Академический Документы

Профессиональный Документы

Культура Документы

Design and Experimental Investigation of Pedal Powered Water Pump

Загружено:

IJRASETPublicationsАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Design and Experimental Investigation of Pedal Powered Water Pump

Загружено:

IJRASETPublicationsАвторское право:

Доступные форматы

International Journal for Research in Applied Science & Engineering Technology (IJRASET)

ISSN: 2321-9653; IC Value: 45.98; SJ Impact Factor: 6.887

Volume 6 Issue XI, Nov 2018- Available at www.ijraset.com

Design and Experimental Investigation of Pedal

Powered Water Pump

L. Manoj kumar1

1

UG Student, Department of Mechanical Engineering, Raghu Institute of Technology college, Andhra University, Visakhapatnam,

Andhra Pradesh, India

Abstract: The aim of this project is to create a pedal powered water pump by using centrifugal pump. The purpose of this work is

to build the pedal powered water pump. Replacing the existing electric system into pedal powered operating system to pump the

water. This is a low cost system and it can be placed anywhere, the main advantage of this system is no use of electricity.

This project deals with pedal powered centrifugal pump. The two main components of a centrifugal pump are the impeller and

the casting. The impeller is a rotating component and the casing is a stationery component. In centrifugal pump, water enters

axially through the impeller eyes and water exists radially. The pump casing is to guide the liquid to the impeller, converts into

pressure. The high velocity kinetic energy of the flow from the impeller discharge and leads away of the energy having imparted

to the liquid comes from the volute casing. The centrifugal pump is the most useful mechanical rotor dynamic machine in fluid

works which widely used in domestic, irrigation, industry, large plant and river water pumping system.

The present work deals with construction and modelling of pedal powered centrifugal pump. A small prototype is made. This can

be achieved by various component such as half HP centrifugal pump, bicycle, stand and various attachments.

Keywords: centrifugal pump, impeller, pedal powered, volute casing, kinetic energy.

I. INTRODUCTION

In under developed countries are used medium head, low volume pumps. Such pumps, however satisfy stringent constraints due to

which they are exposed. The units must be extremely low cost, ultra-reliable and almost elegantly simple. They must be simple

enough in construction that local people dependably trained for the maintenance and operation of these units cost and need of fuel,

lubricants and maintenance eliminate when we used pedal powered water pumps. This leads to the simple power source-human

power. Various schemes have been devised for producing and coupling muscle power. But, by far the most applicable, is the bicycle

and the drives achieved from it. This is due to the world wide availability of low cost bicycles. The mechanism is simplicity, low

cost, low maintenance in the pump unit. The mechanism consists of centrifugal pump which is attached with the rear wheel of the

bicycle. This project could helpful for rural areas.it can be used mainly for irrigation an water drawing water from wells and other

water bodies. This is a centrifugal water pump which is run by rotating the pedal of a cycle. The system comprise a working bicycle,

impeller, pulley and inlet and delivery pipes.The test pump was built by a rear wheel of bicycle is attached to the driving shaft of

pump connected with an impeller through this is used to lift water from a pipe into the form for cultivation. This innovation is useful

for pumping water from river, ponds, wells and similar water sources thus enabling for pumping water for irrigation and cultivation

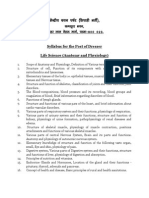

II. MODELLING OF PEDAL POWERED WATER PUMP

A. Components of Centrifugal Pump

A centrifugal pump has two main components:

1) A rotating component comprised of an impeller and a shaft

2) A stationery component comprised of a casing, casing cover and bearing

Fig .1 Components of Pump

©IJRASET: All Rights are Reserved 55

International Journal for Research in Applied Science & Engineering Technology (IJRASET)

ISSN: 2321-9653; IC Value: 45.98; SJ Impact Factor: 6.887

Volume 6 Issue XI, Nov 2018- Available at www.ijraset.com

B. Fabrication of the Stand

Fabrication of the supported stand designed and model is the main part of the whole idea. The fabrication consisted of many other

machining methods like welding, metal cutting etc.

C. Preparation of the Chassis

The preparation of the chassis for the whole set up is considered the main part of the fabrication as it is the main criteria where the

rigidity, balancing and stability of the stand is studied and maintained accordingly.by maintain the balancing and stability the

equipment gives the guarantee of being operated at any condition or environmental . The machining processes that are used in the

making of the chassis are arc welding and metal cutting.

