Академический Документы

Профессиональный Документы

Культура Документы

Rap 14 PDF

Загружено:

angelОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Rap 14 PDF

Загружено:

angelАвторское право:

Доступные форматы

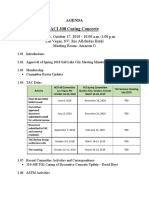

ACI RAP Bulletin 14

American Concrete Institute®

Advancing concrete knowledge

FIELD GUIDE TO Concrete

CONCRETE REPAIR Removal Using

APPLICATION PROCEDURES Hydrodemolition

Concrete Removal Using Hydrodemolition (ACI RAP-14) 1

2 Repair Application Procedures Bulletin

ACI RAP Bulletin 14

Field Guide to Concrete Repair Application Procedures

Concrete Removal Using Hydrodemolition

Reported by ACI Committee E706

David W. Whitmore

Chair

J. Christopher Ball H. Peter Golter Kenneth M. Lozen David A. VanOcker*

Gerald Churry Fred R. Goodwin John S. Lund Patrick M. Watson

Paul E. Gaudette Bob Joyce Kelly M. Page Patrick M. Winkler*

Timothy R. W. Gillespie Brian F. Keane George I. Taylor

*

Primary author.

It is the responsibility of the user of this document to Structural Disclaimer

establish health and safety practices appropriate to the specific

circumstances involved with its use. ACI does not make any This document is intended as a voluntary field guide for

representations with regard to health and safety issues and the use the Owner, design professional, and concrete repair con-

of this document. The user must determine the applicability of tractor. It is not intended to relieve the user of this guide

all regulatory limitations before applying the document and of responsibility for a proper condition assessment and

must comply with all applicable laws and regulations,

including but not limited to, United States Occupational structural evaluation of existing conditions, and for the

Safety and Health Administration (OSHA) health and specification of concrete repair methods, materials, or

safety standards. practices by an experienced engineer/designer.

ACI Repair Application Procedure 14.

Copyright © 2010, American Concrete Institute.

All rights reserved including rights of reproduction and use in any The Institute is not responsible for the statements or

form or by any means, including the making of copies by any photo pro- opinions in its publications. Institute publications are

cess, or by electronic or mechanical device, printed, written, or oral, or

recording for sound or visual reproduction or for use in any knowledge not able nor intended to supplant individual training,

retrieval system or device, unless permission in writing is obtained from responsibility or judgment of the user, or the supplier of

the copyright proprietors. Printed in the United States of America. the information provided.

Concrete Removal Using Hydrodemolition (ACI RAP-14) 3

Introduction

Concrete repair and restoration will typically require

removal of deteriorated concrete, preparation of the repair

surface, and cleaning of the reinforcing steel and embedded

items. Hydrodemolition is a method of concrete removal and

surface preparation using high-pressure water jets. When

used to remove concrete, the remaining surface is roughened

sufficiently to enhance bond and help ensure composite

action between the base concrete and the repair material

(Fig. 1). Unlike impact methods of demolition, hydrodemo-

lition does not induce microcracking, a condition that can be

detrimental to the longevity of a repair. Concrete removal

using hydrodemolition can be fast and efficient, expediting

the repair project. Removal using robotic hydrodemolition

equipment can eliminate fatigue and potential injury to

employees. Using water during concrete removal can Fig. 1—Surface profile after hydrodemolition.

suppress dust and provide a healthier work environment.

This document focuses on the concrete removal and

surface preparation required for the installation of cementitious

repair materials or bonded overlays having a material thickness

of 12 mm (0.5 in.) or greater.

Terms

bruised surface—a surface layer weakened by intercon-

nected microcracks in concrete substrates caused by use of

high-impact, mechanical methods for surface preparation.

hydrodemolition—a method for removal of concrete by

means of water under high pressure directed against a surface.

microcracks—small, numerous cracks that develop in

hardened concrete.

surface preparation—the process of removing deteriorated

or contaminated concrete and roughening and cleaning a

substrate to enhance bond of a repair material or protective

coating.

Fig. 2—Reinforcing steel exposed using hydrodemolition.

