Академический Документы

Профессиональный Документы

Культура Документы

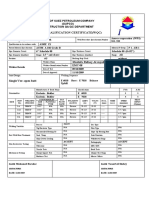

Hoja de Datos - Válvula Modelo WDCL

Загружено:

EnriqueAzuaraОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Hoja de Datos - Válvula Modelo WDCL

Загружено:

EnriqueAzuaraАвторское право:

Доступные форматы

Renaissance Technical Information Sheet

Safety Valve OEM Data Request

Printed from 'GL-WFT-OEPS-L2-02', Revision 001

Date: 12/2/2018

To whom it may concern,

I,(name)_________________, title_________________ with_______________ request that

Weatherford contact the Safety valve manufacturer listed below who supplied the safety valve

installed in our well _________ and request the dimensional data required for an insert Wireline

system.

TRSV/SVLN Manufactu'r :-

TRSV/SVLN Model Num' :-

TRSV/SVLN Serial Number :-

Regards,

Name

Signature

Please print and sign

© 2013 Weatherford All Rights Reserved Proprietary and Confidential.

This document is copyrighted and contains valuable proprietary and confidential information, whether patentable or unpatentable, of

Weatherford. Recipients agree the document is loaned with confidential restrictions, and with the understanding that neither it nor the

information contained therein will be reproduced, used or disclosed in whole or in part for any purpose except as may be specifically authorized

in writing by Weatherford

Renaissance Technical Information Sheet

General Well Information

Printed from 'GL-WFT-OEPS-L2-02', Revision 001

GENERAL INFORMATION

Customer: Rig Name:

Country: Rig Type:

Field: Company Rep:

Well Name/No: Email Address:

Job No: Contact No:

Weatherford Rep: Delivery Date:

Credit Check required: Estimated Job Date:

WELL CONSTRUCTION DETAILS

Safety Valve Type TRSCSSV Wireline SCSSV Safety Valve Depth

TUBING ABOVE SV TUBING BELOW SV

Tubing Size Above SV Tubing Size Below SV N/A

Tubing Weight Above SV Tubing Weight Below SV N/A

Tubing Grade Above SV Tubing Grade Below SV N/A

Packer Depth End of Tubing Depth N/A

Casing Size Casing Weight N/A

Top of Perforations Bottom of Perforations N/A

Well Schematic Provided Yes No Deviation Survey Provided Yes No

WELL ENVIRONMENT AND PRODUCTION DETAILS

Surface Downhole Hole

Flowing WH Pressure Flowing BH pressure

Shut-in WH Pressure Shut-in BH pressure

Gas Injection Pressure Pressure at SV

Flowing Well Head Temperature

Minimum Maximum

Flowing BH Temperature

WATER GAS

Av. Daily Water Rate Av. Daily Gas Rate

Density Produced Water SG Specific Gravity of Gas SG

Chlorides ppm H2S ppm

pH CO2 ppm

Scale Issue Corrosion Issue Yes No

CONDENSATE OIL

Av. Daily Condensate Rate Av. Daily Oil Rate

Gravity of Condensate SG Gravity of Oil deg API

ADDITIONAL PRODUCTION DETAILS

Production Plot Provided Yes No Decline Curve Analysis Yes No

Build up Data Provided Yes No Wax / Sand Issues Yes No

CHEMICAL TREATMENT

Chem Treatment in Place Yes No Paraffin Inhibitor Yes No

Scale Inhibitor Yes No Corrosion Inhibitor Yes No

© 2013 Weatherford All Rights Reserved Proprietary and Confidential.

