Академический Документы

Профессиональный Документы

Культура Документы

Cluster 3 Round 1 ChE 133

Загружено:

AlyssaRamos0 оценок0% нашли этот документ полезным (0 голосов)

11 просмотров1 страницаigi

Авторское право

© © All Rights Reserved

Доступные форматы

DOCX, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документigi

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

11 просмотров1 страницаCluster 3 Round 1 ChE 133

Загружено:

AlyssaRamosigi

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 1

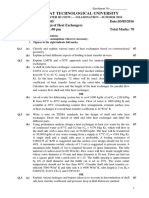

A chemical engineering student is designing a prototype for a double-pass shell

and tube heat exchanger to be used in heating benzene for a reactor and with

saturated steam used as a heating fluid. The heat exchanger is composed of 52

smaller tubes enclosed in a shell casing (tube layout below):

The student wants to determine the length of the tubes to be used. Using the heat

exchanger specifications below, can you help him out?

Exchanger specifications: 52 tubes total; 1” BWG 16 copper tubes (OD=1”,

ID=0.87”)

Tube-side fluid: Benzene entering at 25°C leaving at 120°C, at a rate of

25,000 kg/hr (0.3829 cP, 835.9 kg/m³, 1.17 kJ/kg-K, 0.1705 W/m-K)

Shell-side fluid: Steam condensing at 270.1 kPa and the outer surface has

an average temperature of 100°C (Use Tsat for required heat and area

calculations)

Note: Use SVA for saturated steam properties

Вам также может понравиться

- Gujarat Technological UniversityДокумент2 страницыGujarat Technological UniversityBala DuttОценок пока нет

- Glasgow College of Nautical Studies Engineering DepartmentДокумент2 страницыGlasgow College of Nautical Studies Engineering DepartmentMullah FassudinОценок пока нет

- Design III HX Design Tutorial 3 Solutions PDFДокумент4 страницыDesign III HX Design Tutorial 3 Solutions PDFMziyanda Boet-Bhayi Shumî100% (2)

- H00413783LAB4Документ8 страницH00413783LAB4Huda AlkhouriОценок пока нет

- Kettle ReboilersДокумент6 страницKettle ReboilersHow Jie WeiОценок пока нет

- 03 ME 6022 Design of Heat Transfer EquipmentsДокумент1 страница03 ME 6022 Design of Heat Transfer EquipmentsVenkitaraj K PОценок пока нет

- Ped QuestionsДокумент11 страницPed QuestionsYashPatel100% (1)

- Tutorial 3 - Revised SolutionДокумент11 страницTutorial 3 - Revised Solutionngoc.nguyenlamОценок пока нет

- 2011 MidsemДокумент2 страницы2011 MidsemPrashant PrabhakarОценок пока нет

- Mex306 - Thermodynamics and Fluid Mechanics Referred/Deferred ExaminationДокумент4 страницыMex306 - Thermodynamics and Fluid Mechanics Referred/Deferred ExaminationNiroshan VaratharajahОценок пока нет

- Shell and Tube Heat Exchanger DesignДокумент22 страницыShell and Tube Heat Exchanger Designsuperbugima100% (1)

- Co HenДокумент40 страницCo HenHiltonОценок пока нет

- Heat Transfer Paper 2021Документ1 страницаHeat Transfer Paper 2021Hassan FaheemОценок пока нет

- Heat Exchanger Design: ME 310 Thermo-Fluid System DesignДокумент30 страницHeat Exchanger Design: ME 310 Thermo-Fluid System DesignAlif RifatОценок пока нет

- C5 ExerciseДокумент18 страницC5 ExerciseHƯƠNG NGUYỄN LÊ NGỌCОценок пока нет

- 2023 MteДокумент6 страниц2023 MteISHAAN JAIN 22114039Оценок пока нет

- 1 Recap Exercises - TextДокумент3 страницы1 Recap Exercises - TextGabriel Cabrera PetroneОценок пока нет

