Академический Документы

Профессиональный Документы

Культура Документы

Reaction Paper

Загружено:

Jonelou CusipagАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Reaction Paper

Загружено:

Jonelou CusipagАвторское право:

Доступные форматы

Cusipag, Jonelou A.

BSChE V

On our Plant tour, we explored the processing of meat to produce a “Chicha-rabao” located at

Larion Bajo of Lighthouse Cooperative Incorporation and dairy production sold under the name

“Ytawes Fresh” located at CSU Piat. Chicha-rabao is a variant of “Chicharon” (pork

crackling)Cited from Philippine Daily Inquirer, Arturo Tabbu, the general manager of Lighthouse

Cooperative said that “We process an average of 2,100 kilograms of carabao hide a week to make

Chicha-rabao” Lighthouse cooperative, which, in 2006 started producing the crackling as a part

of menu of items sold under “Ybanag Food Products”.

So from this, if 2,100 kilograms of carabao hide a week is used, approximately 300 kilograms

a day is utilize to process the meat into crackling. In addition to what Sir Tabbu said, about 30 kg

of cracklings are produced from every 100 kilograms of carabao hide onto which the cooperative

buys the hide at P40 per kilogram from slaughterhouses in Tuguegarao City and the towns of Piat,

Lal-lo and Baggao, all in Cagayan Province. Based from this, I generalized that the the utilization

of carabao hide is economical and productive.

For the processing part of meat, the input is the carabao hide which is then sheared, cut into

small squares, boiled to make it soft, and after cooling, boiled again in low fire for 14 to 16 hours.

It takes two to three days to complete the process, which includes deep frying the soft hide and

packaging the finished product. When we went to the processing area, good manufacturing

practices are observed, from the receiving and using the raw materials into packaging. For me, this

should be a must for every food processing since this food is a thing we consume on our daily diet.

Another thing I observed is that on the sealing and packaging, they use Nitrogen gas to purge

food packaging. Well this is a safe practice widely used throughout the food industry. When food

such as crisps for example Chicha-rica (“rica” coming from “rice and cassava”), the bag’s empty

space is filled with an inert gas such as nitrogen to prevent food spoiling so quickly. Another reason

that nitrogen gas is used is to provide a pressurized atmosphere that prevents package collapse.

For the equipment used, rest assured the process it is. Why? Because the Lighthouse Cooperative

has been assisted by the Department of Science and Technology (DOST) and the Department of

Trade and Industry (DTI) for the processing, packaging and labelling.

Next destination we went to was the Dairy Production at CSU-Piat Dairy Center. We first went

to the cow stable but as soon as we get closer to take a look on the cows, we were prevented in

doing such thing because the cows are said to be sensitive to stress which will affect the yield of

milk.

Вам также может понравиться

- Exercise 3 Reporting 1Документ30 страницExercise 3 Reporting 1Lavinia MerceneОценок пока нет

- Pengaruh Pengemasan Vakum Terhadap Kualitas BandenДокумент7 страницPengaruh Pengemasan Vakum Terhadap Kualitas BandenErmaya AulianaОценок пока нет

- Introducing Improved Small-Scale Smoking Technology For Rohu Fish Smoking, Kale Township, Sagaing Region, MyanmarДокумент19 страницIntroducing Improved Small-Scale Smoking Technology For Rohu Fish Smoking, Kale Township, Sagaing Region, MyanmarSeyha L. AgriFoodОценок пока нет

- Business PlanДокумент22 страницыBusiness Planachmad musonifОценок пока нет

- Unpad Sem, PresentasiДокумент17 страницUnpad Sem, Presentasinbk.umrahОценок пока нет

- Jerky: Jerky Is Lean Trimmed Meat That Has Been Cut Into StripsДокумент6 страницJerky: Jerky Is Lean Trimmed Meat That Has Been Cut Into StripsAnonymous E4Rbo2sОценок пока нет

- Meat ProcessingДокумент45 страницMeat ProcessingDavid Košić100% (1)

- Sistem Produksi Olahan Ikan Buntal (Lagocephalus Spadiceeus) Pada Agroindustri Jaya Utama Kota ProbolinggoДокумент8 страницSistem Produksi Olahan Ikan Buntal (Lagocephalus Spadiceeus) Pada Agroindustri Jaya Utama Kota ProbolinggoREYNALDI ARRAZAAQ PUTRAОценок пока нет

