Академический Документы

Профессиональный Документы

Культура Документы

Proposed WPS

Загружено:

Chisom IkengwuИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Proposed WPS

Загружено:

Chisom IkengwuАвторское право:

Доступные форматы

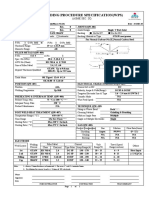

PROPOSED WELDING PROCEDURE SPECIFICATION (pWPS) Page 1 of 2

STEVE INTEGRATED TECH SERVICES

LTD

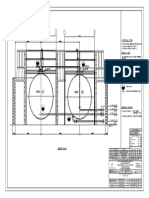

PROJECT NAME OML 100 CAM BUOY WELDING OF DISSIMILAR METALS Rev: 2.0

WPS No.: SITSL19/CBD/WPS/03/18 Supporting PQR: SITSL19/CBD/PQR/03/18

Applicable Code/Spec: AWS D1.1, GS EP STR 301

Welding Process : GTAW Type: Manual

JOINT DETAILS(QW-402)

(See Attached Sketch) BASE METAL (QW-403)

Type: Fillet Weld Plate Material: SA-36 To SA-240 Type 316

Backing: NO P-No.: 1 Group: 1 To P-No.: 8 Group: 1

Root opening: 1.5 – 2.5mm Material Spec: SA-36 To SA-240 Type 316

Groove Angle: N/A Wall Thickness Range: 3.0mm – 10.0mm

Root Face: 1.0 - 1.5mm

FILLER METAL DETAILS (QW- 404)

Parameters Root Pass Hot Pass Filling Capping

SFA specification A 5.9 A 5.9 A 5.9 A 5.9

AWS

ER 309L ER 309L ER 309L ER 309L

Classification

F- No 6 6 6 6

A – No 8 8 8 8

Size 2.4mm 2.4mm 2.4mm 2.4mm

Trade Name Lincoln/ESAB Lincoln/ESAB Lincoln/ESAB Lincoln/ESAB

WELDING POSITION (QW-405) PREHEAT (WQ-406)

Position: 2F Preheat temperature: Ambient, Dry

Only

Welding Progression: Horizontal Inter-Pass temperature: 150ºC MAX

POST WELD HEAT TREATMENT (WQ-407)

PWHT: N/A Method: N/A

Temperature: N/A Holding Time: N/A

Heating and cooling rate: N/A Loading and unloading temp.: N/A

GAS (WQ-408)

Gases Mixture Flow Rate

Shielding Argon 100% 11-14 Lit/min

Trailing N/A N/A N/A

Backing N/A N/A N/A

ELECTRICAL CHARACTERISTICS (QW- 409)

Process Weld Pass Amps (Range) Volts(Range) Travel Speed Polarity Heat Input

A V mm/min KJ/cm

GTAW Root pass 120-170 15 - 18 30 - 60 DCEN 1.1-1.5

GTAW Filling/Capping 120-160 15 - 18 35 - 60 DCEN 0.8-1.2

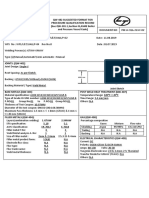

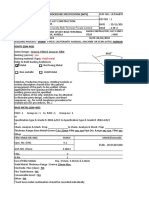

PROPOSED WELDING PROCEDURE SPECIFICATION (pWPS) Page 2 of 2

PROJECT OML 100 CAM BUOY WELDING OF DISSIMILAR METALS Rev: 2.0

TECHNIQUE (QW – 410)

Band width restriction: Stringer beads only. Minor arc oscillation to ensure side wall fusion.

Orifice or Gas Cup size: N/A

Method of Interpass cleaning: Grinding/Power Brush (Stainless Steel)

Type of Heater To be Used: N/A

JOINT DESIGN

Alignment by by Bullet in the Groove Tack weld do not

have to melt the Root

Edge Max Misalignment= 1.5mm

Weld shall be completed in one cycle.