When do I use hydrodemolition?

This method may be used in a broad range of applications Impact removal techniques can bruise the surface, creating

requiring concrete removal and surface preparation prior to a fractured layer typically extending 1/8 to 3/8 in. (3 to 10 mm)

installation of a repair material. Removal of deteriorated deep and frequently results in lower bond strengths

concrete may include concrete that is spalled, cracked, compared to surfaces prepared with nonimpact methods.

delaminated, chloride contaminated, carbonated, or Where impact removal techniques such as jack-hammers,

damaged by fire or cycles of freezing and thawing. It may rotomilling, or similar methods are used, hydrodemolition

also include removal of sound concrete to provide proper may be used to perform final concrete removal and surface

clearance under the reinforcing steel or to provide a preparation to remove resulting microcracking. High-pressure

minimum thickness of repair material. The process may be water jetting may also be used to remove corrosion products

used when vibration of the structure from the use of impact from reinforcing steel (Fig. 3).

removal methods may lead to further damage or where

vibration and sound is easily transmitted and will interfere What should I consider when using

with the simultaneous occupancy and use of the structure. hydrodemolition?

Hydrodemolition is particularly effective in removing The process should not be used in areas where the waste-

concrete from around embedded metal elements such as water cannot be controlled and water leakage into adjacent

reinforcing steel, anchors, and pipe conduits (Fig. 2). areas can cause damage.

Embedded metal elements may block the water jet from Because there is the possibility that the water may enter

removing the concrete directly beneath the element, leaving a the post-tensioned tendon sheathing and cause long-term

concrete shadow. If the concrete removal depth is sufficient, durability issues, hydrodemolition may not be suitable and is

however, the angle of the water jet will undercut the metal not recommended for removing concrete from around post-

element and remove the shadow. Otherwise, the shadow may tensioned tendons. In addition, caution should be exercised

be removed using a hydrodemolition hand lance or chipping with post-tensioned structures, as hydrodemolition may

hammers. remove concrete around the tendon anchorages, resulting in

4 Repair Application Procedures Bulletin

Fig. 3—Reinforcing steel and bar joist top chords exposed Fig. 5—Hydrodemolition robot.

using hydrodemolition.

Fig. 4—Hydrodemolition pump trailer.

movement or de-tensioning of the tendons. Sudden release

of anchorages or removal of support for the tendon profile

could lead to equipment damage, personal injury, or structural

integrity loss. Refer to International Concrete Repair Institute’s

(ICRI’s) ICRI Technical Guideline No. 310.3, “Guide for

the Preparation of Concrete Surfaces Using Hydrodemolition

Methods,” for additional information regarding considerations Fig. 6—Hydrodemolition mower.

for hydrodemolition use.

Removal of concrete can reduce structural capacity. A

qualified engineer should verify the integrity of the structure

and determine whether shoring is required. The weight of the

robotic tractor, if used, should be included in the shoring

calculations. Shoring should be installed prior to the start of

removal, and the shoring layout should accommodate debris

removal because it will remain until after replacement occurs.

What equipment do I need?

Hydrodemolition equipment consists of high-pressure

pumps (Fig. 4); self-propelled robotic units to hold and

maneuver the water jet (Fig. 5); small push or self-propelled

units (mowers) used for small removal areas (Fig. 6); and

hand lances (Fig. 7). The robotic units move the water jet

uniformly over the surface. Where the concrete quality is

consistent, the removal will be uniform and result in a

finished surface profile amplitude approximately the size of

the coarse aggregate. Travel speed of the unit can be adjusted

to control the overall amount and depth of removal. The Fig. 7—Hand lance for hand-held hydrodemolition

Concrete Removal Using Hydrodemolition (ACI RAP-14) 5

removal units may or may not be connected to vacuum

systems to collect the water and debris during the removal

and surface preparation operation.

Specialized equipment is available for a variety of applications

including overhead, vertical, tunnel, and underwater removal.

How do I dispose of the wastewater?

