Академический Документы

Профессиональный Документы

Культура Документы

Simple ERP Coding

Загружено:

Akhil JoseАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Simple ERP Coding

Загружено:

Akhil JoseАвторское право:

Доступные форматы

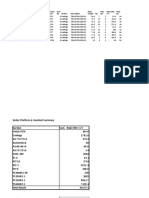

X X XX XX XX XXXX

1st 2nd 3rd 4th 5th 6th

2 Stock

3 Non Stock 01 Pipe 4 Digit

4 Free Issue 02 Flanges Progressive

03 Valves

Number

04 Wrought Fitting

05 Threaded Fitting 0001 to 9999

1 Raw Material

2 Finished Product 06 Forged Fitting

3 Semi-Finished Products 07 Strainers

4 Spare Parts 08 Special Fittings

5 Tools 09 Stud Bolts

6 Consumables 10

11

01 Architectural Items

02 Structural Items

03 Electrical Items

04 Instr. Items

05 Piping Items

06 Plumping Items

07 HVAC Items

08 Fire Fighting Items

09 Painting

10 Assembly

01 Carbon Steel

11 Non Categorized

02 Stainless Steel

03 Inconel

04 Duplex Steel

05 Special Alloy

06

07

Example-

Pipe Seamless SA106 Gr.B PE Sch 120 NACE ASME B36.10 Size: 8'' x 6 mtr. MTC

Code as per existing system- 3/80/20/000/2499 (Nonstock/Process Fitting/Mild Steel/”No Relevant Information”/Serial Number)

Code as per proposed system- 3/1/05/01/01/0001 (Non Stock/Raw Material/Piping Item/Pipe/Carbon Steel/ Serial Number)

Pros and Cons of implementing new system

Pros Cons

Simple and Unique coding philosophy Requires Time and effort to create new codes

Code contains relevant information

Codes can be directly linked with item description creator

As you can see in the above example, existing code doesn’t give you enough details about the material.

The only information you are getting is “Mild steel Non stock Process fitting”.

While in the new coding says “Raw material Carbon steel Non stock pipe”

Some categories of codes are reaching the maximum limit.

Such as “38020000”, we have around 3328 codes now and still counting.

This will not happen with the new coding philosophy, as there is finer categorization of codes.

Author-

Akhil

Вам также может понравиться

- Ten Specs CatalogDataДокумент1 129 страницTen Specs CatalogDatashanz100% (1)

- Ghora Kashtodharana StotramДокумент5 страницGhora Kashtodharana Stotramnarasimma8313Оценок пока нет

- PCDДокумент649 страницPCDSiddhu DudwadkarОценок пока нет

- Isomembrane Write Up & Reference ListДокумент7 страницIsomembrane Write Up & Reference ListgjanklesariaОценок пока нет

- Boiler StructureДокумент100 страницBoiler StructureumashankarsinghОценок пока нет

- Tata ClassEdge Corporate PresentationДокумент34 страницыTata ClassEdge Corporate Presentationvipinks100% (1)

- PPP Pdms NamingДокумент95 страницPPP Pdms NamingErden BaldžiОценок пока нет

- Caesar II-Manual Calc Sustained-Ashish ShrivastavaДокумент1 страницаCaesar II-Manual Calc Sustained-Ashish Shrivastavaashish shrivastavОценок пока нет

- Manual PDSДокумент649 страницManual PDSCristian GuzmánОценок пока нет

- AVEVA Everything 3D 2.1 Supports Chapter 12Документ13 страницAVEVA Everything 3D 2.1 Supports Chapter 12sanmite100% (1)

- DEE MagazineRДокумент70 страницDEE MagazineRChirag ShahОценок пока нет

- Provided THK Is Sufficient: Result 2Документ5 страницProvided THK Is Sufficient: Result 2sagar1503Оценок пока нет

- PDS Commodity Code BreakdownДокумент29 страницPDS Commodity Code BreakdownShahfaraz AhmadОценок пока нет

