Академический Документы

Профессиональный Документы

Культура Документы

Heat Dissipation

Загружено:

madhivananspИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Heat Dissipation

Загружено:

madhivananspАвторское право:

Доступные форматы

IEEE Transactions on Power Apparatus and Systems, Vol. PAS-98,No.

4 July/Aug 1979 1149

HEAT LOSSES FROM ELECTRICAL EQUIPMENT

IN GENERATING STATIONS

I. M. Rubin, Member, IEEE

Burns and Roe, Inc.

Oradell, N.J.

Abstract equipment which do not continuously carry current,

thus neglecting the heat loss of circuit breakers

Heat losses from electrical equipment in gene- which are normally open. Also, the heat losses from

rating stations must be estimated by electrical electrical equipment during shutdown or accident

engineers when information is required by HVAC sys- conditions (such as a LOCA in a nuclear plant) again

tem designers, for inclusion into heat load calcula- may be significantly different, due to operation of

tions being used to size HVAC equipment. 'These such items as emergency motor driven pumps, tie

estimates must often be done quickly, and time does breakers, or diesel generator switchgear.

not allow waiting for equipment manufacturers to

provide accurate heat loss values. This paper pro- A. Power Distribution Equipment

vides a consistent method by which electrical engi-

neers can estimate the heat losses from electrical The auxiliary electrical systems of fossil-fuel

equipment in power stations. Data, consisting of and nuclear power stations oonsist of three major

averages of manufacturers' information, is provided types of power distribution equipment: medium volt-

to enable these heat loss estimates to be prepared. age switchgear, unit substations, and motor control

centers. Medium voltage switchgear consists of

INTRODUCTION power circuit breakers with associated buswork, all

enclosed in free-standing cabinets. Unit substa-

All electrical equipment, when energized, pro- tions generally consist of a medium voltage circuit

duces a certain amount of heat loss to its environ- breaker or airfilled terminal chamber, a dry-type

ment. Where large concentrations of electrical transformer, and a low voltage section containing

equipment are grouped together, such as in power circuit breakers, which are either manually or elec-

generating stations, this waste heat can signifi- trically operated. Motor control centers consist of

cantly affect the heating, air-conditioning, and combination starters and low-current feeder break-

ventilating system (HVAC) design. This paper pro- ers.

vides the necessary procedures and data for the Heat loss values for switchgear, unit substa-

electrical engineer to estimate the total heat loss- tions, and motor control centers are given in Tables

es from the auxiliary electrical equipment in power I, II, and III, respectively. The total heat loss

generating stations. It should be noted that the for any equipment can be estimated as the sumnation

heat loss data presented in this paper is conserva- of its component heat losses. The heat loss of a

tive in nature, and thus the HVAC engineer should be fused switch can be assumed equal to the heat loss

informed that no additional margin is to be added to of an equally-rated circuit breaker. The heat

the values supplied. loss of the incoming line section (medium volt-

age) of unit substations can be directly obtained

from Table I, if a power circuit breaker is used.

If an air-filled terminal chamber is used instead

A significant amount of the electrical equip- of a power circuit breaker, its heat loss can be

ment in a power station does not operate continuous- assumed as 50% of the Table I value.

ly, and therefore its heat loss must be estimated

based on its normal status. The heat loss values B. Transformers

given in this paper are valid only for normal opera-

tion of equipment. When equipment is shut down, its Unit substation transformers, when installed

heat loss will be significantly different, but it indoors, are usually the open-ventilated dry type,

may still have a partial heat loss, possibly due to with a temperature rise of 1500C over a 300C ambi-

the cperation of space heaters. Thus the normal ent. Heat loss values for this type of transformer,

status of the equipment (energized or de-energized, independent of transformer impedance, are given in

open or closed, full load or partial load) must be Table IV. Transformers used to supply lighting and

considered when heat losses are estimated. receptacle panels are generally installed within

In areas where environmental conditions must motor control centers; their heat loss values are

be accurately controlled (such as safety related given in Table III.

areas of nuclear plants), it may be advantageous to

identify those components of power distribution C. Vital Equipment

The vital electrical equipment in power sta-

tions generally consists of one or more station bat-

teries, dc switchgear, battery chargers, and unin-

terruptible power supplies. The heat loss from sta-

tion batteries, during normal operation (float

F 78 304-7.A paper recommended and approved charge), is negligible. Heat loss from dc switch-

by the IEEE Power Generation Committee of gear can be assumed equal to the heat loss from unit

the IEEE Power Engineering Society for pre- substation caoponents of comparable ampere ratings.

sentation at the IEEE/ASME/ASCE Joint Power Battery chargers in a power station normally

Generation Conference, Dallas, TX, Septem- supply the float charging current of the station

ber 10-13, 1978. Manuscript submitted April battery plus any steady state dc load. The float

17, 1978; made available for printing August charging current (I.), per 100 ampere hours of bat-

2, 1978.

