Академический Документы

Профессиональный Документы

Культура Документы

Boiler Types

Загружено:

Jhansi Yerrabolu0 оценок0% нашли этот документ полезным (0 голосов)

61 просмотров5 страницboiler types

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документboiler types

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

61 просмотров5 страницBoiler Types

Загружено:

Jhansi Yerraboluboiler types

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 5

Factors affecting the selection of a boiler

One has to send the technical details to the manufacturer to purchase a boiler.

The technical details that are used to give information about a particular boiler include

the following things

Size of drum (Diameter and length)

Rate of steam generation(kg/hr)

Heating surface (Square meters)

Working pressure (bar)

No. of tubes / drum

Type of boiler

Manufacturer of boiler

Initial cost

Quality of steam

Repair and inspection facility

Detailed specifications of each boiler can be obtained from manufacturer's

catalogue.

Comparison between water-tube and fire tube boilers

Water Tube boiler Fire Tube boiler

Water is inside the tube and flue gases Flue gases inside the tube and water

surrounded to it. surrounded to it.

Operating pressure is up to 170-180 bar Operating pressure is up to 25 bar (low

(high pressure boilers). and medium pressure boilers).

Steam generation rate is very high (more Less steam generation rate.

than 3000 kg/hr)

Suitable for power plants. Suitable for small industries.

Chance of explosion is more due to high Chance of explosion is less due to low

steam pressure. steam pressure.

Provide steam in power plants to develop Provide steam in chemical and

electrical energy. pharmaceutical industries.

Small chance of scale formation due to More chance of scale formation

flue gases are in shell

Example: Bobcock and Wilcox boiler Example: Vertical boiler, locomotive

boiler, Lancashire boiler.

Simple Vertical Boiler

Classification of boiler

Vertical, natural circulation, natural draft, single turbular, stationary, medium pressure,

solid fuel fired, fired tube boiler with internally located furnace.

Construction and working:

Figure: Simple Vertical boiler

Figure depicts a typical water tube boiler of early period. It has a cylindrical fire box

surrounded by a cylindrical water shell connected by one inclined cross tube for improved

water circulation. It is provided with standard safety control and inspection mountings.

Boiler drum is filled with water, the flue gas from the furnace rise in the tube. The

exchange of heat takes place between water and flue gases. The water temperature raises

and it converts into steam. The flue gases temperature drops and low temperature flue gases

enters into environment via chimney. Due to provision of cross tube, the total heat transfer

area increases and more amount of steam is available with the same amount of flue gases.

They can built for small capacity and occupy small space. The boiler is fitted with all the

mountings as per IBR.

Cochran Boiler

Classification of boiler

Vertical drum axis, natural circulation, natural draft, multi tubular, low pressure, solid fuel

fired fire tube boiler with internally located furnace.

Construction and working of boiler

Figure: Cochran Boiler:

Figure depicts a Cochran boiler. It is a modified form of simple vertical boiler. It has a

hemispherical crown to given maximum space for steam and very high strength to withstand

high steam pressure.

Generated flue gas from the furnace pass through large number of smaller diameter

tubes located horizontally in the boiler drum. The large heat transfer area is available for

exchange of heat between water and flue gases. The water is converted into steam from the

steam space it is supplied to the plant where the steam is required. Low temperature flue

gases enter the environment via chimney. All the necessary mountings as per IBR is attached

with above boiler.

The advantages of this boiler are its low chimney height, portability, high beaming rate

and burning of clay kind of solid as well as liquid fuel. But it has poor efficiency for smaller

unit, high head space, difficult to inspect and uneconomical in operation.

Locomotive boiler

Classification of boiler

Horizontal drum axis, natural circulation, artificial draft, multi-tubular, medium pressure,

mobile, solid fuel fired, fired tube boiler with furnace located in tubes.

Construction and working

Figure: Locomotive boiler

It is multi-tubular boiler used in railway engines. It is a mobile boiler and steam

generation rate is higher.

The boiler consists of large number of smaller diameter tubes located in a cylindrical

shell along with a rectangular fire box at one end and a smoke box at the other end. Fuel

burn on the inclined grate and flue gases enter into the tubes because of fire bridge arch.

The flue gases pass through number of tubes. Water is surrounded to the tubes. There

is an exchange of heat between water and flue gases. The water convert into steam and

the flue gases at lower temperature enter into chimney. The steam enters the super heater

and the superheated steam is supplied to the steam engine via steam stop valve. The draft

created in above case is of artificial type.