- Sai Stavan ManjariДокумент20 страницSai Stavan ManjariSОценок пока нет

- Pdms Naming ConventionДокумент58 страницPdms Naming ConventionValesh MonisОценок пока нет

- M P S B 0 4 C B 1: Commodity CodeДокумент9 страницM P S B 0 4 C B 1: Commodity CodetiantaufikОценок пока нет

- EPRI Ash Dep Impacts On Power IndДокумент58 страницEPRI Ash Dep Impacts On Power IndSaishankar L Narayanan100% (1)

- PWHT For T 23 PanelДокумент12 страницPWHT For T 23 PanelSrinivasaОценок пока нет

- Managing Exfoliation in Super Critical BoilersДокумент11 страницManaging Exfoliation in Super Critical BoilersDebabrata GhoshОценок пока нет

- Posiflow Technology of Doosan Babcock For Supercritical BoilersДокумент12 страницPosiflow Technology of Doosan Babcock For Supercritical BoilersKarthick VelayuthamОценок пока нет

- Piping FBE Spool MethodologyДокумент28 страницPiping FBE Spool MethodologyHariharan MОценок пока нет

- FITTINGS WEIGHT CHART - XLSX - PDFДокумент38 страницFITTINGS WEIGHT CHART - XLSX - PDFSriram RОценок пока нет

- Characterization of Ash DepostionДокумент11 страницCharacterization of Ash DepostionKarthi KeyanОценок пока нет

- Testing Blind Plate TableДокумент5 страницTesting Blind Plate TableJossel Panopio JoseОценок пока нет

- Autopipe Local AxisДокумент2 страницыAutopipe Local AxismaniaxpdfОценок пока нет

- T S S S S: Echnical Tandards & Pecifications Including Afety TandardsДокумент18 страницT S S S S: Echnical Tandards & Pecifications Including Afety Tandardspravesh sharmaОценок пока нет

- Methanol Technologies of Tkis: A Brief OverviewДокумент12 страницMethanol Technologies of Tkis: A Brief OverviewMuhammad NaeemОценок пока нет

- Fabricated Basket Strainers: Features OptionsДокумент3 страницыFabricated Basket Strainers: Features OptionsmusaveerОценок пока нет

- Timet Ti HandbookДокумент40 страницTimet Ti HandbookSandeep ParmarОценок пока нет

- Standard Solutions: Innovative Fluid PowerДокумент70 страницStandard Solutions: Innovative Fluid PowerAlex Eiser Delgado PerezОценок пока нет

- Sri Venkateswara Vratha Kalpam EnglishДокумент34 страницыSri Venkateswara Vratha Kalpam EnglishAdithya Rangan100% (1)

- Product Catalog 2019Документ188 страницProduct Catalog 2019Rajiv PalОценок пока нет

- Scope of Work CT-1 RevampingДокумент5 страницScope of Work CT-1 RevampingAbhinav PradhanОценок пока нет

- ASME B16.47 Series A FlangeДокумент7 страницASME B16.47 Series A FlangeManoah StephenОценок пока нет

- PKG CoorgДокумент4 страницыPKG CoorgTh Laifa RamlianaОценок пока нет

- Ferrous Alloys Stainless SteelsДокумент41 страницаFerrous Alloys Stainless SteelsSumedh SinghОценок пока нет

- Kirloskar Brothers Limited, SanandДокумент25 страницKirloskar Brothers Limited, SanandjaydeepsinhОценок пока нет

- Apco Infratech Pvt. LTD: Request For New Item-Code GenerationДокумент13 страницApco Infratech Pvt. LTD: Request For New Item-Code GenerationVenkat Raghav VasireddyОценок пока нет

- Assembly Peanut Final Engineering DWGДокумент1 страницаAssembly Peanut Final Engineering DWGStephen WamburaОценок пока нет

- BPDB Store Inventory Item Category List: 01 ScrapДокумент50 страницBPDB Store Inventory Item Category List: 01 ScrapMedina ConstructionОценок пока нет

- 24.catalogue Breather-Cat-18-In-PowerДокумент39 страниц24.catalogue Breather-Cat-18-In-PowerAngel StragliatiОценок пока нет

