Академический Документы

Профессиональный Документы

Культура Документы

13 Volume Calculations For Primary Cementing - Quartz

Загружено:

RebarОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

13 Volume Calculations For Primary Cementing - Quartz

Загружено:

RebarАвторское право:

Доступные форматы

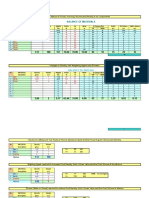

CALCULATION OF VOLUMES FOR PRIMARY CEMENTING

WELL DATA

Csng. #1 13.375 Casing #1 Open Hole

O.D.: 13.375 Ave. Diameter 12.597 in

A I.D.: 12.615 in Float Collar @ 2336.00 m

( 150.00 )m Long. "A": 150.00 m

V1

V2 Casing #2

O.D.: 9.625

B C= 2336.00 m I.D.: 8.921 in

Csng. #2 9.625 ( 1,614.00 )m ( 2,336.00 )m Long. "B": 1,614.00 m

Shoe track: 15.00 m

FC TR Arriba MR: 1.00 m

CALCULATIONS

V3

V1 (Csng/Csng) = 31.79 Bbls Cap. Ann 1= 0.21191 Bbls/m

V2 (Casing / OH)= 339.69 Bbls Cap. Ann 2= 0.21046 Bbls/m

Notes: V3(Shoe Track)= 3.80 Bbls Cap. TR= 0.25361 Bbls/m

Data input in Blue

Calculations in Red Total Volume 375.28 Bbls

Volume of Casing 592.70 Bbls

PUMPING TIME (PT) VS. THICKENING TIME (TT)

Fluid VOLUME (BLS) Flow Rate (BPM) Time (minutes) Thickening Time (hours)

Washer 10 3.0 3.3 4.3 Remarks:

Spacer 30 4.0 7.5

Cement Slurry 375.28 4.0 93.8 Pumping Time (hours)

Mud 100.00 7.5 13.3 4.5

Mud 482.70 4.0 120.7 TT > PT ? NO

Water 10.00 3.0 3.3 "YES" = Start Operation

Contingencies 30.0 "NO" = Inform and Check

DISPLACEMENT VOLUME CONSIDERING OIL BASE MUD COMPRESSIBILITY

Data:

Oil Compr. Factor (OCF)= 6.10E-06 Psi -1

Solids Compr. Factor (SCF)= 2.90E-06 Psi -1

Water Compr. Factor (WCF)= 2.00E-07 Psi -1

Final Pumping Pressure (Pf) = 1500.00 Psi

Mud Density (d) = 1.30 gr/cc 1.30 ppg

% Oil = 65.00 % 0.65

% Solids = 15.00 % 0.15

% Water = 20.00 % 0.2

Float Collar Depth = 487.38 m 1,599.00 m

Volume until FC = 592.70 Bbls

OBM Compress. Factor 4.44E-06 Psi -1

Pressure above FC (Ph + Pf) = 4,451.75 Psi

Pm (Press. above CF/2) = 2,225.88 Psi

Compressibilty Volume (Vcomp) = 5.86 Bbls

Casing Volume + Vcomp = 598.55 Bbls

½ (Shoe Track Volume) = 1.90 Bbls

CALCULOS DE ELONGACION DE TR

DATOS: RESULTADOS

TR

TVD = 2,188 m 7,178.5 Ft

Long. TR: 2,366 m 7,762.5 Ft POR ASENTAMIENTO DE TAPONES

Area Transversal: 10.25 in^2

Esfuerzo admisible: 110,000 psi Presion hidrostatica = Ph 1 = Ph + P asent.

