Академический Документы

Профессиональный Документы

Культура Документы

A4LD

Загружено:

Victor Hugo Parra0 оценок0% нашли этот документ полезным (0 голосов)

297 просмотров11 страницmanual de transmisión automática

Оригинальное название

A4LD (11)

Авторское право

© © All Rights Reserved

Доступные форматы

PDF или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документmanual de transmisión automática

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

297 просмотров11 страницA4LD

Загружено:

Victor Hugo Parramanual de transmisión automática

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

Вы находитесь на странице: 1из 11

Technical Service Information

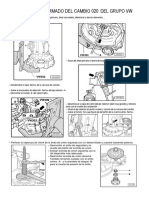

‘Mib NAAO AUTOMATIC OVERDRIVE TRANSANSSION

{BAND ANO CLUTCH APPUICATIONGEAR RATION

‘OvEROAVE

One war Annick

ovenonve overoave SH ‘shite

FORWARD

ran eel

aa

PERERA

i

a a

f uileeautel

fC eR

Automatic Transmission Test Linkage Check Manual Linkage

scarce sess ooercin Tiss aeftica austment Be sur the ©

Dvorsie) ete te renominson cer poponds

Tre nage must botresandmuctretentoidewhen | | Gracy wine sop nthe corsloor court naar

Sate votes oakage ste manca vane cn

ras eye coasters wo or siopng we

tering he nkage's ro propery acted

“Can be purchased as a separate ten.

Technical

Service

Information

Engine Vacuum Procedure

1. Attach a tachometer to the engine and a Vacuum

Gauge, Rotunda Number 059-00008, or

equivalent to the transmission vacuum line at the

manifold vacuum port

MANIFOLD

vacUUM UNE HOSE

ale

madiroro

vACOUM PORT

70 VACUUM GAUGE

DIAPHRAGM CONNECTION

2, Attach a pressure gauge to the control pressure,

‘outlet at the transmission,

CONTROL pRessuRE

TARE OFF HOLE

3. Firmly apply the parking brake and start the

engine,

4, Check the throttle and downshift inkage for a

binding condition. i linkage is satisfactory, check

{for vacuum leaks in the transmission diaphragm

unit and its connecting tubes and hoses. Check all

‘other vacuum-operated units (such as the power

brake) for vacuum leaks.

vacuum TesteR

Refer to the two control pressure diagnostic guides to

‘show what components are inoperative when the

control pressure testis not within specifications. Oo

‘not proceed with the main diagnosis quide until you

have made any repairs, as required, and the control

pressure is within specifications as listed in the

Performance Specifications Book or Special

Specifications Issue of the Technical Service Bulletin,

Vacuum Pump Method

Install an adjustable vacuum source. Disconnect and

‘temporarily plug the vacuum line at the vacuum

diaphragm unit. Apply both the parking and service

brakes. Start the engine and vacuum pump. Set the

vacuum at 15 inches, read and record the control

pressure in all selector positions. Run the engine up to.

‘1000 rpm, and reduce the vacuum to 10 inches. Read

and record the control pressure in @), D-2 and 1. Keep

the engine at 1000 rpm and reduce the vacuum fo 1

inch. Read and record the control pressure in @, D-1,

2and R.

Refer to the two control pressure diagnosis charts to,

‘show what components are inoperative when the

Control pressure test is not within specification. Do not

proceed with the main diagnosis chart until serviced

‘as required, and the control pressure is within

‘specification as listed in the Performance

‘Specifications Book or Special Specifications Issue of

the Technical Service Bulletin,

10

ATSG], Technical Service Information

(CONTROL PRESSURE TEST

ato ealpn eee

saves, anaes fons

|

|

pew ons

ORFRTER, LOOSE Ol. TUBES. | CHECK VACUUM DIAPHRAGM LOW AT VAQUUM BUT

LOOSE VALVE BODY TOCASE | | UNIT. MANIFOLD VACUUM | TON VACUUM LOW AT 3

Boeriaieere ioc | (Or weno er Sit

Bumresreceac| the On core en

Freie aoe’ ee

eum purimaaa wt] | BESS rete

SERNSRRSTARSTTE Arie

a rt

oe

T

|

romeo | [veer | [angen

ronwro | | ooutet. | | ottttewe | | overonive

eee ane mare || ceed

: ewer) | lg | | CHES | | aettiwe| | ave | | ithe

aes ite || a

oe REVERSE REVERSE

eae || xe

n

Вам также может понравиться

- 23E Caja AutomaticaДокумент9 страниц23E Caja AutomaticaVictor Hugo ParraОценок пока нет

- 23E Manual de Caja Automatica Mitsubishi TiburonДокумент26 страниц23E Manual de Caja Automatica Mitsubishi TiburonVictor Hugo Parra100% (1)

