Академический Документы

Профессиональный Документы

Культура Документы

125T

Загружено:

Daniel MendozaАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

125T

Загружено:

Daniel MendozaАвторское право:

Доступные форматы

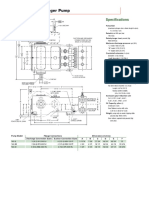

125T-4 Triplex Plunger Pump

Specifications

Pump Size

maximum plunger size x stroke length in.(mm):

21 1/2 4 x 4 (101.6 x 101.6)

Rated bhp at 450 rpm (kw): 125 (93)

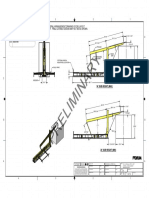

FACE OF SUCTION

E Rated plunger load pounds(Kg): 8250 (3742.2)

AND DISCHARGE

C CRANK

9 7/8 Maximum discharge pressure: psi(kPa)

“L” model: 1500 (10,342)

43 L “M” model: 3180 (21,925)

C PUMP “H” model: 5000 (34,474)

L

Crankshaft extension: in.(mm)

9 7/8 F

Diameter: 3 3/4 (95.25)

E Length: 7 1/2 (191)

21 1/2 Keyway (width x depth):

7/8 x 7/16 (22.2 x 11.1)

3 3/4 4 Maximum recommended sheave

in.(mm): 44 (1118)

3 5/8 Minimum recommended sheave

in.(mm): 24 (610)

For larger sizes: Contact Factory

3.750 Pinion shaft extension,

DIA

3.749

if gear reducer is supplied in.(mm)

7/8 x 7/16 KEYWAY For belt or chain drive: Contact Factory

For direct drive: Diameter: 2 7/8 (73)

Length: 6 3/4 (171)

Keyway (width x depth):

3/4 x 3/8 (19 x 9.5)

Accessory gear reduction unit:

2.596:1, 3.109:1, 3.947:1, 6.192:1

Oil Capacity, gallons (L)

Crankcase & Gear - Approximate: 10 (38)

B 9

Weight, pump only on

wood shipping skids pounds (Kg):

2 3/8 1747 (792)

3 1/4

with Gear reducer, approximate pounds (Kg):

26

1/ 2322 (1053)

54 28

9 1/4 36 3/8

Pump Model Flange Connections Dimensions in inches (mm)

Discharge Connection Sizes Suction Connection Sizes A B C D E F G H J

125T-4L 3 (76.2) Sch. 160, V-Bevel 6 (152.4) Sch. 40, V-bevel 53 2 15 3/4 20 1/2 16 32 6 3 56 7/8

125T-4M 3 (76.2) Sch. 160, V-Bevel 4 (101.6) Sch. 40, V-bevel 52 1/8 4 14 19 7/8 15 30 4 3 56

125T-4H 2 (50.8) Sch. 160, V-Bevel 3 (76.1) Sch. 40, V-bevel 52 1/8 6 3/8 12 3/4 17 7/8 15 30 3 2 56

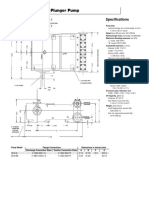

125T-4 Triplex Plunger Pump

Performance Data

PUMP English Units 150 RPM 250 RPM 300 RPM 350 RPM 400 RPM 450 RPM

Plunger Plunger BPD GPM Max.

Dia. Area per per Press.

In. Sq. In. RPM RPM PSI BPD GPM BPD GPM BPD GPM BPD GPM BPD GPM BPD GPM

125T-4L 4.000 12.5664 22.3816 0.6528 657 3358 97.9 5596 163.2 6715 195.8 7834 228.5 8953 261.1 10072 293.8

3.750 11.0447 19.6714 0.5737 747 2951 86.1 4918 143.4 5902 172.1 6885 200.8 7869 229.5 8853 258.2

3.500 9.6211 17.1359 0.4998 857 2571 75.0 4284 124.9 5141 149.9 5998 174.9 6855 199.9 7712 224.9

3.000 7.0686 12.5897 0.3672 1167 1889 55.1 3148 91.8 3777 110.2 4407 128.5 5036 146.9 5666 165.2