- Background of The StudyДокумент2 страницыBackground of The StudyJessa San Pedro100% (1)

- Organic Farming in AustraliaДокумент101 страницаOrganic Farming in AustraliaMike MatthewsОценок пока нет

- Literature Review On Fish SmokingДокумент4 страницыLiterature Review On Fish Smokingqdvtairif100% (1)

- Chapter I. Feasib (LR)Документ12 страницChapter I. Feasib (LR)paxbass5Оценок пока нет

- Internship Report PK Meat & Food CompanyДокумент12 страницInternship Report PK Meat & Food CompanyFatimah KhanОценок пока нет

- Exercise 2: Canning Corned BeefДокумент4 страницыExercise 2: Canning Corned BeefKathe LuceroОценок пока нет

- The processing of mackerel fish canning by International Food Corporation (IFCДокумент10 страницThe processing of mackerel fish canning by International Food Corporation (IFCShort-SceneОценок пока нет

- Odorless Pigpen in Tuguegarao CityДокумент11 страницOdorless Pigpen in Tuguegarao CityMae Anthonette B. Cacho67% (6)

- Proposal Tauco FIXДокумент17 страницProposal Tauco FIXsalsabillarizkiadilaОценок пока нет

- Meat Processing (Burger Patties)Документ55 страницMeat Processing (Burger Patties)Bitter SugarОценок пока нет

- Tigernuts Flour / Harina de ChufasДокумент11 страницTigernuts Flour / Harina de ChufasBeida Omenesa VictorОценок пока нет

- DissertationДокумент86 страницDissertationhaniОценок пока нет

- By: Eirene Eunike Meidiana Gaghauna & Rifa'Atul MahmudahДокумент30 страницBy: Eirene Eunike Meidiana Gaghauna & Rifa'Atul MahmudahRifa'atul MahmudahОценок пока нет

- The Organic FarmerДокумент9 страницThe Organic FarmerHerman MwakoiОценок пока нет

- UCHIDA Et Al-2007-Animal Science JournalДокумент10 страницUCHIDA Et Al-2007-Animal Science JournalZolboo TsolmonbaatarОценок пока нет

- How Much Water Does a Burger NeedДокумент3 страницыHow Much Water Does a Burger NeedTyrone PenningОценок пока нет

- Application of Static Retort Thermal Processing Technology For RendangДокумент8 страницApplication of Static Retort Thermal Processing Technology For RendangOz NingratОценок пока нет

- Banana CoalДокумент13 страницBanana CoalclarienethОценок пока нет

- Development of Parmesan Cheese Production From Local Cow MilkДокумент7 страницDevelopment of Parmesan Cheese Production From Local Cow MilkDea FazriahОценок пока нет

- Background of The StudyДокумент24 страницыBackground of The StudyArdelyn Paybano100% (3)

- Group3 - Organic Pig Production - Feasibility Study)Документ38 страницGroup3 - Organic Pig Production - Feasibility Study)Madelyn Arimado100% (1)

- 13.-susilawati-103-111Документ9 страниц13.-susilawati-103-111Atmadja DzakiyОценок пока нет

- Organizational Structure and History of Tat Macaroni IndustryДокумент20 страницOrganizational Structure and History of Tat Macaroni Industrydamla6k6yl6Оценок пока нет

- Project Report On Biodegradable Package Using Rick HuskДокумент8 страницProject Report On Biodegradable Package Using Rick HuskEIRI Board of Consultants and Publishers0% (1)

- Agriculture SBA - Poultry #2Документ11 страницAgriculture SBA - Poultry #2Juliet Hilaire80% (10)

- Kualitas Kerupuk Kulit Ikan Nila Selama PenyimpanaДокумент11 страницKualitas Kerupuk Kulit Ikan Nila Selama PenyimpanaAndi Aisyah PMОценок пока нет

- Biogas From Starch and SugarДокумент5 страницBiogas From Starch and SugarSebestyén GyörgyОценок пока нет