001 8-9510/79/0700-1149$00.75 1979 IEEE

1150

tery rating, is approximately 0.11 amperes or 0.011

amperes, for either lead-antimony or lead-calcium be estimated 80 percent of the input power.

as

batteries, respectively. The heat loss from the Computer often have strict HVAC require-

roams

battery charger can be estimated as the inefficient ments stated by the manufacturers, who will often

percent of the input power to the charger, derated provide the exact heat loss of their computers.

by a diversification factor which accounts for the When preliminary estimates must be made, however, it

actual percentage of the battery charger's capacity is possible to use a value of 250 watts per linear

being used for the normal load. A safety factor of foot, for a full-height, single-unit depth computer

1.25 is used to slightly increase the diversifica- cabinet.

tion factor. Equations (1) and (2) can be used to

calculate the diversification factor (D) and battery

charger heat loss (HLBd, respectively, where I ssis

the steady-state dc load in amperes, AH is the am- E. Motors

pere hour rating of the station battery, N is the

number of battery chargers normally connected to the

battery, IBCis the ampere rating of the battery Many motors are used in power stations, to

charger output, and V is the voltage rating of the drive the various auxiliary systems. Heat loss from

battery charger outpue. Efficiency (Eff.) can be electric mntors represents a significant amount of

assumed as 85%. the total waste heat, mainly because the motors are

located in environments containing all types of

mechanical equipment which must be cooled and venti-

(IF) (AH) lated, and because rotors primarily use ambient air

D = 1.25 100 aiihr (1) for their own cooling. Heat loss from motors can be

estimated using (4); motor efficiency

(N) (IBC) as 90%, unless the actual value is known.

can be assumed

HL B6watts) = (IBC) (C) (D) (l-Eff ) .

(2)

HtMOTOlwatts)=(HP) (746 watts/HP) (1-Eff.) (4)

Heat loss from uninterruptible power supplies can be

estimated using (3), where efficiency can be assumed

as 80% and power factor (PF) can be assumed as 0.9.

F. Lighting

H1% ps(watts) = (VA rating of UPS) (PF)(l-Eff.) (3)

The total heat loss fron lighting in any area

D. Control Equipment of a power station can be estimated as being equal

to the input power to all luminaires in that area.

Control rooms and relay rooms of power stations If the heat loss is estimated by the sumnation of

normally contain many heat-generating panels and the ratings (watts) of individual luminaires, the

cabinets, some of which may be computers. Heat loss lamp watts of a fluorescent luminaire should be mul-

from control boards and relay cabinets can be esti- tiplied by 1.2, and the lamp watts of a high inten-

mated at 30 watts per square foot of the total panel sity discharge luminaire should be multiplied by

front surface area, or by the sumnation of 10 watts 1.4, to account for the heat loss from ballasts. An

per indicating light, 2 watts per control switch, important assumption that has been made here is that

and 25 watts per relay or meter. If the power input the total power input to a lamp eventually cows out

to the panel is known, heat loss can alternatively as heat, even though some lamp types have a greater

efficiency of light energy vs. heat energy.

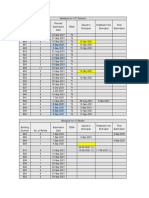

TABLE I

Medium Voltage Switchgear, Heat Loss, Watts per Cubicle

(Including Buswork)

1 ~ 5 kV 7.2 kV 13.8 kV

I I I l I

{Current | 1200 A | 2000 A | 3000 A 1l200 A | 2000 A | 3000 A l200 A | 2000 A | 3000AA

1| p 1 Breaker l Breaker I Breaker I Breaker 1 Breaker I Breaker I Breaker Breaker l Breaker 1

