Академический Документы

Профессиональный Документы

Культура Документы

VNT Brochure New

Загружено:

da vin ciАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

VNT Brochure New

Загружено:

da vin ciАвторское право:

Доступные форматы

E M P O W E R I N G W I R E & C A B L E I N D U S T RY

AJEX & TURNER WIRE DIES COMPANY

QUALITY-INNOVATION & EUROPEAN KNOWHOW - TURNER STOTT LTD.UK

PCD - ND - NANO - Carbide Dies - Extrusion Tips & Dies - Lubricants For

Ferrous & Non Ferrous Wire - Die Polishing Equipments & Accessories

EMAIL : mkt@ajexturner.com, sales@ajexturner.com, info@ajexturner.com

MOBILE : 0091 - 9810111137, 8586976320 WEBSITE : www.ajexturner.com

ADDRESS : A-53 G.T. KARNAL ROAD, AZADPUR - NEW DELHI - 110033 (INDIA)

(VNT) NANO VITRIFIED NANOCRYSTALLINE DIAMOND COMPOSITE

TECHNOLOGY FOR DRAWING & COMPACTING - SOFT & HARD METAL

Ajex & Turner have come up with the new revolutionary Vitrified Nanocrystalline Technology which has completely changed the

traditional way of wire drawing. The Prospects of Vitrified Nanotechnology will definitely put huge impact in near future and will

save material and manufacturing costs for cable companies around the globe. Our R & D team has developed state of the art diamond

coated dies called as VNT Nano. Same VNT nano die can be used for compacting Copper and Aluminium if there is slight difference in

the profile not extreme for stranding 50mm to 2000sqmm for energy saving. Customers who use VNT Nano-Dies for drawing Aluminium

and Alloys report excellent results in which the material strength is enhanced and in many cases the electrical resistance is reduced.

Now our company have developed sector shape & other shape dies in VNT nano crystalline diamond. The Trapezoidal & other shape dies

are very much successful as diamond surface is very hard comparing to carbide & PCD.

Square Triangle

R R

R R

Rectangle Hexagon

STRIP DIE SQUARE DIE HEX DIE

R

Oval Trapezoidal Die

90°

b-002

R

R R1

OVAL DIE GROOVE DIE ROUND DIE R

d-0.02

h

R2

Semi Circle Flat

R

R R

TRAPEZOIDAL DIE TUBE DIE COMPACTING DIE

TYPICAL WIRE SHAPES

Square | Rectangle | Flat | Triangle | Hexagonal | Oval | Half Round |Rhombus | Trolley Wire

Spiral Wire | Tube Die | Trapezoidal Die | Round Dies for - Copper, Cadmium Copper Aluminium

Aluminium Alloy, Stainless Steel Welding, Welding Alloy, Low Carbon, Brass, Nickel Silver

Tel - 0091- 9810111137 / 9811078882 1 E-mail : info@ajexturner.com, sales@ajexturner.com

(VNT) VITRIFIED NANOCRYSTALLINE DIAMOND COMPOSITE

TECHNOLOGY FOR DRAWING & COMPACTING - SOFT & HARD METAL

Uses and Advantages of VNT Nano Dies Tube & Wire Drawing & Compacting

1. To draw copper -Aluminium for Stranding / Compacting / Rod Break Down Sizes / Sector Shape etc.

2. To draw Aluminium Alloy wire / Nickel Silver wire / Brass / Copper Tubes or any metal.

3. To draw stainless steel / high and low carbon steel wire up to 0.6%C, welding wire

or any hard / soft wire of any size & hardness.

4. Lower friction -Better Copper and Aluminium utilization.

5. Better surface quality -high and bright surface finish.

6. Die range: 0.800 to 100mm possible.

7. Improvement of 2-3% in raw material utilization &

better life than PCD and Tungsten Carbide.

8. 0% tolerance for entire working life for any metal.

9. No die polishing/ recutting required for any metal.

10. The die will run for Aluminium, Copper Compacting

approx 10000-12000 cable km, (If proper parameters are

maintained. The production ratio also depends on

metal to metal through Nano Dies).