Fig. 2 Design of chassis

D. Welding

Arc welding is a type that uses a welding power supply to create an electric arc between an electrode and the base material to melt

the metals at the welding point. They can use direct (DC) or alternating (AC) current, and consumable or non-consumable

electrodes. The welding region is usually protected by shielding gas or slag.

III. SPECIFICATIONS OF THE PUMP

1) Capacity of the pump = 0.5Hp

2) Speed of the shaft or impeller = 2500 rpm

3) Head of the pump = 20m

4) Diameter of shaft = 6cm

5) Rotor diameter = 18cm

6) Wheel diameter = 72cm

The torque required for driving the pump during pedaling is obtained by: The power transmitted from pedal to the pump is given by

P=2π / 60 (5)

Where,

N = speed of the pump during manual pedaling and T= torque required to drive the pump.

The torque generated by human pedaling is obtained by:

Recall that the power transmitted from pedaling to the pump is given by

P=2π / 60

Where,

N = pedaling speed and T = torque developed by pedal.

The rated for healthy human being is approximately 250 watts [5].

©IJRASET: All Rights are Reserved 56

International Journal for Research in Applied Science & Engineering Technology (IJRASET)

ISSN: 2321-9653; IC Value: 45.98; SJ Impact Factor: 6.887

Volume 6 Issue XI, Nov 2018- Available at www.ijraset.com

IV. WORKING OF PEDAL POWERED WATER PUMP

The mechanism consists of centrifugal pump which is attached with the rear wheel of the bicycle. The system comprises a working

bicycle, impeller, pulley, inlet and delivery pipes. A rear wheel of bicycle is attached to driving shaft of pump connected with an

impeller through this is used to lift water from a pipe into the form for cultivation. The suction and delivery pipes are then

connected to the suction and delivery ports respectively. Manual priming of the centrifugal pump is done next. By pedaling the rpm

of the rotor shaft is measured using tachometer. The flow rate of water is measured by using measuring tank and stop watch. Such

that the water lifted is measured in terms of liters per seconds.

Fig. 3 Working of Pedal Powered Water Pump

V. RESULTS & DISCUSSIONS

TABLE I.

S.NO SPEED DISCHARGE TIME

(rpm) (liters) (sec)

01 1900 01 18

02 2300 01 12

03 2500 01 10

From the table I, for pedal powered water pump at the speed of 1900 rpm and discharge for 1 liter, the time taken is 18 sec. Thus,

for the speed of 2300 rpm and discharge for 1 liter, the time taken is 12 sec. Therefore, for the speed of 2500 rpm and discharge for

1 liter, the time taken is 10 liters.

It is observed from the fig 4, that as the speed of the pedal powered water pump at various speed increases at same discharge rate,

time decreases gradually

20 18

15 12

10

10

TIME (sec)

0

1900 2300 2500

SPEED (rpm)

Fig. 4 graph show variation of time vs speed

©IJRASET: All Rights are Reserved 57

International Journal for Research in Applied Science & Engineering Technology (IJRASET)

ISSN: 2321-9653; IC Value: 45.98; SJ Impact Factor: 6.887

Volume 6 Issue XI, Nov 2018- Available at www.ijraset.com

It is also observed during experiment that:

1) 1 complete revolution of pedal powered is equal to 3 revolutions of wheel.

2) 1 complete revolution of wheel=72/18=4 revolutions of impeller shaft.

3) 1 complete pedaling = 4*3=12 revolutions of impeller shaft.

VI. CONCLUSION

A. The machine is tested on the farming land and got the satisfactory results.

B. The conventional centrifugal pump needs either electricity or diesel engine, but the present innovation works on pedaling.

C. But the same pedal power can be used for other purposes such as to generate electricity, to operate hand tools or agricultural

tools.

D. This is a non-polluting and environment friendly device.

E. It requires less maintenance and minimum input energy is required to get the maximum output of water.

F. This device can be transported easily from one place to another.

G. The equipment is purposely design for the farmers having small farming land.

H. The performance of the equipment will increase when it is operates on the high speed.

I. The whole study over the topic that the bicycle powered water pump is a very advantage especially for rural areas.

J. By use of this project electricity is saved and a particular water head and supply the water for irrigation.

REFERENCES

[1] Aemolo sumuel akinwanmi, Stephan kwasi adzimah, Fredick oppong “pedal powered centrifugal pump purified water supply device” published innovation

system design and engineering.