Surfaces to be welded must be clean and free from dirt, oil and must have a substrate temperature not less than 500C

Time lapse between the end of the root pass and the beginning of the hot pass shall be minimum of 10mins

SITSL CLIENT THIRD PARTY

NAME

SIGNATURE

DATE

Вам также может понравиться

- PWPS WPS CAP 039 PQR 035Документ15 страницPWPS WPS CAP 039 PQR 035GOPINATH KRISHNAN NAIRОценок пока нет

- Welder'S Qualification Test Certificate: (As Per Asme Sec Ix)Документ2 страницыWelder'S Qualification Test Certificate: (As Per Asme Sec Ix)vijay100% (1)

- Welder Qualification Test Certificate: Weld Test Details Range of ApprovalДокумент1 страницаWelder Qualification Test Certificate: Weld Test Details Range of ApprovalRamkunwar YadavОценок пока нет

- HOANG TRUNG KIEN - 6G GTAW + SMAW (Duplex, T 18.26mm)Документ3 страницыHOANG TRUNG KIEN - 6G GTAW + SMAW (Duplex, T 18.26mm)TuTuy AnОценок пока нет

- Page No: 01: SA 240 GR 304 SA 240 GR 304Документ5 страницPage No: 01: SA 240 GR 304 SA 240 GR 304jobertОценок пока нет

- WPSДокумент6 страницWPSYASH BARDHAN SinghОценок пока нет

- Welding Procedure SpecificationДокумент3 страницыWelding Procedure SpecificationAhmed saber100% (2)

- Welding Procedure Specification For Storage Tank & Piping SystemДокумент3 страницыWelding Procedure Specification For Storage Tank & Piping SystemAhmad MohammadОценок пока нет

- Stoichiometry: Calculations With Chemical Formulas and EquationsДокумент47 страницStoichiometry: Calculations With Chemical Formulas and EquationsAngelo Miguel GarciaОценок пока нет

- 37507022-WPS-PQR-SS-316 LДокумент5 страниц37507022-WPS-PQR-SS-316 LVarun Malhotra100% (5)

- Wps 1010 IfrДокумент28 страницWps 1010 IfrSyed Mahmud Habibur RahmanОценок пока нет

- Welder Performance Qualification-Interactive Form QW-484AДокумент1 страницаWelder Performance Qualification-Interactive Form QW-484AJaved Mohammed100% (5)

- 163 Gmaw Zug Asme (Sri Supatmi 3g) WPQДокумент4 страницы163 Gmaw Zug Asme (Sri Supatmi 3g) WPQMuhammad Fitransyah Syamsuar PutraОценок пока нет

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateДокумент3 страницыWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaОценок пока нет

- Back Gouging ProcedureДокумент8 страницBack Gouging Proceduremahi1437100% (1)

- PQR WPQ Witness Report LatestДокумент1 страницаPQR WPQ Witness Report LatestSatish KeskarОценок пока нет

- QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Документ1 страницаQW-301, Section IX, ASME Boiler and Pressure Vessel Code)rajuОценок пока нет

- Welding Procedure Specification (WPS) : FM-87 Issue - 01 Date: Feb, 12,2015 Page 1 of 2Документ2 страницыWelding Procedure Specification (WPS) : FM-87 Issue - 01 Date: Feb, 12,2015 Page 1 of 2tayyabОценок пока нет

- Pe Fir Handbook 1 2Документ237 страницPe Fir Handbook 1 2Salman JoОценок пока нет

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Документ1 страницаWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (1)

- WPQR No. 2016 02Документ14 страницWPQR No. 2016 02GANESH AОценок пока нет

- Fcaw 16 THKДокумент5 страницFcaw 16 THKparesh2387Оценок пока нет

- Manual Joints (QW - 402) : Page 1 of 12Документ12 страницManual Joints (QW - 402) : Page 1 of 12miteshpatel191Оценок пока нет

