linear misalignment 3.2.13 Linear misalignment

3.2.14 Poor Start/Stop 3.2.14 Poor Start/Stop 3.2.14 Poor Start/Stop

3.2.15 Arc Strike 3.2.15 Arc Strike 3.2.15 Arc Strike

3.2.16 Spatter 3.2.16 Spatter 3.2.16 Spatter

3.2.17 Mechanical Damage 3.2.17 Mechanical Damage 3.2.17 Mechanical Damage

4.0 HYDRO STATIC TEST 4.0 HYDRO STATIC TEST 4.0 HYDRO STATIC TEST

4.1 NDE Clearance /NDE/PWHT Report 4.1 NDE Clearance /NDE/PWHT Report 4.1 NDE Clearance /NDE/PWHT Report

4.2 Testing Equipment calibration and correct rating 4.2 Testing Equipment calibration and correct rating 4.2 Testing Equipment calibration and correct rating

4.3 Visual leakage / deformation during holding time 4.3 Visual leakage / deformation during holding time 4.3 Visual leakage / deformation during holding time

5.0 BLASTING AND PAINTING 5.0 BLASTING AND PAINTING 5.0 BLASTING AND PAINTING

5.1 Material Painting Verification 5.1 Material Painting Verification 5.1 Material Painting Verification

5.2 Verify spool tagging and confirm coating system 5.2 Verify spool tagging and confirm coating system 5.2 Verify spool tagging and confirm coating system

5.3 Check Surface Preparation 5.3 Check Surface Preparation 5.3 Check Surface Preparation

5.4 Painting Mixing/Primer/Tie-coat and Top Coat/DFT/WFT 5.4 Painting Mixing/Primer/Tie-coat and Top Coat/DFT/WFT 5.4 Painting Mixing/Primer/Tie-coat and Top Coat/DFT/WFT

6.0 FINAL INSPECTION, PACKING AND DELIVERY 6.0 FINAL INSPECTION, PACKING AND DELIVERY 6.0 FINAL INSPECTION, PACKING AND DELIVERY

6.1 Final Inspection report 6.1 Final Inspection report 6.1 Final Inspection report

6.2 Check / Verify packing 6.2 Check / Verify packing 6.2 Check / Verify packing

6.3 Carry out protection / Preservation 6.3 Carry out protection / Preservation 6.3 Carry out protection / Preservation

6.4 Verify Protection / Preservation / Tie-in down 6.4 Verify Protection / Preservation / Tie-in down 6.4 Verify Protection / Preservation / Tie-in down

7.0 Note; 7.0 Note; 7.0 Note;

Вам также может понравиться

- Corrective And Preventative Action A Complete Guide - 2020 EditionОт EverandCorrective And Preventative Action A Complete Guide - 2020 EditionОценок пока нет

- EGA SETP TT-CSM 13 Prequal Questionnaire v2.00Документ6 страницEGA SETP TT-CSM 13 Prequal Questionnaire v2.00shijadОценок пока нет

- Visual - Workplace.improvingbusinessperformance - Slideshare.pp1 SafetyДокумент49 страницVisual - Workplace.improvingbusinessperformance - Slideshare.pp1 SafetytrangnhОценок пока нет

- Assignment Safety Report WALTON Factory Mahmudul HaqueДокумент28 страницAssignment Safety Report WALTON Factory Mahmudul Haquepunter07Оценок пока нет

- 1 S, 2 S & 3 S Audit Check Sheet For Miscellaneous ZonesДокумент10 страниц1 S, 2 S & 3 S Audit Check Sheet For Miscellaneous ZonesgcldesignОценок пока нет

- Inspection Final SopДокумент25 страницInspection Final SopSudhakar JainОценок пока нет

- 01fitting in FabricationДокумент11 страниц01fitting in Fabricationv.bhamidi100% (1)

- MS KPI Trend - Management System Compliance - November 2023Документ1 страницаMS KPI Trend - Management System Compliance - November 2023DUSTIN AYEN KERBY DEALOLAОценок пока нет

- ManualДокумент62 страницыManualMelissa CastañedaОценок пока нет

- Milling MachineДокумент1 страницаMilling MachineFikri Maulana100% (1)

- Ehs Committee - NewДокумент4 страницыEhs Committee - NewNand KumarОценок пока нет

- (OHS) Procedure For Identification of Legal and OtherДокумент2 страницы(OHS) Procedure For Identification of Legal and OtherTuan AnhОценок пока нет

