Академический Документы

Профессиональный Документы

Культура Документы

Corus Steel Shape Specification Catalog BS5950 Sept 13

Загружено:

pbp29560 оценок0% нашли этот документ полезным (0 голосов)

35 просмотров1 страницаWhite Storage Stain....Informative

Авторское право

© © All Rights Reserved

Доступные форматы

PDF или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документWhite Storage Stain....Informative

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

35 просмотров1 страницаCorus Steel Shape Specification Catalog BS5950 Sept 13

Загружено:

pbp2956White Storage Stain....Informative

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

Вы находитесь на странице: 1из 1

WET STORAGE STAIN vs WHITE RUST

: Ihave heard the terms “wet storage stain” and

“white rust” used interchangeably. Are they

the same and how do they occur?

Many perceive wet storage stain to be the same

white rust and use the two terms interchange-

ably. The truth is these two phenomenons are

not synonymous and although similar, they do

have distinct differences.

A

Both wet storage stain and white rust occur due to

oxidation on a newly galvanized surface with the presence

of moisture and absence of free flowing air. The protec-

tive zine patina is not allowed to form by converting zine

oxides and hydroxides to zinc carbonates.

Wet storage stain is the commonly known problem of

white surface oxide formed due to packing items too

tightly and/or storing in a humid environment. If moisture

can bridge the gap between galvanized pieces, the local

shortage of oxygen created by this moisture can set up a

galvanic cell that will give rise to rapid attack at those

places where oxygen is deficient. The common solution

for wet storage stain is to store items with room to breathe

and out of a wet and humid environment. Another pre-

emptive solution is to passivate the zine surface after gal-

vanizing.

White rust, on the other hand, is associated with cool-

ing towers. Cooling towers were first galvanized in 1965.

The white rust problem wasn’t noticed until 1986. White

rust appears on the surface of newly galvanized cooling

towers as a patch of white sticky material. The white

material has been identified as basic zinc carbonate

(BZn(OH)2.ZnCO3.H20). White rust can penetrate the

zine coating and quickly reach the iron-zine intermetallic,

layers, forming a visible red iron oxide.

‘The older towers, not plagued with white rust, all

received a chromate treatment after galvanizing, In the

mid 1980s chromate treatments suddenly became taboo

and environmental restrictions on using them for cooling

towers gave way to an alkaline water treatment. The chro-

‘mate treatment effectively protects the newly galvanized

surface from oxidizing before the formation of the zine

patina. The combination of no chromate treatment and an

operating pH level above 8.2 or 8.3 creates the white rust

because the alkaline level in the water is effectively wash-

ing away the corrosion products that help form a protec

tive surface. Likewise, chloride is most corrosive to zine

Vol 44

2 2000

in water, and even more evident in a soft water environ-

‘ment where the carbonate level is lowered. Without the

passivation of the zinc surface, the more predominate the

pH and hardness become in affecting corrosion,

‘Maintaining proper water pH and hardness levels

helps alleviate the white rust problem. The solution is to

use a phosphate treatment and operate the tower at a pH

no higher than 7.8 for a few months, then return to normal

operating levels.

‘Wet storage stain

In the past, the Technical Department attempted to

formally designate the terms of wet storage stain and

white rust and differentiate their occurrences. However, a

majority of galvanized steel owners never picked up on

the differences between the two. Now if someone asks

about white rust and wet storage stain, you can dazzle him

or her with your knowledge of the two processes.