Diametro interior (ID): 8.921 in Ph = 2,282 psi

Peso de TR = 36.00 Lb/ft Ph1 = 3,782 psi

Diametro Exterior (OD): 9.625 in

Lodo Fuerza h1 = F h1 = Ph1 * A1

Densidad Lodo: 1.30 gr/cc 10.83 lpg A1 = 62.51 in^2

Fh1 = Ph1 * A1= 236,371.5 Lb

Cemento

Densidad amarre: 1.90 gr/cc 15.83 lpg CEMENTACION

Long. Amarre: 300 m 984.3 Ft

Densidad Barrido: 1.60 gr/cc 13.33 lpg P h2 = 5,380 psi D equiv = 14.41 lpg

Long. Barrido: 1,766 m 5,794.0 Ft F cmto = A2 * P h2

Densidad lavador: 1.30 gr/cc 10.83 lpg A2 = 72.76 in^2

Long. Lavador: 300 m 984.3 Ft F cmto = 391,434.8 Lb

Dens. Fluido desplaz. 1.30 gr/cc 10.83 lpg

Long. Desplazamiento: 1,235 m 4,051.8 Ft PESO DE TR

Presion Asent. Tapon: 1,500 psi (P asent) F 2 (aire)= Long TR * Lb/ft

F 2 (aire)= 279,448.8 Lb

Delta Temperatura: 158.00 oF

E acero: 30.00E+06 psi Factor de Flotacion = FF = 0.780

Coef. Expansion Term.: 06.90E-06 oF-1 (flotado en cemento)

F 2 (flot)= 217,857.4 Lb

ELONGACION POR FUERZAS

Fuerza Resultante (Fr) = Fh1 + F2 (flot) - F cmto

Fr = 62,794.1 Lb

Esfuerzo (s )= Fr / Atran. = 6,126 psi

Def. Unit ( e ) = s / E = 02.04E-04

Elongacion ( d ) = e * L 0.45 m

ELONGACION POR EXPANSION TERMICA

Expasion Termica ( d term ) = D Temp * L * a

d term = 2.6 m

ELONGACION TOTAL

Elongacion Total ( d Total ) = d term + d

d Total = 3.0 m

CALCULOS DE ELONGACION DE TR

DATOS: RESULTADOS

TR

TVD = 0.0 Ft

Long. TR: 0.0 Ft POR ASENTAMIENTO DE TAPONES

Area Transversal:

Esfuerzo admisible: Presion hidrostatica = Ph 1 = Ph + P asent.

Diametro interior (ID): Ph = 0 psi

Peso de TR = Ph1 = 0 psi

Diametro Exterior (OD):

Lodo Fuerza h1 = F h1 = Ph1 * A1

Densidad Lodo: 0.00 lpg A1 = 0.00 in^2

Longitud de lodo: 0.0 Ft Fh1 = Ph1 * A1= 0.0 Lb

Cemento

Densidad amarre: 0.00 lpg CEMENTACION

Long. Amarre: 0.0 Ft

Densidad Barrido: 0.00 lpg P h2 = 0 psi D equiv = #DIV/0!

Long. Barrido: 0m 0.0 Ft F cmto = A2 * P h2

Densidad lavador: 0.00 lpg A2 = 0.00 in^2

Long. Lavador: 0.0 Ft F cmto = 0.0 Lb

Dens. Fluido desplaz. 0.00 lpg

Long. Desplazamiento: 0.0 Ft PESO DE TR

Presion Asent. Tapon: (P asent) F 2 (aire)= Long TR * Lb/ft

F 2 (aire)= 0.0 Lb

Delta Temperatura:

E acero: 30.00E+06 psi Factor de Flotacion = FF = #DIV/0!

Coef. Expansion Term.: 06.90E-06 oF-1 (flotado en cemento)

F 2 (flot)= #DIV/0!

ELONGACION POR FUERZAS

Fuerza Resultante (Fr) = Fh1 + F2 (flot) - F cmto

Fr = #DIV/0!

Esfuerzo (s )= Fr / Atran. = #DIV/0!

Def. Unit ( e ) = s / E = #DIV/0!

Elongacion ( d ) = e * L #DIV/0!

ELONGACION POR EXPANSION TERMICA

Expasion Termica ( d term ) = D Temp * L * a

d term = 0.0 m

ELONGACION TOTAL

Elongacion Total ( d Total ) = d term + d

d Total = #DIV/0!