1 I1 l~ 1 - I 1- 1 1 .1 '1

200 1 24 1 12 1 9 1 28 14 1 10 l 29 15 l 11

400 94 1 48 1 36 1 111 l 54 40 1 117 1 60 1 49 1

1600

1800 l

1 213

378

108-

1 192

1

1 142

80 1

1

250 1 122

444 1 216

1 90

1 160

1 263 1l 135

1 467 1 240

1

1

100

178

l

11000 1 590 1 300 1 - 222 694 1 338 250 729 1 375 1. 278

11200 -1 850 1 432 l 320 1 1000 486 I 360 1 1050 1 540 400 1

11400 1 --- l 588 436 1 1 662 1 490 1 -- 735 1 544 1

11600 1 --- 1768 .1 569 5 1 864 1 640 1 _ 1 960 1 711

11800 1 --- 1 972 1 720 1 -- - 1094 1 810 1'- -- 1215 1 900 .1

12000 1 - 1200 1 889 1 -- 1350 1000 l- -- 1500 1111 l

12200 1 - 1075 1 -- 1-- 11210 1--- 1--- 1 1344 1

12400 1 --- __ 1 1280 1 -- l- 1 1440 1 1600 - _

12600 1--- l --- 1502 1 -1--- 11690 1-- I -- 1 1878 1

12800 1- 1--- 1 7142 - -1--- 11960 1- I-- 1 2178

13000 l --I - 2000 - --1__ 2250 1 -- 1 2-- _

5 kV 17.2 kV l 13.8 kV I

I 1_ SDace heater. Der cubicle

Iary0compartment 250

300

1400

1400

1

I SMO

500

II

compartmnt 500 i

I

I Auxiliary 300 1400

I rl I

1151

G. Power Cables Conclusions

The heat loss values presented in this -paper

In power stations, power cables are normally have been compiled by averaging the information that

routed in cable trays, with conduit being used for could be obtained from several major manufacturers,

safety related power cables in nuclear plants, or and applying engineering judgement to extrapolate

for short lengths or isolated runs of power cable in values which were not directly obtained. Equipment

both fossil-fuel and nuclear plants. Since it is manufacturers can supply, for the nost part, speci-

unlikely that a large group of power conduits, car- fic heat loss values for specific equipment; how-

rying continuously loaded cable, will be routed to- ever, the time delay associated with waiting for

gether for an apreciable distance, the heat loss specific information is unsatisfactory, highlighting

from conduits can be neglected. the need for a standard oompilation of data such as

this paper. The heat loss values presented herein

The heat loss from cable tray, containing a are intended to be used only for HVAC calculation

mixture of single conductor power cables, filled to purposes; computations of actual energy losses (dol-

40% maximum of the cross sectional area of a 3 inch lars per kilowatt) should not be made using these

eable tray depth, has been calculated based on the values.

ILR losses of the conductor, the conductor tempera-

ture, and the average thermal conductivity of power REFERENCES

cable insulation and jacket material. These calcu-

lated values have been derated by a diversity factor Llj H.N. Hickok, "Electrical Energy Losses in

of 60%, since not all cables are continuously load- Power Systems." IEEE Industry Applications

ed. The resulting values to be used for heat loss Society 12th Anual Meetiin, October, 1977,

estimates are listed in Table V. Section 2-B, pp. 42 - 57.