- Chevon Recipes and Canning Procedures PDFДокумент19 страницChevon Recipes and Canning Procedures PDFJc Ibarra100% (1)

- Daisys Business Plan 1Документ14 страницDaisys Business Plan 1Riza CorpuzОценок пока нет

- Research Paper On BreadДокумент8 страницResearch Paper On Breadiqfjzqulg100% (1)

- Broiler ProductionДокумент13 страницBroiler ProductionisabelaОценок пока нет

- AENG 95 - Learning Activity 1Документ19 страницAENG 95 - Learning Activity 1Rufina RiveraОценок пока нет

- Shelf Life Enhancement of Functional Doda Burfi (Indian Milk Cake) With Biopreservatives ApplicationДокумент15 страницShelf Life Enhancement of Functional Doda Burfi (Indian Milk Cake) With Biopreservatives ApplicationHafizh TaufiqОценок пока нет

- Fish & Seafood SaloДокумент8 страницFish & Seafood SaloThomas BzaОценок пока нет

- Chapter I EditedДокумент30 страницChapter I EditedRhea Mae Joromat100% (1)

- Tetra Pak Long Life Milk Campaign - FinalДокумент2 страницыTetra Pak Long Life Milk Campaign - FinalTayyab RazaОценок пока нет

- Os45 Complete Final ReportДокумент49 страницOs45 Complete Final ReportfrankyОценок пока нет

- Consumer Attitudes To Kangaroo Meat Products PDFДокумент82 страницыConsumer Attitudes To Kangaroo Meat Products PDFjohar MohammadОценок пока нет

- Company Profile - SatakeДокумент4 страницыCompany Profile - SatakeMilling and Grain magazineОценок пока нет

- Prawn ProcessingДокумент21 страницаPrawn ProcessingKrishnaОценок пока нет

- Casava ManufactureДокумент18 страницCasava Manufactureonline cyberОценок пока нет

- RRLДокумент2 страницыRRLMary Grace Peralta ParagasОценок пока нет

- An Overview of The Rabbit Industry in The PhilippinesДокумент3 страницыAn Overview of The Rabbit Industry in The Philippinesallan variasОценок пока нет

- Investigationof Sodium Benzoateand Potassium Sorbate Contentand Evaluationof Microbiological Parametersof Fresh Kashar CheesesДокумент7 страницInvestigationof Sodium Benzoateand Potassium Sorbate Contentand Evaluationof Microbiological Parametersof Fresh Kashar Cheeseshazem alzedОценок пока нет

- Internship ReportДокумент7 страницInternship ReportMercycarr IroraОценок пока нет

- Food ControlДокумент5 страницFood ControlpejeОценок пока нет

- Three Course MenuДокумент7 страницThree Course MenuShreyash BhiwapurkarОценок пока нет

- David Maclennan: Chairman and Chief Executive OfficerДокумент9 страницDavid Maclennan: Chairman and Chief Executive OfficerJohn Samuel0% (1)

- Food Technology NotesДокумент39 страницFood Technology NotesPreeti Joshi SachdevaОценок пока нет

- IOP Conference: Conversion of fisheries by-product into salted-egg fish skin chipsДокумент8 страницIOP Conference: Conversion of fisheries by-product into salted-egg fish skin chipsKaren BenteoОценок пока нет

- A Narrative Report in The Training Undertaken at Baguio Animal and Breeding Center Located at BrgyДокумент7 страницA Narrative Report in The Training Undertaken at Baguio Animal and Breeding Center Located at Brgymac jon earl gacayОценок пока нет

- The Jerky Bible: How to Dry, Cure, and Preserve Beef, Venison, Fish, and FowlОт EverandThe Jerky Bible: How to Dry, Cure, and Preserve Beef, Venison, Fish, and FowlОценок пока нет

- DAY 2 May 2018Документ4 страницыDAY 2 May 2018Jonelou CusipagОценок пока нет

- Summative Test 3 Hope 12 Name: - Track, Year&Section: - Score: - Multiple Choice. Directions: Encircle The Correct AnswerДокумент2 страницыSummative Test 3 Hope 12 Name: - Track, Year&Section: - Score: - Multiple Choice. Directions: Encircle The Correct AnswerJonelou Cusipag0% (1)