11. For Aluminium / Copper RBD process, Nano dies are better for continuous

process with no metal loss & tolerance breakage or scratch on wire.

12. The prices are 10% to 50% lower than PCD dies (depends on bore diameter).

13. Casing - stainless steel grade 304 to avoid rust.

Why NANO is better than TC & PCD for Drawing and Compacting

14. FOR TC - While using Tungsten Carbide Die for soft or hard material, there are chances of dust

accumulation in the die and wire breakage and scratches on the conductor.

15. FOR PCD - While using Polycrystalline diamond die for soft and hard wire

drawing purpose above mentioned problems can be

rectified, diameter can be controlled but variation is

possible after a due course of time, but Nano maintains

0% tolerance throughout its working life, thus there is

no need for re-polishing & re-grinding, moreover Nano

is economical in price than PCD & production is equivalent.

Low Power Consumption & Saving of Metal 2-3%

Low Friction

A smooth surface provides potential for low friction. This is extremely important when the surface finish of your

product needs to be perfect. It is also of tremendous importance in certain applications such as cable compacting

& stranding, where friction causes damage which increases electrical resistance. More damage means more Copper

or Aluminium is required to meet the electrical resistance standards for the cable being manufactured. Using Nano-

Dies can save a cable manufacturer millions of dollars worth of Copper and Aluminium every year.

Price / Performance

A traditional diamond or PCD die uses a solid mass of fiamond at its core.

So the price increases, on average, eight times for every doubling of bore

diameter. The Nano-Die’s diamond surface is manufactured in a chemical

vapor deposition (CVD) Process, as part of process of making the die.

This leads to tremendous economies. A Nano-Die costs rougnly 3-6 time

less than a PCD die of the same diameter. But Nano-Dies are available

upto Ø60mm (>2.3 inches), far exceeding the maximum possible diameter

for PCD die.

Tel - 0091- 9810111137 / 9811078882 2 E-mail : info@ajexturner.com, sales@ajexturner.com

(VNT) VITRIFIED NANOCRYSTALLINE DIAMOND COMPOSITE

TECHNOLOGY FOR DRAWING & COMPACTING - SOFT & HARD METAL

Fine Grain

VNT NANO Standard Specification

β Soft wire Hard wire

product product

Bellangle (α) 70°±20° 60°±20° 1. Soft wire product

VNT

NANO

copper wire aluminium wire

Coating Approch angle (β) 35°±5° 30°±5° brass wire gold wire etc.

Reduction angle ( ) 18°±2° 12°±2° 2. Hard wire product

stainless steel wire.

Bearing Length (D) 20°~50° 40°~60° copper plated steel wire,

galvanised steel wire,

Back relief angle (e) 15°±5° 15°±5° brass plated steel wire,

tungsten wire etc.

D Exit angle ( ) 50°±20° 50°±20°

θ

Standard Configuration for other wire types also available

Die profile specifications for Copper | Aluminium | Aluminium Alloy | Drawing | Compacting | Stranding | Stainless Steel

Low Carbon | Welding Wire | Galvanised Steel Wire | Brass Plated Steel Wire | Tungsten Wire | Copper Tube etc etc.

CASE

BEARING LENGTH - ‘B’ Note :

NIB TUBE DIE (1) RA α=26° ~ 28°, Unless specified

R-15

(2) Approach angle (β)=60° ~ 80°,

45°

Blending y (between) α and β=40° ~ 55°

2

(3) All zones well blended.