Wastewater disposal requirements for the local area must

be determined and followed. The wastewater contains

cement fines with a pH ranging from 11 to 13. Where the

wastewater will be discharged to the local sanitary systems,

a permit may be required, and the water may have to be

treated to meet the sanitary system’s discharge requirements.

Commonly encountered sanitary discharge requirements

may range from 300 to 400 mg/L (0.0025 to 0.0033 lb/gal.)

Fig. 8—Tensile bond test on prepared substrate.

total suspended solids (TSS), and a pH between 5 and 10.

Discharge requirements vary, and the local governing

authority should be contacted prior to discharging water. serious injury or death. Water jets can propel debris at high

In some areas, wastewater may be discharged on the velocity, resulting in injury or death as well as damage to

ground and allowed to evaporate or be absorbed into the property. The water jet should be shielded to minimize the

ground. Wastewater may not be discharged into lakes, possibility of flying debris.

streams or wetlands. Items in the work area that may be damaged should be

protected. Electrical conduits and equipment should be de-

How do I clean up after hydrodemolition? energized. The area both around and below the removal area

Following hydrodemolition, the surface must be cleaned should be closed to prevent access. Anyone entering the

to remove all debris, slurry, and wastewater. This may be work area should wear Personal Protective Equipment (PPE)

done using vacuum equipment, water blasters operating at including safety glasses (face shield if necessary), hearing

up to 70 MPa (10,000 psi), pressure washers, air lances, and protection, hard hat, long pants, long-sleeved shirt, and steel

other equipment that will remove waste from the repair toed boots. Additional protective clothing may be necessary

substrate. Cleanup operations should follow immediately when operating hand-held tools.

behind the hydrodemolition removal to prevent re-solidification

of the debris, which can occur if the debris is allowed to dry. Preconstruction meeting

The surface should be thoroughly rinsed to remove all Prior to proceeding with concrete removal using

cement fines (slurry). hydrodemolition, a preconstruction meeting is recom-

mended. The meeting should include representatives from

How do I check the surface following concrete all participating parties (including the owner, engineer,

removal?

The surface should be visually inspected to verify that it is contractor, and materials manufacturer), and should specifically

free from dirt, dust, debris, oils, slurry, and other bond- address the following:

inhibiting materials. Aggregate protruding from the surface 1. Location and schedule of the work;

should not be fractured or damaged. Clean, crisp aggregate 2. Location and layout of shoring, if required;

protruding from the repair surface will enhance the mechanical 3. Location and layout of the hydrodemolition equipment;

bond between the existing surface and the repair material 4. Location and layout of the temporary water supply,

(Fig. 1). The surface can be sounded using a chain drag or including materials to be used, and any permits required to

hammer to locate any delaminations. secure the use of the water;

The bonding capacity of the prepared surface can be 5. Location and layout of exhaust system to avoid exhaust

randomly checked using a direct tensile pull-off test (Fig. 8) intake into adjacent buildings;

as described in ICRI Technical Guideline No. 210.3, “Guide

6. Location and layout of fuel system required for the

for Using In-Situ Tensile Pull-Off Tests to Evaluate Bond of

equipment, including method of fuel delivery;

Concrete Surface Materials,” and ASTM C1583/C1583M,

“Standard Test Method for Tensile Strength of Concrete 7. Location and layout of the system to be used to contain

Surfaces and the Bond Strength or Tensile Strength of the waste water, including methods of reducing the

Concrete Repair and Overlay Materials by Direct Tension suspended particles to acceptable levels, adjusting the pH, if

(Pull-off Method).” required, and discharging the waste water; any water tests

that will be required and who will perform the tests; and any

How do I operate the equipment safely? permits required to properly discharge the wastewater;

All high-pressure equipment should be operated by 8. The impact tools (jackhammers) required to perform the

individuals experienced in the use and maintenance of this work, whether the vibration noise will affect the structure or

specialized equipment. Hydrodemolition uses high-pressure the occupants, and any additional surface preparation

water jets; the water jet is very dangerous and can cause required in areas in which impact tools were used;

6 Repair Application Procedures Bulletin

9. Equipment and method of removal for the debris from ICRI, 2004b, “Guide to Using In-Situ Tensile Pull-Off Test to Evaluate

concrete demolition, including proposed active drive lanes to Bond of Concrete Surface Materials,” 2004, ICRI Technical Guideline No.