2.750 5.9396 10.5788 0.3085 1389 1587 46.3 2645 77.1 3174 92.6 3703 108.0 4232 123.4 4761 138.8

2.500 4.9087 8.7428 0.2550 1500 1312 38.2 2186 63.7 2623 76.5 3060 89.2 3498 102.0 3935 114.7

2.375 4.4301 7.8904 0.2301 1500 1184 34.5 1973 57.5 2368 69.0 2762 80.5 3157 92.1 3551 103.6

125T-4M 3.000 7.0686 12.5897 0.3672 1167 1889 55.1 3148 91.8 3777 110.2 4407 128.5 5036 146.9 5666 165.2

2.750 5.9396 10.5788 0.3085 1389 1587 46.3 2645 77.1 3174 92.6 3703 108.0 4232 123.4 4761 138.8

2.500 4.9087 8.7428 0.2550 1681 1312 38.2 2186 63.7 2623 76.5 3060 89.2 3498 102.0 3935 114.7

2.250 3.9761 7.0817 0.2065 2075 1063 31.0 1771 51.6 2125 62.0 2479 72.3 2833 82.6 3187 92.9

2.000 3.1416 5.5954 0.1632 2626 840 24.5 1399 40.8 1679 49.0 1959 57.1 2239 65.3 2518 73.4

1.875 2.7612 4.9178 0.1434 2988 738 21.5 1230 35.9 1476 43.0 1722 50.2 1968 57.4 2214 64.5

1.750 2.4053 4.2840 0.1249 3180 643 18.7 1071 31.2 1286 37.5 1500 43.7 1714 50.0 1928 56.2

1.625 2.0739 3.6938 0.1077 3180 555 16.2 924 26.9 1109 32.3 1293 37.7 1478 43.1 1663 48.5

125T-4H 2.250 3.9761 7.0817 0.2065 2075 1063 31.0 1771 51.6 2125 62.0 2479 72.3 2833 82.6 3187 92.9

2.000 3.1416 5.5954 0.1632 2626 840 24.5 1399 40.8 1679 49.0 1959 57.1 2239 65.3 2518 73.4

1.875 2.7612 4.9178 0.1434 2988 738 21.5 1230 35.9 1476 43.0 1722 50.2 1968 57.4 2214 64.5

1.750 2.4053 4.2840 0.1249 3430 643 18.7 1071 31.2 1286 37.5 1500 43.7 1714 50.0 1928 56.2

1.625 2.0739 3.6938 0.1077 3978 555 16.2 924 26.9 1109 32.3 1293 37.7 1478 43.1 1663 48.5

1.500 1.7671 3.1474 0.0918 4669 473 13.8 787 22.9 945 27.5 1102 32.1 1259 36.7 1417 41.3

1.375 1.4849 2.6447 0.0771 5000 397 11.6 662 19.3 794 23.1 926 27.0 1058 30.9 1191 34.7

Brake Horsepower Required 42 70 84 97 111 125

PUMP Metric Units 150 RPM 250 RPM 300 RPM 350 RPM 400 RPM 450 RPM

Plunger Plunger M3/Hr L/Sec. Max.

Dia. Area per per Press.

mm cm2 RPM RPM kPa M3/Hr L/Sec. M3/Hr L/Sec. M3/Hr L/Sec. M3/Hr L/Sec. M3/Hr L/Sec. M3/Hr L/Sec.

125T-4L 102 81.073 0.1483 0.0412 4527 22.2 6.2 37.1 10.3 44.5 12.4 51.9 14.4 59.3 16.5 66.7 18.5

95 71.256 0.1303 0.0362 5150 19.5 5.4 32.6 9.0 39.1 10.9 45.6 12.7 52.1 14.5 58.6 16.3

89 62.072 0.1135 0.0315 5912 17.0 4.7 28.4 7.9 34.1 9.5 39.7 11.0 45.4 12.6 51.1 14.2

76 45.604 0.0834 0.0232 8047 12.5 3.5 20.8 5.8 25.0 6.9 29.2 8.1 33.4 9.3 37.5 10.4

70 38.320 0.0701 0.0195 9577 10.5 2.9 17.5 4.9 21.0 5.8 24.5 6.8 28.0 7.8 31.5 8.8