- Icam (Lille) - Heat Exchanger Course Icam 2 - Autumn 2003 Heat Exchanger Examples - Sheet 2Документ3 страницыIcam (Lille) - Heat Exchanger Course Icam 2 - Autumn 2003 Heat Exchanger Examples - Sheet 2FahmiRamdanОценок пока нет

- Heat Exchanger Tutorial Sheet 5Документ4 страницыHeat Exchanger Tutorial Sheet 5Charlotte BОценок пока нет

- Heat Exchanger Tutorial Sheet 5Документ4 страницыHeat Exchanger Tutorial Sheet 5Charlotte BОценок пока нет

- Tutorial 5 TFP260S PDFДокумент2 страницыTutorial 5 TFP260S PDFHundzukani Ngobeni100% (1)

- Heat Exchanger System For NH3 ReformngДокумент10 страницHeat Exchanger System For NH3 ReformngSalman ShahzadОценок пока нет

- Heatex 02 AwДокумент3 страницыHeatex 02 AwyvethendoОценок пока нет

- Preboards 3-PipeДокумент4 страницыPreboards 3-PipeChyno KangОценок пока нет

- Prepared By: Mr. Harsh PanchalДокумент46 страницPrepared By: Mr. Harsh PanchalKáûshàl PãtëlОценок пока нет

- A Centrifugal Pump Is Drawing Water From An Overhead Tank - Autosaved - AutosavedДокумент16 страницA Centrifugal Pump Is Drawing Water From An Overhead Tank - Autosaved - AutosavedAkshat KhandelwalОценок пока нет

- PEDD Question Bank For STHEДокумент6 страницPEDD Question Bank For STHERajat SrivastavaОценок пока нет

- Lva1 App6892Документ8 страницLva1 App6892BRAHIMОценок пока нет

- ME34 - ME Laboratory 2 - : Signature of Student Under Printed NameДокумент12 страницME34 - ME Laboratory 2 - : Signature of Student Under Printed NameSky FallОценок пока нет

- Jntuworld: R07 Set No. 2Документ6 страницJntuworld: R07 Set No. 2Dolly PriyaОценок пока нет

- MIN-305 Heat & Mass Transfer Tutorial - 6Документ2 страницыMIN-305 Heat & Mass Transfer Tutorial - 6Akhilesh GuptaОценок пока нет

- ME156 Exam 2Документ2 страницыME156 Exam 2Shaina Musa100% (1)

- Issn: 2349-3860Документ18 страницIssn: 2349-3860Pat TejОценок пока нет

- Sample Question Paper Thermal EngineeringДокумент5 страницSample Question Paper Thermal Engineeringरितेश हरोडेОценок пока нет

- Double Pipe Heat Exchanger - SsДокумент72 страницыDouble Pipe Heat Exchanger - SsNathanian100% (2)

- Hexdesign PartialДокумент14 страницHexdesign Partialcoldness_13Оценок пока нет

- Sheet #1-AДокумент2 страницыSheet #1-Aفضائح لا تصدقОценок пока нет

- Tutorial Heat Exchanger Sem 1 2019 2020 PDFДокумент3 страницыTutorial Heat Exchanger Sem 1 2019 2020 PDFmimie azideeОценок пока нет

- Soal Coulson Richardson Page 696-706 (STHE Design)Документ11 страницSoal Coulson Richardson Page 696-706 (STHE Design)Glen gaylandОценок пока нет

- Tutorial Heat ExchangerДокумент2 страницыTutorial Heat ExchangerAhmad Nor Fahmi WalidОценок пока нет

- Design of Heat ExchangerДокумент20 страницDesign of Heat ExchangerSHIVAM GUPTAОценок пока нет

- Uj 37298+SOURCE1+SOURCE1.1Документ12 страницUj 37298+SOURCE1+SOURCE1.1katgenius03Оценок пока нет