TABLE IT

Unit Substation Components

ICircuit Breakers, 600 volts or below

I Heat Loss, watts

{Current I Circuit Breaker Frame Size

I I I

lAmps 225 A | 600 A | 1600 A 2000 A I 3000 A | 4000AA

I I Frame I Frame Frame I Frame Frame

F Frame

F

40 13 4 1 1 1 1 1 1 1

60 1 28 8 1 1 1 2 1 1 -11

l70

190

39 11 2 1 3 2 _ 1 1

1100

1 64 18 1 3 1 5 23

l

79 22 44 I 6 4 1 3 1

1125 1 123 1 - 35 5 1 10 6 1 4 1

150 1 177 50 8 -6 14 9 6 1

175 1 241 1 68 - 11 19 12 1 8

200 1 316 89 14 1 25 1 16 1 10 _

1225 1 400 .1 113 18 32 1 20 1 13 1

1250

1300 I

1

___

138

200

22

32

5

-

39

56 I

l 25

36

1

1

16

23 _ 1

1350 1 __ 272 1 43 76 1 49 .1 31 1

400 355 56 100 64 40

500- 1 555 1 88 1 156 1 100 1 63 l

1600 1 -- 1 800 - 127 225 1 144 1 90 1

1800 l -- - 225 1 400 1 256 1 160 1

11 Ul,

--=----- 1

-_ __ 1 352 I

625 1

40 1 250 1

11200 1_ __ -_ 1 506 1 900 1 576 1 360 1

11600 1 ___ I -- 900 1 1600 1 1024 1 640

12000 1 - _ -- 1 --- 1 2500 1 1600 1000

12500 1 - 1 -__ __ - 1 2500 _ 1562 1

13000 1 --

_ 1 - ._ __ 3600 2250

14000 1 -- I -- _ _ 1 -- 1 4000 1

ISpace Heater 1 400 watts per vertical stack 1

lAuxiliary omprtment 1 400 watts I

IBus losses 1 300 watts per vertical stack I

1152

TABLE III TABLE IV

Motor Control Centers

Item Heat Loss, watts Unit Substation Transformers

Canbination Starter 4160 - 480 V, 6900 - 480 V, 13800 - 480 V

NEMA Size 1 60

NEMA Size 2 90

NEMA Size 3 140

|Transformer Size I Heat Loss (at full load)l

NEMA Size 4 190

l kVA watts

l 300 6 000

NEMA Size 5 350 500 I 10 000 l

750 1 15 000

Molded Case Circuit Breaker (or Fused Switch) l 1000 1 20 000 l

Current, Amps l 1500 25 000

15 - 30 4 l 2000 35 000

40 - 50 16 2500 40 000

60 - 70 20

100 - 125 28

150 - 225 40

250 - 300 60 TABLE V

400 - 500 100

600 - 800 200 Cable Tray Heat Loss (Power Cables)

Auxiliary Relay Ccrpartment 100

Bus Losses, per vertical stack 80 |Tray Width I Heat Loss, watts per foot l

I I I

Space Heater, per vertical stack 200 I l 600 V 5 kV 1 15 kV 1

12" 1 23 l 26 1 26

Power and Lighting Transformers l 18" 1 35 l 39 1 42 l

3 Phase, 480 - 208/120 volt 1 24" i 47 1 53 1 55 l

9 kVA 300 1 30" 1 58 1 65 1 68 l

15 kVA 500

30 kVA 1400

Incoming Line Reactor

Ampere Rating Ira M. Rubin (S'71-M'73) was born in Jersey City,

600 250 N.J., on February 3, 1952. He received the B.E.

700 350 degree in 1973 and the M.M.S. degree in 1978 from

800 500 Stevens Institute of Technology.

1000 700 In 1973, Mr. Rubin joined Burns and Roe, Inc.,

1200 1000 Oradell, N.J., where he has worked as an Electrical

Power and Lighting Panelboards Engineer. He has been involved with the engineering

Number of Single Pole of several power stations, including the Three Mile

Circuit Breakers Island Nuclear Station Unit No. 2; Units 1 and 2 of

12 150

the Big Cajun No. 2 coal-fired station; and Units 3

24 300 and 4 of the Santee Cooper Winyah Station, on which

36 450 he is presently working.

42 500

Mr. Rubin is a registered Engineer-In-Training

in the state of New Jersey.

Вам также может понравиться

- Electrical Load Distribution Schedule Revised 07-05-08Документ84 страницыElectrical Load Distribution Schedule Revised 07-05-08JojolasОценок пока нет

- Electrical Calculations Sheet - Main - Electrical KnowhowДокумент16 страницElectrical Calculations Sheet - Main - Electrical KnowhowUjjal ChakmaОценок пока нет

- Guide For The Design and Production of LV Power Factor Correction CubiclesДокумент76 страницGuide For The Design and Production of LV Power Factor Correction CubiclesGunadevan Chandrasekaran100% (1)

- Building Heat Load Contributions From Medium and Low Voltage SwitchgearДокумент11 страницBuilding Heat Load Contributions From Medium and Low Voltage SwitchgearOmar Graterol100% (1)

- Earthing Calculation - Open ElectricalДокумент11 страницEarthing Calculation - Open ElectricalChihiya Fitria NurhayatiОценок пока нет

- Old Sample Electrical BaseДокумент31 страницаOld Sample Electrical BaseRahulОценок пока нет

- Low Voltage Switchgear Specification GuideДокумент6 страницLow Voltage Switchgear Specification GuidejendrikoОценок пока нет

- Designing Power GridsДокумент19 страницDesigning Power GridsSibtain Ul HassanОценок пока нет