210.3, International Concrete Repair Institute, Des Plaines, IL, 12 pp.

move debris off the structure such that the removal does not

impact the ongoing operations; and

Sources for additional information

10. Methods to insure the safety of all personnel, property, ACI Committee 318, 2008, “Building Code Requirements for Structural

and equipment. Concrete (ACI 318-08) and Commentary,” American Concrete Institute,

Farmington Hills, MI, 473 pp.

References ACI Committee 546, 2004, “Concrete Repair Guide (ACI 546R-04),”

ASTM C1583/C1583M-04e1, 2004, “Standard Test Method for Tensile American Concrete Institute, Farmington Hills, MI, 53 pp.

Strength of Concrete Surfaces and the Bond Strength or Tensile Strength of ICRI, 2006, “Guide for the Repair of Unbonded Post-Tensioned

Concrete Repair and Overlay Materials by Direct Tension (Pull-off Concrete Structures,” ICRI Technical Guideline No. 320.4, International

Method),” ASTM International, West Conshohocken, PA, 5 pp. Concrete Repair Institute, Des Plaines, IL, 24 pp.

ICRI, 2004a, “Guide for the Preparation of Concrete Surfaces for Repair ICRI, 2009, “Guide for Selecting and Specifying Materials for Repair of

Using the Hydrodemolition Method,” ICRI Technical Guideline No. Concrete Surfaces,” ICRI Technical Guideline No. 320.2R, International

310.3, International Concrete Repair Institute, Des Plaines, IL, 16 pp. Concrete Repair Institute, Des Plaines, IL, 34 pp.

Concrete Removal Using Hydrodemolition (ACI RAP-14) 7

Вам также может понравиться

- Rap 2Документ5 страницRap 2mkhibosОценок пока нет

- ACI Crack RepairДокумент6 страницACI Crack RepairelmerbarrerasОценок пока нет

- Surface Repair Using Form-and-Pour Techniques: Reported by ACI Committee E 706Документ7 страницSurface Repair Using Form-and-Pour Techniques: Reported by ACI Committee E 706Carlos Gonzalez100% (1)

- ACI - Shotcrte para ReparaciónДокумент6 страницACI - Shotcrte para ReparaciónJimy Mejia MendozaОценок пока нет

- ACI RAP-2 - Crack Repair by Gravity Feed With Resin - 2011 PDFДокумент6 страницACI RAP-2 - Crack Repair by Gravity Feed With Resin - 2011 PDFilo88100% (1)

- Field Guide To Concrete Repair Application Procedures: RAP Bulletin 3-21Документ8 страницField Guide To Concrete Repair Application Procedures: RAP Bulletin 3-21EMILIO MINORU TAKAGI100% (1)

- Spall Repair by The Preplaced Aggregate Method: Field Guide To Concrete Repair Application ProceduresДокумент7 страницSpall Repair by The Preplaced Aggregate Method: Field Guide To Concrete Repair Application ProcedurescustomerxОценок пока нет

- Surface Repair Using Form-and-Pump Techniques: Field Guide To Concrete Repair Application ProceduresДокумент8 страницSurface Repair Using Form-and-Pump Techniques: Field Guide To Concrete Repair Application ProcedurescustomerxОценок пока нет

- Vertical and Overhead Spall Repair by Hand ApplicationДокумент7 страницVertical and Overhead Spall Repair by Hand Applicationshadab521Оценок пока нет

- ICRI - Guide For Surface Preparation For The Repair of Deteriorated Concrete Resulting From Reinforcing Steel Corrosion 2008 (2016!05!03)Документ16 страницICRI - Guide For Surface Preparation For The Repair of Deteriorated Concrete Resulting From Reinforcing Steel Corrosion 2008 (2016!05!03)Matt100% (8)

- ACI RAP-4 - Surface Repair Using Form-and-Pour Techniques - 2011Документ8 страницACI RAP-4 - Surface Repair Using Form-and-Pour Techniques - 2011ilo88Оценок пока нет