- EHS Manager Manufacturing Mining in United States Resume Ken KempaДокумент3 страницыEHS Manager Manufacturing Mining in United States Resume Ken KempaKenKempaОценок пока нет

- Lab Design Guide ChecklistДокумент9 страницLab Design Guide ChecklistTanveer AzizОценок пока нет

- QCC+Application Registration+FormДокумент4 страницыQCC+Application Registration+FormrajaabidОценок пока нет

- SAFETY Procedures ManualДокумент14 страницSAFETY Procedures Manualarajamani78Оценок пока нет

- Safety Audit MethodologyДокумент5 страницSafety Audit MethodologyLalit Kumar Das MohapatraОценок пока нет

- 1S, 2S & 6S Audit ChecklistДокумент46 страниц1S, 2S & 6S Audit ChecklistSudhagarОценок пока нет

- HSE Monthly Report 2012 PDFДокумент9 страницHSE Monthly Report 2012 PDFHifni GhazaliОценок пока нет

- Central EHS TemplateДокумент4 страницыCentral EHS Templateakshay aryaОценок пока нет

- Hazop Study For Thermic Fluid Heater (At Industry by Heterogeneous Method)Документ11 страницHazop Study For Thermic Fluid Heater (At Industry by Heterogeneous Method)IJRASETPublicationsОценок пока нет

- Layered Process Audits: How To Improve Quality From The Ground UpДокумент22 страницыLayered Process Audits: How To Improve Quality From The Ground UpMoraru Ciprian100% (1)

- Equipment Operating ProcedureДокумент5 страницEquipment Operating ProcedurezaizamОценок пока нет

- BCMP Guideline - English - Final - Supplier PortalДокумент31 страницаBCMP Guideline - English - Final - Supplier PortalSamsul Huda Arpon100% (2)

- 6 Machines and Machine Processs 1aДокумент28 страниц6 Machines and Machine Processs 1aAlfred KuwodzaОценок пока нет

- Weekly Safety Report: Previous Total Safe Man Hour Safe Man Hours Safe Man Hours To DateДокумент1 страницаWeekly Safety Report: Previous Total Safe Man Hour Safe Man Hours Safe Man Hours To DateCecillia F ObejasОценок пока нет

- Flow Process ChartДокумент1 страницаFlow Process ChartjpbhimaniОценок пока нет

- SWP 1 Agustus 2019Документ4 страницыSWP 1 Agustus 2019Jhon Luther PОценок пока нет

- Qcs 2010 Section 11 Part 2.3.11 She Procedures - Permit To Work SysteДокумент20 страницQcs 2010 Section 11 Part 2.3.11 She Procedures - Permit To Work Systebryanpastor106Оценок пока нет

- Fireproofing Spray Mixture Machine ChecklistДокумент1 страницаFireproofing Spray Mixture Machine ChecklistSreejith SureshОценок пока нет

- Earth Compactor Daily Check ListДокумент2 страницыEarth Compactor Daily Check ListpjosesmОценок пока нет

- Hazardous Material Weekly InspectionДокумент1 страницаHazardous Material Weekly InspectionYexiong YIALENGОценок пока нет

- 6 - PPE Specifications PDFДокумент4 страницы6 - PPE Specifications PDFRoberto CarlosОценок пока нет

- Qualification of GMP by Lucy GakuhaДокумент22 страницыQualification of GMP by Lucy Gakuhaemma100% (1)

- GPCB SOP For De-Contamination FacilityДокумент9 страницGPCB SOP For De-Contamination FacilityEHS HalolОценок пока нет

- ATEX Electric Equipment Classification Labelling PDFДокумент1 страницаATEX Electric Equipment Classification Labelling PDFRamius HamdaniОценок пока нет

- Taurus Slim Series 9mmpt709Документ19 страницTaurus Slim Series 9mmpt709daks4u100% (1)

- October - 20 Monthly Meeting PresentationДокумент17 страницOctober - 20 Monthly Meeting PresentationMahmud Al HasanОценок пока нет

- Cost Benefit Analysis ExampleДокумент1 страницаCost Benefit Analysis ExampleMetehanAtayОценок пока нет

- Facility Risk Assessment QuestionnaireДокумент5 страницFacility Risk Assessment QuestionnaireGrayОценок пока нет