- Firetube Heaters: FIG. 8-31 Convection HeaterДокумент7 страницFiretube Heaters: FIG. 8-31 Convection Heatery149487Оценок пока нет

- Thapar University, Patiala Department of Chemical Engineering B.E. - CHE (IV - Semester) MSEДокумент2 страницыThapar University, Patiala Department of Chemical Engineering B.E. - CHE (IV - Semester) MSEazsdxОценок пока нет

- Tutorial 6Документ3 страницыTutorial 6Hoài ThươngОценок пока нет

- Lec#09 PHT - (04 Mar 2013 - Monday) - Design of Shell & Tube Heat ExchangerДокумент30 страницLec#09 PHT - (04 Mar 2013 - Monday) - Design of Shell & Tube Heat ExchangerQamar AbbasОценок пока нет

- PIPE20 PREBOARD202 PDFДокумент15 страницPIPE20 PREBOARD202 PDFJimwell Bobadilla100% (1)

- T1 Ug 90Документ6 страницT1 Ug 90germangsilvaОценок пока нет

- Andrew ProbsДокумент2 страницыAndrew ProbsGiea Patricze ArcaОценок пока нет

- Department of Chemical Engineering Obafemi Awolowo University Engineering Thermodynamics CHE 201 Tutorial Set 3Документ1 страницаDepartment of Chemical Engineering Obafemi Awolowo University Engineering Thermodynamics CHE 201 Tutorial Set 3Chibuike CharlesОценок пока нет

- Step 1: Calculate The LMTD: HOT ColdДокумент34 страницыStep 1: Calculate The LMTD: HOT ColdFrancisca Hanna0% (2)

- Pressure Temperature Dryness FractionДокумент13 страницPressure Temperature Dryness FractionbksinghsОценок пока нет

- Me307 2016 11Документ5 страницMe307 2016 11Kelvin Kindice MapurisaОценок пока нет

- Questions MtechДокумент6 страницQuestions MtechkdsahooОценок пока нет

- Heat Exchanger (New)Документ38 страницHeat Exchanger (New)Rochie DiezОценок пока нет

- Module Title: Plant & Process Design Module Code:: +417.5 KJ/KG)Документ4 страницыModule Title: Plant & Process Design Module Code:: +417.5 KJ/KG)doniaОценок пока нет

- Summer 18Документ2 страницыSummer 18Bala DuttОценок пока нет

- Old Question Papers 2006-11-2 PDF FreeДокумент27 страницOld Question Papers 2006-11-2 PDF FreeAYUSH SINGHALОценок пока нет

- SPIK Annual Report 2016 - List of Major Players and IndustriesДокумент39 страницSPIK Annual Report 2016 - List of Major Players and IndustriesAlyssaRamosОценок пока нет

- Updates On Fertilizer Prices, January 2019Документ3 страницыUpdates On Fertilizer Prices, January 2019AlyssaRamosОценок пока нет

- 03 Script Examples Extraction PDFДокумент31 страница03 Script Examples Extraction PDFJeffersonPalaciosОценок пока нет

- CHEM 154 PROBLEM SET 1 - Chemical Kinetics - September 2018Документ1 страницаCHEM 154 PROBLEM SET 1 - Chemical Kinetics - September 2018AlyssaRamosОценок пока нет

- Molecules in Motion Modified v2Документ55 страницMolecules in Motion Modified v2AlyssaRamosОценок пока нет

- The Philippine KomedyaДокумент30 страницThe Philippine KomedyaAlyssaRamos100% (4)

- 13.9 Numerical Procedures For Binary, Ternary LLE: Excel ProcedureДокумент2 страницы13.9 Numerical Procedures For Binary, Ternary LLE: Excel ProcedureAlyssaRamosОценок пока нет

- Light SpectraДокумент7 страницLight SpectraAlyssaRamosОценок пока нет

- English 4th Qua EssayДокумент1 страницаEnglish 4th Qua EssayAlyssaRamosОценок пока нет