BACK RELIEF ANGLE 30°

R-2.5

+025

BRG SIZE A DIA

-000

CASE DIA - D1

CASE DIA - D2

ENTRY ANGLE 2

F

R

2 BACK RELIEF STAMP ‘A’ DIA ON FRONT

OF EACH DIE

NIB HEIGHT - H2

3

L L HARD WIRE

CASE HEIGHT - H1

The Size of

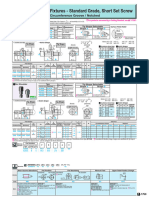

Hole Range Reduction Reduction Zone Bearing Length Note :

Blanks(mm) β(°)

OD*Height

(mm)-d Angle (° ) - α Height (mm)-L1 (mm) - L (1) RA α=20° ~ 20°, Unless specified

13 X10 0.801 - 1.200 20 - 25 3-5 1-2 60 - 80 (2) Approach angle (β)=60° ~ 80°,

13 X 10 1.201 - 2.000 20 - 25 3-5 1-2 60 - 80

Blending y (between) α and β=40° ~ 55°

15 X 13 2.001 - 3.500 20 - 25 3-5 1-2 60 - 80

(3) All zones well blended.

19 X 17 3.00 - 6.00 26 - 30 5-6 1-2 60 - 80

22 X 18 6.00 - 8.00 26 - 30 5-6 1.5 - 2.5 60 - 80

25 X 20 8.00 - 11.00 26 - 30 5-6 1.5 - 2.5 60 - 80

30 X 20 11.00 - 14.00 26 - 30 6-8 2.0 - 3.0 60 - 80

35 X 20 14.00 - 16.00 26 - 30 6-8 2.0 - 3.0 60 - 80

38 X 20 16.00 - 19.00 26 - 30 6-8 2.5 - 3.5 60 - 80

P

40 X 24 19.00 - 21.00 26 - 30 8 - 10 2.0 - 3.5 60 - 80

45 X 24 21.00 - 24.00 26 - 30 8 - 10 3.0 - 4.0 60 - 80

R

50 X 28 24.00 - 28.00 26 - 30 8 - 10 3.0 - 4.0 60 - 80

60 X 30 28.00 - 37.00 26 - 30 10 - 12 3.5 - 4.5 60 - 80

70 X 35 37.00 - 42.00 26 - 30 10 - 12 4.0 - 5.0 60 - 80

75 X 35 42.00 - 50.00 26 - 30 12 - 14 5.0 -6.0 60 - 80

85 X 40 50.00 - 60.00 26 - 30 12 - 14 6.0 - 7.0 60 - 80 L L SOFT WIRE

Tel - 0091- 9810111137 / 9811078882 3 E-mail : info@ajexturner.com, sales@ajexturner.com

(VNT) VITRIFIED NANOCRYSTALLINE DIAMOND COMPOSITE

TECHNOLOGY FOR SECTOR SHAPE WIRE

Compacting & Sector Profile Rollers

Ajex & Turner have developed Sector shape Dies & Rollers. We produce Trapezoidal

Wire Drawing Dies and Sector Shaped Conductor Die with higher quality to meet

customer requirements in all aspect of technologies. Ajex & Turner group are capable

to serve our customers with any special tooling like shape drawing dies (trolley,

oval, trapezoidal, rectangular, square, triangular, sector, etc.) and sector shaped

compacting dies for bunching and stranding line. Fundamentally this kind is using

in the wire design and cables manufacture industries however it includes some

other areas also any special product that the customer needs. We make in 15 sq

mm to 300 sq mm or as per customer’s requirement.

Trapezoidal/Shaped

Apply to: Rod Break Down Machine / Drawing Machine

L2: 2nd layer

Manufacturing Process: Wire Drawing / Compacting 28.700

Area = 22.105

14 wire

20.200 28.700

13.080 5.892

R0.600

0.226

0.146 24.7 4.250

Samples of finish good product: R0.600

3.401

4.386

20.200

Example. L1: 1st layer

Area = 22.0866

6 wire

1. Bare Conductor: ACCC, ACCS, ACFR, 20.200

ACSR (SA)/TW or etc. 7.058

R0.800

2. Underground Cable: High Voltage and low 3.560 3.796

R1.000 3.527

Voltage Underground Power Cable or etc. 13.090

3. Sector Roller Profile

Materials: PCD / (VNT) NANO / Tungsten Carbide / Steel

Tel - 0091- 9810111137 / 9811078882 4 E-mail : info@ajexturner.com, sales@ajexturner.com

(VNT) VITRIFIED NANOCRYSTALLINE DIAMOND COMPOSITE

TECHNOLOGY FOR SECTOR SHAPE WIRE

Sector Shaped Compacting Die (D Shape Sector Die)

Apply to: Rigid Stander Machine

Manufacturing Process: Compacting Stranded Conductor

Samples of finish good product:

Example.

