Академический Документы

Профессиональный Документы

Культура Документы

Alternator Basics PDF

Загружено:

abid azizОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Alternator Basics PDF

Загружено:

abid azizАвторское право:

Доступные форматы

NEWAGE PRODUCT TRAINING

NEWAGE PRODUCT TRAINING

WHAT IS ELECTRICITY ?

Electricity is a NATURAL form of ENERGY, e.g, LIGHTENING,

STATIC CHARGE.

ALL forms of MATTER in the Universe, (solid, liquid or gas), are

made of ATOMS. The electrical force in the atom is called the

ELECTRO-MAGNETIC FORCE. This force holds ELECTRONS in

orbit, around the NUCLEUS of the ATOM.

An electrical CHARGE, (or POTENTIAL DIFFERENCE),measured

in VOLTS), is created when ELECTRONS are stripped from ATOMS.

This CHARGE, (or VOLTAGE), provides the ‘pressure’ in an

electrical circuit, causing ELECTRONS to flow in conductors.

Lets take a closer look at the ATOM

NEWAGE PRODUCT TRAINING

WHAT IS ELECTRICITY ? - THE ATOM

AA

HYDROGEN

COPPER ATOM

ATOM

ELECTRON NUCLEUS

(NEGATIVE CHARGE) (POSITIVE CHARGE)

VALENCE OR

ELECTROMAGNETIC CONDUCTIVE BAND

FORCE

2

ELECTRON ‘SHELL’

8

18

1

The ELECTRO MAGNETIC FORCE is second only in strength to the NUCLEAR

FORCE.

In a COPPER CONDUCTOR, the ELECTRON in the VALENCE band is FREE to flow

from atom to atom, when attracted by a POTENTIAL DIFFERENCE or CHARGE.

NEWAGE PRODUCT TRAINING

WHAT IS ELECTRICITY? - VOLTAGE AND CURRENT

A COPPER CONDUCTOR

+ ELECTRON

ATOMS

20

= 10 per cubic mm FLOW IN A

(100 BILLION BILLION) CONDUCTOR

A POTENTIAL DIFFERENCE or CHARGE ,across a conductor, causes ELECTRONS to

flow towards the positive charge, (electrons are negatively charged).

The level of CHARGE is measured as VOLTAGE .

CURRENT flow is possible because of ‘free’ electrons in the atoms from which the

conductor is made.

CURRENT flow can also be described in terms of electron flow.

1 Ampere flowing in a conductor at a given point in time would be equal to :-

6 X 1018 electrons flowing / per second.

NEWAGE PRODUCT TRAINING

WHAT ARE CONDUCTORS

CONDUCTORS IN CONDUCTORS

A DOMESTIC IN A

CABLE GENERATOR

WINDING

IRON

CORE

Conductors are materials where the atoms have free electrons which can flow from

atom to atom, when induced by an electric charge (voltage).

Most metals are good conductors, some of the best being silver, copper and gold.

Good conductors have a very low resistance to current flow.

Copper conductors are generally chosen for Generator windings because of its

good electrical and thermal conductivity, relatively low cost, ease of use.

NEWAGE PRODUCT TRAINING

WHAT ARE INSULATORS

INSULATION IN INSULATION

A DOMESTIC IN A

CABLE GENERATOR

WINDING

IRON

CORE

Insulators are materials where, the electrons are very tightly bound to the nucleus

and to other atoms, (covalent bonding), hence there are no free electrons to carry an

electrical charge.

As a result, they are are a very poor conductors of electricity.

Typically rubber,plastics, ceramics and glass are good insulators. They have a very

HIGH resistance to current (electron) flow.

The Voltage level, temperature rise, electrical, and mechanical properties, all

determine the type of insulation materials chosen for a Generator winding.

NEWAGE PRODUCT TRAINING

WHAT IS D.C (DIRECT CURRENT)

+ -

12V D.C

BATTERY

Direct Current (DC) Voltage, can be produced by converting chemical

energy directly into electrical energy. This is the BATTERY.

A BATTERY is a storage device, i.e., the battery stores potential energy,

which is known as the ‘charge’.

The first battery was invented by VOLTA in 1800, and was called the

VOLTAIC PILE.

NEWAGE PRODUCT TRAINING

COUNT ALESSANDRO GIUSEPPE ANTONIA VOLTA 1745 - 1827

VOLTAIC PILE

COPPER

& ZINC

CELLS

IN HE FOUND

SALT IT QUITE

WATER SHOCKING!

SOLUTION

In 1800,Volta invented the “VOLTAIC PILE”, which was the first BATTERY, and the

first Electrical device to produce a continuous ELECTRICAL CHARGE.

The VOLTAIC PILE was the fore- runner of the modern battery, with all its many

varieties today.

NEWAGE PRODUCT TRAINING

A SIMPLE D.C CIRCUIT

Electron flow

Copper

Conductor

Light

Switch Bulb

+ + -

D.C

BATTERY

The battery creates a POTENTIAL DIFFERENCE or CHARGE across its terminals.

We measure this charge as VOLTAGE.

The battery acts like a ‘pump’, forcing electrons to flow around the circuit.

When the switch is closed, the potential difference causes free electrons to flow

through the conductors, and the light filament.

The thin tungsten filament in the bulb acts as a ‘restriction’, or ‘resistance’, to the

electron flow, heating the element and producing light.

NEWAGE PRODUCT TRAINING

WHY IS D.C USED IN AN A.C GENERATOR?

A.C GENERATOR SET

ALTERNATING

D.C CONVERTED

CURRENT

FROM A.C

A.C

+V

0v

V

Anode

Gate

Silicon Controlled

Rectifier Diode

Rectifyer (Thyristor)

Cathode

All Generators produce Alternating Current (A.C).

A D.C Generator is an A.C Generator, with its output converted into D.C by means

of commutation, (reversal of the Negative cycle).

In A.C Generators, D.C is produced by means of RECTIFICATION.

D.C is used to produce the ELECTRO MAGNETIC FIELDS in A.C Generators.

NEWAGE PRODUCT TRAINING

WHAT IS A.C ( ALTERNATING CURRENT ) ?

A.C Electricity (Alternating Current ), is produced by converting mechanical

energy into electrical energy. This is the A.C Generator.

The mechanical energy is provided by an Engine, or Turbine which drives the

Generator.

The Engine or Turbine may be powered by various forms of potential energy i.e. :-

Fossil fuels, (Petrol, Diesel, or Gas), or fuels from waste products (Methane).

Steam from the heat produced by burning fossil fuels, or nuclear energy .

Water Turbines, (Hydro Electricity), driven by the pressure of water from a river

or Dam.

Alternative energy produced by wind or wave turbines.