- Erg DRG Eng STR P.01 22 320 001 001 AДокумент1 страницаErg DRG Eng STR P.01 22 320 001 001 Abmanojkumar16Оценок пока нет

- Em Single Disc - Bearing - Mounted - Clutches (EdaДокумент8 страницEm Single Disc - Bearing - Mounted - Clutches (EdaAshok BhatОценок пока нет

- Parts List: Pressure Relief Device Model - T50 With Shroud & Drain HoleДокумент1 страницаParts List: Pressure Relief Device Model - T50 With Shroud & Drain HoleAngel StragliatiОценок пока нет

- Data Sheet - PORV 1500 - 2500 - 4500 (Power) .Документ2 страницыData Sheet - PORV 1500 - 2500 - 4500 (Power) .KumarОценок пока нет

- 2nd OptionДокумент6 страниц2nd OptionMuneeb ButtОценок пока нет

- Cim C.19.007 1231HC Ets 3800 AДокумент19 страницCim C.19.007 1231HC Ets 3800 AJuan Jose Jimenez LopezОценок пока нет

- Best Design For WindowsДокумент6 страницBest Design For WindowsMuneeb ButtОценок пока нет

- Instrument Hookup Drawing OF LEVEL SWITCHДокумент1 страницаInstrument Hookup Drawing OF LEVEL SWITCHEdafe DicksonОценок пока нет

- Proyecto: Ubicación: Propietario: Fecha: Detalle Elemento Dimensiones CantДокумент8 страницProyecto: Ubicación: Propietario: Fecha: Detalle Elemento Dimensiones CantJessica TatianaОценок пока нет

- Design & Analysis of Exhaust Heat Recovery SystemДокумент9 страницDesign & Analysis of Exhaust Heat Recovery SystemGRD JournalsОценок пока нет

- Push Button 04Документ18 страницPush Button 04Vijitha KGОценок пока нет

- Home Appliance - S Ka026 B Eng - LRДокумент98 страницHome Appliance - S Ka026 B Eng - LRwillwОценок пока нет

- Volume Number Volume I - Overall - Index - Tender - Docs Volume II - Contract ConditionsДокумент10 страницVolume Number Volume I - Overall - Index - Tender - Docs Volume II - Contract ConditionsAnonymous uLAATWpfОценок пока нет

- Engineering Folder StructureДокумент1 страницаEngineering Folder StructureAashish Murali100% (1)

- Decorative Perforated Metal Sheets: Hebei Qiusuo Wire Mesh Products Co., LTDДокумент13 страницDecorative Perforated Metal Sheets: Hebei Qiusuo Wire Mesh Products Co., LTDBianca Silva SantanderОценок пока нет

- MBH Metals Catalogue 2018Документ60 страницMBH Metals Catalogue 2018Lorie Banka100% (1)

- A1 Rated Non-Combustible Solid Aluminium SheetДокумент9 страницA1 Rated Non-Combustible Solid Aluminium SheetCarim NahabooОценок пока нет

- Gas Flooding Panel Output PointsДокумент1 страницаGas Flooding Panel Output PointstribhuОценок пока нет

- AT On RoofДокумент1 страницаAT On RoofratmajaОценок пока нет

- Limit LoadДокумент40 страницLimit LoadVictoria NúñezОценок пока нет

- Report 13 Config STD IDCReportДокумент4 страницыReport 13 Config STD IDCReportAkhil JoseОценок пока нет

- Faure Herman PinДокумент2 страницыFaure Herman PinPavan KumarОценок пока нет

- S 003 Coiled Tubing TowerДокумент2 страницыS 003 Coiled Tubing TowerAkhil JoseОценок пока нет

- Zick AnalysisДокумент12 страницZick AnalysisrksahayОценок пока нет

- Design of Saddles For H.VesselДокумент22 страницыDesign of Saddles For H.VesselAkhil JoseОценок пока нет

- Model KCB-Temperarture Gauge (Bimetal) - CommentedДокумент3 страницыModel KCB-Temperarture Gauge (Bimetal) - CommentedAkhil JoseОценок пока нет