1. Low Voltage Underground Power Cable or etc.

R16.0 A

BACK RADIUS 58.0 + 0.1 25.0

ISOMETRIC

R2.5

CORNER

RADIUS

13.7 DEPTH

119° BACK

RELIEF

SECTION A

90°

90°

60°

30°

R2.5 BEARING

A TIP RADIUS

23.5 WIDTH

REAR ISOMETRIC

BA D C E

ELEVATION

4C X 25 Sq.mm

4C X 16 Sq.mm

R7.6000

R6.1 R1.2

R0.9

90° 90°

1.2

3, 3.5, 4 mm Core Sector shape compaction roller for

35, 50, 70, 95, 120, 150, 185, 240, 300, 400 mm2 in 90 & 120°

b

r1

β

Features:

r2 d h

·Reliable

α

·Corrosion resistance r2

·Longer functional life

·New Technologies for Drawn wire and Compacting Stranded Conductor

Tel - 0091- 9810111137 / 9811078882 5 E-mail : info@ajexturner.com, sales@ajexturner.com

Вам также может понравиться

- Mechanical FailuresДокумент33 страницыMechanical Failuresmohamed abd eldayemОценок пока нет

- 1 Introduction To Stress and StrainДокумент32 страницы1 Introduction To Stress and Strainmuhamadsaidi100% (2)

- 7 Common Practical Uses For PlywoodДокумент17 страниц7 Common Practical Uses For PlywoodRobert Kier Tanquerido TomaroОценок пока нет

- ETI 1978-06 JuneДокумент125 страницETI 1978-06 JuneCarlos SoaresОценок пока нет

- A Memorandum for the President of the Royal Audiencia and Chancery Court of the City and Kingdom of GranadaОт EverandA Memorandum for the President of the Royal Audiencia and Chancery Court of the City and Kingdom of GranadaОценок пока нет

- Insulation Systems For HV MotorsДокумент34 страницыInsulation Systems For HV Motorsonderarslan77100% (6)

- A8vo RDE93010-26 LAOXSДокумент7 страницA8vo RDE93010-26 LAOXSjose manuel barroso pantoja100% (1)

- Concrete Bleeding Good or Bad - tcm45-348530Документ2 страницыConcrete Bleeding Good or Bad - tcm45-348530Chris YangОценок пока нет

- Exporters IndiaДокумент52 страницыExporters IndiaRaghav JalanОценок пока нет

- ACI Manuals and Standards ListДокумент20 страницACI Manuals and Standards ListVELOCIRAPTORAОценок пока нет

- OEM Mechanical SealsДокумент63 страницыOEM Mechanical Sealsparatrpr2003100% (1)

- RX Ring Gasket Technical Data SheetДокумент3 страницыRX Ring Gasket Technical Data SheetEnrique HortaОценок пока нет

- 3Документ1 страница3MostafaElrakhawyОценок пока нет

- 4Документ1 страница4MostafaElrakhawyОценок пока нет

- 65Документ1 страница65MostafaElrakhawyОценок пока нет

- Dijet Tools: For High Efficient 5-Axis MachiningДокумент8 страницDijet Tools: For High Efficient 5-Axis MachiningNguyen HoangОценок пока нет

- Carbitool Catalogue 2020Документ184 страницыCarbitool Catalogue 2020AustechsawОценок пока нет

- Danfoss 134 PDFДокумент6 страницDanfoss 134 PDFTN PROОценок пока нет

- Orifice Assembly With D-D2 Taps PDFДокумент1 страницаOrifice Assembly With D-D2 Taps PDFArup MondalОценок пока нет

- FE440# Series Orifice Assembly With D-D/2 Taps: HydropneumaticsДокумент1 страницаFE440# Series Orifice Assembly With D-D/2 Taps: Hydropneumaticsharry_chemОценок пока нет