NEWAGE PRODUCT TRAINING

THE A.C GENERATOR

PRIME MOVER

(ENGINE OR TURBINE) A.C GENERATOR

Mechanical power (HORSEPOWER) is converted into electrical power (KILOWATTS,

or kW) by means of a prime mover (engine) driving the A.C Generator.

NEWAGE PRODUCT TRAINING

WHAT IS A.C POWER ?

AP

PA

R EN

T PO

REACTIV WE

R(

E (kVAr) kV

N S A)

LAGGING

C OS

INDUCTIVE CAPACITIVE 90º

CIRCUIT CIRCUIT ACTIVE POWER ( kW )

ELECTRICAL POWER, (WATTS) in its simplest form = VOLTAGE X CURRENT

A.C creates WASTED CURRENT in INDUCTIVE or CAPACITIVE circuits.

The resultant APPARENT POWER , is called the kVA

The POWER FACTOR, (COSINE of the phase angle ), is a measure of the WASTED

or WATTLESS CURRENT component of the load.

Generator output RATINGS usually give the full load kWATTS and kVA at 0.8 P.F.

SO, HOW DOES AN A.C GENERATOR PRODUCE A.C POWER ?

NEWAGE PRODUCT TRAINING

CAN ANYONE GUESS WHAT THIS IS ?

CAN ANYONE GUESS WHAT THESE ARE ?

ZANUSSI

CORRECT !!

FRIDGE MAGNETS.

BUT WHAT’S THAT GOT TO

DO WITH A.C GENERATORS ?

NEWAGE PRODUCT TRAINING

MAGNETISM IN GENERATORS

MAGNET

MAGNETIC

N S FLUX

Magnetism is the essential force which produces the ELECTRO MOTIVE FORCE

(EMF), in a Generator.

Without MAGNETISM, you would have no fridge to stick your fridge magnets to !!

NEWAGE PRODUCT TRAINING

ELECTRO- MAGNETISM IN GENERATORS

CONVENTIONAL

- + CURRENT FLOW

(AMPERES)

D.C COPPER COIL

BATTERY (MAGNETIC FIELD)

MAGNETIC

N S

FLUX

When a D.C supply is connected to a copper coil, current will flow in one

direction through the coil, creating a magnetic field.

If an iron core is placed into the magnetic field, it will become magnetized. The

magnetic strength is determined by the D.C power (Voltage X Current) in the coil.

This is the principle of ELECTRO-MAGNETISM, which is used to control the

magnetic fields in an A.C Generators.

NEWAGE PRODUCT TRAINING

MICHEAL FARADAY 1791 - 1864

In 1831, Michael Faraday, using a simple magnet and a coil of wire,discovered that

mechanical energy could be converted into electrical energy,

NEWAGE PRODUCT TRAINING

SIMPLE FARADAY GENERATOR

ELECTRIC WATCH THE

LIGHT BULB

LIGHT BULB !

MAGNET

COPPER COIL

(CONDUCTOR)

N S

When the magnet is stationary, no work is being done, so no electricity is generated.

When the magnet is moved rapidly passed the coil, work (energy) is being done, and

this will generate the ELECTRO MOTIVE FORCE, (EMF or VOLTAGE), into the coil.

NEWAGE PRODUCT TRAINING

BASIC PRINCIPLES OF AN A.C GENERATOR

Permanent Magnet Field

Magnetic Field

(Flux)

N

Shaft

Copper Slip-rings

loop and Brushes

S THIS TIME THE

MAGNETS ARE

STATIONARY, BUT THE

COIL IS MOVING !

+VE Output

-VE

A.C Sinusoidal Output Voltage with A Permanent Magnet Field

NEWAGE PRODUCT TRAINING

BASIC PRINCIPLES OF AN A.C GENERATOR

Electro- Magnetic

Magnetic Field Field

(Flux)

ADJUSTABLE

D.C SUPPLY

Shaft

Copper Slip-rings

loop and Brushes

+VE Output

-VE

By controlling the D.C current into the magnetic field, the voltage level can be

adjusted, allowing control of the output voltage.

NEWAGE PRODUCT TRAINING

SIMPLE A.C GENERATOR

AIR GAP ELECTRO

(MAGNETIC MAGNETIC

LINES OF FIELD

FORCE OR

D.C FIELD POLES

FLUX)

A.C OUTPUT

CARBON

BRUSHES

SHAFT

SLIPRINGS

A.C

ARMATURE

WINDINGS ADJUSTABLE

D.C SUPPLY

The output Voltage is a product of (A), the strength of the magnetic field, (B),

the length of conductors in the A.C armature (turns), and (C), the velocity

(speed) of the conductors cutting the magnetic lines of force.

NEWAGE PRODUCT TRAINING

WHY DO WE CHOOSE A.C, AND NOT D.C ?

Magnetic Lines THE TRANSFORMER

of Force

(Alternating Laminated

flux) Steel Core

Primary Secondary

Winding Winding

(Input) (Output)

A.C can be increased or decreased by means of MUTUAL INDUCTION.

This is achieved by the TRANSFORMER, and is essential for POWER DISTRIBUTION.

SECONDARY VOLTAGE = RATIO OF PRIMARY TURNS : SECONDARY TURNS

The A.C transformer enables us to distribute A.C POWER over very large distances.

D.C cannot be transformed, and can only be distributed at the generated voltage.

WHY IS THIS IMPORTANT ?

NEWAGE PRODUCT TRAINING

DISTRIBUTION OF A.C POWER

MAINS SUPPLY STEP UP

A.C GENERATOR TRANSFORMER

CB SUPER HIGH

TENSION

400,000V

MCB

STEP DOWN

TRANSFORMER

MCB

A.C Voltage can be increased or decreased by transformers,

By increasing the Voltage, overhead supply cables can be made much lighter.

This allows load currents to be distributed over long distances at very high voltages.

NEWAGE PRODUCT TRAINING

TYPICAL ROTATING ARMATURE A.C GENERATOR

MAGNETIC CARBON

FLUX BRUSHES

D.C FIELD POLES OUTPUT A.C

SHAFT A.C.ARMATURE

SLIPRINGS

BEARINGS

D.C INPUT

Before the Late 1960’s, Newage A.C Generators were designed with a rotating A.C

armature, from which the Generator output was taken.

This was achieved by means SLIP-RINGS and carbon ‘ BRUSHES’

These had a tendency to wear out, spark, burn, and required regular maintenance.

Newage switched to Brushless Generator design in the Late 1960’s.

This became feasible following the invention of the Silicon Diode Rectifier

NEWAGE PRODUCT TRAINING

TYPICAL ROTATING D.C FIELD GENERATOR

OUTPUT A.C CARBON

BRUSHES

MAGNETIC A.C STATOR D.C SUPPLY

FLUX

SHAFT D.C.FIELD (ROTOR)

SLIPRINGS

BEARINGS

This generator has a rotating field (rotor), which is supplied with D.C via two slip-rings.