64 31.669 0.0579 0.0161 10342 8.7 2.4 14.5 4.0 17.4 4.8 20.3 5.6 23.2 6.4 26.1 7.2

60 28.581 0.0523 0.0145 10342 7.8 2.2 13.1 3.6 15.7 4.4 18.3 5.1 20.9 5.8 23.5 6.5

125T-4M 76 45.604 0.0834 0.0232 8047 12.5 3.5 20.8 5.8 25.0 6.9 29.2 8.1 33.4 9.3 37.5 10.4

70 38.320 0.0701 0.0195 9577 10.5 2.9 17.5 4.9 21.0 5.8 24.5 6.8 28.0 7.8 31.5 8.8

64 31.669 0.0579 0.0161 11588 8.7 2.4 14.5 4.0 17.4 4.8 20.3 5.6 23.2 6.4 26.1 7.2

57 25.652 0.0469 0.0130 14306 7.0 2.0 11.7 3.3 14.1 3.9 16.4 4.6 18.8 5.2 21.1 5.9

51 20.268 0.0371 0.0103 18106 5.6 1.5 9.3 2.6 11.1 3.1 13.0 3.6 14.8 4.1 16.7 4.6

48 17.814 0.0326 0.0090 20601 4.9 1.4 8.1 2.3 9.8 2.7 11.4 3.2 13.0 3.6 14.7 4.1

44 15.518 0.0284 0.0079 21925 4.3 1.2 7.1 2.0 8.5 2.4 9.9 2.8 11.4 3.2 12.8 3.5

41 13.380 0.0245 0.0068 21925 3.7 1.0 6.1 1.7 7.3 2.0 8.6 2.4 9.8 2.7 12.8 3.1

125T-4H 57 25.652 0.0469 0.0130 14306 7.0 2.0 11.7 3.3 14.1 3.9 16.4 4.6 18.8 5.2 21.1 5.9

51 20.268 0.0371 0.0103 18106 5.6 1.5 9.3 2.6 11.1 3.1 13.0 3.6 14.8 4.1 16.7 4.6

48 17.814 0.0326 0.0090 20601 4.9 1.4 8.1 2.3 9.8 2.7 11.4 3.2 13.0 3.6 14.7 4.1

44 15.518 0.0284 0.0079 23649 4.3 1.2 7.1 2.0 8.5 2.4 9.9 2.8 11.4 3.2 12.8 3.5

41 13.380 0.0245 0.0068 27427 3.7 1.0 6.1 1.7 7.3 2.0 8.6 2.4 9.8 2.7 11.0 3.1

38 11.401 0.0208 0.0058 32189 3.1 0.9 5.2 1.4 6.3 1.7 7.3 2.0 8.3 2.3 9.4 2.6

35 9.580 0.0175 0.0049 34474 2.6 0.7 4.4 1.2 5.3 1.5 6.1 1.7 7.0 1.9 7.9 2.2

Kilowatts Required 31 52 63 73 83 93

Volumetric Rate is based on 100% Volumetric Efficiency. Brake Horsepower/Kilowatts Required is based on 90% Mechanical Efficiency. Not all plunger sizes are shown. Contact

National-Oilwell for additional information.

The information and data on this sheet is accurate to the best of our knowledge and belief, but are intended for general information only. Applications suggested for the materials are described only to help readers make their own

evaluations and decisions, and are neither guarantees nor to be construed as express or implied warranties of suitability for these or other applications. National Oilwell makes no warranty either express or implied beyond that

stipulated in National Oilwell Standard Terms and Conditions of Sale.