[2] M.serazul Islam, M. Zakaria Hossain and M.abdul khair “design and development of pedal pump for low –lift irrigation” publisher JARD.

[3] Atul.P.Ganorkar, K.S.Zakiuddin, H.A.Hussain, “An Experiment on Development of Pedal Operated Water Pump”, IOSR, e-ISSN:2278-1684,(2014).

[4] Vishal Garg, Neelesh Khandare, Gautam Yadav, “ An Experimental Setup and Design of Pedal Powered Water Pump”, International Journal of Engineering

Research and Technology (Vol.2, Issue.1) (2013).

[5] Khurmi R.S., Gupta J.K. (2005): A Textbook of Machine Design, Fourteenth Edition, ERASIA Publishing House (PVT) LTD. Ram Nagar, New Dheli, India

[6] Bryan Lee, “A Design of Simple Human Powered Water Pump”, International Journal of Technology (2007).

[7] Rajesh Kannan Megalingam, Pranav Sreedharan Veliyara ,Raghavendra Murali Prabhu, Rocky Katoch,’pedal power generation”, International Journal of

applied engineering research,ISSN 0973-4562 Vol.7No.11(2012)

©IJRASET: All Rights are Reserved 58

Вам также может понравиться

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideОт EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideРейтинг: 4 из 5 звезд4/5 (8)

- Pedal Operated Centrifugal Water PumpДокумент19 страницPedal Operated Centrifugal Water PumpNeelmani100% (3)

- Specificities of The Terminology in AfricaДокумент2 страницыSpecificities of The Terminology in Africapaddy100% (1)

- TCL LD24D50 - Chassis MS09A-LA - (TKLE2413D) - Manual de Servicio PDFДокумент41 страницаTCL LD24D50 - Chassis MS09A-LA - (TKLE2413D) - Manual de Servicio PDFFabian OrtuzarОценок пока нет

- Water Hydraulic Actuators For ITER Maintenance DevicesДокумент5 страницWater Hydraulic Actuators For ITER Maintenance DevicesRaja GoshОценок пока нет

- Design of High Efficiency Pelton Turbine For Microhydropower PlantДокумент14 страницDesign of High Efficiency Pelton Turbine For Microhydropower PlantMohamed MagdyОценок пока нет

- Treadle Pump Operation With Rotary MotionДокумент8 страницTreadle Pump Operation With Rotary MotionKanishk JainОценок пока нет

- Ijert Ijert: Design and Experimental Setup of Pedal Operated Water PumpДокумент5 страницIjert Ijert: Design and Experimental Setup of Pedal Operated Water PumpSri LekhaОценок пока нет

- 2design of Hydraulic Power Pack For Vertical Turret Lathe GM21Feb14 PDFДокумент10 страниц2design of Hydraulic Power Pack For Vertical Turret Lathe GM21Feb14 PDFSamik MukherjeeОценок пока нет

- Design of Cross Flow Turbine (Runner and Shaft) : San San Yi, Aung Myo Htoo, Myint Myint SeinДокумент5 страницDesign of Cross Flow Turbine (Runner and Shaft) : San San Yi, Aung Myo Htoo, Myint Myint SeinmirfanwibisonoОценок пока нет

- V2i1 Ijertv2is1264Документ6 страницV2i1 Ijertv2is1264swapnil kaleОценок пока нет

- Paddle Powered Water PumpДокумент35 страницPaddle Powered Water PumpJahanzaib Khan100% (1)

- KCE074BCE009 Centrifugal PumpДокумент8 страницKCE074BCE009 Centrifugal Pumpबम सरकार धिरेन्द्रОценок пока нет

- Design of Cross Flow Turbine (Runner and Shaft) : San San Yi, Aung Myo Htoo, Myint Myint SeinДокумент5 страницDesign of Cross Flow Turbine (Runner and Shaft) : San San Yi, Aung Myo Htoo, Myint Myint SeinSamvel HayrapetyanОценок пока нет