CALCULOS DE ELONGACION DE TR

DATOS: RESULTADOS

TR

TVD = 0.0 Ft

Long. TR: 0.0 Ft POR ASENTAMIENTO DE TAPONES

Area Transversal:

Esfuerzo admisible: Presion hidrostatica = Ph 1 = Ph + P asent.

Diametro interior (ID): Ph = 0 psi

Peso de TR = Ph1 = 0 psi

Diametro Exterior (OD):

Fuerza h1 = F h1 = Ph1 * A1

A1 = 0.00 in^2

Fh1 = Ph1 * A1= 0.0 Lb

Cemento

Densidad amarre: 0.00 lpg CEMENTACION

Long. Amarre: 0.0 Ft

Densidad Barrido: 0.00 lpg P h2 = 0 psi D equiv = #DIV/0!

Long. Barrido: 0.0 Ft F cmto = A2 * P h2

Densidad lavador: 0.00 lpg A2 = 0.00 in^2

Long. Lavador: 0.0 Ft F cmto = 0.0 Lb

Densidad lodo: 0.00 lpg

Long. Lodo: 0m 0.0 Ft

Dens. Fluido desplaz. 0.00 lpg

Long. Desplazamiento: 0.0 Ft PESO DE TR

Presion Asent. Tapon: (P asent) F 2 (aire)= Long TR * Lb/ft

F 2 (aire)= 0.0 Lb

Delta Temperatura: 199.40 oF

E acero: 30.00E+06 psi Factor de Flotacion = FF = #DIV/0!

Coef. Expansion Term.: 06.90E-06 oF-1 (flotado en cemento)

F 2 (flot)= #DIV/0!

ELONGACION POR FUERZAS

Fuerza Resultante (Fr) = Fh1 + F2 (flot) - F cmto

Fr = #DIV/0!

Esfuerzo (s )= Fr / Atran. = #DIV/0!

Def. Unit ( e ) = s / E = #DIV/0!

Elongacion ( d ) = e * L #DIV/0!

ELONGACION POR EXPANSION TERMICA

Expasion Termica ( d term ) = D Temp * L * a

d term = 0.0 m

ELONGACION TOTAL

Elongacion Total ( d Total ) = d term + d

d Total = #DIV/0!

ELONGACION PARA ASENTAR TBG HANGER

T = tension aplicada

T = 10,000.0 Lb

Esfuerzo (s )= T / Atran. = #DIV/0! O.K. s adm. > s

Def. Unit ( e ) = s / E = #DIV/0!

TOC = 2,175.0 m 7,135.8 Ft

Esfuerzo Adm.Ten. (s Tadm. )= 100,000 psi

#DIV/0!

Elongacion ( d ) = e * L #DIV/0!

A= 7.03 m

B= 0.37 m

Long. Total = #DIV/0!

Long. Tubo ancla = 9.63 m

Long. Arriba mesa rotaria = #DIV/0!

Вам также может понравиться

- Galaxy ClassIficationДокумент4 страницыGalaxy ClassIficationkОценок пока нет

- 06 Trip Sheet For DS & CasingДокумент4 страницы06 Trip Sheet For DS & CasingRebar100% (2)

- Safety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingДокумент12 страницSafety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingthjamesОценок пока нет

- MaximumOverPull CalculationДокумент1 страницаMaximumOverPull CalculationEmad JamshidiОценок пока нет

- Welltrain Subsea Vertical Kill Sheet - API Field Units - Revised July 2010Документ4 страницыWelltrain Subsea Vertical Kill Sheet - API Field Units - Revised July 2010ElrohirPendragonОценок пока нет

- Overpull CalculatorДокумент5 страницOverpull Calculatorzaideid100% (1)

- Understanding Coal Power Plant CycleДокумент47 страницUnderstanding Coal Power Plant CycledaveОценок пока нет