Authorized Distributor:

www.natoil.com / customer.service@natoil.com

10000 Richmond, Houston, Texas 77042

(713)346-7500 (phone) • (713)346-7366 (fax)

Вам также может понравиться

- 30T-2 Parts ListДокумент24 страницы30T-2 Parts ListOrlando RojasОценок пока нет

- 125T-4L Parts ListДокумент11 страниц125T-4L Parts ListDaniel MendozaОценок пока нет

- 1887 125HP Union TD 120 Triplex Sour Pump PackageДокумент11 страниц1887 125HP Union TD 120 Triplex Sour Pump PackageIvan Jojic100% (1)

- Varco TDS-4S & TDS-4H Top Drive Pocket GuideДокумент21 страницаVarco TDS-4S & TDS-4H Top Drive Pocket GuideMuhammad SaiedОценок пока нет

- Maintenance Interval Schedule c15 MCW PDFДокумент3 страницыMaintenance Interval Schedule c15 MCW PDFVictor NunezОценок пока нет

- Model 3500 Multi-Pin PDFДокумент3 страницыModel 3500 Multi-Pin PDFAlejandro ZanellaОценок пока нет

- 375T-7 Parts List PDFДокумент23 страницы375T-7 Parts List PDFGhassen NouailiОценок пока нет

- Anelli Di Tenuta - Paraolio: Mescola NBRДокумент12 страницAnelli Di Tenuta - Paraolio: Mescola NBRcorsini999Оценок пока нет

- 165t-5parts List PDFДокумент26 страниц165t-5parts List PDFjoseОценок пока нет

- 100T Pump Parts List PDFДокумент30 страниц100T Pump Parts List PDFGabriel Andres ValenciaОценок пока нет

- PVWJ Open Loop Pumps: Bulletin 47085Документ24 страницыPVWJ Open Loop Pumps: Bulletin 47085CARLOS RAMIREZ100% (1)

- 1034 FG FXG Duplex Power Pump PDFДокумент2 страницы1034 FG FXG Duplex Power Pump PDFJunior Francisco QuijanoОценок пока нет

- GEB22A-NC Electric MotorДокумент153 страницыGEB22A-NC Electric Motorerminhusagic2308Оценок пока нет

- Rineer Hydraulics: GeneralДокумент2 страницыRineer Hydraulics: Generalwilo100% (1)

- CouplingsДокумент9 страницCouplingssam abusiОценок пока нет

- Ideco h25 Technical SpecsДокумент20 страницIdeco h25 Technical SpecsSergio Fabian VasicekОценок пока нет

- 65590-gd Cutsheet Template gd-600 2015 LRДокумент2 страницы65590-gd Cutsheet Template gd-600 2015 LRjys_yanqui100% (1)

- Sprocket GuideДокумент22 страницыSprocket Guideayman akrabОценок пока нет

- 125T-4 Triplex Plunger Pump: Installation, Care and Operation ManualДокумент38 страниц125T-4 Triplex Plunger Pump: Installation, Care and Operation ManualDaniel MendozaОценок пока нет

- Parts ListДокумент26 страницParts ListArman MalikОценок пока нет

- NitrogenoДокумент139 страницNitrogenoEmanuelLopezОценок пока нет

- Neztch PCP Pump Cavidades ProgresivasДокумент24 страницыNeztch PCP Pump Cavidades Progresivasgregorio2407Оценок пока нет

- PLC Allen Bradley MAnualДокумент76 страницPLC Allen Bradley MAnualFrancisco TorresОценок пока нет

- LRCS NGAS SSH - 1st - 3 18Документ2 страницыLRCS NGAS SSH - 1st - 3 18Worldwide Equipment SolutionsОценок пока нет

- 使用说明书Operation ManualДокумент84 страницы使用说明书Operation ManualMohamed el attarОценок пока нет

- Catalogo Bombas GORMAN RUPPДокумент71 страницаCatalogo Bombas GORMAN RUPPalejandro ariza chaves100% (1)

- Pump GDДокумент2 страницыPump GDdelcololalunaОценок пока нет

- Válvula ContrabalanceДокумент16 страницVálvula ContrabalanceMauricio Ariel H. Orellana100% (1)

- Instruction Manual For Operating and Maintenance: - Counter Clockwise RotationДокумент9 страницInstruction Manual For Operating and Maintenance: - Counter Clockwise RotationAОценок пока нет

- Amfg L0918BCDДокумент5 страницAmfg L0918BCDLuis AparcanaОценок пока нет

- Instalacion Bombas de Presion CatДокумент2 страницыInstalacion Bombas de Presion CatTito Zenon100% (1)