The chimney of this boiler is very short. As such enough draft cannot be created by

chimney. The draft is obtained by passing the steam exhausted from the engine through a

blast-pipe located in the smoke box. The steam passing through the nozzle above the blast

pipe creates enough suction to draw in the air through the tubes. A circular door is provided

at the end of smoke box for inspection and cleaning.

The rate of steam generation accelerated due to vibrations caused by the

movement of the boiler. The boiler has a very low efficiency and cannot carry high overloads

without suffering heavy damage due to overheating.

Babcock and wilcox boiler

Classification of boiler

Horizontal drum axis, natural circulation, natural draft, multitubular, high pressure,

stationary, solid fuel fired, water tube boiler with furnace located externally.

Construction and working

Figure depicts Bobcock and Wilcox boiler. This is high pressure boiler used in power

plants. It consists horizontal boiler drum connected by uptake header and down take header

which in turn are connected by number of inclined tubes of water. The flue gases are

exchange the heat with the water. The position of baffles cause the gas to move in zigzag

way and more heat transfer is possible. A counter flow heating is used. The draft is regulated

by dempers. The water enters the tube through down take header. Due to inclined tubes,

the entire tube is not filled with the water. Due to exchange of heat, the steam is separated

from the water and through uptake header, it enter the steam space inside the boiler drum.

Anti priming pipe is provided to ensure that only the dry saturated steam enter the super

heater via steam stop valve.

It can be built for any width and height because of sectional construction, good

circulation, rapid steaming,, safe and free from explosion, fast response to overloads, ease of

repair, maintenance and cleaning. It is costlier and fluctuation in water level.

Figure: Babcock and Wilcox boiler

Lancashire Boiler

Classification of boiler

Horizontal drum axis, natural circulation, natural draft, two-tubular, medium pressure,

stationary, fire tube boiler with furnace located internally.

Construction and working

Figure shows the constructional details of Lancashire boiler along with different boiler

mountings, brick work, path of flue gases, furnace etc. Fuel is burnt on the grate and the flue

gases can flow from one furnace end to other end of tubes (i.e. from front side to back side

of furnace). This is first pass of flue gas through the boiler tubes. The water is surrounded to the

tube. The heat between the water in the boiler drum and the flue gases inside the tube. So

the steam is formed. Flue gases available at the backside of the furnace can be diverted in

the downward direction due to presence of brick work. (Brick is a very poor conductor of

heat energy and can works as insulating material for a given system). So the flue gases can

flow from the bottom part of the boiler drum and exchange the heat with water. This is

second pass of flue gases outside the tube. So the flue gases are available at front side. From

front, because of brick work, they are divided into two side flues and once again flow

backward from the sides of boiler drum and finally are expelled out to stack chimney through

main flue. Dampers are provided at the end of side flues to regulate the flow of flue gases.

Figure: Lancashire boiller

The disadvantages of the boiler include more floor space, leakage problems through

brick-settings, more steaming time, sluggish water circulation, limitation of high pressure of

steam and limited space for grate area of furnace.

The advantage of Lancashire boiler are large steam space, load fluctuations can easily

be met, easy to clean and inspect, reliable, easy to operate and maintain.

Steam boiler mountains

In accordance with the Indian boiler regulations the following mountings should be

fitted to boilers.

Safety valves: The function of the valve is to blow off the steam when the pressure of the

steam in the boiler exceeds the working pressure

Water level Indicator: Its function is to indicate level of water, its upper and open in steam

space and lower and opens to water space

Pressure gauge: It is for indicating the pressure of steam in a boiler

Steam stop valve: It stops or allows the flow of steam from the boiler to the steam pipe.

Feed check valve: It allows or stops the supply of water to the boiler

Blow off cock: It is for removal of sediment periodically collected at the bottom of the

boiler

Man hole: It is provided in opening from which a man can enter in a boiler for cleaning

Fusible plug: Its function is to extinguish fire in the furnace of a boiler when the water level

in the boiler fails to an unsafe extent thereby preventing the explosion which may takes

place furnace plate

Boiler accessories

Economizers

Air pre-heaters

Super heaters

Feed pump

Injectors

Economizers

Using economizer some of the heat recovered and sent back to the boilers in the

feed water if an economizer is placed between the boiler and chimany.

The waste fire gases flow outside the economizer tubes and heat is transferred to the

fuel water which flows upward inside the tubes. The external surfaces of the tubes are kept

free from soft by scrapers which travels slowly and continuously up and down the tubes.