- Design of High Efficiency Pelton Turbine For Micro-HydropowerДокумент13 страницDesign of High Efficiency Pelton Turbine For Micro-HydropowergertjaniОценок пока нет

- Design and Testing of Hydraulic Actuator in Typical Areospace VehicleДокумент9 страницDesign and Testing of Hydraulic Actuator in Typical Areospace VehicleIJRASETPublicationsОценок пока нет

- A Review On Design and Flow Simulation in An Axial Flow Hydro TurbineДокумент3 страницыA Review On Design and Flow Simulation in An Axial Flow Hydro TurbineAron H OcampoОценок пока нет

- Ijert Ijert: Design and Flow Through CFD Analysis of Enclosed ImpellerДокумент8 страницIjert Ijert: Design and Flow Through CFD Analysis of Enclosed ImpellerguganesannnОценок пока нет

- Water Energy Drive Spindle Supported by Water Nakao Exp SpindleДокумент5 страницWater Energy Drive Spindle Supported by Water Nakao Exp SpindleAlice MarinescuОценок пока нет

- Ijert Ijert: Design and Modelling of A Pelton Wheel BucketДокумент3 страницыIjert Ijert: Design and Modelling of A Pelton Wheel BucketDwi ApОценок пока нет

- Flow Simulation and Efficiency Hill Chart Prediction For A Propeller TurbineДокумент11 страницFlow Simulation and Efficiency Hill Chart Prediction For A Propeller TurbinehoracioОценок пока нет

- The Design of A Peristaltic Pump: Interim ReportДокумент8 страницThe Design of A Peristaltic Pump: Interim ReportVaruna PriyankaОценок пока нет

- DESIGNOFHIGHEFFICIENCYPELTONTURBINEFORMICRO HYDROPOWERplant PDFДокумент13 страницDESIGNOFHIGHEFFICIENCYPELTONTURBINEFORMICRO HYDROPOWERplant PDFSadrakhОценок пока нет

- A CFD Model For Orbital Gerotor MotorДокумент13 страницA CFD Model For Orbital Gerotor Motorkanteron6443Оценок пока нет

- Flow Simulation and Efficiency Hill Chart Prediction For A Propeller TurbineДокумент11 страницFlow Simulation and Efficiency Hill Chart Prediction For A Propeller TurbineFabio FolpiniОценок пока нет

- 7 Chapter 7 Hydro WaterPowerPlantДокумент84 страницы7 Chapter 7 Hydro WaterPowerPlantKhadar teeriОценок пока нет

- Design and Development of Centrifugal Pump ImpellerДокумент7 страницDesign and Development of Centrifugal Pump ImpellerAmpera marzelaОценок пока нет

- 6E - Group Assignment Fluid Mechanics IIДокумент22 страницы6E - Group Assignment Fluid Mechanics IIAfnan MazОценок пока нет

- 7 Chapter 7 Hydro WaterPowerPlantДокумент84 страницы7 Chapter 7 Hydro WaterPowerPlantJim Lee LorenzoОценок пока нет

- Design and Development of Centrifugal Pump ImpellerДокумент7 страницDesign and Development of Centrifugal Pump ImpellerSindhurОценок пока нет

- Solar Agriculture Water Sprayer: ProjectreportДокумент65 страницSolar Agriculture Water Sprayer: ProjectreportVenkatram PrabhuОценок пока нет

- Zhao 2013Документ9 страницZhao 2013haris shehzadОценок пока нет

- MEM - Project Pump and TurbineДокумент22 страницыMEM - Project Pump and TurbineAbhi ChavanОценок пока нет

- Mech FinalДокумент16 страницMech FinalBabu JmldОценок пока нет

- IJETR021761 LibreДокумент3 страницыIJETR021761 LibreLindgrenОценок пока нет

- Ce ReportДокумент29 страницCe ReportDhiraj NayakОценок пока нет

- 7 Chapter 7 Hydro WaterPowerPlant PDFДокумент84 страницы7 Chapter 7 Hydro WaterPowerPlant PDFEasy WriteОценок пока нет

- Axial Pump Impeller DesignДокумент8 страницAxial Pump Impeller DesignRioEstikaОценок пока нет

- I RJ Mets 40300097618Документ10 страницI RJ Mets 40300097618design gipfelОценок пока нет