- Hexagon Nuts/Cotter Pins Spring Pins/Retaining Rings E Type: (Technical Data) (Technical Data)Документ1 страницаHexagon Nuts/Cotter Pins Spring Pins/Retaining Rings E Type: (Technical Data) (Technical Data)ilo iloОценок пока нет

- JMiscellaneousEquipment 5 PDFДокумент1 страницаJMiscellaneousEquipment 5 PDFalvaro_arcvОценок пока нет

- GRW Bearings CatalogДокумент105 страницGRW Bearings CatalogShubh BhawsarОценок пока нет

- Telescopic CylinderДокумент2 страницыTelescopic CylinderReference mapiyeОценок пока нет

- Bending Technical Guide: Processes, Dimensions & CalculationsДокумент2 страницыBending Technical Guide: Processes, Dimensions & CalculationsأبومحمدالزياتОценок пока нет

- RE HiMisExtДокумент1 страницаRE HiMisExtJulien LardyОценок пока нет

- Tme BX: Technical Data SheetДокумент2 страницыTme BX: Technical Data SheetEnrique HortaОценок пока нет

- Hardness conversion and metric screw thread excerptsДокумент1 страницаHardness conversion and metric screw thread excerptsNatthawut CheencharoenОценок пока нет

- Winstar 2021 Cutting Tools CatalogueДокумент702 страницыWinstar 2021 Cutting Tools CataloguegkhnОценок пока нет

- Painted Panels: Ventilation HoleДокумент1 страницаPainted Panels: Ventilation HoleAli ZubairОценок пока нет

- Sd06e01b01 07enДокумент1 страницаSd06e01b01 07enAli Abdul MannanОценок пока нет

- Restriction Orifice T95500enДокумент2 страницыRestriction Orifice T95500enCarlos SopasОценок пока нет

- Opampper1019 LRДокумент40 страницOpampper1019 LRBeto YoshidaОценок пока нет

- Insert Grades Guide for Turning, Milling, Drilling & MoreДокумент21 страницаInsert Grades Guide for Turning, Milling, Drilling & MoreYogeshОценок пока нет

- Plastic Section Moduli For I.S. Rolled Steel Beam Sections Zpy About Y-Y AxisДокумент8 страницPlastic Section Moduli For I.S. Rolled Steel Beam Sections Zpy About Y-Y AxisIJRASETPublicationsОценок пока нет

- SN SeriesДокумент49 страницSN SeriesSam WangОценок пока нет

- Globe Valve - Disk TipleriДокумент2 страницыGlobe Valve - Disk TipleriErcan YilmazОценок пока нет

- DriveTechnology p174 p193 Steel Laminae CouplingsДокумент20 страницDriveTechnology p174 p193 Steel Laminae CouplingsNhật Quang PhạmОценок пока нет

- Practice01 01: Din Standerd - N5Документ1 страницаPractice01 01: Din Standerd - N5ابراهيم الزهرانيОценок пока нет

- Chain Descriptions and Dimensions: Standard Attachment Roller ChainДокумент4 страницыChain Descriptions and Dimensions: Standard Attachment Roller ChainmakanakiliОценок пока нет

- ANSI / ASME B16.5 (2003) Pipe Flanges: L L L P K P KДокумент15 страницANSI / ASME B16.5 (2003) Pipe Flanges: L L L P K P KsterlingОценок пока нет

- 02 Grav Exe Gro Fe R+1 BS 311 0B PDFДокумент1 страница02 Grav Exe Gro Fe R+1 BS 311 0B PDFNguyen Khac DatОценок пока нет

- Ficha Aislador de Vibración Neopreno Sísmico Mason BR RCAДокумент2 страницыFicha Aislador de Vibración Neopreno Sísmico Mason BR RCAFernando FuentealbaОценок пока нет

- Stainless Steel Worms: Spur Gears Spur GearsДокумент3 страницыStainless Steel Worms: Spur Gears Spur GearsOriental BearingОценок пока нет