- Output Summary: SI UnitsДокумент42 страницыOutput Summary: SI UnitsAkhil JoseОценок пока нет

- WRC 107 Amp 297 - CompressДокумент10 страницWRC 107 Amp 297 - CompressAkhil JoseОценок пока нет

- Incoloy Alloy 925Документ12 страницIncoloy Alloy 925kahutzed666Оценок пока нет

- Output Summary: SI UnitsДокумент42 страницыOutput Summary: SI UnitsAkhil JoseОценок пока нет

- Valve List For Filter Skid Ref. No. Mak-3010/3020/3030/3040Документ1 страницаValve List For Filter Skid Ref. No. Mak-3010/3020/3030/3040Akhil JoseОценок пока нет

- Output Summary: SI UnitsДокумент42 страницыOutput Summary: SI UnitsAkhil JoseОценок пока нет

- Relief Valves FlyerДокумент1 страницаRelief Valves FlyerAkhil JoseОценок пока нет

- Stud Bolt Heavy Hex Bolt - InchДокумент98 страницStud Bolt Heavy Hex Bolt - InchAkhil JoseОценок пока нет

- Max-Allowable-Pressure-of-Pipes-and-Pipellines-CER-04022013-1 (V. S. Kumar-Unprotected)Документ74 страницыMax-Allowable-Pressure-of-Pipes-and-Pipellines-CER-04022013-1 (V. S. Kumar-Unprotected)chemical509Оценок пока нет

- Pipe Dimensions - CS - SS - HDPE100 - HDPE80Документ14 страницPipe Dimensions - CS - SS - HDPE100 - HDPE80Akhil JoseОценок пока нет

- Beam SIДокумент24 страницыBeam SIAkhil JoseОценок пока нет

- Bolt Dia USДокумент1 страницаBolt Dia USAkhil JoseОценок пока нет

- Pipe Thickness ChartДокумент4 страницыPipe Thickness ChartAkhil JoseОценок пока нет

- Stud Bolt Heavy Hex Bolt - InchДокумент98 страницStud Bolt Heavy Hex Bolt - InchAkhil JoseОценок пока нет

- Sample Vibration ProblemsДокумент2 страницыSample Vibration ProblemsAkhil JoseОценок пока нет

- S Curve Analysis of Battery TechnologyДокумент5 страницS Curve Analysis of Battery TechnologyAkhil Jose100% (1)

- Flanges General - ASME B16.5 - List of ... Cations - Pressure Temperature RatingsДокумент5 страницFlanges General - ASME B16.5 - List of ... Cations - Pressure Temperature RatingsAkhil JoseОценок пока нет

- Beam SIДокумент24 страницыBeam SIAkhil JoseОценок пока нет

- DFA Manual TheoryДокумент59 страницDFA Manual TheoryAkhil JoseОценок пока нет

- Fabricated Assembly Analysis: DFM Concurrent Costing DfmaДокумент6 страницFabricated Assembly Analysis: DFM Concurrent Costing DfmaAkhil JoseОценок пока нет

- Natural FrequencyДокумент2 страницыNatural FrequencyAkhil JoseОценок пока нет

- TSI CP 203 FM 001 Training PlanДокумент4 страницыTSI CP 203 FM 001 Training PlanAkhil JoseОценок пока нет

- TSI-CP-203-FM-001 - Training PlanДокумент4 страницыTSI-CP-203-FM-001 - Training PlanAkhil JoseОценок пока нет

- Asme Pvho-2-2019Документ61 страницаAsme Pvho-2-2019Vijay KumarОценок пока нет

- TIP - IPBT M - E For MentorsДокумент3 страницыTIP - IPBT M - E For Mentorsallan galdianoОценок пока нет

- Personal Information: Witec Smaranda 11, A3 Bis, Blvd. Chisinau, Bucharest, Romania 0040722597553Документ6 страницPersonal Information: Witec Smaranda 11, A3 Bis, Blvd. Chisinau, Bucharest, Romania 0040722597553MirelaRoșcaОценок пока нет