- CFD Analysis of Centrifugal Pump ImpelleДокумент9 страницCFD Analysis of Centrifugal Pump Impelleبلال بن عميرهОценок пока нет

- Fpe DBC 5th Sem AssignmentДокумент10 страницFpe DBC 5th Sem AssignmentJain shahilkumarОценок пока нет

- Fabrication of Cross-Flow Bio-Micro-TurbineДокумент4 страницыFabrication of Cross-Flow Bio-Micro-TurbineDragana LekicОценок пока нет

- Design, Development and Automation of Hydraulic Broaching MachineДокумент8 страницDesign, Development and Automation of Hydraulic Broaching MachineMuftah AhmedОценок пока нет

- Mini ProjectДокумент33 страницыMini Projectprakash059050% (4)

- Power Plant Lecture Notes - CHAPTER-7 Hydro-Water Power PlantДокумент84 страницыPower Plant Lecture Notes - CHAPTER-7 Hydro-Water Power PlantHiteshОценок пока нет

- Design and Analysis of Conical Draft TubeДокумент31 страницаDesign and Analysis of Conical Draft TubeDhiraj NayakОценок пока нет

- Hydraulic System Design of Combined Harvester HeadДокумент7 страницHydraulic System Design of Combined Harvester HeadEmma OkurutОценок пока нет

- An Exploratory Review On Energy Efficient Techniques For DC Drive SystemДокумент7 страницAn Exploratory Review On Energy Efficient Techniques For DC Drive SystemIJIERT-International Journal of Innovations in Engineering Research and TechnologyОценок пока нет

- Gear PumpДокумент21 страницаGear PumpMudassir Hussain86% (7)

- 7 Chapter 7 Hydro WaterPowerPlantДокумент84 страницы7 Chapter 7 Hydro WaterPowerPlantPADMAJAREDDYОценок пока нет

- Performance Analysis of Mixed Flow Pump Impeller Using CFDДокумент6 страницPerformance Analysis of Mixed Flow Pump Impeller Using CFDFauzi AkmalОценок пока нет

- Design and Fabrication of Impeller For SДокумент7 страницDesign and Fabrication of Impeller For Sdesign gipfelОценок пока нет

- 909design of High Efficiency Pelton Turbine For Micro-HydropowerДокумент13 страниц909design of High Efficiency Pelton Turbine For Micro-HydropowerrachidtuОценок пока нет

- An Example Design of The Crossflow TurbineДокумент58 страницAn Example Design of The Crossflow TurbineBryan NanaОценок пока нет

- 7 Chapter 7 Hydro WaterPowerPlantДокумент84 страницы7 Chapter 7 Hydro WaterPowerPlantmlsawhney2996Оценок пока нет

- 908design of High Efficiency Cross-Flow TurbineДокумент4 страницы908design of High Efficiency Cross-Flow TurbineAdi Setiadi100% (1)

- Design, Fabrication and Test of A Polymer Air Driven Microturbine For Micropower GenerationДокумент5 страницDesign, Fabrication and Test of A Polymer Air Driven Microturbine For Micropower GenerationL̶e̶o̶v̶a̶r̶d̶o̶ A̶l̶v̶a̶r̶e̶z̶Оценок пока нет

- Modern Borehole Analytics: Annular Flow, Hole Cleaning, and Pressure ControlОт EverandModern Borehole Analytics: Annular Flow, Hole Cleaning, and Pressure ControlОценок пока нет

- IoT-Based Smart Medicine DispenserДокумент8 страницIoT-Based Smart Medicine DispenserIJRASETPublications100% (1)

- Advanced Wireless Multipurpose Mine Detection RobotДокумент7 страницAdvanced Wireless Multipurpose Mine Detection RobotIJRASETPublicationsОценок пока нет

- Design and Analysis of Fixed-Segment Carrier at Carbon Thrust BearingДокумент10 страницDesign and Analysis of Fixed-Segment Carrier at Carbon Thrust BearingIJRASETPublicationsОценок пока нет

- Skill Verification System Using Blockchain SkillVioДокумент6 страницSkill Verification System Using Blockchain SkillVioIJRASETPublicationsОценок пока нет

- Controlled Hand Gestures Using Python and OpenCVДокумент7 страницControlled Hand Gestures Using Python and OpenCVIJRASETPublicationsОценок пока нет