- Concrete RepairДокумент7 страницConcrete RepairjjahaddinОценок пока нет

- Section 3-4 Paper 2 ICRI Guideline 03737Документ16 страницSection 3-4 Paper 2 ICRI Guideline 03737Héctor Yamill López AmpiéОценок пока нет

- Aci Rap-1Документ7 страницAci Rap-1Mauricio De Stefani100% (1)

- Crack Repair by Gravity Feed With ResinДокумент6 страницCrack Repair by Gravity Feed With ResinEladio Almengor100% (1)

- Icri 310Документ54 страницыIcri 310Romilson De Andrade100% (1)

- Masonry Tutorial Spanish BlondetДокумент14 страницMasonry Tutorial Spanish BlondetStevens NinanyaОценок пока нет

- Installation of Embedded Galvanic Anodes: Reported by ACI Committee E 706Документ6 страницInstallation of Embedded Galvanic Anodes: Reported by ACI Committee E 706Vijay KumarОценок пока нет

- 2101r2016 Guideline Verifying Field Performance Epoxy Injection Concrete CracksДокумент18 страниц2101r2016 Guideline Verifying Field Performance Epoxy Injection Concrete CracksEdgar Joel Perez Carvajal100% (1)

- ACI E-706 Spall Repair of Horizontal Concrete SurfacesДокумент6 страницACI E-706 Spall Repair of Horizontal Concrete SurfacesmirzaОценок пока нет

- Icri 710-2-2014Документ22 страницыIcri 710-2-2014jabh311100% (2)

- 2017 Pub Catalog PublishWEBДокумент14 страниц2017 Pub Catalog PublishWEBJohn PinkОценок пока нет

- ACI 201.1R Guide To Conducting A Visual Inspection of Concrete in ServiceДокумент19 страницACI 201.1R Guide To Conducting A Visual Inspection of Concrete in ServiceRenato Rocha100% (1)

- Field Guide To Concrete Repair Application Procedures: Structural Crack Repair by Epoxy Injection ACI RAP Bulletin 1Документ3 страницыField Guide To Concrete Repair Application Procedures: Structural Crack Repair by Epoxy Injection ACI RAP Bulletin 1jamjam75Оценок пока нет

- 510 1 2013Документ26 страниц510 1 2013AshrafОценок пока нет

- 320 3R-2012 PDFДокумент13 страниц320 3R-2012 PDFJorge Andrés100% (1)

- Guide To Concrete Repair (2015)Документ376 страницGuide To Concrete Repair (2015)Fernando EscriváОценок пока нет

- Contents-Concrete Repair Manual: Third EditionДокумент4 страницыContents-Concrete Repair Manual: Third Editionmy09Оценок пока нет

- Icri 310-2R-2013Документ55 страницIcri 310-2R-2013joel_garcia_112100% (1)

- 3101R2008 ReinforcingSteelCorrosion PDFДокумент16 страниц3101R2008 ReinforcingSteelCorrosion PDFjuli_radОценок пока нет

- ACI 201.1R-08 Guide For Conducting A Visual Inspection of Concrete in ServiceДокумент19 страницACI 201.1R-08 Guide For Conducting A Visual Inspection of Concrete in ServicehoustonhimselfОценок пока нет

- Cracks InvestigationДокумент11 страницCracks InvestigationLobsang Matos100% (1)

- 503.7-07 Specification for Crack Repair by Epoxy Injection-مفتوحДокумент11 страниц503.7-07 Specification for Crack Repair by Epoxy Injection-مفتوحMohamed Ismail ShehabОценок пока нет

- Repair Application ProceduresДокумент6 страницRepair Application ProceduresSatheesh Rama SamyОценок пока нет

- ACI - Troubleshooting Surface ImperfectionsДокумент18 страницACI - Troubleshooting Surface ImperfectionsADav100% (3)

- Icri 310-2R-2013Документ54 страницыIcri 310-2R-2013Anjali Anju100% (1)

- ACI 364.10T-14 TechNoteДокумент4 страницыACI 364.10T-14 TechNotedddОценок пока нет