- Understanding Omega Fatty AcidsДокумент5 страницUnderstanding Omega Fatty Acidsdrubwang100% (1)

- WPS 2014-002 006 - 6G PipeДокумент3 страницыWPS 2014-002 006 - 6G PipejeswinОценок пока нет

- PQR With-PwhtДокумент2 страницыPQR With-PwhtKarthikОценок пока нет

- WPS PQR 12Документ9 страницWPS PQR 12Ranjan KumarОценок пока нет

- Welding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Документ2 страницыWelding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Karam Fta Al-andalusОценок пока нет

- WPS Format For AWS D1.1 - WPS - FCAWДокумент1 страницаWPS Format For AWS D1.1 - WPS - FCAWThe Welding Inspections CommunityОценок пока нет

- Welding Proposed Pwps For Our Jubail WorkДокумент2 страницыWelding Proposed Pwps For Our Jubail WorkAlam MD Sazid100% (1)

- Weld Test Checklist: Welder (S) DetailsДокумент2 страницыWeld Test Checklist: Welder (S) DetailsScott Trainor100% (1)

- WPS - Smaw - 2Документ6 страницWPS - Smaw - 2Harkesh RajputОценок пока нет

- Welding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Документ5 страницWelding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Rajesh Owaiyar100% (1)

- WPS-PQR (Er309l Mo)Документ4 страницыWPS-PQR (Er309l Mo)Hamza Nouman0% (1)

- 004 Gtaw P5aДокумент16 страниц004 Gtaw P5aMuhammad Fitransyah Syamsuar Putra100% (1)

- Aws 001Документ1 страницаAws 001akshay sarfareОценок пока нет

- Welding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001Документ2 страницыWelding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001neerajОценок пока нет

- Transformers: Erection, Commissioning, Operation and Maintenance Manual FORДокумент229 страницTransformers: Erection, Commissioning, Operation and Maintenance Manual FORJyoti Prakash Prusty100% (1)

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDДокумент5 страницWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDIskak TabriОценок пока нет

- Joints (Qw-402) DetailsДокумент3 страницыJoints (Qw-402) DetailsNaqqash SajidОценок пока нет

- (Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2Документ2 страницы(Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2amit singh100% (2)

- 19403955-WPS M.S. Is 2062Документ10 страниц19403955-WPS M.S. Is 2062Varun Malhotra100% (1)

- Wqt-Visual-Mag - BS 2Документ24 страницыWqt-Visual-Mag - BS 2KyОценок пока нет

- According To ASME IX: Welding Procedure Specification (W.P.S)Документ4 страницыAccording To ASME IX: Welding Procedure Specification (W.P.S)Mohamed SalehОценок пока нет

- PQR / WPQ Witness Report: Weld Layer (S) Welding Process Electrode Current Voltag e Travel Speed Dia. Class Polarity AmpДокумент1 страницаPQR / WPQ Witness Report: Weld Layer (S) Welding Process Electrode Current Voltag e Travel Speed Dia. Class Polarity AmpSatish KeskarОценок пока нет

- Wps Gmaw SawДокумент2 страницыWps Gmaw Sawupedro26Оценок пока нет

- L.P.T Reports.Документ12 страницL.P.T Reports.Shaikh AdilОценок пока нет

- WPS & WPQR (Asme Section IX)Документ7 страницWPS & WPQR (Asme Section IX)Rizaldy PhoenksОценок пока нет

- Wps Mma PipeДокумент2 страницыWps Mma PipeDimitris NikouОценок пока нет

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDДокумент5 страницWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedОценок пока нет

- Wps Aws d1.1 NEWДокумент2 страницыWps Aws d1.1 NEWIkhy Tohepaly100% (1)

- Smaw PQR FinalДокумент3 страницыSmaw PQR Finalsheikmoin100% (1)

- Qualified Welder List Valid Until - 03-12-2019Документ2 страницыQualified Welder List Valid Until - 03-12-2019csolanki6586100% (1)