Вам также может понравиться

- Steam Boilers ME 1103 Introduction To MeДокумент27 страницSteam Boilers ME 1103 Introduction To MePriyadarshee ShaswatОценок пока нет

- Introduction: Marine Boiler Safety ValvesДокумент2 страницыIntroduction: Marine Boiler Safety ValvesSahil MishraОценок пока нет

- Boiler Q&A FurtherДокумент7 страницBoiler Q&A FurtherRachitОценок пока нет

- Coc Oral Exam Preparation (Part - 17) : Boiler Safety ValveДокумент3 страницыCoc Oral Exam Preparation (Part - 17) : Boiler Safety ValveshashankrawatОценок пока нет

- Hydraulic TestДокумент33 страницыHydraulic TestAshok RasekarОценок пока нет

- Boiler MountingsДокумент7 страницBoiler MountingsPoloju Srinath100% (1)

- Coc Oral Boiler Safety Valve13 PDFДокумент6 страницCoc Oral Boiler Safety Valve13 PDFshamratОценок пока нет

- Troubleshooting Boiler OperationДокумент5 страницTroubleshooting Boiler OperationRahul ChandrawarОценок пока нет

- Condenser & BoilerДокумент33 страницыCondenser & BoilerShaun Patrick Albao100% (1)

- Crankcase Inspection Safety & Procedure MMD Favourite QuestionsДокумент1 страницаCrankcase Inspection Safety & Procedure MMD Favourite QuestionsAnkit ChatterjeeОценок пока нет

- List The Starting Procedure You Are Doing To Start The Fresh Water Generator Using Main Engine Jacket Heating - Nclude All The Checks You Are MakingДокумент2 страницыList The Starting Procedure You Are Doing To Start The Fresh Water Generator Using Main Engine Jacket Heating - Nclude All The Checks You Are MakingDen EdiОценок пока нет

- 34 - 244Документ208 страниц34 - 244rohithunni100% (1)

- Phase II Boiler QuestionsДокумент12 страницPhase II Boiler QuestionsNithin VargheseОценок пока нет

- Purifier Manual DesludgeДокумент1 страницаPurifier Manual Desludgesubscru100% (1)

- Oil Centrifuge TrainingДокумент65 страницOil Centrifuge Trainingsayed2allОценок пока нет

- EX-7 Overhauling of Boiler BurnerДокумент2 страницыEX-7 Overhauling of Boiler BurnerAayush Agrawal100% (1)

- Operational Information The Air Start ValveДокумент5 страницOperational Information The Air Start ValveHrishikesh More100% (1)

- Meo Class 4Документ55 страницMeo Class 4adam shaneОценок пока нет

- Safety Valve Setting BoilerДокумент2 страницыSafety Valve Setting BoilerkrishnaОценок пока нет

- 08 Exhaust ValveДокумент66 страниц08 Exhaust ValveSky RОценок пока нет

- Cylinder Liner WearДокумент1 страницаCylinder Liner WearThuria Tun100% (1)

- Cochran BoilerДокумент30 страницCochran BoilerDr. BIBIN CHIDAMBARANATHAN100% (1)

- Lubricating System DescriptionДокумент4 страницыLubricating System DescriptionjamesОценок пока нет

- PURIFIERSДокумент7 страницPURIFIERSjames dogelioОценок пока нет

- Boiler Emergencies - 2017Документ10 страницBoiler Emergencies - 2017RAJKUMAR100% (1)

- Boiler Safety ValveДокумент11 страницBoiler Safety ValveAayush Agrawal100% (1)

- Mep Oral AnswersДокумент28 страницMep Oral AnswersAshjo Gamer100% (1)

- FWG TroubleshootingДокумент7 страницFWG TroubleshootingMariappan Na100% (5)

- Boiler Start-Up & Shut-DownДокумент42 страницыBoiler Start-Up & Shut-DownBurhan Khan100% (1)

- Class 4 Frequent Asked Qs Shashwat000Документ168 страницClass 4 Frequent Asked Qs Shashwat000Lovy Singh100% (1)

- Basic Principles of Steam Turbine1Документ141 страницаBasic Principles of Steam Turbine1Durga Prasad PadhyОценок пока нет

- Centrifugal PumpДокумент39 страницCentrifugal PumpGogot Pantja Parijogo100% (1)

- Self Cleaning PurifierДокумент2 страницыSelf Cleaning PurifierPar Nd Oo100% (1)