This document is copyrighted and contains valuable proprietary and confidential information, whether patentable or unpatentable, of

Weatherford. Recipients agree the document is loaned with confidential restrictions, and with the understanding that neither it nor the

information contained therein will be reproduced, used or disclosed in whole or in part for any purpose except as may be specifically authorized

in writing by Weatherford

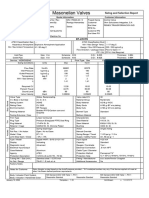

Renaissance Technical Information Sheet

Safety Valve

Printed from 'GL-WFT-OEPS-L2-02', Revision 001

GENERAL INFORMATION

Customer: Rig Name:

Country: Rig Type:

Field: Company Rep:

Well Name/No: Email Address:

Job No: Contact No:

Weatherford Rep: Delivery Date:

Credit Check required: Estimated Job Date:

SAFETY VALVE DATA REQUIRED

SYSTEM APPLICATION

WDCL

Tubing Size Tubing Weight

Flow Coupling Above SV Yes No Equalizing System Yes No

Flow Coupling ID

TRSV or SVLN Manufacturer:

TRSV or SVLN model number:

TRSV serial number (If Applicable):

SEAL BORE PROFILE SIZE

Other:-

NIPPLE PROFILE TYPE

X OR QN F AF B R Other(please detail)

Other:-

PRESSURE

Well pressure at the setting depth of the safety valve

Capillary string injection pressure (WCS systems only) See notes 5, 6 & 7 N/A

WORKING TEMPERATURE RANGE

Min: Max

MAXIMUM FAILSAFE SETTING DEPTH

1,000ft 2,000ft

© 2013 Weatherford All Rights Reserved Proprietary and Confidential.

This document is copyrighted and contains valuable proprietary and confidential information, whether patentable or unpatentable, of

Weatherford. Recipients agree the document is loaned with confidential restrictions, and with the understanding that neither it nor the

information contained therein will be reproduced, used or disclosed in whole or in part for any purpose except as may be specifically authorized

in writing by Weatherford

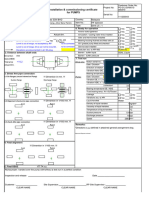

Renaissance Technical Information Sheet

Safety Valve

Printed from 'GL-WFT-OEPS-L2-02', Revision 001

VALVE BASE MATERIAL REQUIREMENTS

13Cr (SS-301) +17/4PH (SS-401) Alloy 925 (WN-302) Alloy 718 (WN-301) Other (provide details)

Other

NACE MR0175 Material: Yes No

Elastomers

NBR (e.g. Nitrile) HNBR (e.g. Therban) FKM (e.g. Viton) FEPM (e.g. Aflas) FFKM (e.g. Kalrez) Other(please detail)

Other:-

Product Traceability Level Level 4 Level 5

Quality Plan Yes No

CONTROL LINE / CAPILLARY DATA REQUIRED

Control/Capillary Line Size 1/4in 3/8in 1/2in 5/8in

Control/Capillary Line material grade 2205 825 625

Control/Capillary Line wall thickness 0.035in 0.049in 0.065in

Request for Competitor safety valve data Yes No

NOTES:

1. All fields must be completed and the necessary information provided.

2. There is a high degree of Eng / QA documentation required for interface information, initiated

by the completion of this form. Weatherford personnel should contact

DLGlobalRenaissanceTechnicalSupport@weatherford.com if they require further information.

3. Maximum differential pressure at Staubli connector is limited to 5,000 psi.

4. Maximum Control Line pressure is limited to 10,000 psi.

5. Maximum Capillary Injection pressure is limited to 10,000 psi (WCS systems only)

Other Relevant Information:

© 2013 Weatherford All Rights Reserved Proprietary and Confidential.

This document is copyrighted and contains valuable proprietary and confidential information, whether patentable or unpatentable, of

Weatherford. Recipients agree the document is loaned with confidential restrictions, and with the understanding that neither it nor the

information contained therein will be reproduced, used or disclosed in whole or in part for any purpose except as may be specifically authorized

in writing by Weatherford

Renaissance Technical Information Sheet

Control Line Hanger

Printed from 'GL-WFT-OEPS-L2-02', Revision 001

GENERAL INFORMATION

Customer: Rig Name:

Country: Rig Type:

Field: Company Rep:

Well Name/No: Email Address:

Job No: Contact No:

Weatherford Rep: Delivery Date:

Credit Check required: Estimated Job Date:

Xmas Tree Company: Xmas Tree Rep:

Tubing Hanger Company: Tubing Hanger Rep:

Control Line Hanger Data Required

System Application Tree Type Penetration

WDCL Surface Subsea REN-Gate Spool Piece TBD

Control/Capillary Line Size Injection Application if WCS

1/4in 3/8in 1/2in 5/8in N/A

Control/Capillary Line Material Grade Control/Capillary Line Wall Thickness

2205 835 625 0.035in 0.049in 0.065in

Lower Master Valve Manufacturer, Model and Size

Tubing Hanger Profile Manufacturer, Type and Size

Profile Material Profile Material Min Yield

Modified Lower Seat Seal Bore and Length Bore Length

Drawing MUST be supplied showing Penetration Port Position - Drawing supplied? Yes No

Date

Accurate and Confirmed distance between no-go & lower face of LMV Yes No

ID Restriction Directly Below the Hanger Profile

Distance From Profile to Restriction Min ID BPV will pass through

Minimum Tree ID Restriction above Lower Seat

Production Tubing Size, Weight & Grade Above SV ,,

Pressure in Control/Capillary Line:

Injection Rate (WCS Only): N/A

Flowing Surface Temperature Minimum: Maximum:

Material Requirements

Base Metallic Material of Hanger: 13Cr+17/4PH Alloy 925 Alloy 718 Min Yield:

Elastomeric Material: NBR HNBR FKM FEPM FFKM Other (detail)

Material of Injection Wetted Parts (if WCS Application): N/A

Christmas Tree Internal Dimensional Drawings Supplied: Yes No Date:

Tubing Hanger Internal Dimensional Drawings Supplied: Yes No Date:

Other Relevant Information:

© 2013 Weatherford All Rights Reserved Proprietary and Confidential.

This document is copyrighted and contains valuable proprietary and confidential information, whether patentable or unpatentable, of

Weatherford. Recipients agree the document is loaned with confidential restrictions, and with the understanding that neither it nor the

information contained therein will be reproduced, used or disclosed in whole or in part for any purpose except as may be specifically authorized

in writing by Weatherford

Вам также может понравиться

- Well Completions QuestionaireДокумент27 страницWell Completions QuestionaireashwaniОценок пока нет

- Transformer InspectionДокумент1 страницаTransformer InspectionJoe_Average100% (2)

- DH-DHRS Series Commission Report FormДокумент3 страницыDH-DHRS Series Commission Report Formandy habibiОценок пока нет

- Cakasa (Nigeria) Company Limited: Welding Summary ReportДокумент7 страницCakasa (Nigeria) Company Limited: Welding Summary ReportOgheneruemu EtasОценок пока нет

- D-Series Commissioning ReportДокумент3 страницыD-Series Commissioning Reportandy habibiОценок пока нет

- Professional visual cylinder inspection evaluation formДокумент2 страницыProfessional visual cylinder inspection evaluation formJose E RafolsОценок пока нет

- WesTech Clarifier QuestionnaireДокумент1 страницаWesTech Clarifier QuestionnaireCarlos TovarОценок пока нет

- Welding Procedure Specification For Storage Tank & Piping SystemДокумент3 страницыWelding Procedure Specification For Storage Tank & Piping SystemAhmad MohammadОценок пока нет

- Welder Qualification Certificate (WQC) : Gulf of Suez Petroleum Company (Gupco) Construction Qa/Qc DepartmentДокумент1 страницаWelder Qualification Certificate (WQC) : Gulf of Suez Petroleum Company (Gupco) Construction Qa/Qc DepartmentMohamad ShafeyОценок пока нет

- Vacuum Testing ReportДокумент9 страницVacuum Testing ReportDoris DorisОценок пока нет

- Annex M AWS D1.1/D1.1M:2015: Sample WPS Form (GMAW & FCAW) Welding Procedure Specification (WPS)Документ2 страницыAnnex M AWS D1.1/D1.1M:2015: Sample WPS Form (GMAW & FCAW) Welding Procedure Specification (WPS)Daniel ZapataОценок пока нет

