Академический Документы

Профессиональный Документы

Культура Документы

Pelton Turbine Ta Notes

Загружено:

Shafiq HakimiАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Pelton Turbine Ta Notes

Загружено:

Shafiq HakimiАвторское право:

Доступные форматы

PELTON TURBINE EXPERIMENT

T.A. Notes

12/05/06 Doug Houser

The IIHR Pelton turbine experiment demonstrates to the students a complete

hydroelectric power system, from generation to consumer usage. The experiment is

instrumented as to allow the students to measure hydraulic pressure and flow, turbine

speed and torque, and generator speed, voltage, and current.

SETTING THE POWER & WATER FOR THE EXPERIMENTAL SETUP

The pump feeding this circuit is set in a pit in the neighborhood of the experiment (N side

of East Annex), as shown in Figure 1. The power to this pump is supplied by a set of

control panels as shown in Figure 1 and 2.

Check to make sure that the following connections on the water supply system are in

place (see Figure 1)

- Valve 1, fully open

- Valve 2, fully closed

- The only valve controlling the water to the turbine is the one set near the turbine

housing. It should be in the close position at the beginning of the experiment.

- Make sure that the handle on the on the SAFETY SWITCH located on the wall in

the pump pit is in the On position (this is a switch used only for repairing

situations)

Sequence of steps to power the pump (see Figure 2):

- Turn the handle on the PRIMARY DISCONNECT to On.

- Set the handle on the DOUBLE DISCONNECT to the upper On position (that

corresponds for the Pelton experiment).

- On the digital display, push the Enter key to go into the Frequency menu. Set the

desired frequency on the VFD using the and keys (for safety set the desired

frequencies using small steps until you reach the targeted one; avoid setting

frequencies larger that 90%. Note: the key for frequency setting runs in

increasing frequency steps if kept continuously pressed. Consequently, monitor

the display and push repeatedly the button). Push the Enter key on VFD to make

the frequency effective.

- Finally, push Run.

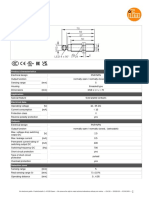

Figure 1. Layout of the pump pit associated with the water feeding system to the Pelton

turbine

Figure 2. Power control panel

Before and after the measurements:

Before: Close the drain valves on the bottom of the basin. Make sure the discharge

controlling valve (the yellow valve next to the pressure gauge) is open at all

times. The cooling water valves for the friction plates have to be opened.

After: Turn the pump off, and open the drainage valves so that the holding tank will

completely empty.

RUNNING THE EXPERIMENT

The reservoir elevation (head pressure) is simulated by the pump running at 90% of full

speed, and is measured by the pressure gauge on the input to the turbine. The flow to the

turbine is adjusted by the valve on the input to the turbine, and is measured by the point

gage on the v-notch wear discharge of the turbine. The turbine speed is adjusted by the

input flow valve and is measured by the digital turbine speed panel meter (RPM). The

turbine torque is measured by an in-line rotating torque sensor and is displayed on the

digital panel meter (lb-in).

A power curve for the turbine can be obtained by applying a frictional load to the

output of the torque sensor by way of the small handwheel on the front panel. As load is

applied to the turbine, the torque and speed can be measured by the digital panel meters,

while the pressure and flow are measured by the pressure gauge and the point gage.

Thus, by applying different loads at different speeds, you can obtain a power curve over

the entire speed range of the turbine.

For the electrical generation part of the experiment, the frictional load is removed

by turning the small handwheel out several revolutions.

The generator clutch is engaged at very low turbine speed by the front panel

switch, and the generator is brought up to 60Hz as measured by the digital generator

speed panel meter, using the input flow valve. It should be noted on the digital displays

that the generator speed and the turbine speed are not the same, but the ratio between the

two is constant. This shows that the generator must operate at 3600 RPM (60Hz), but the

turbine can operate at its optimum design speed for maximum torque, and the connecting

drivetrain between the two must compensate for this speed difference through a gearbox,

sheave ratio, etc. At this point, even though we have no electrical load connected to the

system, as evidenced by the generator voltage meter reading of approximately 240V AC

and the generator current meter reading of 0, students can measure the input hydraulic

pressure and flow to the turbine, and the output torque and speed of the turbine. This

shows the energy used by the power company itself, before it has any energy available

for sale to the public, and is used up in the forms of pipe friction, bearing and drivetrain

friction, turbine efficiency, and generator excitation.

As the first electrical load (600w overhead lights) is applied to the generator,

through the front panel switch, it will be seen that the generator speed slows down and

the output voltage drops. The input valve must opened somewhat to maintain the

standard 60Hz power line frequency. The input hydraulic energy (pressure and flow), the

mechanical energy (turbine speed and torque) and electrical energy (voltage and current)

can all be calculated. As the second electrical load (600w overhead lights) is applied to

the generator along with the first, through the second front panel switch, it will be seen

that again the generator speed slows down and the output voltage drops. Again, the input

valve must be opened slightly to maintain 60Hz; energy losses and efficiencies can be

calculated throughout the system. The process is repeated for electrical loads 3 and 4,

each time measuring the hydraulic, mechanical, and electrical properties, and then

calculating the efficiencies or losses.