- Blasting Painting Report (Example)Документ1 страницаBlasting Painting Report (Example)DoddyОценок пока нет

- BP-5.1.2D OJT Effectiveness SHEET - Level-2Документ1 страницаBP-5.1.2D OJT Effectiveness SHEET - Level-2shinuОценок пока нет

- Work Permit ProcedureДокумент2 страницыWork Permit Procedureवात्सल्य कृतार्थОценок пока нет

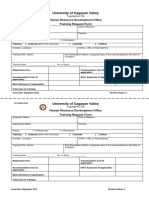

- Training Request Form OriginalДокумент2 страницыTraining Request Form OriginalGlynish MacapiaОценок пока нет

- Breakdown RagisterДокумент1 страницаBreakdown RagisterJayant MistriОценок пока нет

- Venkateswaraa Insulation Achieve 100Ppm / SQ Mark - Check ListДокумент14 страницVenkateswaraa Insulation Achieve 100Ppm / SQ Mark - Check ListdysonОценок пока нет

- Safety OfficerДокумент2 страницыSafety OfficerAathithyaОценок пока нет

- "Red" High (1) "Yellow" Medium (2) "Green" Low (3) : IllnessДокумент2 страницы"Red" High (1) "Yellow" Medium (2) "Green" Low (3) : IllnessBarb O'NeillОценок пока нет

- Corrective Action Log TemplateДокумент20 страницCorrective Action Log Templatendayiragije JMVОценок пока нет

- REGDOC2 1 2 Safety Culture Final EngДокумент31 страницаREGDOC2 1 2 Safety Culture Final Engnagatopein6Оценок пока нет

- Good Manufacturing Practices (GMP) Checklist Name of Winner's Outlet: Month: DateДокумент4 страницыGood Manufacturing Practices (GMP) Checklist Name of Winner's Outlet: Month: DateYashini BhuguthОценок пока нет

- Bearing Housing Assembly Procedure EXTERNALДокумент10 страницBearing Housing Assembly Procedure EXTERNALAlejandroZegarraОценок пока нет

- 6s Evaluation FormДокумент3 страницы6s Evaluation FormDhananjay PatilОценок пока нет

- HSEQ - Calibration KitdddeeДокумент4 страницыHSEQ - Calibration KitdddeeSalim MuftahОценок пока нет

- Structured What If Technique A Complete Guide - 2020 EditionОт EverandStructured What If Technique A Complete Guide - 2020 EditionОценок пока нет

- Job Order Job Order: Information and Communication Technology Center Information and Communication Technology CenterДокумент1 страницаJob Order Job Order: Information and Communication Technology Center Information and Communication Technology Centerロ ー ゼОценок пока нет

- Failure Indication Tag (Pink)Документ2 страницыFailure Indication Tag (Pink)PalОценок пока нет

- Bank of Baroda Bank of Baroda Bank of Baroda: No.: 2086601 No.: 2086601 No.: 2086601Документ1 страницаBank of Baroda Bank of Baroda Bank of Baroda: No.: 2086601 No.: 2086601 No.: 2086601Såñdèëp KОценок пока нет

- Aws D18.2 (1999)Документ2 страницыAws D18.2 (1999)ittiphon3150% (2)

- Pipe's Wall Thickness: ASTM A312, A358, A778, A53, A106, API 5L ASME/ANSI B36.19 B36.10Документ0 страницPipe's Wall Thickness: ASTM A312, A358, A778, A53, A106, API 5L ASME/ANSI B36.19 B36.10Siddiqui Abdul KhaliqОценок пока нет

- Asme Sec Viii-1 Quick ReferenceДокумент1 страницаAsme Sec Viii-1 Quick ReferenceManish542Оценок пока нет

- Welding Table WPS & PQR Check List (Sheet, 2 Pages)Документ2 страницыWelding Table WPS & PQR Check List (Sheet, 2 Pages)abomanar100486375% (4)

- ITP (Inspection and Test Plans) - NSW, AUSДокумент14 страницITP (Inspection and Test Plans) - NSW, AUSJaques Brice Lo Nascimento50% (2)

- Welding Run SheetДокумент1 страницаWelding Run Sheetittiphon31100% (2)

- Basics of Piping Scribd PDFДокумент60 страницBasics of Piping Scribd PDFmohamed sheerazОценок пока нет

- ITP For Storage TankДокумент6 страницITP For Storage Tankittiphon3194% (17)