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Effect of C & Cr. On Brightness of Galvanizing SurfaceДокумент1 страницаEffect of C & Cr. On Brightness of Galvanizing Surfacepbp2956Оценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Kaizen PrinciplesДокумент42 страницыKaizen PrinciplesRaj100% (2)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Selecting Statistically Valid Sampling Plans: Dr. Wayne A. TaylorДокумент15 страницSelecting Statistically Valid Sampling Plans: Dr. Wayne A. Taylorpbp2956Оценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Beta SD RSquared-Mutual Fund KnowledgeДокумент2 страницыBeta SD RSquared-Mutual Fund Knowledgepbp2956Оценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Tolerance For CHSДокумент1 страницаTolerance For CHSpbp2956Оценок пока нет

- GSL Appearance GuideДокумент4 страницыGSL Appearance Guidepbp2956Оценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Steel 2141967Документ388 страницSteel 2141967Seifeldin Ali Marzouk100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Thomas Cook 13D 12N-Premimum Budget13Документ9 страницThomas Cook 13D 12N-Premimum Budget13pbp2956Оценок пока нет

- GB 1591 Q420 Steel PropertiesДокумент6 страницGB 1591 Q420 Steel Propertiespbp2956Оценок пока нет

- ASTM D1018-1999 Standard Specification For PVC Plastic Pipe Schedule 40,80 & 120Документ11 страницASTM D1018-1999 Standard Specification For PVC Plastic Pipe Schedule 40,80 & 120pbp2956Оценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Freezing Points of High-Purity Hydrocarbons: Standard Test Method ForДокумент11 страницFreezing Points of High-Purity Hydrocarbons: Standard Test Method Forpbp2956Оценок пока нет

- Advance To BS5950 Sept 13Документ60 страницAdvance To BS5950 Sept 13getnihalОценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Nonvolatile Residue of Polymerization Grade Butadiene: Standard Test Method ForДокумент2 страницыNonvolatile Residue of Polymerization Grade Butadiene: Standard Test Method Forpbp2956Оценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Hydrogen in Petroleum Fractions: Standard Test Method ForДокумент4 страницыHydrogen in Petroleum Fractions: Standard Test Method Forpbp2956Оценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Satrangi Europe 11D 10MДокумент6 страницSatrangi Europe 11D 10Mpbp2956Оценок пока нет

- Basic Understanding of FCAWДокумент4 страницыBasic Understanding of FCAWpbp2956Оценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Adhesion Tape Specification 51596.Документ1 страницаAdhesion Tape Specification 51596.pbp2956Оценок пока нет

- PresentingSixSigma NewДокумент56 страницPresentingSixSigma Newpbp2956Оценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Inspection of HDG After FabricationДокумент27 страницInspection of HDG After Fabricationpbp2956Оценок пока нет

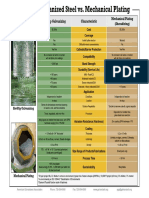

- Hot-Dip Galvanizing Vs Mechanical PlatingДокумент2 страницыHot-Dip Galvanizing Vs Mechanical Platingpbp2956Оценок пока нет

- Defects Per Million OpportunitiesДокумент6 страницDefects Per Million Opportunitiespbp2956100% (1)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- SlaДокумент13 страницSlapbp2956Оценок пока нет

- GB700-88 Stanadard Extract PageДокумент1 страницаGB700-88 Stanadard Extract Pagepbp2956Оценок пока нет

- Chemical Reaction Between Chromates and Galvanized SteelДокумент1 страницаChemical Reaction Between Chromates and Galvanized Steelpbp2956Оценок пока нет

- B897 - 03 - Zinc Jumbo BlockДокумент4 страницыB897 - 03 - Zinc Jumbo Blockpbp2956Оценок пока нет

- Influence of Alloy Elements On Structure and Corrosion ResistanceДокумент10 страницInfluence of Alloy Elements On Structure and Corrosion Resistancepbp2956Оценок пока нет

- Flux Skimming PDFДокумент6 страницFlux Skimming PDFpbp2956Оценок пока нет

- Pipe Galvanizing ProcessДокумент32 страницыPipe Galvanizing ProcessPatrick DominguezОценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Corrosion Behaviour of Zinc Coating by Polarization MeasurementДокумент6 страницCorrosion Behaviour of Zinc Coating by Polarization Measurementpbp2956Оценок пока нет