- What Is Ovality of Auxiliary Engine Crank Pin?Документ62 страницыWhat Is Ovality of Auxiliary Engine Crank Pin?sumitsinha89Оценок пока нет

- Ram Steering Gear - OperationsДокумент8 страницRam Steering Gear - Operationsnarendra rathoreОценок пока нет

- Presentation On Condensers and EvaporatorsДокумент32 страницыPresentation On Condensers and Evaporatorsvipul sharma100% (1)

- How To Operate An Oily Water SeparatorДокумент2 страницыHow To Operate An Oily Water SeparatorKHOI TIMОценок пока нет

- CoC Oral Exam Preparation (Part - 16) - CO2 Flooding System - Marine StudyДокумент6 страницCoC Oral Exam Preparation (Part - 16) - CO2 Flooding System - Marine StudyShaip Sankar100% (1)

- Boiler PantingДокумент3 страницыBoiler PantingAnkit DedhiyaОценок пока нет

- Purifier Basics - Basic For Junior Marine Engineers-Rammarsea - PURIFIERSДокумент6 страницPurifier Basics - Basic For Junior Marine Engineers-Rammarsea - PURIFIERSmanjuОценок пока нет

- Exhaust ValvesДокумент3 страницыExhaust ValvesJitendra Kumar100% (1)

- Refrigeration NotesДокумент4 страницыRefrigeration NotesWai Phyo AungОценок пока нет

- AALBORG ThermalFluidSystemДокумент10 страницAALBORG ThermalFluidSystemrafiradityaОценок пока нет

- Boiler Module VДокумент23 страницыBoiler Module VdeepanckОценок пока нет

- Boiler Safety Valve Examination and Attention During OverhaulingДокумент11 страницBoiler Safety Valve Examination and Attention During OverhaulingSwarg VibhaОценок пока нет

- Operational Information The Two Stroke Crosshead Engine The Stuffing BoxДокумент6 страницOperational Information The Two Stroke Crosshead Engine The Stuffing BoxAbhishek Singh ChauhanОценок пока нет

- Steam TurbineДокумент77 страницSteam TurbineAmit KhadkaОценок пока нет

- Chemicalcleaning For BoilerДокумент16 страницChemicalcleaning For Boilerak_thimiriОценок пока нет

- Instruction Manual Boiler LYF SeriesДокумент19 страницInstruction Manual Boiler LYF SeriesSergeyОценок пока нет

- Boiler Mountings and AccessoriesДокумент12 страницBoiler Mountings and AccessoriesGokulAgОценок пока нет

- MAIN ENGINE ALARMS AND INTERLOCKS & Engine Monitoring System (CSIM) & PAM)Документ32 страницыMAIN ENGINE ALARMS AND INTERLOCKS & Engine Monitoring System (CSIM) & PAM)Harishbhusan PanigrahiОценок пока нет

- Oral GeneralДокумент8 страницOral GeneralPrakhyati RautОценок пока нет

- What Is Lamont Boiler?Документ3 страницыWhat Is Lamont Boiler?Muhammad Fahmi HidayatullohОценок пока нет

- Boiler Operation EngineerДокумент10 страницBoiler Operation EngineerSarah Frazier100% (2)

- Types Liner Material Problems in Liner Liner Inspection Liner Calibration Difference Between MAN B&W and SULZER LinersДокумент7 страницTypes Liner Material Problems in Liner Liner Inspection Liner Calibration Difference Between MAN B&W and SULZER LinersRicardo Garing100% (2)

- Crankcase ExplosionДокумент9 страницCrankcase ExplosionSrini VasanОценок пока нет

- Babcock and Wilcox Boiler 1Документ6 страницBabcock and Wilcox Boiler 1CK CkkouОценок пока нет

- BoilerДокумент73 страницыBoilerMahesh Babu TalupulaОценок пока нет

- Industrial BoilersДокумент32 страницыIndustrial BoilersNipun SabharwalОценок пока нет

- TemplateДокумент10 страницTemplateAudrey LaiОценок пока нет

- (Chapter 6) Examples PDFДокумент6 страниц(Chapter 6) Examples PDFKarwan GoodОценок пока нет

- Effect of Axial Gap Between Inlet Nozzle and Impeller On EfficienyДокумент12 страницEffect of Axial Gap Between Inlet Nozzle and Impeller On EfficienyHüseyin Atakan BaytaşОценок пока нет