The output is taken from the static A.C windings ( Stator),

This design is still popular today, as the rotating field system is easier to design than

a rotating armature, and more economical to manufacture.

The main components of a Brushless Generator are of a similar design to above.

However, Brushless Generators are designed without slip-rings and brushes.

NOW LETS LOOK AT A BRUSHLESS GENERATOR

NEWAGE PRODUCT TRAINING

TYPICAL BRUSHLESS A.C GENERATOR

RECTIFIER EXCITER ROTOR

OUTPUT A.C DIODES EXCITER STATOR

MAGNETIC A.C STATOR

FLUX

SHAFT D.C.FIELD (ROTOR)

BEARINGS

The SLIPRINGS and BRUSHES are now replaced with :-

The RECTIFYER ASSEMBLY which converts A.C VOLTAGE into D.C VOLTAGE.

The EXCITER ROTOR, which provides A.C POWER to the RECTIFIER.

The EXCITER STATOR, which is the ELECTRO-MAGNETIC FIELD for the

EXCITER ROTOR.

NOW LETS SEE HOW A BRUSHLESS GENERATOR WORKS

NEWAGE PRODUCT TRAINING

BRUSHLESS GENERATOR COMPONENT ASSEMBLY (TWO BEARING)

Main Rotor Main Stator

Exciter Rotor

Exciter Stator Fan

Bearing Bearing

Cartridge Cartridge

N.D.E D.E

Key

Shaft

P.M.G

Rotor

Rectifier

P.M.G

Stator

NEWAGE PRODUCT TRAINING

BRUSHLESS GENERATOR COMPONENT ASSEMBLY (SINGLE BEARING)

Main Rotor Main Stator

Single bearing

Exciter Rotor

Coupling

Exciter Stator Fan

Bearing

Cartridge

N.D.E

P.M.G

Rotor

Rectifier

P.M.G

Stator

NEWAGE PRODUCT TRAINING

Main

HC Generator Assembly

Terminals

Main Rotor

A.V.R.

on A.V.M,s Main Stator

Drive end

Fabricated

Bracket

Non drive Frame

end Bracket

& Exciter

Stator assy

P.M.G

Rotor

P.M.G

Stator

NEWAGE PRODUCT TRAINING

Air flow through Generator

Air flow must not be restricted

NEWAGE PRODUCT TRAINING

NEWAGE PRODUCT TRAINING

Excitation System

Main Stator

Exciter

Rotor

& Stator

Bearing

Main Rotor

Shaft

Rectifier

Fan

NEWAGE PRODUCT TRAINING

Excitation System - Exciter Stator

Exciter

Stator

Main Stator

Exciter

Rotor

& Stator

Bearing

Main Rotor

Shaft

Rectifier

Fan

NEWAGE PRODUCT TRAINING

Excitation System - Wound Exciter Stator

X+ (F1)

XX- (F2) To A.V.R Terminals

COIL CONNECTIONS

N S N S

High-remanence steel core

Stores Residual Magnetism

12-14 pole magnet field

High frequency Generator

NEWAGE PRODUCT TRAINING

Excitation System - Exciter Rotor

Exciter

Rotor

Main Stator

Exciter

Rotor

& Stator

Bearing

Main Rotor

Shaft

Rectifier

Fan

NEWAGE PRODUCT TRAINING

Excitation system - Exciter Rotor Assembly

W

U

SHAFT V

W

3 Phase A.C output, each Phase connected to 2 diodes on Main Rectifier.

High Frequency output, ( from12 to 14 Pole Exciter Stator ).

Exciter generator is a magnetic power amplifier for the main rotor current.

NEWAGE PRODUCT TRAINING

Excitation System - Exciter Rotor/ Main Rectifier

Exciter Rotor and

Main Rectifier

Circuit

Main Stator

Exciter

Rotor

& Stator

Bearing

Main Rotor

Shaft

Rectifier

Fan

NEWAGE PRODUCT TRAINING

Exciter Rotor and Rectifier Assembly

Wound Exciter Rotor

W

U

Rectifier Assembly

SHAFT

SHAFT V

W

Rectifier Assembly Mounted on Exciter rotor Core, (drive end side).

NOTE: BC & Frame 8 Generators are mounted at the non-drive end side.

NEWAGE PRODUCT TRAINING

Exciter Rotor & Main Rectifier Assembly

Exciter Rotor 3 Phase

with Internal Star Point

SHAFT

NEWAGE PRODUCT TRAINING

Exciter Rotor & Main Rectifier Connections

Rectifier Input Terminal

SHAFT

SHAFT

3 Phase A.C Exciter Rotor Connected to Rectifier input terminals

NEWAGE PRODUCT TRAINING

Excitation System - The Main Rectifier

Main

Rectifier

Main Stator

Exciter

Rotor

& Stator

Bearing

Main Rotor

Shaft

Rectifier

Fan

NEWAGE PRODUCT TRAINING

The Main Rectifier Assembly

3 Phase A.C Input Aluminium

from Exciter Rotor. Heat-sinks

(Insulated Terminals)

Varistors

(Surge Suppressors)

Rectifier Hub

Rectifier Diodes

Negative Plate

Anode Stud SHAFT

Rectifier Diodes

Positive Plate

Cathode Stud

Output to

Main Rotor

NEWAGE PRODUCT TRAINING

Main Rectifier Assembly- Operation of a Diode

+VE

A.C Input to Rectifier 0

Diodes

Rectifier Diode -VE

Positive Heatsink

Cathode Stud

+VE

+ 0

-VE

Rectifier Diode

Negative Heatsink +VE

Anode Stud

0

-VE

for a 12 pole exciter field the frequency will be 150 or 180 HZ

(cycles/second).

NEWAGE PRODUCT TRAINING

Main Rectifier Assembly- 3 Phase Rectification

A.C Input to Rectifier

Diodes

D.C output to Main Rotor

+

-

Full wave 3 Phase rectification will produce a D.C output of 1.35 X A.C input

voltage

NEWAGE PRODUCT TRAINING

Metal Oxide Varistor (Surge Suppressor)

UC & BC Type 350 Volt HC & F8 Type 778 Volt

Clamping @ 30 Amp 680 Volts Clamping @ 100 Amp 1365 Volts

Diode Protection Device

For Transient Suppression

SHAFT SHAFT

Main Rotor

Connections

NEWAGE PRODUCT TRAINING

Metal Oxide Varistor (Surge Suppressor)

DIODE PROTECTION DEVICE

Typical high voltage transient created by

Direction of transient

fault condition in the distribution system.

Up to 2- 3000V (peak voltage)

High Transient surges can be created by:-

Energy absorbed ‘ Crash’ Synchronising onto live bus-bars.

by Varistor.

