Академический Документы

Профессиональный Документы

Культура Документы

Jsa R B 6 Forklift

Загружено:

oscarОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Jsa R B 6 Forklift

Загружено:

oscarАвторское право:

Доступные форматы

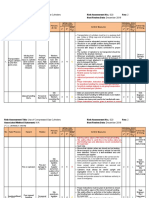

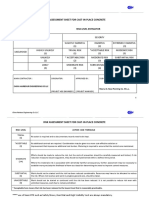

JOB SAFETY ANALYSIS (JSA)

Job: Operating Forklift Dept.: Road & Bridge Date: 9.24.10

Supervisor: JSA No. #6 Analysis Performed By: Road & Bridge Employees &

Joe Carter New Revised Safety Coordinator

Approved by: Operator: Operators & Note: Danger: Tipping forklift over - Always wear seatbelt,

Joe Carter Laborers maintain stability triangle and proper center of gravity at all times.

Required/Recommended Personal Protective Equipment (PPE): Safety Vest, safety-toed

boots should be worn at all times. Appropriate gloves should be worn as needed. Hard hat

protection required as needed.

Item Sequence of Basic Job Steps Potential Incident/Hazard Recommended Safe Job Procedure

1. Pre-operation Safety Check *Untrained operator *Training on forklift design, controls

and instrumentation.

*Training on the forklift stability and

2. Walk around inspection: tires, lights, *Spills/oil & fuel on hands & clothing *Wear protective clothing (coveralls)

frame (stress), leaks, fluid levels, mirrors *Pinch points or have change of clothes available

*Slip, trip & fall *Wear appropriate gloves

3. Vehicle startup: check gauges, oil & air *Slip, trip & fall climbing into vehicle *Maintain 3 point contact

pressure, hydraulics, and brakes * Check for ice build up if working

outside in cold months

4 Cranking & Driving *Rolling the wheels off an edge, ramps *Buckle your seat belt when you’re in

and loading docks. the truck.

*Stay well back from any edge.

*Never turn around on the slope.

*Drive with your load on the uphill

side. This means you drive up slopes

with your load in front and drive down

slopes in reverse.

5. Operating the forks *Running into obstacles *Slow down and sound your horn at

corners, intersections and places with

limited view.

*Slow down for turns.

*Drive in reverse if your vision is

obstructed.

*Make sure that you have enough

overhead clearance.

6. Loading *Load falling off forklift. *Spread forks as wide as possible for

*Damage to material by loading transporting the load.

improperly. *Tilt the mast slightly forward and

*Overloading align the forks with the base of the

*Pinching hands between the truck and load.

other objects. *Proceed slowly and insert the forks

* into the base of the load. Ensure that

at least 2/3rd the length of the fork

enter the base of the load.

*Lift forks approximately 8 inches for

the load to clear the floor.

*Tilt mast back in preparation for

traveling.

7. Transporting the load *Struck against - Running into objects. *BE ALERT

*Struck by - Collisions with other *Wear gloves to protect your hands.

equipment. *Keep your arms and hands in the

truck.

*Keep the controls and your hands

clean and dry.

8. Unloading *Injury to other personnel *Position the truck at the desired

*Damage to other equipment location.

*If stacking loads, adjust the height of

the load as appropriate.

*Tilt the mast forward to place the

forks parallel to the ground.

*Once the load is set, slowly back

away from the load.

*When clear of the load, place the

forks at the proper height for traveling.

9. Parking the Forklift *Running over and crushing the *Never leave the truck until you lower

operator. the lifting mechanism, put controls in

*Slip, trip, and fall neutral and set the brakes. Turn the

truck off.

*Always administer the emergency

brake.

*Leave the truck- Keeping your

balance by maintaining a 3 point

stance.

*Be aware of condition of walking

surface.

Вам также может понравиться

- Jsa forOperatingAForkliftДокумент2 страницыJsa forOperatingAForkliftsupahing supahingОценок пока нет

- Job Hazard AssessmentДокумент26 страницJob Hazard AssessmentGeherson AbustanОценок пока нет

- RISK ASSESSMENT (Concrete Pouring & Vehicular Movement)Документ2 страницыRISK ASSESSMENT (Concrete Pouring & Vehicular Movement)Raza Muhammad Soomro100% (1)

- Risk Assessment - Lifting OperationsДокумент3 страницыRisk Assessment - Lifting Operationsdnmule100% (1)

- DewateringДокумент1 страницаDewateringChandruОценок пока нет

- Soft Landscaping Risk Assessment SheetДокумент1 страницаSoft Landscaping Risk Assessment SheetMuhammad Ibrahim100% (3)

- HSW2 Workplace Risk AssessmentДокумент3 страницыHSW2 Workplace Risk AssessmentNoel Nico Fernando100% (1)