- Guideline For Inorganic Repair Material Data Sheet ProtocolДокумент10 страницGuideline For Inorganic Repair Material Data Sheet ProtocolMauricio Javier León TejadaОценок пока нет

- ACI Committee 546-ACI 546R-04 - Concrete Repair Guide-American Concrete Institute (ACI) (2004)Документ53 страницыACI Committee 546-ACI 546R-04 - Concrete Repair Guide-American Concrete Institute (ACI) (2004)cp1r3sОценок пока нет

- 304R-00 Guide For Measuring, Mixing, Transporting, and Placing ConcreteДокумент48 страниц304R-00 Guide For Measuring, Mixing, Transporting, and Placing ConcreteJoseph MendozaОценок пока нет

- Causes and Evaluation of Cracks in Concrete StructuresДокумент5 страницCauses and Evaluation of Cracks in Concrete StructuresInternational Jpurnal Of Technical Research And ApplicationsОценок пока нет

- ACI-207.4R-93 Cooling and Insulating Systems For Mass ConcreteДокумент22 страницыACI-207.4R-93 Cooling and Insulating Systems For Mass Concreteorlandomanriquez100% (2)

- Concrete Repair Manual (2017)Документ59 страницConcrete Repair Manual (2017)Fernando EscriváОценок пока нет

- Aci 201 Guide To Durable ConcreteДокумент17 страницAci 201 Guide To Durable ConcreteRoxana GabrielaОценок пока нет

- ACI 117-90 Tolerances ConcreteДокумент23 страницыACI 117-90 Tolerances ConcreteJhordy Moises Pinedo CàrdenasОценок пока нет

- Specification For Tolerances For Concrete Construction and Materials (ACI 117-10) and CommentaryДокумент80 страницSpecification For Tolerances For Concrete Construction and Materials (ACI 117-10) and CommentaryLord AslanОценок пока нет

- Types of CracksДокумент3 страницыTypes of CracksShativel ViswanathanОценок пока нет

- Aci 548.3R-03Документ40 страницAci 548.3R-03jerryОценок пока нет

- ACI Technical Notes-3Документ7 страницACI Technical Notes-3Moloy GoswamiОценок пока нет

- Rap 6Документ8 страницRap 6nimalranasinghe2505100% (1)

- Guide For The Preparation of Concrete Surfaces For Repair Using Hydrodemolition MethodsДокумент80 страницGuide For The Preparation of Concrete Surfaces For Repair Using Hydrodemolition MethodschabaloonОценок пока нет

- Methacrylate Flood Coat: Field Guide To Concrete Repair Application ProceduresДокумент6 страницMethacrylate Flood Coat: Field Guide To Concrete Repair Application ProceduresangelОценок пока нет

- Application: Concrete Repair by ShotcreteДокумент5 страницApplication: Concrete Repair by ShotcreteJuan Carlos Donayre SalasОценок пока нет

- Specification Guidelines For Surface Preparation of Concrete Prior To RepairДокумент9 страницSpecification Guidelines For Surface Preparation of Concrete Prior To RepairRafafuenmaОценок пока нет

- Concrete Crack Repair PDFДокумент6 страницConcrete Crack Repair PDFNawshad KhОценок пока нет

- ACI RAP-7 Spall Repair of Horizontal Concrete SurfacesДокумент7 страницACI RAP-7 Spall Repair of Horizontal Concrete SurfacesGeorgie MachaОценок пока нет

- 503 6R-97 PDFДокумент4 страницы503 6R-97 PDFsaeidcivil89Оценок пока нет

- Guide For The Preparation of Concrete Surfaces For Repair Using Hydrodemolition MethodsДокумент3 страницыGuide For The Preparation of Concrete Surfaces For Repair Using Hydrodemolition MethodsHamza MamiОценок пока нет

- 555r 01Документ26 страниц555r 01Varun RamcharitarОценок пока нет

- 544 4R-182 PDFДокумент45 страниц544 4R-182 PDFangel0% (3)