Electric storm, (lightning), and field effects on

overhead lines (distribution systems).

Varistor clamping Arcing, caused by faulty switching, motor

(Protection) level. failure, short circuits in the distribution system.

Full load D.C D.C supply

output from t = µ sec's. to Main

main Rectifier rotor

NEWAGE PRODUCT TRAINING

Excitation System - The Main Rotor

Main Rotor

Main Stator

Exciter

Rotor

& Stator

Bearing

Main Rotor

Shaft

Rectifier

Fan

NEWAGE PRODUCT TRAINING

Main Rectifier Connections to Main Rotor

Main Rectifier Main Rotor

Aluminium

Heat-sinks

SHAFT D.C

The Rectifier Output is a smooth D.C Supply across the Aluminium Heat Sinks

This is fed to the Main Rotor windings

NEWAGE PRODUCT TRAINING

Wound Main Rotor - Coil Group connections

ANTI CLOCK

D.C Input

From Main S

Rectifier

CLOCK CLOCK

N N

ANTI CLOCK

The Rotor coils are connected in Series (4 Pole Rotor shown).

Each coil is reversed to the adjacent coil, producing the required polarity

NEWAGE PRODUCT TRAINING

Wound Main Rotor - Poles & Frequency

Generator Frequency (HZ) = Speed (N) X Pairs of poles (P)

60

6 Pole Available

4 Pole in Frame 7

2 Pole

S

N

SHAFT

N

N

SHAFT

S

S

NEWAGE PRODUCT TRAINING

Wound Main Rotor - Poles & Frequency

Main Stator Core

Main Stator Coils in Slots (section) (section)

4 Pole Main Rotor

Air Gap

1 Cycle S

N

SHAFT

Consider the Coils in the slot at 12 O'clock position, marked with the ARROW.

The NEGATIVE Pole of the 4 pole Rotor is directly under the slot, therefore the

coil conductors in this slot will be going fully NEGATIVE

NEWAGE PRODUCT TRAINING

Wound Main Rotor - Poles & Frequency

Main Stator Coils in Slots Main Stator Core

4 Pole Main Rotor

Air Gap

1 Cycle

N

S

S

H

A

FT

N

S

The Rotor has now rotated Clockwise 45 º, until exactly half-way between

Negative and Positive Poles appears beneath the 12 O'clock position.

The coil conductors in this slot will now be at ZERO VOLTAGE.

NEWAGE PRODUCT TRAINING

Wound Main Rotor - Poles & Frequency

Main Stator Coils in Slots Main Stator Core

4 Pole Main Rotor

Air Gap

1 Cycle N

S

SHAFT

The Rotor has now rotated Clockwise 90 º, until the POSITIVE Pole is DIRECTLY

UNDERNEATH the 12 O'clock position.

The coil conductors in this slot will now be at the FULLY POSITIVE position

The 4 Poles will produce 2 FULL CYCLES for each 360 º FULL REVOLUTION.

NEWAGE PRODUCT TRAINING

Wound Main Rotor - Poles & Frequency

Generator Frequency (HZ or CYCLES) = Speed (N) X Pairs of poles (P)

60

FRQUENCY NUMBER ENGINE

HZ (CYCLES) POLES (P) SPEED (N)

50 2 3000

2 Pole 1 HZ = 60 RPM

50 4 1500 4 Pole 1 HZ = 30 RPM

6 Pole 1 HZ = 20 RPM

50 6 1000

60 2 3600

60 4 1800

60 6 1200

NEWAGE PRODUCT TRAINING

Main Rotor- Amortisseur (Damper) Windings

S Amortisseur Winding (Damper Bars)

(Aluminium Damper Bars Welded to End Plates )

N

N

SHAFT

NEWAGE PRODUCT TRAINING

Main Rotor- Amortisseur (Damper) Windings

Helps dampen speed oscillations resulting from cyclic

irregularities in the engine, (cause of ‘light flicker’).

Stabilises the mechanical systems during large load

changes.

Stabilises load sharing with other Generators in Parallel.

Improves Harmonic Distortion in the Generator waveform

NEWAGE PRODUCT TRAINING

Operation - Main Stator

Main Stator

Main Stator

Exciter

Rotor

& Stator

Bearing

Main Rotor

Shaft

Rectifier

Fan

NEWAGE PRODUCT TRAINING

Wound Main Stator Assembly

The Main stator insulation is class H as standard, allowing up to 165º C temperature.

The laminated core is built from high grade Electrical Steel to minimise Iron losses.

12 Ends Out Re-connectable, or 6 Ends out Star / Delta, or Dedicated Windings.

Windings are standard for most voltages, special windings required for some

voltages

Output Leads Laminated Steel core Copper Windings

NEWAGE PRODUCT TRAINING

Wound Main Stator Assembly

Core length of Stator & Rotor (L) Determines KVA Rating for each Frame size,e.g.

HC4 C, D ,E, F Core Lengths = 250 KVA to 400 KVA (@ 50 HZ)

HC5 C, D, E, F Core Lengths = 450 KVA to 675 KVA (@ 50 HZ)

HC6 G, H, J, K Core Lengths = 800 KVA to 1110 KVA (@ 50 HZ)

HC7 E, F, G, H Core Lengths = 1350 KVA to 2000 KVA (@ 50 HZ)

Core lengths

Output Leads Copper Windings

Laminated Steel core

NEWAGE PRODUCT TRAINING

Wound Main Stator Assembly

Stator Winding Coils (Lap winding)

COIL PHASE GROUP

OUTPUT CONDUCTORS

OUTPUT

CONDUCTORS

COIL END

(OVERHANG)

COIL

STATOR SPAN COIL

CORE (PITCH) TURNS

LENGTH

The output voltage of the stator is determined by the number of turns per coil, the

stator core length, the velocity of the magnetic field (rotor), and the strength of the

magnetic field.

The Current capacity of the coil is determined by the conductor cross sectional

area, and number of conductors in parallel.