- ChE BE Nov 2017 PDFДокумент5 страницChE BE Nov 2017 PDFJulia GimenezОценок пока нет

- Tomato PasteДокумент2 страницыTomato PasteJonelou CusipagОценок пока нет

- Process FlowДокумент1 страницаProcess FlowJonelou CusipagОценок пока нет

- Contemporary ArtДокумент1 страницаContemporary ArtJonelou CusipagОценок пока нет

- Honylyn M. Detomal: Address: 15A Narag St. Linao East, Tuguegarao City, CagayanДокумент1 страницаHonylyn M. Detomal: Address: 15A Narag St. Linao East, Tuguegarao City, CagayanJonelou CusipagОценок пока нет

- CrusherДокумент2 страницыCrusherJonelou CusipagОценок пока нет

- USES (Wind)Документ1 страницаUSES (Wind)Jonelou CusipagОценок пока нет

- When Preparing TomatoДокумент1 страницаWhen Preparing TomatoJonelou CusipagОценок пока нет

- Basis For Schematic DiagramДокумент5 страницBasis For Schematic DiagramJonelou CusipagОценок пока нет

- Experiment No 4 (DRYING)Документ20 страницExperiment No 4 (DRYING)Jonelou CusipagОценок пока нет

- Homework #2 1. Enumerate and Discuss The 4 Most Difficult Problems Encountered Relating Air Pollution To HealthДокумент2 страницыHomework #2 1. Enumerate and Discuss The 4 Most Difficult Problems Encountered Relating Air Pollution To HealthJonelou CusipagОценок пока нет

- Cusipag, Lozano, Telan - Production of Tomato PasteДокумент24 страницыCusipag, Lozano, Telan - Production of Tomato PasteJonelou CusipagОценок пока нет

- Discuss How The Global Wind Pattern Is FormedДокумент9 страницDiscuss How The Global Wind Pattern Is FormedJonelou CusipagОценок пока нет

- Energy BalДокумент1 страницаEnergy BalJonelou CusipagОценок пока нет

- Naseach Ko Lang KaninaДокумент64 страницыNaseach Ko Lang KaninaJonelou CusipagОценок пока нет

- USES (Wind)Документ1 страницаUSES (Wind)Jonelou CusipagОценок пока нет

- SLE Experiment (REPORT)Документ8 страницSLE Experiment (REPORT)Kuknesvary PuniamurthyОценок пока нет

- IntroductionДокумент1 страницаIntroductionJonelou CusipagОценок пока нет

- FINAL LAB Report (Experiment 2)Документ40 страницFINAL LAB Report (Experiment 2)Jonelou CusipagОценок пока нет

- RecommendationsДокумент1 страницаRecommendationsJonelou CusipagОценок пока нет

- Create Excel Functions in MinutesДокумент3 страницыCreate Excel Functions in MinutesJonelou CusipagОценок пока нет

- ACT1Документ2 страницыACT1Jonelou CusipagОценок пока нет

- Ps Na Bago Sa ECONДокумент10 страницPs Na Bago Sa ECONJonelou CusipagОценок пока нет

- SolutionДокумент1 страницаSolutionJonelou CusipagОценок пока нет

- Computer Application To CheДокумент8 страницComputer Application To CheJonelou CusipagОценок пока нет

- Batch Distillation ExperimentДокумент8 страницBatch Distillation ExperimentJonelou CusipagОценок пока нет

- Cruise Control: Vehicle Speed Control: Principles of Operation and ImplementationДокумент22 страницыCruise Control: Vehicle Speed Control: Principles of Operation and ImplementationJonelou CusipagОценок пока нет

- Value Added Food ProductsДокумент12 страницValue Added Food ProductsEal EnderezОценок пока нет

- 130 Years of Brewing Education: Siebel's World Brewing Academy in ChicagoДокумент3 страницы130 Years of Brewing Education: Siebel's World Brewing Academy in Chicagobookslover1Оценок пока нет

- Doris CaterДокумент1 страницаDoris CaterDianne Karla CruzОценок пока нет

- Registered RestaurantsДокумент1 236 страницRegistered RestaurantsJenalyn YangaОценок пока нет