- Jackson Electrodynamics 3rd Edition SolutionsДокумент18 страницJackson Electrodynamics 3rd Edition SolutionsKadir Simsek50% (2)

- Caculate Ecd With Engineering Formula 1Документ2 страницыCaculate Ecd With Engineering Formula 1NurJan AmAnovОценок пока нет

- Surge Tank: Pressurized Vessel H S Gas Leaving The Surge Tank Is Burned OffДокумент13 страницSurge Tank: Pressurized Vessel H S Gas Leaving The Surge Tank Is Burned OffMahmoud Ahmed Ali AbdelrazikОценок пока нет

- Filling The HoleДокумент1 страницаFilling The HolestevebeardsleyОценок пока нет

- Pickering 1-18 Intermediate: Inner CSNGДокумент1 страницаPickering 1-18 Intermediate: Inner CSNGscrbdgharaviОценок пока нет

- 16 - BOP Pressure Test RecordsДокумент1 страница16 - BOP Pressure Test Recordsrajesh_rathОценок пока нет

- Wellbore Schematic: GOK-12 - End of Well ReportДокумент5 страницWellbore Schematic: GOK-12 - End of Well Report-BloodSeeker-Оценок пока нет

- 19 Well ControlДокумент133 страницы19 Well ControlAvazdordi SadriОценок пока нет

- Stuck Point WorksheetДокумент5 страницStuck Point Worksheetjose perozoОценок пока нет

- IWCF Kill Sheet RevДокумент11 страницIWCF Kill Sheet RevAnuranjanОценок пока нет

- SDU Ver142beta1 - Demo Print 1 PDFДокумент12 страницSDU Ver142beta1 - Demo Print 1 PDFreza khОценок пока нет

- Balanced Cement Plug CalculationДокумент7 страницBalanced Cement Plug CalculationAlejandro ViscarraОценок пока нет

- Cementing Program For The 13 38 Inch CasingДокумент40 страницCementing Program For The 13 38 Inch CasingMarvin OmañaОценок пока нет

- Deviated Well Kill Sheet 6.125 SECTION 08-Sep-2020.Документ7 страницDeviated Well Kill Sheet 6.125 SECTION 08-Sep-2020.yousef nОценок пока нет

- Drilling Application: Name of Company: Well Name & Number: DateДокумент1 страницаDrilling Application: Name of Company: Well Name & Number: DatescrbdgharaviОценок пока нет

- 7'' Liner CMT CalculationДокумент1 страница7'' Liner CMT CalculationEslam Atif AzkolОценок пока нет

- Avg Downhole Losses: 4 BBLS/HR.: G.P.C Daily Drilling Report Att. Eastern Desert Rig Heading: 206°Документ1 страницаAvg Downhole Losses: 4 BBLS/HR.: G.P.C Daily Drilling Report Att. Eastern Desert Rig Heading: 206°Mahmoud Ahmed Ali AbdelrazikОценок пока нет

- 12 Casing Running Speed - QuartzДокумент1 страница12 Casing Running Speed - QuartzRebarОценок пока нет

- Job Sheet For 11-7/8" Intermediate Casing: 12.5 4,000' Low PH Desco 1,527.33' 9,850 4.276Документ1 страницаJob Sheet For 11-7/8" Intermediate Casing: 12.5 4,000' Low PH Desco 1,527.33' 9,850 4.276scrbdgharaviОценок пока нет

- Kill Sheet IWCFДокумент2 страницыKill Sheet IWCFGourav RanaОценок пока нет

- 08 Heavy Slug Calculations - QuartzДокумент2 страницы08 Heavy Slug Calculations - QuartzRebarОценок пока нет

- 14b-Kill Sheet PreparationДокумент10 страниц14b-Kill Sheet PreparationLorenaStămulescuОценок пока нет

- Hoja de Cálculo Sin TítuloДокумент44 страницыHoja de Cálculo Sin TítuloJose GarciaОценок пока нет

- Kick Tolerance Calculations For Well Design and Drilling OperationsДокумент2 страницыKick Tolerance Calculations For Well Design and Drilling Operationsi oОценок пока нет