- MODEL PROPELLER-ModelДокумент1 страницаMODEL PROPELLER-ModelThe AzmodeusОценок пока нет

- Locating Pins For Fixtures - Standard Grade, Short Set ScrewДокумент1 страницаLocating Pins For Fixtures - Standard Grade, Short Set ScrewDicky PratamaОценок пока нет

- Avesta Pharma-5tf Cre LayoutДокумент1 страницаAvesta Pharma-5tf Cre LayoutSaurabh KadamОценок пока нет

- P1 RW Grids H V VRT A VRW HRT HRW Paste T P2 A1 Grid Weight A2 Weight Wet PasteДокумент1 страницаP1 RW Grids H V VRT A VRW HRT HRW Paste T P2 A1 Grid Weight A2 Weight Wet Pasteav3888871Оценок пока нет

- Shattaf Sink Sprayer 39219UAE - Shattaf Sink Sprayer With Push Button SprayДокумент1 страницаShattaf Sink Sprayer 39219UAE - Shattaf Sink Sprayer With Push Button Spraytvshow zeeОценок пока нет

- Aluminium End MillsДокумент28 страницAluminium End MillsAjdinОценок пока нет

- Vibratory Single Drum Roller: Proven Vibratory Compaction PerformanceДокумент2 страницыVibratory Single Drum Roller: Proven Vibratory Compaction PerformanceFadhlan SОценок пока нет

- Tme R: Technical Data SheetДокумент5 страницTme R: Technical Data SheetEnrique HortaОценок пока нет

- Purlins and Girts: Engineered Solutions Engineered ServiceДокумент8 страницPurlins and Girts: Engineered Solutions Engineered ServiceyeahhomieОценок пока нет

- Nine9 30 45 60 90 Degree Engraving ToolsДокумент16 страницNine9 30 45 60 90 Degree Engraving ToolsLuthier37Оценок пока нет

- B 126 GДокумент4 страницыB 126 GJitendra BagalОценок пока нет

- FYH ZK - EnglishДокумент17 страницFYH ZK - EnglishRicardo TurlaОценок пока нет

- Type-8sq MS.4010.0318Документ2 страницыType-8sq MS.4010.0318علاء السعيد حرازОценок пока нет

- Rooster RandДокумент1 страницаRooster Randapi-371028301Оценок пока нет

- Tabelas Roscas TrapezoidaisДокумент49 страницTabelas Roscas TrapezoidaisDesenvolvimento MHОценок пока нет

- Condition of The Surface of Commutators and Rings-Roughness: Technical Note Sta Be 16-1 GBДокумент2 страницыCondition of The Surface of Commutators and Rings-Roughness: Technical Note Sta Be 16-1 GBloulou_beОценок пока нет

- Pure Precision Sure Performance: Precision-Made Hydraulic SealsДокумент3 страницыPure Precision Sure Performance: Precision-Made Hydraulic SealshufuentsОценок пока нет

- Djei Opi Kahru Ioeg4Документ1 страницаDjei Opi Kahru Ioeg4P DОценок пока нет

- E60H Series: Rotary EncoderДокумент1 страницаE60H Series: Rotary EncoderkopihitammorningbakeryОценок пока нет

- Tonepad RealmctubeДокумент1 страницаTonepad RealmctubeultratumbaОценок пока нет

- Premier Magnetics Inc.: 100watt PFC Universal Off-Line Switching MagneticsДокумент2 страницыPremier Magnetics Inc.: 100watt PFC Universal Off-Line Switching Magneticsanon_316469432Оценок пока нет

- РазверткиДокумент10 страницРазверткиСергей РыбаковОценок пока нет

- Poster-TIPURI IMB SUD, SIMBOLURI-engДокумент1 страницаPoster-TIPURI IMB SUD, SIMBOLURI-engLucian HoudiniОценок пока нет

- Stock Statement December 2011Документ1 страницаStock Statement December 2011da vin ciОценок пока нет

- March 2012 Stock StatementДокумент1 страницаMarch 2012 Stock Statementda vin ciОценок пока нет