NEWAGE PRODUCT TRAINING

Typical Main Stator 12 Wire Re-connectable

GROUP 1

2/3RDS PITCH

WINDING LEADS V6 V2

8 SLOTS

START OF COIL U5 W1

( SPAN 1 TO 9)

GROUP U1

W5 ONE PHASE GROUP

WINDING LEADS W2

( 4 COILS PER GROUP)

FINISH OF COIL U6

GROUP

W6 FULL PITCH

12 SLOTS

S U2

( SPAN 1 - 13)

V5

GROUP 3 UP 4

V1 GRO

N

SHAFT

V1

V5

U2 S

W6

U6 W2

W5

U1

W1 U5 MAIN STATOR WINDING

V2 V6

MAIN ROTOR SECTION ( 48 SLOT )

GRO UP 2

(4 POLE)

NEWAGE PRODUCT TRAINING

Typical Main Stator 12 Wire Re-connectable

Connections shown in Series Star

6

WV6

N U6 Neutral

6 W5

W1

W2 W

AVR Sensing 3 Phase Output

& Power supply 7 V5

from Main Stator V2

V V1

U5

8

U2

U U1

NEWAGE PRODUCT TRAINING

Wound Main Stator 12 Wire Re-connectable

Series Star Parallel Star

Voltage Range (winding 311) Voltage Range (winding 311)

380 to 440 V @ 50 HZ U U 190 to 220 V @ 50 HZ

416 to 480 V @ 60 HZ 208 to 240 V @ 60 HZ

U1 8

U1 U5

U2 U5

8

U2 U6

W6 U6 N

W2 N V6

6 V6

V2

W2 V5

W1

W5 V5

W1 7 V1 6 W6 V2

w v w W5 V1 v

7

The stator windings are connected into six groups.

The groups can be connected by Newage, or the customer, to provide different voltage

requirements.

Special Voltage requirements require special windings, e.g.; 690 Volt for Co-Generation.

NEWAGE PRODUCT TRAINING

Wound Main Stator 12 Wire Re-connectable

Series Delta Double Delta

U

8 6

Centre W6 U1

Tap V1

W5 U2 V5 W2 W6

W2 U5 V2

V6 W1 W5

6 W1 U6 7 8 7

V6 V5 V2 V1 U1 U2 U5 U6

w v U N w

Voltage Range (winding 311) Voltage Range (Winding 311)

220 to 250 V @ 50 HZ, 240 to 277 V @ 60 HZ 220 to 250 V @ 50 HZ, 240 to 277 V @ 60 HZ

No Neutral connection. Single Phase Only, output across U & W

Centre Tap for low volts 1ph only Centre Tap (N) for low volts

110 to 125 @ 50 HZ, 120 to 138 @ 60 HZ

NEWAGE PRODUCT TRAINING

Wound Main Stator 6 Ends Out

Star

U

8

Voltage Range (winding 312) Number of Stator leads in parallel

380 to 440 V @ 50 HZ, 416 to 480 V @ 60 HZ U1 multiply’s with current rating

Single Phase (N) = 3 of Phase voltage of generator,

Dropper transformer required ie: 12, 18, 24, 36, or 48 leads out.

for AVR sensing U2

N

W2 V2

7

6 W1 V1

w v

Each phase group is producing the full line voltage, (all coil groups in each phase are in

parallel).

NEWAGE PRODUCT TRAINING

AVR INPUT TERMINALS - SENSING SUPPLY

Sensing Supply to A.V.R for 6 ends out STAR connected

U

8

Examples - 6 ends Stators

Winding 312 U1

380 to 440 V @ 50 HZ

416 to 480 V @ 60 HZ

Single Phase (N) = 3 of L-L

U2 Isolation transformer

Winding 26 8

660 - 690 Volts @ 50 HZ N

W2 V2

7

W1 V1 7

w v

6 6

The AVR Sensing supply is connected to the main stator via a sensing

isolation transformer, which is fitted in the main terminal box.

Other windings producing higher voltage requirements will require a different

transformer ratio, to supply the AVR with the correct voltage adjustment range

NEWAGE PRODUCT TRAINING

Excitation Control - Automatic Voltage Regulator (A.V.R)

The A.V.R

A.V.R

Main Stator

Exciter

Rotor

& Stator

Bearing

Main Rotor

Shaft

Rectifier

Fan

NEWAGE PRODUCT TRAINING

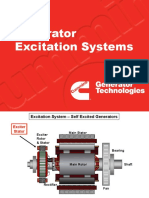

Excitation System - Self Excited Generators

X+ (F1)

D.C Output A.C Power &

XX- (F2) A.V.R

From A.V.R Feedback Signal

Into (Sensing)

Exciter Stator From Main Stator

Main Stator

Exciter

Rotor

& Stator

Bearing

Main Rotor

Shaft

Rectifier

Fan

NEWAGE PRODUCT TRAINING

Automatic Voltage Regulator (AVR) Type SX460/2 (Self -Excited)

VOLTS X XX 6 7 8

1

2

3

4 WARNING!

ELECTRIC SHOCK

[Live Terminals]

UFRO

50HZ

C

60HZ

STABILITY

NEWAGE PRODUCT TRAINING

Automatic Voltage Regulator (AVR) Type SX440 (Self Excited)

K2 K1 P2 P3 P4 XX X 3 2 2 1

S2 S1 A2 A1

TRIM

Input Var/ PFC3

[Live Terminals]

ELECTRIC SHOCK

WARNING!

DROOP Input Droop C/T

8 7 6 5 4 3 2 1

8 7 6 5 4 3 2 1

VOLTS

Linking for

3 Phase

Sensing Unit

UFRO STABILITY C B A

50 C 60

NEWAGE PRODUCT TRAINING

Automatic Voltage Regulator (AVR) Type MX341 P/N E000-23412/1P

K2 K1 P2 P3 P4 XX X 3 2 2 1

S2 S1 A2 A1

TRIM

MX341-2 E000-23412

[Live Terminals]

ELECTRIC SHOCK

WARNING!

DROOP

8 7 6 5 4 3 2 1

8 7 6 5 4 3 2 1

VOLTS Linking for

3 Phase

Sensing Unit

EXC

DIP TRIP

UFRO STABILITY

3 2 C B A

1

NEWAGE PRODUCT TRAINING

Automatic Voltage Regulator (AVR)

P4

Type MX321 P/N E000 -23212

K2 K1 P2 P3 P4 XX X 6 7 8 1 2

VOLTS

RAMP

FREQUECY I /LIMIT

SELECTION

UFRO

3 2 1

ELECTRIC SHOCK

[Live Te rminals]

WARNING!

DIP

R.M.S

DWELL

STABILITY

STABILITY

SELECTION

OVER/VOLT U V W DROOP TRIM

EXC TRIP S1 S2 S1 S2 S1 S2 A1 A2

E0 E1 B0 B1 C B A

NEWAGE PRODUCT TRAINING

Operation of AVR - as an electronic switch

DIODE CIRCUIT SILICON CONTROLLED RECTIFIER (SCR)

Gate

A.C Power A.C Power

Supply AVR Supply

Control

Circuit

X

1/2 Wave D.C 1/2 Wave D.C

Exciter field Exciter field

A DIODE will conduct continuously, producing half wave rectification of the A.C supply.

A DIODE, however, would not CONTROL the D.C into the exciter field, which is necessary

to control the Generator voltage.

A SILICON CONTROLLED RECTIFIER (SCR or THYRISTOR) is a diode with a control

GATE.

The SCR will only switch ON when the GATE receives a signal from the AVR controls.