- How To Size DG Set - CumminsДокумент4 страницыHow To Size DG Set - CumminsNalin KumarОценок пока нет

- Electrical Thumb Rules - (Part 1)Документ4 страницыElectrical Thumb Rules - (Part 1)Electrical Radical100% (3)

- GRC-ES005 - r2 - Lighting & Power Distribution BoardДокумент13 страницGRC-ES005 - r2 - Lighting & Power Distribution BoardAdityaОценок пока нет

- Chapter 1.Документ31 страницаChapter 1.Nurhidayah AnuarОценок пока нет

- Bus BarsДокумент36 страницBus Barstceterex100% (1)

- 2500 Busbar CalculationДокумент4 страницы2500 Busbar CalculationPramod B.Wankhade100% (1)

- CT & PTДокумент34 страницыCT & PTsasikumar100% (4)

- Actis - WA - FY19-20 - 152 - Utility MCC-12 Panel Drawing - R00Документ13 страницActis - WA - FY19-20 - 152 - Utility MCC-12 Panel Drawing - R00p mahesh goudОценок пока нет

- Grounding and Bonding For Electrical Systems-Rev01Документ11 страницGrounding and Bonding For Electrical Systems-Rev01Mohamed Hamed100% (1)

- Cable Etap 01-18-2IN1Документ77 страницCable Etap 01-18-2IN1umamaheshwarraoОценок пока нет

- Transformer Sizing CalculationДокумент2 страницыTransformer Sizing CalculationfacebookcnuОценок пока нет

- DG Fault Current & Earth Flat SizingДокумент2 страницыDG Fault Current & Earth Flat SizingPalani100% (1)

- 630A MCC BUSBAR SIZING CALCULATIONДокумент42 страницы630A MCC BUSBAR SIZING CALCULATIONAnonymous OKkHA0NzОценок пока нет

- Short Circuit Current Calculation (Base KVA Method) - Electrical Notes & ArticlesДокумент17 страницShort Circuit Current Calculation (Base KVA Method) - Electrical Notes & ArticlesAnonymous mNQq7ojОценок пока нет

- Bulk Water Supply Electrical System Design ParametersДокумент6 страницBulk Water Supply Electrical System Design ParametersPrasenjit DeyОценок пока нет

- 5-Power & Control Cables PDFДокумент11 страниц5-Power & Control Cables PDFAnonymous ufMAGXcskMОценок пока нет

- Electrical Design-StepsДокумент13 страницElectrical Design-Stepsnadeem UddinОценок пока нет

- Electrical Thumb Rules (Part 3)Документ4 страницыElectrical Thumb Rules (Part 3)Manish TiwariОценок пока нет

- VCB PanelsДокумент17 страницVCB PanelsSenthil Prasadh100% (1)

- SP3.6 Array Voltage ConsiderationsДокумент8 страницSP3.6 Array Voltage ConsiderationsSIDI ahmedou yahyaОценок пока нет

- Arar Ups SizingДокумент6 страницArar Ups Sizingsrigirisetty208Оценок пока нет

- TP 141aДокумент37 страницTP 141aakmezimОценок пока нет

- Stabilizing Resistor in Motor Earth-Fault ProtectionДокумент12 страницStabilizing Resistor in Motor Earth-Fault ProtectionSuhas AcharyaОценок пока нет

- Sewage Treatment Package Cable Sizing: Project: Ardebil Gas Turbine Power PlantДокумент5 страницSewage Treatment Package Cable Sizing: Project: Ardebil Gas Turbine Power Plantnourfarmajid0% (1)

- Power Electronics Unit 4Документ89 страницPower Electronics Unit 4Ajju K AjjuОценок пока нет

- Client: Project: Motor: 800 HP Motor Case: Utility Supply & Base Data: TransformerДокумент4 страницыClient: Project: Motor: 800 HP Motor Case: Utility Supply & Base Data: TransformerWidhi ImranovichОценок пока нет

- Iec Standard / Normal Inverse Iec Long Time Inverse: Iec Characteristics Curve For IdmtДокумент2 страницыIec Standard / Normal Inverse Iec Long Time Inverse: Iec Characteristics Curve For IdmtSoumik KarОценок пока нет

- 2240 162 Pve U 004 SHT 3 3 01Документ13 страниц2240 162 Pve U 004 SHT 3 3 01Anagha DebОценок пока нет