- Essay #1 - The Start of Something NewДокумент2 страницыEssay #1 - The Start of Something NewAlyssaRamosОценок пока нет

- Chap 9 PracДокумент8 страницChap 9 Pracyiiluk'Moo SineОценок пока нет

- Definitions - Topic 9 The Periodic Table - CAIE Chemistry IGCSE PDFДокумент1 страницаDefinitions - Topic 9 The Periodic Table - CAIE Chemistry IGCSE PDFAtif BakhshОценок пока нет

- Surge Arresters: Selection, Application and Testing: Pass YouДокумент30 страницSurge Arresters: Selection, Application and Testing: Pass YouOoi Ban JuanОценок пока нет

- Lesson+Check Energy+and+States+of+Matter SEДокумент4 страницыLesson+Check Energy+and+States+of+Matter SEAbdelrhman AhmedОценок пока нет

- Service Factors BaldorДокумент1 страницаService Factors BaldornautelОценок пока нет

- Software Quality EngineeringДокумент26 страницSoftware Quality EngineeringSYED SUMAIR AHMED JAFFRIОценок пока нет

- The Comparison of Two Activation Techniques To Prepare Activated Carbon From Corn CobДокумент7 страницThe Comparison of Two Activation Techniques To Prepare Activated Carbon From Corn CobRafaelaMarinhoFonsecaОценок пока нет

- ET4117 Electrical Machines and Drives Lecture5Документ31 страницаET4117 Electrical Machines and Drives Lecture5farhan beighОценок пока нет

- Flow Properties of Bulk SolidsДокумент2 страницыFlow Properties of Bulk Solidstaibook100% (1)

- Ifem PDFДокумент619 страницIfem PDFMiky CastenОценок пока нет

- 9702 w22 QP 36 PDFДокумент16 страниц9702 w22 QP 36 PDFsangdeepОценок пока нет

- Textile AssignmentДокумент8 страницTextile AssignmentMahmudul Hasan Khan40% (5)

- Athene S Theory of Everything PDFДокумент19 страницAthene S Theory of Everything PDFAdriana Ealangi0% (1)

- Huawei KPIs 10thsep2011Документ15 страницHuawei KPIs 10thsep2011Amr Mohamed Abd El-baryОценок пока нет

- Linear ProgrammingДокумент29 страницLinear ProgrammingBrejohn McCrary100% (1)

- Electrical Systems (Engine) - (S - N 512911001 - 512911999) - 331Документ3 страницыElectrical Systems (Engine) - (S - N 512911001 - 512911999) - 331Ronaldo Javier Vergara AnayaОценок пока нет

- Venturi and OrificemeterДокумент10 страницVenturi and OrificemeterVikrant KumarОценок пока нет

- Video Display DevicesДокумент66 страницVideo Display DevicesshabanaОценок пока нет

- Condensatoare MLCC-1837944Документ130 страницCondensatoare MLCC-1837944gigiОценок пока нет

- Introduction To Fission and FusionДокумент19 страницIntroduction To Fission and FusionZubair Hassan100% (1)

- RF10 (A4)Документ4 страницыRF10 (A4)Dewa Made Astika YathaОценок пока нет

- PumpsДокумент8 страницPumpskannagi198Оценок пока нет

- Physics - OPTIONS - K.A. Tsokos - Sixth Edition - Cambridge 2014Документ359 страницPhysics - OPTIONS - K.A. Tsokos - Sixth Edition - Cambridge 2014Aditya Pawar100% (3)

- 1520 0477 Bams D 22 0164.1Документ22 страницы1520 0477 Bams D 22 0164.1Slobodna DalmacijaОценок пока нет

- BookSellerFlyer 9781484241660Документ1 страницаBookSellerFlyer 9781484241660超揚林Оценок пока нет

- Siemens Profiset 3030 enДокумент11 страницSiemens Profiset 3030 enBoasu FlorinОценок пока нет