NEWAGE PRODUCT TRAINING

Operation of AVR - as an electronic switch

D.C Pulses

From A.V.R Into A.V.R A.C power supply from

Exciter Stator Main Stator

X+ (F1) XX- (F2) Sensing Supply

Exciter (2 or 3 phase)

Rotor

& Stator

Bearing

Main Rotor

Shaft

Rectifier

Fan

The AVR switches the D.C power supply ON and OFF 50 - 60 times per second.

For PMG powered AVR,s 100 - 120 times per second.

NEWAGE PRODUCT TRAINING

Operation of AVR - as an electronic switch

Phase Control of AVR power supply (Self Excited)

AC power supply to

AVR 170 to 240V.

50 or 60 HZ .

D.C Power supply (1/2 cycle rectification)

Power ON

After time (T)

Number of pulses are the same as the A.C power

OFF OFF

supply frequency (50 or 60/second)

NO LOAD D.C Pulses into the Exciter Stator X+(F1) XX-(F2)

(T) The power device (Thyristor or SCR) is switched ON by the control

circuit, after time delay (T).

The Thyristor automatically switches OFF as the power supply pulse

falls to zero after each cycle.

NEWAGE PRODUCT TRAINING

Operation of AVR - as an electronic switch

Phase Control of AVR power supply (Self Excited)

Power ON

After time

(T)

OF OF

F F

FULL LOAD D.C Pulses into the Exciter Stator X+(F1) XX-(F2)

(T)

As LOAD is increased , the time delay (T), will automatically decrease.

The larger the pulse area (in RED) the higher the D.C power into the exciter stator..

. The AVR will stabilise at the new output level , when the sensing signal into the

AVR has returned to normal (nominal) voltage, as pre-set on the ‘VOLTS’ adjustment.

NEWAGE PRODUCT TRAINING

Operation of AVR - as an electronic switch

Phase Control of AVR power supply (Self Excited)

Power ON

After time (T)

OFF OFF

OVERLOAD D.C Pulses into the Exciter Stator X+(F1) XX-(F2)

(T)

Although the red pulses are now termed ‘OVERLOAD’, the AVR requires this

additional power to provide a rapid response to transient load application, ( to

reduce voltage DIP).

This short term response demands ALL of the power supply available for

approximately 0.3 seconds, until the output voltage has returned to normal.

NEWAGE PRODUCT TRAINING

Excitation System - Separately Excited Generators

The Permanent Magnet Generator

(PMG)

P2, P3, P4 Power Supply To A.V.R

Generator Shaft (Non-Drive -End)

Dowel Pin for PMG Rotor Location

Ceramic Magnet Rotor, highly magnetic saturated field. 8 Pole Rotor , 100 HZ

(at 1500 RPM ) or 120 HZ (at 1800 RPM )

Through Bolt fixture to Shaft non drive end

Permanent Magnet Stator 3 Phase A.C 170 to 220 Volts, separate power

supply for the A.V.R

NEWAGE PRODUCT TRAINING

P.M.G Assembly UC Frame sizes

NEWAGE PRODUCT TRAINING

PMG Rotor & Stator Assembly - HC Frames

Optional on HC4,& HC5

3 Phase A.C, 170- 220 Volts

P.M.G

Rotor

P.M.G

Stator

in Housing

NEWAGE PRODUCT TRAINING

Excitation System - Separately Excited Generators

PMG

Power

P2 -P3 -P4 X+ (F1) A.V.R A.C Feedback

Supply 6-7-8 Signal only.

To A.V.R

XX- (F2) (Sensing)

Main Stator from Stator

Exciter

Rotor

& Stator

Bearing

Main Rotor

Shaft

Rectifier

Fan

NEWAGE PRODUCT TRAINING

Excitation System - Separately Excited Generators

Advantages of the PMG System

The PMG is a separate power supply for AVR, which is

unaffected by adverse loading conditions such as :-

Waveform distortion caused by non linear loads

Transient fault conditions in the distribution system.

Provides a powerful voltage build up system on initial run-

up, (does not rely upon residual magnetism)

Provides sustained short circuit current under fault

conditions, (requirement for all Marine classifications).

NEWAGE PRODUCT TRAINING

NEWAGE PRODUCT TRAINING

Вам также может понравиться

- Practical Troubleshooting of Electrical Equipment and Control CircuitsОт EverandPractical Troubleshooting of Electrical Equipment and Control CircuitsРейтинг: 4 из 5 звезд4/5 (5)

- An Introduction To Synchronous AlternatorДокумент44 страницыAn Introduction To Synchronous AlternatorPradeep Rajasekeran100% (4)

- Generator Excitation System Desing ConsiderationДокумент44 страницыGenerator Excitation System Desing ConsiderationSrinu Srinivasarao100% (6)

- Power Generator For MT-8BДокумент60 страницPower Generator For MT-8BTyan ScreamouscoreОценок пока нет

- EE360 - Synchronous MachinesДокумент85 страницEE360 - Synchronous MachinesAliAl-jaziriОценок пока нет

- ABB - Fuses Vs FuselessДокумент18 страницABB - Fuses Vs Fuselesskhalid100% (1)

- Power Pack Iom-952415 PDFДокумент1 305 страницPower Pack Iom-952415 PDFDev Dragos100% (1)

- Ch24 DynModelsДокумент155 страницCh24 DynModelselectrical_1012000Оценок пока нет

- Emergency Diesel Generator QUESTION AND ANSWERSДокумент19 страницEmergency Diesel Generator QUESTION AND ANSWERSRukma Goud ShakkariОценок пока нет

- Eddy Probe Systems PDFДокумент44 страницыEddy Probe Systems PDFVanessa Pajares LanciatoОценок пока нет

- Agn013 CДокумент10 страницAgn013 Cmohsen_cumminsОценок пока нет

- Masterpact Maint Guide 0613IB1202Документ204 страницыMasterpact Maint Guide 0613IB1202LeomonkeylrОценок пока нет

- Deep Sea Electronics: Typical Wiring Diagram DSE8610 MKII Installation InstructionsДокумент2 страницыDeep Sea Electronics: Typical Wiring Diagram DSE8610 MKII Installation InstructionsMohammad Badii Mosli0% (1)

- Induction Motor TorquesДокумент40 страницInduction Motor TorquesJaniel MalitОценок пока нет

- Commissioning Dept.: Power Systems DivisionДокумент84 страницыCommissioning Dept.: Power Systems DivisionMohamed Hamdallah100% (1)

- Modbus TCP TrainingДокумент45 страницModbus TCP Training123sam456Оценок пока нет

- 4.negative and Zero SequenceДокумент6 страниц4.negative and Zero Sequencebalaer0550% (2)

- Parallel Operation of GeneratorsДокумент7 страницParallel Operation of GeneratorsHeru SetiawanОценок пока нет