- Drilling Engineering and OperationsДокумент30 страницDrilling Engineering and Operationsreza khОценок пока нет

- Well Control ExerciseمهمДокумент133 страницыWell Control ExerciseمهمAsad babil BabilОценок пока нет

- 05 - SRB Hydraulic ProgramsДокумент22 страницы05 - SRB Hydraulic ProgramsnelsonhugoОценок пока нет

- Cementing Design Liner GeneralДокумент5 страницCementing Design Liner GeneralnkhamidyОценок пока нет

- Hydraulics - Summary: Including Cutting Weight & Tool JointДокумент17 страницHydraulics - Summary: Including Cutting Weight & Tool Jointmsu6383Оценок пока нет

- Basic Well Control Presentation 2Документ30 страницBasic Well Control Presentation 2Luis Fernando Soto Londoño100% (2)

- MACP and Well Control RecordДокумент6 страницMACP and Well Control RecordSudish BhatОценок пока нет

- CDAMnemonicsДокумент18 страницCDAMnemonicsvanthodcОценок пока нет

- Kicktolerance Berekeningen: Kick Zone ParametersДокумент1 страницаKicktolerance Berekeningen: Kick Zone ParametersHerbertLansinkОценок пока нет

- 31 - Well Control Data Sheet For Vertical Wells Wt. & Wt. MethodДокумент1 страница31 - Well Control Data Sheet For Vertical Wells Wt. & Wt. MethodJunaid MateenОценок пока нет

- 29 - Well Control Data Sheet For Directional Wells Wt. & Wt. MethodДокумент1 страница29 - Well Control Data Sheet For Directional Wells Wt. & Wt. MethodJunaid MateenОценок пока нет

- Mud PlanДокумент6 страницMud PlanHarjan Philipp C. GopaldasОценок пока нет

- (Training Documents) Strokes Bit To SurfaceДокумент2 страницы(Training Documents) Strokes Bit To SurfaceHeris SitompulОценок пока нет

- IWCF Surface BOP: Kill SheetДокумент6 страницIWCF Surface BOP: Kill SheetMrSebollini0% (1)

- TVD & Kill Weight CalculationsДокумент40 страницTVD & Kill Weight Calculationsfrancisryan4519Оценок пока нет

- Casing ModuleДокумент12 страницCasing ModuleFarahKhanJamaliОценок пока нет

- 1.basic Formulas PDFДокумент30 страниц1.basic Formulas PDFKevin AtochaОценок пока нет

- BHA#006 8.5in PDXceed +EcoScope+ TeleScopeДокумент1 страницаBHA#006 8.5in PDXceed +EcoScope+ TeleScopeKelly Cubillos quirozОценок пока нет

- Check List For SOBM Take On BoardДокумент5 страницCheck List For SOBM Take On BoardVimal SinghОценок пока нет

- What Is ECD ? - GSR/WGP/WGO - G Fletcher Jan 2008Документ9 страницWhat Is ECD ? - GSR/WGP/WGO - G Fletcher Jan 2008Joaquin Dix'sОценок пока нет

- Well Control FdreДокумент27 страницWell Control FdreKhairi OmarОценок пока нет

- Spot Heavy MudДокумент1 страницаSpot Heavy MudstevebeardsleyОценок пока нет

- 02 WH & XTreeДокумент47 страниц02 WH & XTreeilkerkozturkОценок пока нет

- Hydraulics - Summary: Including Cutting Weight & Tool JointДокумент5 страницHydraulics - Summary: Including Cutting Weight & Tool JointAnonymous U5t9NYzhLWОценок пока нет

- Max Pull On Drill StringДокумент8 страницMax Pull On Drill StringMuhammad ShahrukhОценок пока нет

- Surface & Production Casing DesignДокумент11 страницSurface & Production Casing DesignscrbdgharaviОценок пока нет