- TS For 1 MVA 33-0.433KV TransformerДокумент16 страницTS For 1 MVA 33-0.433KV TransformerParvesh JhaОценок пока нет

- Design and Assembly of an Automatic Power Factor Correction Electrical PanelДокумент4 страницыDesign and Assembly of an Automatic Power Factor Correction Electrical PanelqxzyОценок пока нет

- Power Cable ScheduleДокумент40 страницPower Cable ScheduleAnupam0103Оценок пока нет

- EE Portal - Short Circuit Current CalculationДокумент5 страницEE Portal - Short Circuit Current CalculationRobert GalarzaОценок пока нет

- Latest Updated Electrical ENGINEERING & DESIGNДокумент92 страницыLatest Updated Electrical ENGINEERING & DESIGNShivani GuptaОценок пока нет

- Design Concept of 3311 KV SubstationДокумент39 страницDesign Concept of 3311 KV SubstationKarth IkkОценок пока нет

- Electrical thumb rules guideДокумент5 страницElectrical thumb rules guideAshwin NarayanОценок пока нет

- 5855292-Avr Users Manual Ea63-5 CДокумент8 страниц5855292-Avr Users Manual Ea63-5 CAbhoe StankОценок пока нет

- MNS-MCC LV SpecificationДокумент16 страницMNS-MCC LV SpecificationRaju MbkОценок пока нет

- Fault Current Calculation: DownloadДокумент7 страницFault Current Calculation: DownloadSuresh Krish0% (1)

- DG BusductДокумент16 страницDG BusductanandpurushothamanОценок пока нет

- Electrical Thumb Rules for Motors, Transformers & MoreДокумент4 страницыElectrical Thumb Rules for Motors, Transformers & MoreElectrical Radical100% (1)

- Ampacity Calculation by Finite Element MethodДокумент4 страницыAmpacity Calculation by Finite Element Methodthedt1147Оценок пока нет

- ARC RESISTANCE CALCULATIONДокумент10 страницARC RESISTANCE CALCULATIONLaurence Michael100% (1)

- Fault Current Calculator Excel SheetДокумент2 страницыFault Current Calculator Excel SheetAbdulyunus AmirОценок пока нет

- Generator Sizing CalculatorДокумент4 страницыGenerator Sizing CalculatorNedunuri.Madhav Murthy100% (1)

- Circuit Breaker SpecificationДокумент60 страницCircuit Breaker SpecificationYash YadavОценок пока нет

- Cable CapacityДокумент15 страницCable Capacityvijay_raina3114Оценок пока нет

- Capacitor Catalogue PDFДокумент84 страницыCapacitor Catalogue PDFrajveer kumarОценок пока нет

- Stabilizing Resistor CalculationДокумент4 страницыStabilizing Resistor CalculationAbhishek RajputОценок пока нет

- Table - 14 Typical Diversity Factors For Large BldgsДокумент1 страницаTable - 14 Typical Diversity Factors For Large Bldgskiran raghukiranОценок пока нет

- Calculate Cable Size and Voltage Drop Electrical Notes Articles PDFДокумент10 страницCalculate Cable Size and Voltage Drop Electrical Notes Articles PDFKamugasha Kagonyera100% (1)

- Fault Level CalculationsДокумент18 страницFault Level CalculationsSatheesh Kumar NatarajanОценок пока нет

- Current TransformersДокумент24 страницыCurrent TransformersArif KhanОценок пока нет

- Electrical Equipment Heat Loss CalculatorДокумент14 страницElectrical Equipment Heat Loss CalculatorAnonymous n5GA81cОценок пока нет

- Ansi MV Techtopics09 enДокумент2 страницыAnsi MV Techtopics09 enLeonela GuzmanОценок пока нет

- Chapter 5bestДокумент10 страницChapter 5bestyibelta abebeОценок пока нет

- Power Transformer DesignДокумент13 страницPower Transformer DesignMohammad AliОценок пока нет

- 250 Series Microprocessor Controller: Enhanced Display and SettingsДокумент1 страница250 Series Microprocessor Controller: Enhanced Display and SettingsmadhivananspОценок пока нет

- Enith Series Accessory Group Matrix Enith Series Accessory de FinitionsДокумент1 страницаEnith Series Accessory Group Matrix Enith Series Accessory de FinitionsmadhivananspОценок пока нет

- Zenith ZTS Series Automatic Transfer Switches: Neutral SwitchingДокумент1 страницаZenith ZTS Series Automatic Transfer Switches: Neutral SwitchingmadhivananspОценок пока нет