- Plunger PumpДокумент8 страницPlunger Pumpmember1000Оценок пока нет

- Yanmar Industrial Engine: Gaskets/Washers/O-ringsДокумент1 страницаYanmar Industrial Engine: Gaskets/Washers/O-ringscabdirisaaq shaqaleОценок пока нет

- Cement Metering ValveДокумент11 страницCement Metering ValveWise SoОценок пока нет

- HD 2250Документ47 страницHD 2250- Emslie100% (1)

- Electric Drive Drilling Equipment: Emeri InternationalДокумент196 страницElectric Drive Drilling Equipment: Emeri InternationalKhedr HamoudОценок пока нет

- Asi X Packer 105243965Документ3 страницыAsi X Packer 105243965Esteban RochaОценок пока нет

- Maintenance Instructions For Power SystemДокумент3 страницыMaintenance Instructions For Power Systemsanach100% (1)

- TRIPLEX NATIONAL OIL WELL BARCO-165T-5parts-list PDFДокумент26 страницTRIPLEX NATIONAL OIL WELL BARCO-165T-5parts-list PDFPlaneación y ConfiabilidadОценок пока нет

- Serva C PumpsДокумент4 страницыServa C Pumpschengcaiwang100% (1)

- Performance Criteria: Work Force 360 Mud PumpДокумент1 страницаPerformance Criteria: Work Force 360 Mud PumpMIGUEL ANGEL100% (1)

- Hy30 8249 Uk PDFДокумент72 страницыHy30 8249 Uk PDFВалентин ДимитровОценок пока нет

- SKF Epb Pump en MMДокумент4 страницыSKF Epb Pump en MMEbied Yousif AlyОценок пока нет

- CLE14000DPcerev9 09 PDFДокумент139 страницCLE14000DPcerev9 09 PDFAdhie WaelacxhОценок пока нет

- PP010000734 02Документ2 страницыPP010000734 02rdos140% (1)

- 122 - Bando Serpentine Belt Cross ReferenceДокумент2 страницы122 - Bando Serpentine Belt Cross ReferenceNil Acuña100% (2)

- Fluid EndДокумент1 страницаFluid EndpabloasotoОценок пока нет

- PC-0088 9A Valve and Coil ChangeДокумент3 страницыPC-0088 9A Valve and Coil ChangeMarcelo ArayaОценок пока нет

- GD Qf450sb FeДокумент11 страницGD Qf450sb FeCesar MoraОценок пока нет

- AOSS AccumulatorsДокумент7 страницAOSS AccumulatorsPiero Fabrizzio Mendoza FuenteОценок пока нет

- Bomba de Pistones RexrothДокумент8 страницBomba de Pistones RexrothDaniel Fernando Jejen PaezОценок пока нет

- SPRAGUE J Pump BrochureДокумент8 страницSPRAGUE J Pump BrochurechauduonguyenОценок пока нет

- Product Information Bulletin: All 6 Series Injectors Chain Tension SystemДокумент3 страницыProduct Information Bulletin: All 6 Series Injectors Chain Tension SystemJose Leonardo Materano PerozoОценок пока нет

- Swivel S135 Explode ViewДокумент1 страницаSwivel S135 Explode ViewingcalderonОценок пока нет

- Back PoshtДокумент2 страницыBack Poshtmhn yОценок пока нет

- National 165T5 J165 Triplex SpecsДокумент2 страницыNational 165T5 J165 Triplex SpecsCamilo Andres Cardozo FajardoОценок пока нет

- 30T-2 Triplex Plunger Pump: SpecificationsДокумент2 страницы30T-2 Triplex Plunger Pump: SpecificationsLen KerekanichОценок пока нет

- 267Q-6 Quintuplex Plunger Pump: SpecificationsДокумент2 страницы267Q-6 Quintuplex Plunger Pump: SpecificationsLen KerekanichОценок пока нет

- National 300Q-5 J-275 Quintuplex SpecsДокумент2 страницыNational 300Q-5 J-275 Quintuplex Specsorlando perezОценок пока нет

- Booster Pump Dayton PDFДокумент34 страницыBooster Pump Dayton PDFaoabyОценок пока нет