- Forklift Truck Risk AssessmentДокумент2 страницыForklift Truck Risk AssessmentAshis Das100% (1)

- Risk Assessment - House and BuildingДокумент1 страницаRisk Assessment - House and Buildingnayanahari0% (1)

- Use of Hand ToolsДокумент2 страницыUse of Hand Toolsvictor100% (1)

- Risk Assessment (Snake Bites, Scorpion Sting, Reptiles Bites)Документ3 страницыRisk Assessment (Snake Bites, Scorpion Sting, Reptiles Bites)Raza Muhammad SoomroОценок пока нет

- RISK ASSESSMENT AND ANALYSISДокумент6 страницRISK ASSESSMENT AND ANALYSISabhinav dj50% (2)

- Back FillingДокумент2 страницыBack FillingChandruОценок пока нет

- Risk Assessment Hollowcore WF-ALLДокумент8 страницRisk Assessment Hollowcore WF-ALLChoubi ChoubacaОценок пока нет

- Risk Assessment Excavation For Trenches, Duct Bank, Pole Foundations and Back-FillingДокумент3 страницыRisk Assessment Excavation For Trenches, Duct Bank, Pole Foundations and Back-FillingSafety Professional0% (1)

- HAZARD IDENTIFICATION & RISK ASSESSMENT FOR EXCAVATION OF ROAD WITH TLBДокумент7 страницHAZARD IDENTIFICATION & RISK ASSESSMENT FOR EXCAVATION OF ROAD WITH TLBCharles LambОценок пока нет

- Risk Analisis Ramming WorksДокумент2 страницыRisk Analisis Ramming Worksdefidmsp39Оценок пока нет

- Risk Assessment for Loading and Offloading of SteelДокумент3 страницыRisk Assessment for Loading and Offloading of SteelSarfraz Randhawa100% (3)

- Risk Assessment For Repair of ManholeДокумент5 страницRisk Assessment For Repair of Manholeflmm09Оценок пока нет

- Risk Assessment Distribution Board DB Junction Box Junction Box InstallationДокумент6 страницRisk Assessment Distribution Board DB Junction Box Junction Box InstallationAnonymous HeA9HEbtDmОценок пока нет

- 7 Hand Held Power ToolsДокумент4 страницы7 Hand Held Power ToolsGilmar MonteiroОценок пока нет

- 2.risk Assessment of Working at HeightДокумент7 страниц2.risk Assessment of Working at HeightRisal Sinu50% (2)

- Working-at-Height RAДокумент10 страницWorking-at-Height RADan NixonОценок пока нет

- Risk AssesmentДокумент3 страницыRisk Assesmentmrogers72100% (4)

- RA For Plumbing and HeatingДокумент8 страницRA For Plumbing and HeatingAngela DaveyОценок пока нет

- JSO Cable Drum (02 Sept.'07)Документ2 страницыJSO Cable Drum (02 Sept.'07)Francis Enriquez TanОценок пока нет

- Risk Assessment New Site Lifting Operations 07-06-2015Документ3 страницыRisk Assessment New Site Lifting Operations 07-06-2015ANAND MLОценок пока нет

- Excavation Risk AssessmentДокумент3 страницыExcavation Risk Assessmentkhalef100% (1)

- Generic Risk Assessment Form: (To Be Used For Routine Tasks and For Reference When Developing Project Specific RДокумент6 страницGeneric Risk Assessment Form: (To Be Used For Routine Tasks and For Reference When Developing Project Specific Rghada gattouchОценок пока нет

- Confined Space Entry - SH&E Risk Assessment: Middle EastДокумент5 страницConfined Space Entry - SH&E Risk Assessment: Middle EastyahiyaОценок пока нет

- Genie E Series Slab Scissor Lift OperationДокумент11 страницGenie E Series Slab Scissor Lift OperationSanket Arun MoreОценок пока нет

- EHS RISK ASSESSMENT FOR MATERIAL HANDLINGДокумент4 страницыEHS RISK ASSESSMENT FOR MATERIAL HANDLINGshamshu123100% (1)

- Risk Assessment for Compressed Gas Cylinder UseДокумент7 страницRisk Assessment for Compressed Gas Cylinder UsejeffreyОценок пока нет

- Project: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSДокумент2 страницыProject: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSJohn100% (1)

- Risk Assessment Form-2Документ2 страницыRisk Assessment Form-2Badar AlsiyabiОценок пока нет

- RA-for Glass Installation 30-04-2022Документ6 страницRA-for Glass Installation 30-04-2022Muideen Oyedele100% (2)

- Risk Assessment for Canal Construction WorksДокумент9 страницRisk Assessment for Canal Construction WorksAshoka Indunil WickramapalaОценок пока нет