- Control Valves FinaleДокумент111 страницControl Valves FinaleAndrei SabaterОценок пока нет

- Fluid Power Automation: Unit-IДокумент36 страницFluid Power Automation: Unit-ISelva BabuОценок пока нет

- HIDRAULICO Cat 772Документ2 страницыHIDRAULICO Cat 772Tom SouzaОценок пока нет

- Verona DiagramДокумент9 страницVerona DiagramPhillipe LysОценок пока нет

- Siddhi ConstructionДокумент16 страницSiddhi Constructionsamyak munotОценок пока нет

- Series TD: Type TDL Type TDMДокумент16 страницSeries TD: Type TDL Type TDMAhmadОценок пока нет

- Module 5 - Rotodynamic Pumps-Part 1Документ28 страницModule 5 - Rotodynamic Pumps-Part 1ASHITA K B100% (1)

- Cameron WKM M Pow-R-Seal Gate Valve - PDS0139Документ1 страницаCameron WKM M Pow-R-Seal Gate Valve - PDS0139Karl TbsgОценок пока нет

- !TG Filter Cross Reference2021-Rev01Документ225 страниц!TG Filter Cross Reference2021-Rev01Алексей ГалайдинОценок пока нет

- Static Pressure CalculatorДокумент6 страницStatic Pressure CalculatorVictor ValenciaОценок пока нет

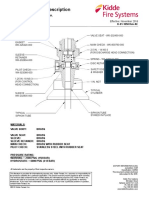

- CO Component Description: Type "I" Cylinder Valve, 5/8-In. With Typical Cylinder P/N: WK-840253-000Документ1 страницаCO Component Description: Type "I" Cylinder Valve, 5/8-In. With Typical Cylinder P/N: WK-840253-000RAFAEL NASCIMENTO DA SILVAОценок пока нет

- Instrument Data Sheets: IndraДокумент462 страницыInstrument Data Sheets: Indramed chabaneОценок пока нет

- Fluid System Energy TransferДокумент19 страницFluid System Energy TransferRetarudОценок пока нет

- Hyundai Crawler Excavator Service GuideДокумент227 страницHyundai Crawler Excavator Service Guidemohammed barghothi100% (3)

- 52VC1200 DUAL Desglose Parts. Clutches y Sistema de Aire - EL BROCAL (EA PDFДокумент6 страниц52VC1200 DUAL Desglose Parts. Clutches y Sistema de Aire - EL BROCAL (EA PDFJoseОценок пока нет

- Planos Hidraulicos 385cДокумент2 страницыPlanos Hidraulicos 385cmarco gonzalezОценок пока нет

- Solucionario Cohen Turbinas A GasДокумент84 страницыSolucionario Cohen Turbinas A GasErickson Brayner MarBer100% (2)

- Compressed Air SizingДокумент6 страницCompressed Air SizingAshish PawarОценок пока нет

- INSTALACION Valvula Reguladora de PresionДокумент2 страницыINSTALACION Valvula Reguladora de Presionfabian cardenasОценок пока нет

- Wilo Mather and Platt Pumps Pvt. LTD.: Technical DatasheetДокумент2 страницыWilo Mather and Platt Pumps Pvt. LTD.: Technical DatasheetTrung Trần MinhОценок пока нет

- Lab Manual-H & P-1me2603Документ40 страницLab Manual-H & P-1me2603Hi helloОценок пока нет

- Pressure Equipment Directive (Ped) - An IntroductionДокумент4 страницыPressure Equipment Directive (Ped) - An Introductionjamil voraОценок пока нет

- Jockey Pumps: Peerless Pump Company MTH Tool Co. Series T41, T51, 150, 160 Regenerative Turbine Vane TypeДокумент2 страницыJockey Pumps: Peerless Pump Company MTH Tool Co. Series T41, T51, 150, 160 Regenerative Turbine Vane TypeAndri AjaОценок пока нет

- Activity Fluid MachineryДокумент1 страницаActivity Fluid MachineryDryx LetranОценок пока нет

- Kadanwari Produced Water System AnalysisДокумент15 страницKadanwari Produced Water System AnalysisBurhan AyubОценок пока нет

- Flow Sheet Eh-500fk 1000-030-9846Документ1 страницаFlow Sheet Eh-500fk 1000-030-9846thanh thien nguyenОценок пока нет

- 3000l001 (PARKER)Документ16 страниц3000l001 (PARKER)Ânderson Silva BrasilОценок пока нет