- Data Sheet For Pig Receiver (Sr-101) : Arvandan Oil and Gas CompanyДокумент3 страницыData Sheet For Pig Receiver (Sr-101) : Arvandan Oil and Gas Companyamini_mohiОценок пока нет

- Shutdown Valve: B224 323 HPCL Rajasthan Refinery Limited Rajasthan Refinery Project OffsitesДокумент1 страницаShutdown Valve: B224 323 HPCL Rajasthan Refinery Limited Rajasthan Refinery Project OffsitesMirhasan GaziОценок пока нет

- Welder Qualification Certificate (WQC) : Gulf of Suez Petroleum Company (Gupco) Construction Qa/Qc DepartmentДокумент1 страницаWelder Qualification Certificate (WQC) : Gulf of Suez Petroleum Company (Gupco) Construction Qa/Qc DepartmentMohamad ShafeyОценок пока нет

- RO#66 GR-TCL Indent For Depth Coorelation 26.07.2023Документ3 страницыRO#66 GR-TCL Indent For Depth Coorelation 26.07.2023Koteswara RaoОценок пока нет

- FM Opr-E001 Test Report For Insulation ResistanceДокумент2 страницыFM Opr-E001 Test Report For Insulation ResistanceAbdul LatifОценок пока нет

- Separated water pump data sheetДокумент1 страницаSeparated water pump data sheetSara KhanОценок пока нет

- Well Integrity Management System (WIMS) OverviewДокумент2 страницыWell Integrity Management System (WIMS) OverviewazareiforoushОценок пока нет

- Daily Spot Check ListДокумент2 страницыDaily Spot Check ListAnilkumar G NairОценок пока нет

- Daily Welding Chamber Skirt AssemblyДокумент1 страницаDaily Welding Chamber Skirt AssemblyMa'ruf firmansyahОценок пока нет

- PT 001 PDFДокумент1 страницаPT 001 PDFDang sonОценок пока нет

- Method Statemetn FormДокумент11 страницMethod Statemetn FormEswar ReddyОценок пока нет

- Agcc & DBB (JV) Painting Inspection Report: Verified By: Verified byДокумент6 страницAgcc & DBB (JV) Painting Inspection Report: Verified By: Verified byJoseph DarwinОценок пока нет

- Model Visual and Mpi ReportДокумент3 страницыModel Visual and Mpi ReportBLY YEDEKPA NOEL BENITOОценок пока нет

- Welding Procedure Specifications (WPS) : AWS D1.1Документ2 страницыWelding Procedure Specifications (WPS) : AWS D1.1BS AhnОценок пока нет

- Aluminum Weld Procedure Qualification Record: (AWS D1.2-2008)Документ1 страницаAluminum Weld Procedure Qualification Record: (AWS D1.2-2008)Amin ThabetОценок пока нет

- Welder Monitoring SheetДокумент1 страницаWelder Monitoring SheetQC apollohx100% (1)

- 0-WD792-CJ250-01504 - Rev.A - Inspection and Test Plan For Instrument Cables (Checklist)Документ2 страницы0-WD792-CJ250-01504 - Rev.A - Inspection and Test Plan For Instrument Cables (Checklist)ResearcherОценок пока нет

- Circuit Breaker - For SwitchayrdДокумент9 страницCircuit Breaker - For SwitchayrdSindhuKumarОценок пока нет

- Transformer Test Report: Transformers Technical Data Field Service RepresentiveДокумент14 страницTransformer Test Report: Transformers Technical Data Field Service RepresentiveAldhi PriambudiОценок пока нет

- MN-176323-24 (2)Документ3 страницыMN-176323-24 (2)nawaz.ahmed.spnutra.comОценок пока нет

- C2C Manual Valve Data SheetДокумент13 страницC2C Manual Valve Data Sheetpraveen kumar vengadasamyОценок пока нет