- 2.fuel SystemДокумент41 страница2.fuel SystemMech DTUОценок пока нет

- Fire Pump Hydrant Inspection ChecklistДокумент2 страницыFire Pump Hydrant Inspection Checklistkukuh nugОценок пока нет

- Drawing Technical Statement Sewage Bulandshahar FinalДокумент13 страницDrawing Technical Statement Sewage Bulandshahar Finalankur yadavОценок пока нет

- Mobatec Modeller Intorduction Course Tutorial IIДокумент13 страницMobatec Modeller Intorduction Course Tutorial IIMohammad Yasser RamzanОценок пока нет

- Fuel - in Tank Fuel Pump Replacement PDFДокумент14 страницFuel - in Tank Fuel Pump Replacement PDFBeniamin KowollОценок пока нет

- Types of ValvesДокумент5 страницTypes of Valvesjeamnard balitaanОценок пока нет

- Pps 922903 2l Tfsi Caeb Enigine W Acs EngДокумент55 страницPps 922903 2l Tfsi Caeb Enigine W Acs Eng2791957100% (1)

- Catalog CDPHДокумент4 страницыCatalog CDPHAhmad KoriemОценок пока нет

- ME - (2.900) 10V-180.5/2BC: Product DescriptionДокумент5 страницME - (2.900) 10V-180.5/2BC: Product Descriptionshjnbe18Оценок пока нет

- Basics Sealing Fundamental (BPS-Pertamina) 2Документ91 страницаBasics Sealing Fundamental (BPS-Pertamina) 2Yahya AyasОценок пока нет

- Straalsund JHE 2018Документ22 страницыStraalsund JHE 2018alvin bautistaОценок пока нет

- PP Aaa PP1 105Документ21 страницаPP Aaa PP1 105Rabah AmidiОценок пока нет

- OISD Standard - 119Документ25 страницOISD Standard - 119Viveka SaravananОценок пока нет

- Basics of Hydrauluic SystemДокумент47 страницBasics of Hydrauluic SystemHarish GouthamОценок пока нет

- CNC Router User Manual PDFДокумент47 страницCNC Router User Manual PDFIonCeaparu60% (5)

- Typical Turbine System and DescriptionДокумент85 страницTypical Turbine System and DescriptionManjunath AithalОценок пока нет

- Maintenance Manual For NDM5 ZDM5 NG Locomotive PDFДокумент413 страницMaintenance Manual For NDM5 ZDM5 NG Locomotive PDFMohan RaoОценок пока нет

- Testo 340 Flue Gas Analyzer: FeaturesДокумент16 страницTesto 340 Flue Gas Analyzer: FeaturesAizen SousukeОценок пока нет

- Caja de Cambio John DeereДокумент52 страницыCaja de Cambio John Deerenelson.oyanadel21Оценок пока нет

- Golden Dragon ChaoYang Diesel Engine Model 100-102-105 Operation ManualДокумент210 страницGolden Dragon ChaoYang Diesel Engine Model 100-102-105 Operation Manualorphee mandji100% (1)

- PCSB Inspection and Maintenance Guidelines Volume 1Документ124 страницыPCSB Inspection and Maintenance Guidelines Volume 1JaiОценок пока нет

- Post-Construction Initial Performance Evaluation Report (Iper)Документ15 страницPost-Construction Initial Performance Evaluation Report (Iper)Bhavish RamroopОценок пока нет

- Wind Pumps For Irrigation PDFДокумент95 страницWind Pumps For Irrigation PDFOana ArdeleanuОценок пока нет

- IPCO Power Fuel TreatmentДокумент2 страницыIPCO Power Fuel TreatmentBart SluimerОценок пока нет

- Bulletin 116.1387Документ13 страницBulletin 116.1387HoàngViệtAnhОценок пока нет

- SAES-Q-004 Installation Piles Offshore Structures 2004Документ22 страницыSAES-Q-004 Installation Piles Offshore Structures 2004ymaseda100% (2)

- GPM RevДокумент138 страницGPM RevJuan Cortes TorizОценок пока нет

- Maintenance and Repair For Diesel EnginesДокумент424 страницыMaintenance and Repair For Diesel EnginesHanafi Ajah100% (5)