- Stock Statement December 2011Документ1 страницаStock Statement December 2011da vin ciОценок пока нет

- Stock Statement December 2011Документ1 страницаStock Statement December 2011da vin ciОценок пока нет

- Stock Statement December 2011Документ1 страницаStock Statement December 2011da vin ciОценок пока нет

- Data Delivery Process in Mobile NetworksДокумент5 страницData Delivery Process in Mobile Networksda vin ciОценок пока нет

- Class D: Demolition and Site ClearanceДокумент11 страницClass D: Demolition and Site ClearanceHi LowОценок пока нет

- Clay bricks languageДокумент1 страницаClay bricks languageRKОценок пока нет

- Chinnaraju PDFДокумент5 страницChinnaraju PDFkarthikaОценок пока нет

- 4) Double Reinforced BeamДокумент3 страницы4) Double Reinforced BeamVanessa Rosal PalerОценок пока нет

- Soil Cement StabilizationДокумент16 страницSoil Cement StabilizationMohamed MamdohОценок пока нет

- Design and Control of Concrete Mixtures (1929)Документ80 страницDesign and Control of Concrete Mixtures (1929)flukemonsterОценок пока нет

- T02 NsaДокумент2 страницыT02 NsaSanjay C BhattОценок пока нет

- Polypropylene-Clay Composite Prepared From Indian Bentonite: Bulletin of Materials Science February 2008Документ7 страницPolypropylene-Clay Composite Prepared From Indian Bentonite: Bulletin of Materials Science February 2008Chandra WauranОценок пока нет

- Crystalline and Noncrystalline StructuresДокумент22 страницыCrystalline and Noncrystalline StructuresYong Meng HowОценок пока нет

- Optimizing Unit Load In Productivity at CHF Coal Handling FacilityДокумент10 страницOptimizing Unit Load In Productivity at CHF Coal Handling Facilityzayen prana kusmuriОценок пока нет

- Repair and Rehabiliation PDFДокумент210 страницRepair and Rehabiliation PDFSivaramakrishnaNalluri100% (1)

- Materials and SpecificationsДокумент553 страницыMaterials and Specificationspavanmarella1986Оценок пока нет

- CAMPISA - Quick Construction Techniques For Docks With Pits For Dock LevellersДокумент26 страницCAMPISA - Quick Construction Techniques For Docks With Pits For Dock LevellersYasher Meera SaibОценок пока нет

- EP Equipment: Leading Manufacturer of Electric Pallet Trucks and Li-Ion Powered EquipmentДокумент27 страницEP Equipment: Leading Manufacturer of Electric Pallet Trucks and Li-Ion Powered EquipmentFerry IrawanОценок пока нет

- Aluminum+foam ENG NewДокумент32 страницыAluminum+foam ENG Newchompo83Оценок пока нет

- High Performance Coatings SpecsДокумент47 страницHigh Performance Coatings Specshasanriaz36150% (2)

- Using The Hollomon Model To Predict Strain-Hardening in MetalsДокумент4 страницыUsing The Hollomon Model To Predict Strain-Hardening in MetalsGuilherme ResendeОценок пока нет

- Tord Boontje SpecsДокумент3 страницыTord Boontje Specsprasence21Оценок пока нет

- Increasing The Performance of Chain Sprocket by Using Cryogenic Treated and Normalizing in Superficial Heat TreatmentДокумент25 страницIncreasing The Performance of Chain Sprocket by Using Cryogenic Treated and Normalizing in Superficial Heat Treatmentthai avvaiОценок пока нет

- Investigation For Using Precast Vs Insitu Concrete For Bridge ConstructionДокумент40 страницInvestigation For Using Precast Vs Insitu Concrete For Bridge ConstructionBihanChathurangaОценок пока нет

- Three Axis Pneumatic Modern TrailerДокумент6 страницThree Axis Pneumatic Modern TrailerUNITED CADDОценок пока нет

- Release Concrete Forms Easily With PIDIPART 55Документ1 страницаRelease Concrete Forms Easily With PIDIPART 55nickdash09Оценок пока нет