- WPQ WeldCanada PDFДокумент1 страницаWPQ WeldCanada PDFAhmad DanielОценок пока нет

- WPQ Formats NEWДокумент4 страницыWPQ Formats NEWMANABENDRA MAITRAОценок пока нет

- ASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationДокумент2 страницыASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationAmit SharmaОценок пока нет

- Wps Is 2062 GR B Butt-OkДокумент2 страницыWps Is 2062 GR B Butt-OkAnand Kesarkar33% (3)

- Welding Procedure Specification For GTAW & GMAWДокумент4 страницыWelding Procedure Specification For GTAW & GMAWanh thoОценок пока нет

- QW-484A (WPQ) GTAW 4MM FilletДокумент2 страницыQW-484A (WPQ) GTAW 4MM FilletBalkishan Dyavanapelly100% (1)

- Val Caraig WPQTДокумент1 страницаVal Caraig WPQTMark Jason M. BrualОценок пока нет

- WPS PQR PDFДокумент23 страницыWPS PQR PDFAhmad Daniel100% (1)

- Wps No. 0 Rev. No. 19: Asme Section Ix Welding Procedure SpecificationДокумент5 страницWps No. 0 Rev. No. 19: Asme Section Ix Welding Procedure SpecificationAmit ChapagainОценок пока нет

- Graycor WPS 19 SampleДокумент5 страницGraycor WPS 19 SampleRaul SebastiamОценок пока нет

- Wps For Akbtpl E-6013 - ModifiedДокумент13 страницWps For Akbtpl E-6013 - ModifiedvinayОценок пока нет

- 001 Reduction of Weld Fabrication Costs The Effect of Weld Shielding Gas CompositionДокумент37 страниц001 Reduction of Weld Fabrication Costs The Effect of Weld Shielding Gas CompositionChisom IkengwuОценок пока нет

- Executive Summary: 80:19:67:CF:B3:FCДокумент10 страницExecutive Summary: 80:19:67:CF:B3:FCChisom IkengwuОценок пока нет

- DR - I - y - Suleiman PDFДокумент9 страницDR - I - y - Suleiman PDFChisom IkengwuОценок пока нет

- DR - I - y - Suleiman PDFДокумент9 страницDR - I - y - Suleiman PDFChisom IkengwuОценок пока нет

- International LTD: Report of Thorough ExaminationДокумент1 страницаInternational LTD: Report of Thorough ExaminationChisom IkengwuОценок пока нет

- Annex A PHC Jet A1 Rev2Документ30 страницAnnex A PHC Jet A1 Rev2Chisom IkengwuОценок пока нет

- NG PHC Npy Sit 050103 Rev 3.1 Model 3Документ1 страницаNG PHC Npy Sit 050103 Rev 3.1 Model 3Chisom IkengwuОценок пока нет

- 1.3 Photovoltaics PDFДокумент16 страниц1.3 Photovoltaics PDFChisom IkengwuОценок пока нет

- Annex A PHC Jet A1 Rev2Документ30 страницAnnex A PHC Jet A1 Rev2Chisom IkengwuОценок пока нет

- 1 6 1Документ1 страница1 6 1Chisom IkengwuОценок пока нет

- Kami Export - Hanna Huff - Amoeba Sisters - DNA Vs RNA 1Документ1 страницаKami Export - Hanna Huff - Amoeba Sisters - DNA Vs RNA 1hannakhuffОценок пока нет

- Isensee Robert W1943Документ17 страницIsensee Robert W1943DŨNG VŨ NGUYỄN TUẤNОценок пока нет

- 11 Iajps11072017Документ7 страниц11 Iajps11072017Baru Chandrasekhar RaoОценок пока нет

- The Big Picture: EnzymesДокумент54 страницыThe Big Picture: EnzymesSoumiya SrinivasanОценок пока нет

- Biology Remedial Module PDFДокумент185 страницBiology Remedial Module PDFBetseha Merawi67% (3)