- ComAp Hybrid Solution PDFДокумент31 страницаComAp Hybrid Solution PDFRakih SajidОценок пока нет

- Breaker Sace EmaxДокумент97 страницBreaker Sace EmaxfujitoОценок пока нет

- 3500 Series Competitive Presentation (50 HZ)Документ40 страниц3500 Series Competitive Presentation (50 HZ)Mohamed HamdallahОценок пока нет

- Cat 3512 Land Electric-Drive Drilling ModulesДокумент57 страницCat 3512 Land Electric-Drive Drilling ModulesBilel Ben SlamaОценок пока нет

- Lecture Notes-Basic Electrical and Electronics Engineering Notes PDFДокумент30 страницLecture Notes-Basic Electrical and Electronics Engineering Notes PDFMDR PRAPHU100% (1)

- Npt56 Excitation SystemsДокумент13 страницNpt56 Excitation Systemsengmohsen.ramadanhotmail.comОценок пока нет

- 2.041 Woodward - EasyGen O&M PDFДокумент69 страниц2.041 Woodward - EasyGen O&M PDFJoséОценок пока нет

- Manual FriwoДокумент7 страницManual FriwoLeonardo Pizetta FerreiraОценок пока нет

- Gen Reactance STAMFORDДокумент6 страницGen Reactance STAMFORDHashim Othman IIОценок пока нет

- Protection Relay REX 521: Technical Reference Manual, Standard ConfigurationsДокумент250 страницProtection Relay REX 521: Technical Reference Manual, Standard Configurationsjof853Оценок пока нет

- MTU Diesel & Gas Turbine Electric Propulsion For Cruise ShipsДокумент6 страницMTU Diesel & Gas Turbine Electric Propulsion For Cruise Shipsamin_corporation100% (1)

- InteliDrive Getting StartedДокумент17 страницInteliDrive Getting StartedthyagoenergОценок пока нет

- Broadcrown CatalogueДокумент28 страницBroadcrown CatalogueSerimОценок пока нет

- Avtron Load BanksДокумент53 страницыAvtron Load BanksPaul RasmussenОценок пока нет

- Synchronous CondensersДокумент2 страницыSynchronous CondensersChandra Sekaran Saravanan100% (1)

- Seminar On .: Lubricating SystemДокумент25 страницSeminar On .: Lubricating SystemPradyumna Keshari NahakОценок пока нет

- Manual de Aprendizaje de Generación Eléctrica WoodwardДокумент54 страницыManual de Aprendizaje de Generación Eléctrica Woodwardmanuel100% (2)

- Diesel & GT Worldwide Jan-Feb 16Документ44 страницыDiesel & GT Worldwide Jan-Feb 16ratninp9368Оценок пока нет

- Derating Stamford PDFДокумент1 страницаDerating Stamford PDFPowerTechОценок пока нет

- COMAP-Electronic Engines Support January-08Документ163 страницыCOMAP-Electronic Engines Support January-08mahmod alrousanОценок пока нет

- 2-Pole Turbine Driven Generators - Brushless ExcitationДокумент2 страницы2-Pole Turbine Driven Generators - Brushless ExcitationChandrasekar Karuppasamy100% (1)

- Leroy SomerДокумент6 страницLeroy SomerRicky jОценок пока нет

- Operator 2011Документ68 страницOperator 2011romulooliveiraaraujo100% (1)

- PF CalculationДокумент7 страницPF CalculationsanjayОценок пока нет

- ComAP Powermanagement Load Reserve Calculation V3Документ8 страницComAP Powermanagement Load Reserve Calculation V3pdealersОценок пока нет

- STAMFORD Industrial Ratings Book 2Документ64 страницыSTAMFORD Industrial Ratings Book 2Murali SubramaniОценок пока нет

- Wip May2013Документ56 страницWip May2013Orlando BarriosОценок пока нет

- Parallel Operation of GeneratorsДокумент6 страницParallel Operation of GeneratorsKhaldoon AlnashiОценок пока нет

- Tor Knowledge 20Документ89 страницTor Knowledge 20Manual StoreeОценок пока нет

- Ddec Features PreliminaryДокумент120 страницDdec Features PreliminaryAntony MorenoОценок пока нет

- Auto Synchronizing 6200 SeriesДокумент2 страницыAuto Synchronizing 6200 SeriesJawid YousofОценок пока нет

- Induction MotorДокумент11 страницInduction MotorMsKarolyОценок пока нет

- Voltage Regulator and Parallel OperationДокумент29 страницVoltage Regulator and Parallel Operationsaulcastano6556Оценок пока нет

- PMG PDFДокумент6 страницPMG PDFrajan_2002eeeОценок пока нет

- CGT - How A Generator WorksДокумент84 страницыCGT - How A Generator WorksStephane TronquetОценок пока нет

- Engineering Utilities 1: Engr. Ianness Glen P. SabillaДокумент38 страницEngineering Utilities 1: Engr. Ianness Glen P. SabillaSherrie Anne AbolocОценок пока нет

- Electricity IntroДокумент31 страницаElectricity IntroMike Jacson BautistaОценок пока нет

- Lab 1-1a IntroductionДокумент32 страницыLab 1-1a IntroductionafsОценок пока нет

- EECE 1312: Chapter 1: Introduction To Electronics Section 10 & 11 DR Aliza Aini MD RalibДокумент51 страницаEECE 1312: Chapter 1: Introduction To Electronics Section 10 & 11 DR Aliza Aini MD RalibMuhammad nuruddinОценок пока нет

- Q4-L5 - Electric Currents, Circuits, & Ohm's Law (For Notes)Документ22 страницыQ4-L5 - Electric Currents, Circuits, & Ohm's Law (For Notes)rhenzmarielle.pasionОценок пока нет

- Ankush Physics ProjectДокумент6 страницAnkush Physics ProjectSAVITRI GURJARОценок пока нет

- MSQs BiochemistryДокумент2 страницыMSQs Biochemistryabid azizОценок пока нет

- Introduction To The NEC: 1: Purpose and HistoryДокумент13 страницIntroduction To The NEC: 1: Purpose and Historyabid azizОценок пока нет

- UPS Weekly Check ListДокумент5 страницUPS Weekly Check Listabid azizОценок пока нет

- 28 Days Diet PlanДокумент9 страниц28 Days Diet Planabid azizОценок пока нет

- Etsyllabus 2016Документ104 страницыEtsyllabus 2016abid azizОценок пока нет

- Basic GC Measurements and Calculations: LC - GC Europe - February 2001Документ5 страницBasic GC Measurements and Calculations: LC - GC Europe - February 2001abid azizОценок пока нет

- .Au ProductsAndServices Pages LubricantProДокумент3 страницы.Au ProductsAndServices Pages LubricantProabid azizОценок пока нет