As the fifth electrical load is applied to the generator, it will be shown that the

input valve has reached the maximum and still the generator speed has not reached the

standard operating frequency of 60Hz. This shows that consumer demand for power has

exceeded the generating capability of our hydroelectric facility and a “brownout”

condition has occurred. At this point, what usually happens is that the power utility

company will disconnect a block of consumers so that the energy demand again falls

within the generating capability of the system. This causes a “blackout” for those who

were disconnected, but the remainder of the system operates at the standard of 60Hz.

This is shown by turning off the fifth electrical load, and the students will see that the

generator speed has exceeded 60Hz, and the input valve must be closed slightly to obtain

the 60Hz standard generator speed.

Loads 4 through 1 are turned off one at a time, and each time it will be shown that

the input valve must be closed somewhat to maintain the desired 60Hz generator speed.

It should be pointed out to the students that even though this experiment is simplified, the

relationship is still true in the “real world” systems, that as the electrical load demand of

the consumer network increases and decreases, minute by minute, someone or something

is compensating for that change by opening or closing the input flow to a turbine to

maintain the 60Hz power frequency standard.

Вам также может понравиться

- 02 Laboratory Practicum - Pelton TurbineДокумент10 страниц02 Laboratory Practicum - Pelton TurbineShafiq HakimiОценок пока нет

- JuuuuuДокумент7 страницJuuuuuShafiq HakimiОценок пока нет

- GE FormA1Документ5 страницGE FormA1Syazwan RozhanОценок пока нет

- Sustainability Report2012 2013Документ9 страницSustainability Report2012 2013Shafiq HakimiОценок пока нет

- Head, Efficiency and BHP vs Flow RateДокумент6 страницHead, Efficiency and BHP vs Flow RateShafiq HakimiОценок пока нет

- Discussion Advance ManufacturingДокумент6 страницDiscussion Advance ManufacturingShafiq HakimiОценок пока нет

- Shapes Guide HydroДокумент53 страницыShapes Guide HydroShafiq HakimiОценок пока нет

- Sustainability Report2012 2013 PDFДокумент128 страницSustainability Report2012 2013 PDFMardhiah RamlanОценок пока нет

- Improving Efficiency of Micro Hydro Power PlantsДокумент15 страницImproving Efficiency of Micro Hydro Power PlantsShafiq HakimiОценок пока нет

- R Grenville Thesis 1992 PDFДокумент196 страницR Grenville Thesis 1992 PDFShafiq HakimiОценок пока нет

- l310 360 365 Ink Tank System PrinterДокумент4 страницыl310 360 365 Ink Tank System PrinterShafiq HakimiОценок пока нет

- Thumpstar 125cc Engine Parts ListДокумент17 страницThumpstar 125cc Engine Parts ListMinibikeTech67% (3)

- Step 1Документ1 страницаStep 1Shafiq HakimiОценок пока нет

- AiyaДокумент7 страницAiyaShafiq HakimiОценок пока нет

- DFHGDH HKHJKHJKДокумент1 страницаDFHGDH HKHJKHJKShafiq HakimiОценок пока нет

- Sprocket Engineering DataДокумент32 страницыSprocket Engineering DataCesar Dominguez ParedesОценок пока нет

- Experimental Procedure: Procedure 1: To Determine The Spring Constant KДокумент1 страницаExperimental Procedure: Procedure 1: To Determine The Spring Constant KShafiq HakimiОценок пока нет

- 6.0 Data TabulationДокумент9 страниц6.0 Data TabulationShafiq HakimiОценок пока нет

- Cover Page Assingment 22Документ1 страницаCover Page Assingment 22Shafiq HakimiОценок пока нет

- Background and Theory Flow Pass A Circular CylinderdocxДокумент8 страницBackground and Theory Flow Pass A Circular CylinderdocxShafiq HakimiОценок пока нет

- 1Документ3 страницы1Shafiq HakimiОценок пока нет

- 1 Flyer Quality - Engineering-2015Документ2 страницы1 Flyer Quality - Engineering-2015Shafiq HakimiОценок пока нет

- Ikhlas P.A Permata Takaful Pds - Eng RevisedДокумент4 страницыIkhlas P.A Permata Takaful Pds - Eng RevisedShafiq HakimiОценок пока нет

- Liquid H2O Is The Sine Qua Non of LifeДокумент2 страницыLiquid H2O Is The Sine Qua Non of LifeShafiq HakimiОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Electrical Power T&D System: Module Iii - SubstationДокумент60 страницElectrical Power T&D System: Module Iii - SubstationYusup SuryadiОценок пока нет