- LB6054.693-EN_enДокумент4 страницыLB6054.693-EN_enmadhivananspОценок пока нет

- Enith Eries: Z Zts SДокумент1 страницаEnith Eries: Z Zts SmadhivananspОценок пока нет

- Thorn 96628932 COLLEGE LED4200-840 HF L1200 (STD) /: Luminaire Data SheetДокумент1 страницаThorn 96628932 COLLEGE LED4200-840 HF L1200 (STD) /: Luminaire Data SheetmadhivananspОценок пока нет

- Project 1: QP Client 1 TypicalДокумент1 страницаProject 1: QP Client 1 TypicalmadhivananspОценок пока нет

- Luminaire Parts List: QP Client 1 TypicalДокумент1 страницаLuminaire Parts List: QP Client 1 TypicalmadhivananspОценок пока нет

- Thorn 96628932 COLLEGE LED4200-840 HF L1200 (STD) /: Luminaire Data SheetДокумент1 страницаThorn 96628932 COLLEGE LED4200-840 HF L1200 (STD) /: Luminaire Data SheetmadhivananspОценок пока нет

- Seismic Test Quali Fied To:: Speci Fication AssistanceДокумент1 страницаSeismic Test Quali Fied To:: Speci Fication AssistancemadhivananspОценок пока нет

- Thorn 96631488 OMEGA C LED1500-830 HF R300 (STD) /: Luminaire Data SheetДокумент1 страницаThorn 96631488 OMEGA C LED1500-830 HF R300 (STD) /: Luminaire Data SheetmadhivananspОценок пока нет

- Thorn 92920058 OP2 3800-840 CKIT+ MPT E3 Q600 (STD) /: Luminaire Data SheetДокумент1 страницаThorn 92920058 OP2 3800-840 CKIT+ MPT E3 Q600 (STD) /: Luminaire Data SheetmadhivananspОценок пока нет

- Thorn 96645147 ARENA LED5000-840 HF TW WL6 EDP (STD) /: Luminaire Data SheetДокумент1 страницаThorn 96645147 ARENA LED5000-840 HF TW WL6 EDP (STD) /: Luminaire Data SheetmadhivananspОценок пока нет

- Boundary Wall LightingДокумент8 страницBoundary Wall LightingmadhivananspОценок пока нет

- Thorn 96627770 OMEGA C LED2800-840 HF R400 (STD) /: Luminaire Data SheetДокумент1 страницаThorn 96627770 OMEGA C LED2800-840 HF R400 (STD) /: Luminaire Data SheetmadhivananspОценок пока нет

- GWC Logistics Village: ClientДокумент1 страницаGWC Logistics Village: ClientmadhivananspОценок пока нет

- Final Submission Schedule For 107 Tenants Schedule For 41 RetailsДокумент2 страницыFinal Submission Schedule For 107 Tenants Schedule For 41 RetailsmadhivananspОценок пока нет

- Thorn 96242095 CETUS LED 1000 HF 830 (STD) /: Luminaire Data SheetДокумент1 страницаThorn 96242095 CETUS LED 1000 HF 830 (STD) /: Luminaire Data SheetmadhivananspОценок пока нет

- Request Form For Changes in Demographics: Tracker/ID No.: Branch CodeДокумент2 страницыRequest Form For Changes in Demographics: Tracker/ID No.: Branch CodewaftmoversОценок пока нет

- Infographic - 9 Common Grid Problems - Critical Power - EN-US - v3Документ1 страницаInfographic - 9 Common Grid Problems - Critical Power - EN-US - v3madhivananspОценок пока нет

- Keep Power Uncritical: Fundamentals of Critical PowerДокумент30 страницKeep Power Uncritical: Fundamentals of Critical PowermadhivananspОценок пока нет

- 41 Retails & 101 Tenants Schedule - R2Документ1 страница41 Retails & 101 Tenants Schedule - R2madhivananspОценок пока нет

- Qatar Design Consortium: Training AttendanceДокумент1 страницаQatar Design Consortium: Training AttendancemadhivananspОценок пока нет

- MAT Related RoomsДокумент1 страницаMAT Related RoomsmadhivananspОценок пока нет

- Norma L: LB6056.510-ENДокумент3 страницыNorma L: LB6056.510-ENmadhivananspОценок пока нет