- Concrete WorkДокумент1 страницаConcrete WorkChandruОценок пока нет

- Example Risk Assessment For Excavations Updated 21-11-12Документ3 страницыExample Risk Assessment For Excavations Updated 21-11-12rishi100% (3)

- 6-Steel Work Risk Assessment ReportДокумент7 страниц6-Steel Work Risk Assessment ReportSyed Ali Hassan67% (3)

- Man-machine-interface-Training Module SAMIR 11 R4Документ10 страницMan-machine-interface-Training Module SAMIR 11 R4Sheri Diĺl0% (1)

- Job Hazard Analysis Worksheet: Page 1 of 2Документ2 страницыJob Hazard Analysis Worksheet: Page 1 of 2Lourdes Marianne MenesesОценок пока нет

- Risk Assessment ConcreteДокумент1 страницаRisk Assessment Concretemohamed ghaly0% (1)

- Manual Handling RisksДокумент7 страницManual Handling RisksDáithí O'LaoghaireОценок пока нет

- Risk Assessment for Lifting OperationsДокумент2 страницыRisk Assessment for Lifting OperationsPrem Shiva100% (1)

- International: Red Sea S.T.A.R.R.TДокумент1 страницаInternational: Red Sea S.T.A.R.R.TJunard Lu Hap83% (6)

- HIRA For Concrete Pouring of Diaphragm WallДокумент4 страницыHIRA For Concrete Pouring of Diaphragm WallLoc Nguyen0% (1)

- RA-For Tile & Granite WorksДокумент9 страницRA-For Tile & Granite Worksfaizan khan67% (3)

- Manual Handling Risk AssessmentДокумент4 страницыManual Handling Risk Assessmentnelson100% (1)

- Risk Assessment For Demolition WorksДокумент5 страницRisk Assessment For Demolition Worksappu pocom3100% (1)

- Risk Generator Risk AssessmentДокумент2 страницыRisk Generator Risk AssessmentBaher MohamedОценок пока нет

- Subject: Work at Height: Unit: Maihar Cement WorksДокумент3 страницыSubject: Work at Height: Unit: Maihar Cement Workskaka100% (1)

- Installing Cladding Risk AssessmentДокумент3 страницыInstalling Cladding Risk AssessmentAhmed Tarek67% (3)

- Heavy Lifting Safety ChecklistДокумент1 страницаHeavy Lifting Safety ChecklistMock ProjectОценок пока нет

- Shuttering WorksДокумент3 страницыShuttering WorksAbdul GhaffarОценок пока нет

- Excavation Risk Assessment KTPS - 8 PAGESДокумент7 страницExcavation Risk Assessment KTPS - 8 PAGESrajalingam100% (1)

- Cast-In Place Concrete - Risk Assessment SheetДокумент3 страницыCast-In Place Concrete - Risk Assessment SheetYash SharmaОценок пока нет

- Jsa R B 6 ForkliftДокумент3 страницыJsa R B 6 ForkliftsinghajitbОценок пока нет

- Checklist Espaço Confinado - InglesДокумент2 страницыChecklist Espaço Confinado - InglesoscarОценок пока нет

- Checklist Espaço Confinado - InglesДокумент2 страницыChecklist Espaço Confinado - InglesoscarОценок пока нет

- Labeller 3Документ1 страницаLabeller 3oscarОценок пока нет

- Checklist Espaço Confinado - InglesДокумент2 страницыChecklist Espaço Confinado - InglesoscarОценок пока нет

- Da LuzДокумент1 страницаDa LuzoscarОценок пока нет

- Application For Admission: Designated Emphasis in Development EngineeringДокумент1 страницаApplication For Admission: Designated Emphasis in Development EngineeringoscarОценок пока нет

- Plant and Equipment Risk FormДокумент9 страницPlant and Equipment Risk FormoscarОценок пока нет

- W Hhwsop2 09Документ9 страницW Hhwsop2 09oscarОценок пока нет

- Nelson LinaДокумент1 страницаNelson LinaoscarОценок пока нет

- Designated Emphasis in Development Engineering Spring 2017 Course OfferingДокумент4 страницыDesignated Emphasis in Development Engineering Spring 2017 Course OfferingoscarОценок пока нет

- Setting Goals TemplateДокумент2 страницыSetting Goals TemplateoscarОценок пока нет

- Video PDFДокумент1 страницаVideo PDFoscarОценок пока нет

- EHS-00040-F1 R6 Crane Work PermitДокумент2 страницыEHS-00040-F1 R6 Crane Work PermitoscarОценок пока нет

- Safety Data Sheet: Multifak EP 2Документ10 страницSafety Data Sheet: Multifak EP 2oscarОценок пока нет

- JSA PhysiologyДокумент73 страницыJSA PhysiologyoscarОценок пока нет

- JSA PhysiologyДокумент73 страницыJSA PhysiologyoscarОценок пока нет

- Waste Management As An Entry Point For Sustainable DevelopmentДокумент5 страницWaste Management As An Entry Point For Sustainable DevelopmentoscarОценок пока нет