- Air Conditioning Heat Load Analysis of A CabinДокумент9 страницAir Conditioning Heat Load Analysis of A CabinIJRASETPublicationsОценок пока нет

- 11 V May 2023Документ34 страницы11 V May 2023IJRASETPublicationsОценок пока нет

- BIM Data Analysis and Visualization WorkflowДокумент7 страницBIM Data Analysis and Visualization WorkflowIJRASETPublicationsОценок пока нет

- Design and Analysis of Components in Off-Road VehicleДокумент23 страницыDesign and Analysis of Components in Off-Road VehicleIJRASETPublicationsОценок пока нет

- Design and Analysis of Fixed Brake Caliper Using Additive ManufacturingДокумент9 страницDesign and Analysis of Fixed Brake Caliper Using Additive ManufacturingIJRASETPublicationsОценок пока нет

- Credit Card Fraud Detection Using Machine Learning and BlockchainДокумент9 страницCredit Card Fraud Detection Using Machine Learning and BlockchainIJRASETPublications100% (1)

- Real Time Human Body Posture Analysis Using Deep LearningДокумент7 страницReal Time Human Body Posture Analysis Using Deep LearningIJRASETPublications100% (1)

- TNP Portal Using Web Development and Machine LearningДокумент9 страницTNP Portal Using Web Development and Machine LearningIJRASETPublicationsОценок пока нет

- A Review On Speech Emotion Classification Using Linear Predictive Coding and Neural NetworksДокумент5 страницA Review On Speech Emotion Classification Using Linear Predictive Coding and Neural NetworksIJRASETPublicationsОценок пока нет

- Experimental Study of Partial Replacement of Cement by Pozzolanic MaterialsДокумент9 страницExperimental Study of Partial Replacement of Cement by Pozzolanic MaterialsIJRASETPublicationsОценок пока нет

- Real-Time Video Violence Detection Using CNNДокумент7 страницReal-Time Video Violence Detection Using CNNIJRASETPublicationsОценок пока нет

- A Blockchain and Edge-Computing-Based Secure Framework For Government Tender AllocationДокумент10 страницA Blockchain and Edge-Computing-Based Secure Framework For Government Tender AllocationIJRASETPublicationsОценок пока нет

- Comparative in Vivo Study On Quality Analysis On Bisacodyl of Different BrandsДокумент17 страницComparative in Vivo Study On Quality Analysis On Bisacodyl of Different BrandsIJRASETPublicationsОценок пока нет

- Skin Lesions Detection Using Deep Learning TechniquesДокумент5 страницSkin Lesions Detection Using Deep Learning TechniquesIJRASETPublicationsОценок пока нет

- Low Cost Scada System For Micro IndustryДокумент5 страницLow Cost Scada System For Micro IndustryIJRASETPublicationsОценок пока нет

- Design and Development of Cost-Effective 3D-PrinterДокумент7 страницDesign and Development of Cost-Effective 3D-PrinterIJRASETPublicationsОценок пока нет

- CryptoDrive A Decentralized Car Sharing SystemДокумент9 страницCryptoDrive A Decentralized Car Sharing SystemIJRASETPublications100% (1)

- Preparation of Herbal Hair DyeДокумент12 страницPreparation of Herbal Hair DyeIJRASETPublications100% (1)

- Literature Review For Study of Characteristics of Traffic FlowДокумент10 страницLiterature Review For Study of Characteristics of Traffic FlowIJRASETPublicationsОценок пока нет

- Vehicles Exhaust Smoke Detection and Location TrackingДокумент8 страницVehicles Exhaust Smoke Detection and Location TrackingIJRASETPublications100% (1)

- Achieving Maximum Power Point Tracking With Partial ShadingДокумент10 страницAchieving Maximum Power Point Tracking With Partial ShadingIJRASETPublicationsОценок пока нет

- An Automatic Driver's Drowsiness Alert SystemДокумент7 страницAn Automatic Driver's Drowsiness Alert SystemIJRASETPublications100% (1)

- Smart Video Surveillance Using YOLO Algorithm and OpenCVДокумент8 страницSmart Video Surveillance Using YOLO Algorithm and OpenCVIJRASETPublications100% (1)