- 09 Spotting LCM Pill in The Annulus - QuartzДокумент1 страница09 Spotting LCM Pill in The Annulus - QuartzRebarОценок пока нет

- Kill Sheet: Prerecorded Infromation Pump Strokes RequiredДокумент17 страницKill Sheet: Prerecorded Infromation Pump Strokes RequiredscrbdgharaviОценок пока нет

- ADVANTAGE Hydraulics Spreadsheet Report: Case - RomaniaДокумент1 страницаADVANTAGE Hydraulics Spreadsheet Report: Case - RomaniatibismtxОценок пока нет

- Well: B-166 18-5/8" Casing Cementing DesignДокумент8 страницWell: B-166 18-5/8" Casing Cementing DesignIbnu HasanОценок пока нет

- Drilling CalculationsДокумент7 страницDrilling CalculationsBrahim LetaiefОценок пока нет

- Max Pull On Drill StringДокумент1 страницаMax Pull On Drill StringMuhammad ShahrukhОценок пока нет

- Calculate Leak Off TestДокумент5 страницCalculate Leak Off Testmt59cool2089Оценок пока нет

- Wave Propagation in Drilling, Well Logging and Reservoir ApplicationsОт EverandWave Propagation in Drilling, Well Logging and Reservoir ApplicationsОценок пока нет

- Squre Footing Design (WSD)Документ3 страницыSqure Footing Design (WSD)api-19753598Оценок пока нет

- Balance of Materials: Density of A Mixture of Fluids, Knowing Volume and Density of Its ComponentsДокумент2 страницыBalance of Materials: Density of A Mixture of Fluids, Knowing Volume and Density of Its ComponentsRebarОценок пока нет

- 15 Survey Calculations - QuartzДокумент2 страницы15 Survey Calculations - QuartzRebarОценок пока нет

- 16 Directional Drilling Calculations - QuartzДокумент8 страниц16 Directional Drilling Calculations - QuartzRebarОценок пока нет

- 12 Casing Running Speed - QuartzДокумент1 страница12 Casing Running Speed - QuartzRebarОценок пока нет

- 14 Balanced Plug Calculations & Procedure - QuartzДокумент2 страницы14 Balanced Plug Calculations & Procedure - QuartzRebarОценок пока нет

- 09 Spotting LCM Pill in The Annulus - QuartzДокумент1 страница09 Spotting LCM Pill in The Annulus - QuartzRebarОценок пока нет

- 11 Hydraulics & Well Control Calculations - QuartzДокумент29 страниц11 Hydraulics & Well Control Calculations - QuartzRebarОценок пока нет

- 07 Circulation Times and Volumes - QuartzДокумент1 страница07 Circulation Times and Volumes - QuartzRebarОценок пока нет

- 08 Heavy Slug Calculations - QuartzДокумент2 страницы08 Heavy Slug Calculations - QuartzRebarОценок пока нет

- 05 Trip Sheet - IPM - QuartzДокумент7 страниц05 Trip Sheet - IPM - QuartzRebarОценок пока нет

- Slipping & Cutting Calculation of Drilling Lines (API RP 9B)Документ8 страницSlipping & Cutting Calculation of Drilling Lines (API RP 9B)RebarОценок пока нет

- IV BSFS - Forensic Toxicology, Forensic Ballistics & Explosives - 02ABSFS19411Документ17 страницIV BSFS - Forensic Toxicology, Forensic Ballistics & Explosives - 02ABSFS19411ALC VijayawadaОценок пока нет

- 4, Transient Spin Dynamics in A Single-Molecule MagnetДокумент7 страниц4, Transient Spin Dynamics in A Single-Molecule MagnetJHOAN ALEXIS FERNANDEZ SANCHEZОценок пока нет

- Global Technology Investments Project Proposal InfographicsДокумент35 страницGlobal Technology Investments Project Proposal Infographicsaljc2517Оценок пока нет

- Practical 2 - Determining The Content of Salt in Sea WaterДокумент3 страницыPractical 2 - Determining The Content of Salt in Sea WatersmarakОценок пока нет