- Company Analysis (GROUP 2)Документ15 страницCompany Analysis (GROUP 2)JennylinRiveraMagcalas50% (2)

- suratPERNYATAAN Approval NumberДокумент4 страницыsuratPERNYATAAN Approval NumberSimon lahengkoОценок пока нет

- Business PlanДокумент16 страницBusiness PlanErika MarcellanaОценок пока нет

- How To Make Bregedel TempeДокумент14 страницHow To Make Bregedel Tempeidaayu reinaОценок пока нет

- Cutlery Selection Guide - Choose the Right Knife for Any TaskДокумент1 страницаCutlery Selection Guide - Choose the Right Knife for Any TaskjlgallardoОценок пока нет

- Types of Menus and Menu Writing TipsДокумент8 страницTypes of Menus and Menu Writing TipsTiffany Joy Punzalan GonzalesОценок пока нет

- Grocery Checklist: Critical Meat Canned Sauces / Oils PersonalДокумент7 страницGrocery Checklist: Critical Meat Canned Sauces / Oils Personalnanch1071416988Оценок пока нет

- Recipes Harvest MoonДокумент36 страницRecipes Harvest MoonraitokenОценок пока нет

- Vegan Crème Caramel Recipe - Great British ChefsДокумент3 страницыVegan Crème Caramel Recipe - Great British ChefsDam VassilevОценок пока нет

- SFI Meat Processor CategoriesДокумент4 страницыSFI Meat Processor CategoriesGladieJohnAlcuirezОценок пока нет

- Beating The Lunch Box Blues by J.M. Hirsch (Excerpt)Документ14 страницBeating The Lunch Box Blues by J.M. Hirsch (Excerpt)Atria Books0% (3)

- 5 Ways of Healthy Living: Teliti Poster Di Bawah Dan Jawab Soalan-Soalan Yang BerikutДокумент2 страницы5 Ways of Healthy Living: Teliti Poster Di Bawah Dan Jawab Soalan-Soalan Yang BerikutMichael EllisОценок пока нет

- Chickpe Curry: Ingredients 4 Portions Prep R TionДокумент1 страницаChickpe Curry: Ingredients 4 Portions Prep R TionMaria JesicОценок пока нет

- Preparing A Variety of Salad Dressings: Technology and Livelihood EducationДокумент2 страницыPreparing A Variety of Salad Dressings: Technology and Livelihood EducationTeacher KristelОценок пока нет

- Nitzana E MenuДокумент11 страницNitzana E MenusandeepОценок пока нет

- Centeno Activity 4Документ6 страницCenteno Activity 4Ralph Lawrence CentenoОценок пока нет

- Easy Fluffy Potato Dinner RollsДокумент11 страницEasy Fluffy Potato Dinner RollsBryan Abd AzizОценок пока нет

- Tinolang Manok (Chicken Tinola) - Kawaling PinoyДокумент12 страницTinolang Manok (Chicken Tinola) - Kawaling PinoyErrol John P. SahagunОценок пока нет

- Baking PowderДокумент20 страницBaking PowderNguyen Chi DzungОценок пока нет

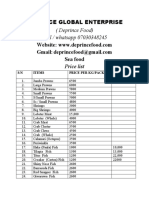

- Deprince Global EnterpriseДокумент6 страницDeprince Global EnterpriseAli oseniОценок пока нет

- Makalah Jenis Masakan Jawa Timur Dalam BHS InggrisДокумент21 страницаMakalah Jenis Masakan Jawa Timur Dalam BHS InggrisSartini TiniОценок пока нет

- Evidencia 5 y 6 de InglésДокумент16 страницEvidencia 5 y 6 de Inglésgerman gomez lopez100% (1)

- Foods of OdishaДокумент9 страницFoods of OdishatajinderlimОценок пока нет

- Cookery-Classification of DessertДокумент13 страницCookery-Classification of DessertCarla Grace Tobias-Samoy RocОценок пока нет

- SANDWICHES Topic PortioningДокумент3 страницыSANDWICHES Topic PortioningPolitio MonsaludОценок пока нет

- Factsheet 001 - Heat Treatment 1 1Документ4 страницыFactsheet 001 - Heat Treatment 1 1ThE BoNg TeChniCaLОценок пока нет