- Structural Design of Underwater Drone Using Brushless DC MotorДокумент9 страницStructural Design of Underwater Drone Using Brushless DC MotorIJRASETPublicationsОценок пока нет

- Application For Road Accident RescueДокумент18 страницApplication For Road Accident RescueIJRASETPublications100% (1)

- Oracle Forms & Reports 12.2.1.2.0 - Create and Configure On The OEL 7Документ50 страницOracle Forms & Reports 12.2.1.2.0 - Create and Configure On The OEL 7Mario Vilchis Esquivel100% (1)

- Parliament of India: Rajya SabhaДокумент64 страницыParliament of India: Rajya SabhaSivapothuraju KonathalaОценок пока нет

- My Personal Code of Ethics1Документ1 страницаMy Personal Code of Ethics1Princess Angel LucanasОценок пока нет

- Chapter13 PDFДокумент34 страницыChapter13 PDFAnastasia BulavinovОценок пока нет

- Functional DesignДокумент17 страницFunctional DesignRajivSharmaОценок пока нет

- What Is TranslationДокумент3 страницыWhat Is TranslationSanskriti MehtaОценок пока нет

- Harper Independent Distributor Tri FoldДокумент2 страницыHarper Independent Distributor Tri FoldYipper ShnipperОценок пока нет

- Dialogue Au Restaurant, Clients Et ServeurДокумент9 страницDialogue Au Restaurant, Clients Et ServeurbanuОценок пока нет

- B. Geoinformatics PDFДокумент77 страницB. Geoinformatics PDFmchakra720% (1)

- Work ProblemsДокумент19 страницWork ProblemsOfelia DavidОценок пока нет

- Negotiating Skills Negotiating Skills: To Provide You With The Skills To Plan & Implement Successful NegotiationДокумент32 страницыNegotiating Skills Negotiating Skills: To Provide You With The Skills To Plan & Implement Successful NegotiationKanimozhi.SОценок пока нет

- CX Programmer Operation ManualДокумент536 страницCX Programmer Operation ManualVefik KaraegeОценок пока нет

- Regions of Alaska PresentationДокумент15 страницRegions of Alaska Presentationapi-260890532Оценок пока нет

- Blue Prism Data Sheet - Provisioning A Blue Prism Database ServerДокумент5 страницBlue Prism Data Sheet - Provisioning A Blue Prism Database Serverreddy_vemula_praveenОценок пока нет

- Networker Performance Tuning PDFДокумент49 страницNetworker Performance Tuning PDFHarry SharmaОценок пока нет

- Science7 - q1 - Mod3 - Distinguishing Mixtures From Substances - v5Документ25 страницScience7 - q1 - Mod3 - Distinguishing Mixtures From Substances - v5Bella BalendresОценок пока нет

- Organizational ConflictДокумент22 страницыOrganizational ConflictTannya AlexandraОценок пока нет

- Guidelines For SKPMG2 TSSP - Draft For Consultation 10.10.17Документ5 страницGuidelines For SKPMG2 TSSP - Draft For Consultation 10.10.17zqhnazОценок пока нет

- Solved Simplex Problems PDFДокумент5 страницSolved Simplex Problems PDFTejasa MishraОценок пока нет

- NDY 9332v3Документ8 страницNDY 9332v3sulphurdioxideОценок пока нет

- Syllabus DresserДокумент2 страницыSyllabus DresserVikash Aggarwal50% (2)

- Making Effective Powerpoint Presentations: October 2014Документ18 страницMaking Effective Powerpoint Presentations: October 2014Mariam TchkoidzeОценок пока нет

- DNA ReplicationДокумент19 страницDNA ReplicationLouis HilarioОценок пока нет

- DarcДокумент9 страницDarcJunior BermudezОценок пока нет

- Computing of Test Statistic On Population MeanДокумент36 страницComputing of Test Statistic On Population MeanKristoffer RañolaОценок пока нет

- PR KehumasanДокумент14 страницPR KehumasanImamОценок пока нет

- Laboratory Manual (CIV 210) Engineering Surveying (2018-19) (For Private Circulation Only)Документ76 страницLaboratory Manual (CIV 210) Engineering Surveying (2018-19) (For Private Circulation Only)gyanendraОценок пока нет

- Psychological Contract Rousseau PDFДокумент9 страницPsychological Contract Rousseau PDFSandy KhanОценок пока нет