- ARL07008 IIW Design Report (Rev 01)Документ72 страницыARL07008 IIW Design Report (Rev 01)Fareed KhanОценок пока нет

- Basf MasterGlenium SKY 8614 Tds PDFДокумент2 страницыBasf MasterGlenium SKY 8614 Tds PDFSambelteri SelorejoОценок пока нет

- CHIMEI MSDS - KIBILAC ASA (General) (更新REACH註冊碼)Документ8 страницCHIMEI MSDS - KIBILAC ASA (General) (更新REACH註冊碼)wida acОценок пока нет

- Daily Events Check With Horary and Birth Chart: Branches of AstrologyДокумент18 страницDaily Events Check With Horary and Birth Chart: Branches of AstrologySudharshan Srinath50% (2)

- Pharmaceutica L Packaging: Unit - IiiДокумент69 страницPharmaceutica L Packaging: Unit - IiisumanchyОценок пока нет

- Gibbs Free Energy of Formation - Gaussian PDFДокумент19 страницGibbs Free Energy of Formation - Gaussian PDFRudolf KiraljОценок пока нет

- Protein and Peptide Drug Delivery SystemsДокумент55 страницProtein and Peptide Drug Delivery SystemsFree Escort ServiceОценок пока нет

- Module 5: Failure Criteria of Rock and Rock MassesДокумент5 страницModule 5: Failure Criteria of Rock and Rock Massesفردوس سليمانОценок пока нет

- Atmosphere 13 00593 v2Документ24 страницыAtmosphere 13 00593 v2ricardo calderon garciaОценок пока нет

- Ohmic Contacts On Ntype and PtypeДокумент4 страницыOhmic Contacts On Ntype and PtypePiyush ParasharОценок пока нет

- Discussions On IE Irodov's Problems in General Physics Arihant Books ArihantBooksДокумент2 страницыDiscussions On IE Irodov's Problems in General Physics Arihant Books ArihantBooksShootingStarPhotonsОценок пока нет

- Amino Acid UmmuДокумент25 страницAmino Acid UmmuYuniWahyuniОценок пока нет

- 7.4 Center of Mass Cog TorqueДокумент7 страниц7.4 Center of Mass Cog TorqueWong SunОценок пока нет

- Use of Mattsson's Solution of PH 7.2 To Evaluate The Stress-Corrosion Cracking Susceptibility of Copper-Zinc AlloysДокумент3 страницыUse of Mattsson's Solution of PH 7.2 To Evaluate The Stress-Corrosion Cracking Susceptibility of Copper-Zinc AlloysGrato Jr SingcoОценок пока нет

- Shield Water Spray NozzleДокумент17 страницShield Water Spray NozzleMd. Asrafujjaman (Livon)Оценок пока нет

- Kaolin Lab ReportДокумент15 страницKaolin Lab ReportEmeso OjoОценок пока нет

- Dynamics Quiz SolutionsДокумент3 страницыDynamics Quiz SolutionsTom AlterОценок пока нет

- Buffering Systems in The Human BodyДокумент2 страницыBuffering Systems in The Human Bodyjp08121972Оценок пока нет

- Nuflo 1502 Weco Union Liquid Turbine Flow Meter DatasheetДокумент3 страницыNuflo 1502 Weco Union Liquid Turbine Flow Meter DatasheetPad TruОценок пока нет

- Industrial Crops and ProductsДокумент7 страницIndustrial Crops and ProductsAndreeaSОценок пока нет

- Quantum Mechanics Notes - Ii: Amit Kumar Jha (Iitian)Документ15 страницQuantum Mechanics Notes - Ii: Amit Kumar Jha (Iitian)Tiasha DevОценок пока нет

- How Effective Is Current Solids Control Equipment For Drilling Fluids Weighted With Micron-Sized Weight Material?Документ7 страницHow Effective Is Current Solids Control Equipment For Drilling Fluids Weighted With Micron-Sized Weight Material?Jaime MartinezОценок пока нет