- 41 Retails & 101 Tenants Status - R1Документ1 страница41 Retails & 101 Tenants Status - R1madhivananspОценок пока нет

- ICBF-Insurance-Enrollment-Form - BlankДокумент1 страницаICBF-Insurance-Enrollment-Form - BlankmadhivananspОценок пока нет

- 03 Wrench Training - 19.08.21Документ1 страница03 Wrench Training - 19.08.21madhivananspОценок пока нет

- Qatar Design TrainingДокумент1 страницаQatar Design TrainingmadhivananspОценок пока нет

- Qatar Design Consortium IMS TrainingДокумент1 страницаQatar Design Consortium IMS TrainingmadhivananspОценок пока нет

- Enviline VLD ENДокумент4 страницыEnviline VLD EN8b8m724mb9Оценок пока нет

- Bee Worksheet No-2 (2018-19)Документ5 страницBee Worksheet No-2 (2018-19)vikhli sallagargiОценок пока нет

- Technical and Economic Impacts of Distributed Generation On Distribution SystemДокумент5 страницTechnical and Economic Impacts of Distributed Generation On Distribution Systemआश्विन मरहट्टाОценок пока нет

- Why bundled conductors improve transmission efficiencyДокумент2 страницыWhy bundled conductors improve transmission efficiencySureshraja9977100% (2)

- Center of MassДокумент27 страницCenter of Massm 418Оценок пока нет

- Auto Re CloseДокумент19 страницAuto Re Closeprateek43513100% (1)

- Simoreg DC Master: Application SIMOREG For DC-Motor Generator Set ControlДокумент24 страницыSimoreg DC Master: Application SIMOREG For DC-Motor Generator Set Controlanas raddawiОценок пока нет

- Power Supply Eng91245767806Документ17 страницPower Supply Eng91245767806pavloneОценок пока нет

- Multiple Re-Strikes Phenomenon When Using Vacuum CircuitДокумент8 страницMultiple Re-Strikes Phenomenon When Using Vacuum Circuitsrinivas80Оценок пока нет

- Ee0041l-Finals (Sa) KilakigaДокумент85 страницEe0041l-Finals (Sa) KilakigaKYLE LEIGHZANDER VICENTEОценок пока нет

- Maharashtra State Electricity Distribution Co. consumer information for 7 KW solar installationДокумент2 страницыMaharashtra State Electricity Distribution Co. consumer information for 7 KW solar installationarun dhakeОценок пока нет

- Bhel Project Report CJДокумент36 страницBhel Project Report CJChandrajeet SinghОценок пока нет

- CombinepdfДокумент255 страницCombinepdfjbОценок пока нет

- Catalogo General Salicru enДокумент60 страницCatalogo General Salicru enMohamedElsawiОценок пока нет

- Unit-2 Induction MotorДокумент8 страницUnit-2 Induction MotorJayantSharmaОценок пока нет

- RME REE Review QuestionsДокумент32 страницыRME REE Review QuestionsAllan BitonОценок пока нет

- VLF FaqДокумент4 страницыVLF Faqminhduc ngoОценок пока нет

- Pros and cons of primary vs secondary metered connectionsДокумент1 страницаPros and cons of primary vs secondary metered connectionsIvan BliminseОценок пока нет

- 4.1 Transformer Part 2Документ16 страниц4.1 Transformer Part 2Mizta HariОценок пока нет

- Pamphlet - System Earthing - English VersionДокумент8 страницPamphlet - System Earthing - English VersionDhanraj chavanОценок пока нет

- Select Cable Size for Current CapacityДокумент96 страницSelect Cable Size for Current CapacitybenjaminОценок пока нет

- Amo Motors Sourcebook Web PDFДокумент96 страницAmo Motors Sourcebook Web PDFalvaronicolas89Оценок пока нет

- GXT-MT 1-3kva - Hoja de DatosДокумент2 страницыGXT-MT 1-3kva - Hoja de DatosGermanYPОценок пока нет

- Man 1200S24Документ14 страницMan 1200S24RameshОценок пока нет

- Auxiliary Relay For Railways: Type PC8AHXДокумент4 страницыAuxiliary Relay For Railways: Type PC8AHXNikki AgarwalОценок пока нет

- PROJECT REVIEW PRESENTATION On Seven Level Grid Connected To PVДокумент17 страницPROJECT REVIEW PRESENTATION On Seven Level Grid Connected To PVKarnam Thojeswar ChowdharyОценок пока нет