- V 1 Preparation of AZ31 Magnesium Alloy Strips Using Vertical Twin-Roll CasterДокумент7 страницV 1 Preparation of AZ31 Magnesium Alloy Strips Using Vertical Twin-Roll CasterVidya me20d015Оценок пока нет

- Nta Abhyas Test-65 CДокумент5 страницNta Abhyas Test-65 CMIITY EDUОценок пока нет

- ID Rentokil Blatannex 2 15 Gel en SDS 01Документ10 страницID Rentokil Blatannex 2 15 Gel en SDS 01Abdurrosyid officialОценок пока нет

- Inconel 625Документ5 страницInconel 625koushkiОценок пока нет

- Distortions: M. Vedani Failure and Control of Metals - AY 2020/21Документ7 страницDistortions: M. Vedani Failure and Control of Metals - AY 2020/21MarcoОценок пока нет

- Casting in AviationДокумент32 страницыCasting in AviationJCОценок пока нет

- 1st Yr Lec3Документ16 страниц1st Yr Lec3abhijeetnarkhede69198Оценок пока нет

- Major Intermediates in Organophosphate Synthesis (PCL, Pocl, PSCL, and Their Diethyl Esters) Are Anticholinesterase Agents Directly or On ActivationДокумент7 страницMajor Intermediates in Organophosphate Synthesis (PCL, Pocl, PSCL, and Their Diethyl Esters) Are Anticholinesterase Agents Directly or On ActivationYancy JuanОценок пока нет

- Biodentine IFUДокумент2 страницыBiodentine IFUbabbalaОценок пока нет

- Influence of Sequence of Cold Working and Aging Treatment On Mechanical Behaviour of 6061 Aluminum AlloyДокумент8 страницInfluence of Sequence of Cold Working and Aging Treatment On Mechanical Behaviour of 6061 Aluminum AlloywicaksonoОценок пока нет

- Influence of Morinda Citrifolia (Noni) On Expression of DNA Repair Genes in Cervical Cancer CellsДокумент5 страницInfluence of Morinda Citrifolia (Noni) On Expression of DNA Repair Genes in Cervical Cancer CellsAtika Nur NabilaОценок пока нет

- MetalCoat 470 480 Brochure enДокумент9 страницMetalCoat 470 480 Brochure endanceОценок пока нет

- Durability of ConcreteДокумент89 страницDurability of ConcreteRamu NeupaneОценок пока нет

- Samsung Electric Dryer Dve54r7600 Dve54r7200 Manual OptimizedДокумент124 страницыSamsung Electric Dryer Dve54r7600 Dve54r7200 Manual OptimizedArgus JazminОценок пока нет

- Evaporation Rate of Solvents PDFДокумент2 страницыEvaporation Rate of Solvents PDFsyamlokОценок пока нет

- DesalinationTechnologiesforDevelopingCountriesAReview PDFДокумент22 страницыDesalinationTechnologiesforDevelopingCountriesAReview PDFlebob12Оценок пока нет

- Nanofabrication For Pattern Transfer Purpose.: Etching Is Done Either in "Dry" or "Wet" MethodsДокумент19 страницNanofabrication For Pattern Transfer Purpose.: Etching Is Done Either in "Dry" or "Wet" MethodsPRAVEEN MОценок пока нет

- Astm d1785Документ5 страницAstm d1785Kehinde AdebayoОценок пока нет

- Nitobond SBR PDFДокумент4 страницыNitobond SBR PDFhelloitskalaiОценок пока нет

- Mass Spectral Databases For LC-MS - and GC-MS-based Metabolomics PDFДокумент13 страницMass Spectral Databases For LC-MS - and GC-MS-based Metabolomics PDFciborg1978Оценок пока нет

- Proposed OS&E Requirement - Measuring Ozone DosageДокумент3 страницыProposed OS&E Requirement - Measuring Ozone DosageProteina QuitinaseОценок пока нет