- 6 0LDies PDFДокумент101 страница6 0LDies PDFscodavnx100% (1)

- Symbols of Oil Gas PipingДокумент3 страницыSymbols of Oil Gas PipingDelvin Davis M0% (1)

- Economics 101: Interactive BrokersДокумент11 страницEconomics 101: Interactive BrokersDennys FreireОценок пока нет

- Secure Remote Services Installation Guide PDFДокумент70 страницSecure Remote Services Installation Guide PDFDavid GiriОценок пока нет

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindОт EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindОценок пока нет

- The Fabric of Civilization: How Textiles Made the WorldОт EverandThe Fabric of Civilization: How Textiles Made the WorldРейтинг: 4.5 из 5 звезд4.5/5 (58)

- Hero Found: The Greatest POW Escape of the Vietnam WarОт EverandHero Found: The Greatest POW Escape of the Vietnam WarРейтинг: 4 из 5 звезд4/5 (19)

- Sully: The Untold Story Behind the Miracle on the HudsonОт EverandSully: The Untold Story Behind the Miracle on the HudsonРейтинг: 4 из 5 звезд4/5 (103)

- The End of Craving: Recovering the Lost Wisdom of Eating WellОт EverandThe End of Craving: Recovering the Lost Wisdom of Eating WellРейтинг: 4.5 из 5 звезд4.5/5 (81)

- Reality+: Virtual Worlds and the Problems of PhilosophyОт EverandReality+: Virtual Worlds and the Problems of PhilosophyРейтинг: 4 из 5 звезд4/5 (24)

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestОт EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestРейтинг: 4 из 5 звезд4/5 (28)

- Pale Blue Dot: A Vision of the Human Future in SpaceОт EverandPale Blue Dot: A Vision of the Human Future in SpaceРейтинг: 4.5 из 5 звезд4.5/5 (588)

- The Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyОт EverandThe Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyОценок пока нет

- Packing for Mars: The Curious Science of Life in the VoidОт EverandPacking for Mars: The Curious Science of Life in the VoidРейтинг: 4 из 5 звезд4/5 (1395)

- The Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaОт EverandThe Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaОценок пока нет

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerОт EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerРейтинг: 4.5 из 5 звезд4.5/5 (54)

- A Place of My Own: The Architecture of DaydreamsОт EverandA Place of My Own: The Architecture of DaydreamsРейтинг: 4 из 5 звезд4/5 (242)

- The Future of Geography: How the Competition in Space Will Change Our WorldОт EverandThe Future of Geography: How the Competition in Space Will Change Our WorldРейтинг: 4 из 5 звезд4/5 (5)

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerОт EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerРейтинг: 4.5 из 5 звезд4.5/5 (122)

- The Weather Machine: A Journey Inside the ForecastОт EverandThe Weather Machine: A Journey Inside the ForecastРейтинг: 3.5 из 5 звезд3.5/5 (31)

- Broken Money: Why Our Financial System is Failing Us and How We Can Make it BetterОт EverandBroken Money: Why Our Financial System is Failing Us and How We Can Make it BetterРейтинг: 5 из 5 звезд5/5 (3)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansОт EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansОценок пока нет

- Dirt to Soil: One Family’s Journey into Regenerative AgricultureОт EverandDirt to Soil: One Family’s Journey into Regenerative AgricultureРейтинг: 5 из 5 звезд5/5 (125)

- The Technology Trap: Capital, Labor, and Power in the Age of AutomationОт EverandThe Technology Trap: Capital, Labor, and Power in the Age of AutomationРейтинг: 4.5 из 5 звезд4.5/5 (46)

- Data-ism: The Revolution Transforming Decision Making, Consumer Behavior, and Almost Everything ElseОт EverandData-ism: The Revolution Transforming Decision Making, Consumer Behavior, and Almost Everything ElseРейтинг: 3.5 из 5 звезд3.5/5 (12)