- TWMC O&m Manual - 5000 Frames PlusДокумент146 страницTWMC O&m Manual - 5000 Frames Plusabid azizОценок пока нет

- 8 - Control LoopsДокумент10 страниц8 - Control Loopsabid azizОценок пока нет

- GPCDOC Local TDS Canada Shell Turbo T 68 (en-CA) TDS v1Документ2 страницыGPCDOC Local TDS Canada Shell Turbo T 68 (en-CA) TDS v1abid azizОценок пока нет

- Motor Selection Guide: A Kaizen Project: By: Jeff Andrus & Andrew FindlayДокумент11 страницMotor Selection Guide: A Kaizen Project: By: Jeff Andrus & Andrew Findlayabid azizОценок пока нет

- BP Texas City Incident: Baker ReviewДокумент2 страницыBP Texas City Incident: Baker Reviewabid azizОценок пока нет

- Basic Instrumentation: Delivered byДокумент7 страницBasic Instrumentation: Delivered byabid azizОценок пока нет

- Parasitic CapacitanceДокумент6 страницParasitic Capacitanceabid azizОценок пока нет

- Captured by Data: Enterprise Asset Management Systems (EAM) and The Aims of Modern MaintenanceДокумент14 страницCaptured by Data: Enterprise Asset Management Systems (EAM) and The Aims of Modern Maintenanceabid azizОценок пока нет

- Original: C40 - Données Techniques Technical DataДокумент61 страницаOriginal: C40 - Données Techniques Technical Dataabid aziz100% (1)

- Handouts Mike Gehloff Wrench Time PDFДокумент8 страницHandouts Mike Gehloff Wrench Time PDFabid azizОценок пока нет

- LG-H930DS IND UG Web V1.0 171128Документ178 страницLG-H930DS IND UG Web V1.0 171128corustОценок пока нет

- Carpeta Tecnica, Formato Digital PDFДокумент202 страницыCarpeta Tecnica, Formato Digital PDFAugusto Francisco Diaz LaraОценок пока нет

- Instruction Sheet: DOP-107BV (Front View)Документ2 страницыInstruction Sheet: DOP-107BV (Front View)Víctor Josemaria Rivero DunoОценок пока нет

- Manual On Lead Acid BatteriesДокумент100 страницManual On Lead Acid Batterieschandra mouliОценок пока нет

- FaqДокумент9 страницFaqesteban lizamaОценок пока нет

- Clack EI Programming ManualДокумент16 страницClack EI Programming ManualAndres GarciaОценок пока нет

- Lan Wmbus g2 P v2 2Документ1 страницаLan Wmbus g2 P v2 2David SchmidtОценок пока нет

- Design of Electrical Wiring Harness For EV and Charging of Battery by Wind Energy Ijariie20194Документ6 страницDesign of Electrical Wiring Harness For EV and Charging of Battery by Wind Energy Ijariie20194arun.nagarkarОценок пока нет

- Installation Manual: Glendinning Electronic Engine ControlsДокумент56 страницInstallation Manual: Glendinning Electronic Engine ControlsFedilino P. Fornolles100% (1)

- Citizen Instruction Manual J810 PDFДокумент17 страницCitizen Instruction Manual J810 PDFKridsadaTKsОценок пока нет

- Turnigy D2830-11 1000kV - Ecalc - PropcalcДокумент2 страницыTurnigy D2830-11 1000kV - Ecalc - PropcalcdurrohОценок пока нет

- Mshe 112 002 - C4Документ18 страницMshe 112 002 - C4Automan IntertradeОценок пока нет

- 4104 inДокумент1 страница4104 inDanielОценок пока нет

- S8 ConnectionДокумент406 страницS8 ConnectionsujingthetОценок пока нет

- Kodak Easyshare Dx7440 Zoom Digital Camera: User'S GuideДокумент67 страницKodak Easyshare Dx7440 Zoom Digital Camera: User'S GuideMaría Paula MorenoОценок пока нет

- MH320 Eng ManualДокумент27 страницMH320 Eng Manualnang ndutОценок пока нет

- A Hierarchical Active Balancing Architecture For Lithium-Ion BatteriesДокумент12 страницA Hierarchical Active Balancing Architecture For Lithium-Ion BatteriestgangwarОценок пока нет

- Manual Bomag BW 180-184 AdДокумент118 страницManual Bomag BW 180-184 AdРуденко Роман100% (4)

- User Manual: PF0.9 1K/1.5K/2K/3K Online UPSДокумент19 страницUser Manual: PF0.9 1K/1.5K/2K/3K Online UPSDuvan VacaОценок пока нет

- DS3000 USER MANUAL EN Rev0-51 Release 130613Документ57 страницDS3000 USER MANUAL EN Rev0-51 Release 130613Luis AlbertoОценок пока нет

- TP 5024Документ62 страницыTP 5024Mike McCauleyОценок пока нет

- Widex Moment™ Mini Ric Rechargeable With V.2 Ric M-Receiver V.2 Ric M-Receiver Mrr2DДокумент2 страницыWidex Moment™ Mini Ric Rechargeable With V.2 Ric M-Receiver V.2 Ric M-Receiver Mrr2DAdna GezoОценок пока нет

- Bendix King kx99 Operator ManualДокумент35 страницBendix King kx99 Operator ManualGlenn Martin100% (2)

- Operation Manual: Battery ChargerДокумент6 страницOperation Manual: Battery Chargerkenjyaitc100% (1)

- Rev DДокумент28 страницRev DAdrian LepadatuОценок пока нет

- OPM - VHU0K73K0XU - TNR Installation and Instruction - OPM - VHU0K73K0XU - PDF&filename GE - UPS - OPM - VHU - 0K7 - 3K0 - XUS - V011Документ25 страницOPM - VHU0K73K0XU - TNR Installation and Instruction - OPM - VHU0K73K0XU - PDF&filename GE - UPS - OPM - VHU - 0K7 - 3K0 - XUS - V011Khách Sạn Hoàng PhốОценок пока нет

- NP-DK50 DS-23 08-2018 en de FRДокумент78 страницNP-DK50 DS-23 08-2018 en de FRSoporte Técnico Grupo SIM100% (1)

- FTA1100J Diesel Engine Fire Pump Controllers Product DescriptionДокумент2 страницыFTA1100J Diesel Engine Fire Pump Controllers Product Descriptionrahu2260100% (1)

- SSC Gr10 Electronics Q4 Module 5 WK 5 - v.01-CC-released-1June2021Документ18 страницSSC Gr10 Electronics Q4 Module 5 WK 5 - v.01-CC-released-1June2021Vj AleserОценок пока нет

- Service Manual Liftstar-2014Документ46 страницService Manual Liftstar-2014Adam SchwemleinОценок пока нет