- EI6602 Power Plant InstrumentationДокумент2 страницыEI6602 Power Plant Instrumentationjayashree avanthikaОценок пока нет

- Ig5595 00 - en GBДокумент3 страницыIg5595 00 - en GBw automationОценок пока нет

- A Review of Transmission Losses in Planning StudiesДокумент54 страницыA Review of Transmission Losses in Planning StudiesJosiah Jonathan SuatanОценок пока нет

- Protection Settings for #01 Startup/Standby TransformerДокумент46 страницProtection Settings for #01 Startup/Standby TransformerAmaresh NayakОценок пока нет

- Numerical Relay Protection of Transformer PDFДокумент19 страницNumerical Relay Protection of Transformer PDFShubham Sharma100% (1)

- FR100 Series User Manual en V1.5 20180511Документ131 страницаFR100 Series User Manual en V1.5 20180511RICHARD0% (2)

- Electrical Commissioning ProblemsДокумент18 страницElectrical Commissioning ProblemsAshroof AbdoОценок пока нет

- Ups Data Sheet 60kva - Falx5Документ4 страницыUps Data Sheet 60kva - Falx5Rajesh ThulasiramОценок пока нет

- Chapter 1Документ29 страницChapter 1Ranjan DhungelОценок пока нет

- Safety of Kudankulam Nuclear Power Plant and Impact of Its Operation On The SurroundingsДокумент77 страницSafety of Kudankulam Nuclear Power Plant and Impact of Its Operation On The SurroundingsSathish ChelliahОценок пока нет

- Overvoltage, Undervoltage and Residual Voltage Relay Spau 320 CДокумент12 страницOvervoltage, Undervoltage and Residual Voltage Relay Spau 320 CWalter Andres Estevez VasquezОценок пока нет

- Wind Energy Conversion System Topologies and Converters: Comparative ReviewДокумент10 страницWind Energy Conversion System Topologies and Converters: Comparative Reviewtayeb deОценок пока нет

- X4020126-302 OutgoingДокумент35 страницX4020126-302 Outgoingbobb djОценок пока нет

- 5000-W5: SO-5000/5100/5600 POWER SUPPLY INTER-CONNECTORS: Scan Optics Service Manual - Wiring Diagrams Page 67 of 75Документ1 страница5000-W5: SO-5000/5100/5600 POWER SUPPLY INTER-CONNECTORS: Scan Optics Service Manual - Wiring Diagrams Page 67 of 75Madhavesh KulkarniОценок пока нет

- PDS Project Profile 500-kV Hassayampa SwitchyardДокумент1 страницаPDS Project Profile 500-kV Hassayampa SwitchyardKCGeraghtyОценок пока нет

- ECE 404 HW #6 Power Systems CalculationsДокумент7 страницECE 404 HW #6 Power Systems CalculationsRodrigo BabijisОценок пока нет

- PDF Version - PAC World MagazineДокумент7 страницPDF Version - PAC World Magazinenutchai2538Оценок пока нет

- Static Ups Testing.1Документ5 страницStatic Ups Testing.1322399mk7086Оценок пока нет

- 2565 Engineering Tech Awards Dip MechДокумент92 страницы2565 Engineering Tech Awards Dip MechTharindu Samith AbeywickramaОценок пока нет

- OMRON Inverter PDFДокумент64 страницыOMRON Inverter PDFK.S. BalasubramaniamОценок пока нет

- Vishay Library Components ListДокумент55 страницVishay Library Components ListCristian Alejandro Ayon TzintzunОценок пока нет

- Protection Relays TrainingДокумент5 страницProtection Relays Trainingrajpre1213Оценок пока нет

- Compensated Drum LevelДокумент1 страницаCompensated Drum LevelFarrukh MajeedОценок пока нет

- AC Machine (Generator-Alternator) - WPS OfficeДокумент88 страницAC Machine (Generator-Alternator) - WPS OfficeJohnray HabolОценок пока нет

- Branch Circuit Calculations Feeders Services and Overcurrent DevicesДокумент61 страницаBranch Circuit Calculations Feeders Services and Overcurrent DevicesVic Rizenn Isidore BobilesОценок пока нет

- DC Power SupplyДокумент8 страницDC Power Supplyweaam raedОценок пока нет

- Circuit Protection PrincipleДокумент44 страницыCircuit Protection PrincipleNoli OtebaОценок пока нет

- SREDA Module 3 Energy Efficiency in Electrical SystemsДокумент257 страницSREDA Module 3 Energy Efficiency in Electrical SystemstowkirОценок пока нет

- DataSheet Cummins QSK60 PDFДокумент10 страницDataSheet Cummins QSK60 PDFCarlos Andrés Marín ArcosОценок пока нет