- Sesion 2 - Copia-1Документ14 страницSesion 2 - Copia-1Maeva FigueroaОценок пока нет

- Certification "Products Made of Compostable Materials" Procedure No. 3355757Документ3 страницыCertification "Products Made of Compostable Materials" Procedure No. 3355757Rei BymsОценок пока нет

- Unit 9 Organic Law On Provincial and Local-Level Government (OLPLLG) - SlidesДокумент29 страницUnit 9 Organic Law On Provincial and Local-Level Government (OLPLLG) - SlidesMark DemОценок пока нет

- Durock Cement Board System Guide en SA932Документ12 страницDurock Cement Board System Guide en SA932Ko PhyoОценок пока нет

- Drill Site Audit ChecklistДокумент5 страницDrill Site Audit ChecklistKristian BohorqzОценок пока нет

- Earth As A PlanetДокумент60 страницEarth As A PlanetR AmravatiwalaОценок пока нет

- Edgie A. Tenerife BSHM 1108: Page 1 of 4Документ4 страницыEdgie A. Tenerife BSHM 1108: Page 1 of 4Edgie TenerifeОценок пока нет

- Lathe Operators Manual 96-8900 Rev A English January 2014Документ458 страницLathe Operators Manual 96-8900 Rev A English January 2014coyoteassasin0% (1)

- Cooling Tower (Genius)Документ7 страницCooling Tower (Genius)JeghiОценок пока нет

- Social Connectedness and Role of HopelessnessДокумент8 страницSocial Connectedness and Role of HopelessnessEmman CabiilanОценок пока нет

- Current and Voltage Controls 3-Phase AC Max. Current Control Type S 178Документ3 страницыCurrent and Voltage Controls 3-Phase AC Max. Current Control Type S 178Felipe FarfanОценок пока нет

- CH 13 RNA and Protein SynthesisДокумент12 страницCH 13 RNA and Protein SynthesisHannah50% (2)

- Quinta RuedaДокумент20 страницQuinta RuedaArturo RengifoОценок пока нет

- Microbial Communities From Arid Environments On A Global Scale. A Systematic ReviewДокумент12 страницMicrobial Communities From Arid Environments On A Global Scale. A Systematic ReviewAnnaОценок пока нет

- Grounds of Divorce Under Hindu Religion or Hindu Law Unit-A: Chapter-IiДокумент42 страницыGrounds of Divorce Under Hindu Religion or Hindu Law Unit-A: Chapter-IiSatyam PathakОценок пока нет

- Generic 5S ChecklistДокумент2 страницыGeneric 5S Checklistswamireddy100% (1)

- Chan v. ChanДокумент2 страницыChan v. ChanjdpajarilloОценок пока нет

- Depression List of Pleasant ActivitiesДокумент3 страницыDepression List of Pleasant ActivitiesShivani SinghОценок пока нет

- #1 - The World'S Oldest First GraderДокумент6 страниц#1 - The World'S Oldest First GraderTran Van ThanhОценок пока нет

- Leadership PresentationДокумент10 страницLeadership Presentationapi-404415990Оценок пока нет

- Assistive TechnologyДокумент3 страницыAssistive Technologyapi-547693573Оценок пока нет

- C 1 WorkbookДокумент101 страницаC 1 WorkbookGeraldineОценок пока нет

- Citizen's 8651 Manual PDFДокумент16 страницCitizen's 8651 Manual PDFtfriebusОценок пока нет

- BRC1B52-62 FDY-F Ducted Operation Manual - OPMAN01!1!0Документ12 страницBRC1B52-62 FDY-F Ducted Operation Manual - OPMAN01!1!0Justiniano Martel67% (3)

- Exercise 8 BeveragewareДокумент9 страницExercise 8 BeveragewareMae Cleofe G. SelisanaОценок пока нет

- Full Bridge Phase Shift ConverterДокумент21 страницаFull Bridge Phase Shift ConverterMukul ChoudhuryОценок пока нет

- Rotary Screw Gas: CompressorsДокумент2 страницыRotary Screw Gas: CompressorsLucas SilvestreОценок пока нет

- 45096Документ12 страниц45096Halusan MaybeОценок пока нет

- Corn Fact Book 2010Документ28 страницCorn Fact Book 2010National Corn Growers AssociationОценок пока нет

- Science 9-Quarter 2-Module-3Документ28 страницScience 9-Quarter 2-Module-3Mon DyОценок пока нет