- Control of Cracking in Concrete E-C107Документ56 страницControl of Cracking in Concrete E-C107Ye Kyaw KhaungОценок пока нет

- Rap 14 PDFДокумент7 страницRap 14 PDFangelОценок пока нет

- Designing Concrete Structures:: Acceptance of Concrete Compressive Strength Test Results According To ACI 318-14Документ6 страницDesigning Concrete Structures:: Acceptance of Concrete Compressive Strength Test Results According To ACI 318-14angelОценок пока нет

- License KeyДокумент17 страницLicense KeyDouglas AlvesОценок пока нет

- Rap 14 PDFДокумент7 страницRap 14 PDFangelОценок пока нет

- Rap 9 PDFДокумент7 страницRap 9 PDFangel100% (1)

- Methacrylate Flood Coat: Field Guide To Concrete Repair Application ProceduresДокумент6 страницMethacrylate Flood Coat: Field Guide To Concrete Repair Application ProceduresangelОценок пока нет

- Leveling and Reprofiling of Vertical and Overhead Surfaces: Field Guide To Concrete Repair Application ProceduresДокумент6 страницLeveling and Reprofiling of Vertical and Overhead Surfaces: Field Guide To Concrete Repair Application ProceduresMahmoud saidОценок пока нет

- Slabjacking: Field Guide To Concrete Repair Application ProceduresДокумент7 страницSlabjacking: Field Guide To Concrete Repair Application ProceduresangelОценок пока нет

- License KeyДокумент17 страницLicense KeyDouglas AlvesОценок пока нет

- License KeyДокумент17 страницLicense KeyDouglas AlvesОценок пока нет

- Pervious Concrete Cert and Verification-BC 1slideДокумент30 страницPervious Concrete Cert and Verification-BC 1slideangelОценок пока нет

- License KeyДокумент17 страницLicense KeyDouglas AlvesОценок пока нет

- Control of Cracking in Concrete E-C107Документ56 страницControl of Cracking in Concrete E-C107Ye Kyaw KhaungОценок пока нет

- Tip 15 WДокумент1 страницаTip 15 WangelОценок пока нет

- 544 4R-182 PDFДокумент45 страниц544 4R-182 PDFangel20% (5)

- 308R 16 PDFДокумент41 страница308R 16 PDFangel0% (1)

- State-Of-The-Art Report On Fiber Reinforced Concrete ACI 544-2002Документ66 страницState-Of-The-Art Report On Fiber Reinforced Concrete ACI 544-2002Attie761367% (3)

- 27252Документ8 страниц27252angelОценок пока нет

- Concrete Cap1Документ16 страницConcrete Cap1familyrusmiОценок пока нет

- ACI 308 Main Fall 2018 Las Vegas AgendaДокумент2 страницыACI 308 Main Fall 2018 Las Vegas AgendaangelОценок пока нет

- 3632r 98 PDFДокумент18 страниц3632r 98 PDFFred PrzОценок пока нет

- Read Mixed ConcreteДокумент8 страницRead Mixed ConcreteRkantvyasОценок пока нет

- CarbonCure Technical Note - CarbonCure and Pore Solution PHДокумент2 страницыCarbonCure Technical Note - CarbonCure and Pore Solution PHangelОценок пока нет

- Tip 4Документ1 страницаTip 4Susana DeLara Sto TomasОценок пока нет

- Monkman 2016 - Properties and Durability of Concrete Produced Using CO2 As An Accelerating AdmixtureДокумент7 страницMonkman 2016 - Properties and Durability of Concrete Produced Using CO2 As An Accelerating AdmixtureangelОценок пока нет

- Should Minimum Cementitious Contents For Concrete Be Specified?Документ8 страницShould Minimum Cementitious Contents For Concrete Be Specified?angelОценок пока нет

- YeldДокумент1 страницаYeldBijaya RaulaОценок пока нет

- Exercise 4Документ3 страницыExercise 4rasyid_hasanОценок пока нет

- Ropaque™ Ultra E: Technical Data Sheet For Europe, Middle East and AfricaДокумент3 страницыRopaque™ Ultra E: Technical Data Sheet For Europe, Middle East and AfricahongducxxxОценок пока нет