- Motronic 1.0 Flores, Vargas, MoralesДокумент5 страницMotronic 1.0 Flores, Vargas, MoralesVictor Hugo ParraОценок пока нет

- Bombas Rotativas ElectronicasДокумент3 страницыBombas Rotativas ElectronicasVictor Hugo Parra100% (1)

- Bobinas de Encendido PDFДокумент5 страницBobinas de Encendido PDFVictor Hugo ParraОценок пока нет

- Cdabs Peugeot 405 BendixДокумент3 страницыCdabs Peugeot 405 BendixVictor Hugo ParraОценок пока нет

- 8.catálogo PUERTAS DE BALLESTA V-20201127 PDFДокумент21 страница8.catálogo PUERTAS DE BALLESTA V-20201127 PDFRAFAEL RUIZОценок пока нет

- Manejo Defensivo SS - Ee. 2023Документ59 страницManejo Defensivo SS - Ee. 2023JOSEОценок пока нет

- Arnold RenfeZaragoza HN2043Документ3 страницыArnold RenfeZaragoza HN2043José Manuel EspinosaОценок пока нет

- Sistema de DistribuciónДокумент19 страницSistema de DistribuciónJuan Pablo Soto CabreraОценок пока нет

- Cartilla Mini Planta de AsfaltoДокумент5 страницCartilla Mini Planta de AsfaltoDaniel Rojas0% (1)

- Ceccato - 150manualДокумент43 страницыCeccato - 150manualFranco ValtortaОценок пока нет

- Kicks, 2019-20MYДокумент392 страницыKicks, 2019-20MYSugey ArayaОценок пока нет

- Fresadora SustentacionДокумент7 страницFresadora SustentacionDiego LunaОценок пока нет

- Caja VW 020 MANUALДокумент8 страницCaja VW 020 MANUALZapsОценок пока нет

- Acabados GeN2 Light - Hospital NavalДокумент5 страницAcabados GeN2 Light - Hospital NavalKarly OrtegaОценок пока нет

- Tractor Sobre Ruedas CAT-814F2Документ7 страницTractor Sobre Ruedas CAT-814F2Lucia Rales MoraОценок пока нет

- Reporte de Revicion de Camiones de AcarreoДокумент37 страницReporte de Revicion de Camiones de Acarreocristian frayreОценок пока нет

- Excavadora CAT M322DДокумент28 страницExcavadora CAT M322DNoelia GarcíaОценок пока нет

- Tarea 2. Funcionamiento de Un Motor de Combustión InternaДокумент5 страницTarea 2. Funcionamiento de Un Motor de Combustión InternaChristian Javier Maldonado HernandezОценок пока нет

- Continental GT SpecsДокумент2 страницыContinental GT SpecsSergioОценок пока нет

- Tacografo Vdo Vs StoneridgeДокумент7 страницTacografo Vdo Vs StoneridgeGianmarco CastilloОценок пока нет

- TIM01Документ4 страницыTIM01gallega30081989Оценок пока нет

- 1.2 Cigueñal, Balanceadores, Damper y Cojinetes-03 EstuДокумент30 страниц1.2 Cigueñal, Balanceadores, Damper y Cojinetes-03 Estujose pirulliОценок пока нет

- Ficha t680 2020Документ3 страницыFicha t680 2020Javier Oaxaca arenas100% (1)

- Soluciones para Larga Distancia: Capacidades Y PesosДокумент2 страницыSoluciones para Larga Distancia: Capacidades Y PesosJorge KitanovichОценок пока нет

- Prosec Abril2022-Directorio 20220418-20220418Документ774 страницыProsec Abril2022-Directorio 20220418-20220418suelenthortiz100% (1)

- Cargador Hyundai HL760-9S PDFДокумент12 страницCargador Hyundai HL760-9S PDFAmy Alvarez100% (1)

- Combat 125Документ59 страницCombat 125Real MotosОценок пока нет

- Guia de Seleccion Danfoss 102Документ1 страницаGuia de Seleccion Danfoss 102Jader Alonso Acosta GuarinОценок пока нет

- Catalogo Aplicaciones Camion ColombiaДокумент18 страницCatalogo Aplicaciones Camion Colombiaancelot99100% (1)

- Motor Serie 60 DetroitДокумент127 страницMotor Serie 60 DetroitYahir Bañuelos100% (2)

- Constancia GPS AUQ736Документ1 страницаConstancia GPS AUQ736juan pablo oconОценок пока нет

- Pavimetos Metodo ASHTO 93Документ11 страницPavimetos Metodo ASHTO 93Fernando MafaileОценок пока нет

- Publica 20200624163719Документ13 страницPublica 20200624163719aroldo arrietaОценок пока нет

- Manual Ec e 2011 EspДокумент68 страницManual Ec e 2011 EsplmjimenezhОценок пока нет