- (1895) Indianapolis Police ManualДокумент122 страницы(1895) Indianapolis Police ManualHerbert Hillary Booker 2ndОценок пока нет

- Q3 Week 1 Homeroom Guidance JGRДокумент9 страницQ3 Week 1 Homeroom Guidance JGRJasmin Goot Rayos50% (4)

- Second Division: Republic of The Philippines Court of Tax Appeals Quezon CityДокумент8 страницSecond Division: Republic of The Philippines Court of Tax Appeals Quezon CityCamille CastilloОценок пока нет

- NGOs in Satkhira PresentationДокумент17 страницNGOs in Satkhira PresentationRubayet KhundokerОценок пока нет

- Che 342 Practice Set I IДокумент4 страницыChe 342 Practice Set I IDan McОценок пока нет

- 04.CNOOC Engages With Canadian Stakeholders PDFДокумент14 страниц04.CNOOC Engages With Canadian Stakeholders PDFAdilОценок пока нет

- Course Syllabus: Ecommerce & Internet MarketingДокумент23 страницыCourse Syllabus: Ecommerce & Internet MarketingMady RamosОценок пока нет

- Phet Body Group 1 ScienceДокумент42 страницыPhet Body Group 1 ScienceMebel Alicante GenodepanonОценок пока нет

- Maths VIII FA4Документ3 страницыMaths VIII FA4BGTM 1988Оценок пока нет

- Scheduled Events in MySQL Load CSV Fileto MysqltabДокумент11 страницScheduled Events in MySQL Load CSV Fileto Mysqltabboil35Оценок пока нет

- Step Recovery DiodesДокумент3 страницыStep Recovery DiodesfahkingmoronОценок пока нет

- Scientific American - Febuary 2016Документ84 страницыScientific American - Febuary 2016Vu NguyenОценок пока нет

- Remote SensingДокумент30 страницRemote SensingVijay RajОценок пока нет

- BP Azspu Driver Fatigue & Tiredness Management ProcedureДокумент11 страницBP Azspu Driver Fatigue & Tiredness Management ProcedureEl Khan100% (1)

- Rajkumar Kitchen Model Oil Expeller - INRДокумент1 страницаRajkumar Kitchen Model Oil Expeller - INRNishant0% (1)

- Leadership Style SurveyДокумент3 страницыLeadership Style SurveyJanelle BergОценок пока нет

- CV Najim Square Pharma 4 Years ExperienceДокумент2 страницыCV Najim Square Pharma 4 Years ExperienceDelwarОценок пока нет

- Study For 33KV Sub-Marine Cable Crossings PDFДокумент80 страницStudy For 33KV Sub-Marine Cable Crossings PDFOGBONNAYA MARTINSОценок пока нет

- Formula Retail and Large Controls Planning Department ReportДокумент235 страницFormula Retail and Large Controls Planning Department ReportMissionLocalОценок пока нет

- 3.2.3 Practice - Taking The PSAT (Practice)Документ5 страниц3.2.3 Practice - Taking The PSAT (Practice)wrighemm200Оценок пока нет

- Kilifi HRH Strategic Plan 2018-2021Документ106 страницKilifi HRH Strategic Plan 2018-2021Philip OlesitauОценок пока нет

- DCF ModelДокумент14 страницDCF ModelTera ByteОценок пока нет

- Radix Sort - Wikipedia, The Free EncyclopediaДокумент13 страницRadix Sort - Wikipedia, The Free EncyclopediasbaikunjeОценок пока нет

- About UPSC Civil Service Examination Schedule and Subject ListДокумент4 страницыAbout UPSC Civil Service Examination Schedule and Subject Listjaythakar8887Оценок пока нет

- E14r50p01 800 MhaДокумент4 страницыE14r50p01 800 Mha'Theodora GeorgianaОценок пока нет

- Where To Eat PizzaДокумент3 страницыWhere To Eat PizzaLiliancitaLcJsОценок пока нет

- q2 Long Quiz 002 EntreДокумент8 страницq2 Long Quiz 002 EntreMonn Justine Sabido0% (1)