- TMP 29292-WF1802WF-03061A XEU1554776476 PDFДокумент44 страницыTMP 29292-WF1802WF-03061A XEU1554776476 PDFAlupului CristinaОценок пока нет

- Liquid Extraction OperationДокумент19 страницLiquid Extraction OperationOky TresiaОценок пока нет

- Choosing The Correct Coating For Cargo Tank PDFДокумент8 страницChoosing The Correct Coating For Cargo Tank PDFKUKUОценок пока нет

- Catalogo de Filtros Separador de Aire (Parker)Документ112 страницCatalogo de Filtros Separador de Aire (Parker)Mikel1020Оценок пока нет

- Desalination DCMD Report 3Документ11 страницDesalination DCMD Report 3Abdulaziz AlmaymuniОценок пока нет

- Onan RV GenSet Service ManualДокумент136 страницOnan RV GenSet Service ManualAlbert A Ghazaleh100% (2)

- Compact Repeater 972-0RB12 3Документ16 страницCompact Repeater 972-0RB12 3Kelly Perez LopezОценок пока нет

- Test FireДокумент11 страницTest FireMario UyОценок пока нет

- Advanced FRP Panel Tank DesignДокумент4 страницыAdvanced FRP Panel Tank DesignEstimasi ATI SurabayaОценок пока нет

- Size Reduction PDFДокумент53 страницыSize Reduction PDFnofriadyОценок пока нет

- Pig SigДокумент6 страницPig SigdmitosОценок пока нет

- Consolidated - Parts COMPLETE SRV Parts Book PDFДокумент259 страницConsolidated - Parts COMPLETE SRV Parts Book PDFJeffry Karundeng100% (1)

- Assignment AASДокумент2 страницыAssignment AASdean016026Оценок пока нет

- Hot Rolling TesisДокумент284 страницыHot Rolling TesisJoselo HR100% (1)

- Lec 7 (Design of Pumping Station)Документ17 страницLec 7 (Design of Pumping Station)hawkswimmer66100% (1)

- Vegapuls 64Документ84 страницыVegapuls 64milasko86Оценок пока нет

- BASIC DIFFERENCES BETWEEN COUPLINGS, CLUTCHES AND BRAKESДокумент41 страницаBASIC DIFFERENCES BETWEEN COUPLINGS, CLUTCHES AND BRAKESKadiyam VijayОценок пока нет

- Aegi ClampsДокумент12 страницAegi ClampssssydorenkoОценок пока нет

- Mel ZG611Документ5 страницMel ZG611jitendraОценок пока нет

- AF2000 Series (0.6MB)Документ4 страницыAF2000 Series (0.6MB)Syarifudin ZuhriОценок пока нет

- URAI ManualДокумент28 страницURAI ManualSesFasabiSaavedraОценок пока нет

- Pec RulesДокумент2 страницыPec RulesMhayson LpaguipoОценок пока нет

- Uni Interface ZündДокумент3 страницыUni Interface Zündmaxime100% (1)

- Equivalent Cross Valve Cast PDFДокумент2 страницыEquivalent Cross Valve Cast PDFshaonaaОценок пока нет

- Technical Data Workshop Manual for TAD940GE, TAD941GE, TAD940VE, TAD941VE, TAD942VE, TAD943VE, TAD950VE, TAD951VE and TAD952VE Industrial EnginesДокумент42 страницыTechnical Data Workshop Manual for TAD940GE, TAD941GE, TAD940VE, TAD941VE, TAD942VE, TAD943VE, TAD950VE, TAD951VE and TAD952VE Industrial EnginesEdson Goncalves100% (2)

- Commissioning Report For Biomass BoilerДокумент3 страницыCommissioning Report For Biomass Boilersugandaraj522Оценок пока нет

- 2011specific Kobelco BookДокумент169 страниц2011specific Kobelco Bookmas_munir7174Оценок пока нет

- SHOP MANUAL Sen00203-18 D475Документ1 617 страницSHOP MANUAL Sen00203-18 D475Wilfredo Escobar Gutierrez100% (3)