- PQR FC-12-22Документ2 страницыPQR FC-12-22cycsi02Оценок пока нет

- Boiler Data Sheet: Process Design ConditionsДокумент6 страницBoiler Data Sheet: Process Design ConditionsecsuperalОценок пока нет

- Specification For Adsorbent Bed Accumulator Item No: V-05202Документ3 страницыSpecification For Adsorbent Bed Accumulator Item No: V-05202amlanfacebookОценок пока нет

- Ac Inspection Report1Документ2 страницыAc Inspection Report1shahnawaz.onyxОценок пока нет

- WQT Record for Welder QualificationДокумент1 страницаWQT Record for Welder Qualificationdandiar1100% (1)

- WPS PQR FormulirДокумент2 страницыWPS PQR FormulirAZaiОценок пока нет

- Afe Perforation. PetramДокумент13 страницAfe Perforation. PetramErich Ricardo Croes RojasОценок пока нет

- Blank - Osi Data SheetДокумент2 страницыBlank - Osi Data SheetMuhammad DaudОценок пока нет

- Content 20240115185834Документ2 страницыContent 20240115185834BLY YEDEKPA NOEL BENITOОценок пока нет

- FPSO Motion Load - VerticalДокумент109 страницFPSO Motion Load - VerticalSu Kil SungОценок пока нет

- Item Code Quantity UOM Description Stock / Non Stock Item Estimated Unit Cost ($) Total Cost ($)Документ2 страницыItem Code Quantity UOM Description Stock / Non Stock Item Estimated Unit Cost ($) Total Cost ($)DILОценок пока нет

- Draft WPSДокумент3 страницыDraft WPSWale OyeludeОценок пока нет

- WPS ExampleДокумент2 страницыWPS ExampleMarcio Jr.Оценок пока нет

- WPS-2 InchДокумент2 страницыWPS-2 InchKarthikeyan MpОценок пока нет

- SP - 58R1 - Prachi Costruction - 1600 KVA - 33 - 6 - 6 KV - 18 - 06 - 2021Документ8 страницSP - 58R1 - Prachi Costruction - 1600 KVA - 33 - 6 - 6 KV - 18 - 06 - 2021M O7Оценок пока нет

- Welding 2Документ2 страницыWelding 2Kilerz 91Оценок пока нет

- Boiler ChecklistДокумент2 страницыBoiler ChecklistJoydev GangulyОценок пока нет

- Qaswa - 100 ABFV 17.06.21Документ1 страницаQaswa - 100 ABFV 17.06.21FLOW VALVE AUTOMATIONОценок пока нет

- BHA AD 68 NOT# 200000708382 RepДокумент13 страницBHA AD 68 NOT# 200000708382 RepArun SidharthОценок пока нет

- Sample - RP Commissioning Form (Dialog)Документ2 страницыSample - RP Commissioning Form (Dialog)Mohd Firdaus Mohd ShukriОценок пока нет

- Pdip Wa0115.-2Документ1 страницаPdip Wa0115.-2dannyhendraОценок пока нет

- Well Completion or Recompletion Report and Well LogДокумент2 страницыWell Completion or Recompletion Report and Well LogJati LionОценок пока нет

- API Pump Quote Request Form - EN (Standard)Документ2 страницыAPI Pump Quote Request Form - EN (Standard)Deep PatelОценок пока нет

- Testing Report For Pressure Relief Valves: Petrofac International (UAE) LLCДокумент1 страницаTesting Report For Pressure Relief Valves: Petrofac International (UAE) LLCmurthy challapalliОценок пока нет

- Transformer ChecklistДокумент1 страницаTransformer Checklistengrabbas75Оценок пока нет

- The Complete Rigger's Apprentice: Tools and Techniques for Modern and Traditional RiggingОт EverandThe Complete Rigger's Apprentice: Tools and Techniques for Modern and Traditional RiggingОценок пока нет

- Multiple Choice Question (MCQ) of Alternator and Synchronous Motors PageДокумент29 страницMultiple Choice Question (MCQ) of Alternator and Synchronous Motors Pagekibrom atsbha0% (1)