- Da LuzДокумент1 страницаDa LuzoscarОценок пока нет

- The Challenge of Sustainable Waste ManagementДокумент12 страницThe Challenge of Sustainable Waste ManagementoscarОценок пока нет

- SLTRT Service Level Testing Reporting ToolДокумент110 страницSLTRT Service Level Testing Reporting ToolChedli Dhouibi50% (2)

- BPO2-Module 9 PROJECT PLANДокумент16 страницBPO2-Module 9 PROJECT PLANJudame Charo ZozobradoОценок пока нет

- HP w2007 w2007v SMДокумент75 страницHP w2007 w2007v SMfeliОценок пока нет

- NX Training Syllabus Module IДокумент5 страницNX Training Syllabus Module IDharaiya HardikОценок пока нет

- Extrusion-Spheronization Process Variables and CharacterizationДокумент57 страницExtrusion-Spheronization Process Variables and CharacterizationKhanh Le0% (1)

- Section11 Proportional ValvesДокумент52 страницыSection11 Proportional ValvesyogitatanavadeОценок пока нет

- c600 17lookinsideДокумент6 страницc600 17lookinsideИван МинчевОценок пока нет

- What Is AmplifierДокумент18 страницWhat Is AmplifierEbayLunaОценок пока нет

- WWW - Incar.tw-Kobelco SK 75 Service ManualДокумент5 страницWWW - Incar.tw-Kobelco SK 75 Service Manualpurnomo0% (1)

- Avio 550 Max ICP-OES ASTM D5185 In-Service Oils Application NoteДокумент4 страницыAvio 550 Max ICP-OES ASTM D5185 In-Service Oils Application Notec1nthiacruzОценок пока нет

- Mktech Is1-19Hd & Receptor: Receptor PVR de Satelit Si Semnal Terestru Raport de TestareДокумент7 страницMktech Is1-19Hd & Receptor: Receptor PVR de Satelit Si Semnal Terestru Raport de TestareAlexander WieseОценок пока нет

- GEC - Sample Resume For StudentsДокумент2 страницыGEC - Sample Resume For StudentsNiketОценок пока нет

- Novajet Refference GuideДокумент74 страницыNovajet Refference GuideoralbnetworkОценок пока нет

- Grove GMK 4080Документ6 страницGrove GMK 4080Deiver BarrazaОценок пока нет

- Desizing of CottonДокумент16 страницDesizing of CottonDeepali RastogiОценок пока нет

- Stoichiometry - Determination of Percent by Mass of NaHCO3 in Alka Seltzer TabletsДокумент6 страницStoichiometry - Determination of Percent by Mass of NaHCO3 in Alka Seltzer Tabletsgabbal009Оценок пока нет

- GuidewireClaimCenter Performance TestPlanДокумент18 страницGuidewireClaimCenter Performance TestPlanshanthan117Оценок пока нет

- Air Conditioning Fact SheetДокумент6 страницAir Conditioning Fact SheetrjchpОценок пока нет

- SN 761672 AДокумент19 страницSN 761672 ANhất TríОценок пока нет

- Flyer M 10id 12 ENДокумент2 страницыFlyer M 10id 12 ENTrevor SalazarОценок пока нет

- 70005144e 1314001 PDFДокумент501 страница70005144e 1314001 PDFLuis FernandoОценок пока нет

- LMS Adaptive FiltersДокумент14 страницLMS Adaptive FiltersalialibabaОценок пока нет

- PilotstarD AP02-S01 Mar09Документ168 страницPilotstarD AP02-S01 Mar09Dharan NarayananОценок пока нет

- Brandt M FR Btd500blnДокумент74 страницыBrandt M FR Btd500blnStéphane JoussetОценок пока нет

- EML 4507 Spring 2017 HW11 SolutionДокумент7 страницEML 4507 Spring 2017 HW11 SolutionUnmil PatelОценок пока нет

- Product Catalog: Ipe ProfilesДокумент2 страницыProduct Catalog: Ipe ProfilesGokul royalveritasОценок пока нет

- Hybrid or Standard?: Why The Urge To "Go Green"Документ20 страницHybrid or Standard?: Why The Urge To "Go Green"Tyler McPhersonОценок пока нет

- Float Trap PennantДокумент2 страницыFloat Trap PennantJinalkumarОценок пока нет

- Premium Swab Rigs Since 1925Документ8 страницPremium Swab Rigs Since 1925fabricio3fabricio-1Оценок пока нет

- Study of Buffer Overflows and Keyloggers in The Linux Operating SystemДокумент8 страницStudy of Buffer Overflows and Keyloggers in The Linux Operating Systemrobyrulz100% (1)