- Mba Assignment SampleДокумент5 страницMba Assignment Sampleabdallah abdОценок пока нет

- Notes On Lesson: Faculty Name Code Subject Name CodeДокумент108 страницNotes On Lesson: Faculty Name Code Subject Name CodeJeba ChristoОценок пока нет

- Software EngineeringДокумент3 страницыSoftware EngineeringImtiyaz BashaОценок пока нет

- Yamaha Nmax 155 - To Turn The Vehicle Power OffДокумент1 страницаYamaha Nmax 155 - To Turn The Vehicle Power Offmotley crewzОценок пока нет

- Sample Property Management AgreementДокумент13 страницSample Property Management AgreementSarah TОценок пока нет

- ABBBAДокумент151 страницаABBBAJeremy MaraveОценок пока нет

- Well Control Kill Sheet (Low Angle Wells)Документ8 страницWell Control Kill Sheet (Low Angle Wells)Tatita ValenciaОценок пока нет

- Weka Tutorial 2Документ50 страницWeka Tutorial 2Fikri FarisОценок пока нет

- DHPL Equipment Updated List Jan-22Документ16 страницDHPL Equipment Updated List Jan-22jairamvhpОценок пока нет

- DSA NotesДокумент87 страницDSA NotesAtefrachew SeyfuОценок пока нет

- Continue: Adobe Project Voco DownloadДокумент3 страницыContinue: Adobe Project Voco DownloadLazlo SecretОценок пока нет

- Open Compute Project AMD Motherboard Roadrunner 2.1 PDFДокумент36 страницOpen Compute Project AMD Motherboard Roadrunner 2.1 PDFakok22Оценок пока нет

- CCT AsqДокумент12 страницCCT Asqlcando100% (1)

- Hardened Concrete - Methods of Test: Indian StandardДокумент16 страницHardened Concrete - Methods of Test: Indian StandardjitendraОценок пока нет

- The SAGE Handbook of Digital JournalismДокумент497 страницThe SAGE Handbook of Digital JournalismK JОценок пока нет

- Berry B Brey Part IДокумент49 страницBerry B Brey Part Ikalpesh_chandakОценок пока нет

- ABS Rules for Steel Vessels Under 90mДокумент91 страницаABS Rules for Steel Vessels Under 90mGean Antonny Gamarra DamianОценок пока нет

- Peter Wilkinson CV 1Документ3 страницыPeter Wilkinson CV 1larry3108Оценок пока нет

- MN AG v. SANOFI - 3:18-cv-14999 - Defendants' Joint Motion To Dismiss - 2019-08-12Документ124 страницыMN AG v. SANOFI - 3:18-cv-14999 - Defendants' Joint Motion To Dismiss - 2019-08-12The Type 1 Diabetes Defense FoundationОценок пока нет

- Sop EcuДокумент11 страницSop Ecuahmed saeedОценок пока нет

- Case Study 2 F3005Документ12 страницCase Study 2 F3005Iqmal DaniealОценок пока нет

- Terms and Condition PDFДокумент2 страницыTerms and Condition PDFSeanmarie CabralesОценок пока нет

- Make a Battery Level Indicator using LM339 ICДокумент13 страницMake a Battery Level Indicator using LM339 ICnelson100% (1)

- An Overview of Tensorflow + Deep learning 沒一村Документ31 страницаAn Overview of Tensorflow + Deep learning 沒一村Syed AdeelОценок пока нет

- Continuation in Auditing OverviewДокумент21 страницаContinuation in Auditing OverviewJayОценок пока нет

- A320 Normal ProceduresДокумент40 страницA320 Normal ProceduresRajesh KumarОценок пока нет

- Max 761 CsaДокумент12 страницMax 761 CsabmhoangtmaОценок пока нет

- Haul Cables and Care For InfrastructureДокумент11 страницHaul Cables and Care For InfrastructureSathiyaseelan VelayuthamОценок пока нет

- Las Q1Документ9 страницLas Q1Gaux SkjsjaОценок пока нет