Академический Документы

Профессиональный Документы

Культура Документы

Fatigue Behaviour of Recasted Removable Partial Denture Alloys

Загружено:

Feny NursyaputriОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Fatigue Behaviour of Recasted Removable Partial Denture Alloys

Загружено:

Feny NursyaputriАвторское право:

Доступные форматы

ISSN 0975-8437 INTERNATIONAL JOURNAL OF DENTAL CLINICS 2011:3(4):20-22

ORIGINAL RESEARCH ARTICLE

Fatigue behaviour of Recasted Removable partial denture alloys

Abdul Aziz Al Kheraif, Murali Ramamoorthi

Abstract

Clasps undergo fatigue fracture under repeated flexures caused by denture insertion, removal and

mastication. This study was to compare the fatigue behaviour of different generations and different proportions

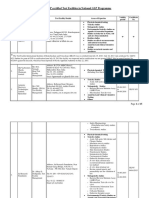

of as cast and recasted alloys used for removable partial denture. A total of 210 specimens were casted and

divided into 21 groups each 10 specimens for four different alloy groups. The alloys studied were low gold

alloy, medium gold alloy, and palladium alloy and cobalt chromium alloy group. Different proportions used

were 100%, 50%, 75% new alloy and alloys were studied up to three generations. One way deflection fatigue

test was used. The number of cycles required to fracture each specimen was recorded and subjected to statistical

analysis [95%confidence level]. Results revealed invariably decreased fatigue resistance for the alloy groups

studied for the second and third generation. Also it is decreasing if the new alloy percentage used was less than

100%. Recasting apart from compromising the biocompatibility, fatigue resistance is also compromised.

Key Words: Deflection fatigue test;Noble alloys;Recasting

Introduction fabrication. This study was conducted to evaluate

Casting procedures require use of more the fatigue behaviour of different combinations and

metal than is needed to produce a restoration. generations of recasted noble alloys and base

Dental laboratories often reuse the casting surplus alloys.

like sprue and metal remaining in the crucible Materials and Method

former to produce castings when high cost alloys The basic test specimen used was the

are used. Alloy reproducibility is an important prefabricated clasp wax pattern of dimension

factor to consider when choosing the alloy material 15mm length and 10mm outer diameter similar to

due to its oxidation, component volatilization by the studies done by Vallitu and Kokkonen. The

the heat source. A recast alloy may not have the wax patterns were invested and casted using type

same reproducibility as a new alloy. Since physical IV noble alloys [yellow special, pontor MPF,

properties of new and recasted alloys are not ceradelta] and a cobalt chromium base metal alloy

always the same. Tucillo et al compared the effects [metalloy cc] with a phosphate bonded investment.

of different melting techniques on the physical A total of ten specimens for each alloy group were

properties of recasted noble alloys.(1) They casted. Groupings of the alloys studied for the

concluded that the amount of noble metals [gold, fatigue behaviour were showed in the Table 1 and

platinum and palladium] and other major elements 2. Different generations and different proportions

[silver, copper] in the alloy composition remained of new and recasted alloy were studied. Up to three

stable. Literature guidelines for recasting dental generations were studied and three casting

alloy vary from adding no new metal to some new protocols were compared according to the

metal to 50% new metal with previously melted proportion of as received and recast alloy. In the

buttons or sprues removed from castings.(2-4) first group all metal was used for the first time

Although several publications have characterized [100% as received metal]. In the second group the

the material science aspects of recasted alloys, no sprue assembly was carefully removed, cleaned,

mention has been made in the technical literature weighed and combined with an appropriate amount

about the effect of recasting on fatigue behaviour of new alloy to maintain an equal balance of new

of the alloy. Removable Partial denture and recast material [50%wt to 50%wt ratio]. In the

frameworks are designed based on theoretical third group new metal and recasted metal were

biomechanical requirements and fabricated using a combined to maintain a ratio of 75:25 [75% wt new

sequence of technical steps, their behaviour over metal and 25% wt recast metal]. The composition

time is important. Fatigue behaviour and survival and material properties of the alloys used were

rates of the clasps have not been well described in shown in table-1and table-2. The casting

the literature. Fatigue was first mentioned in the procedures were determined following the

mid 1970’s. The loss of a material’s mechanical manufacturer’s instructions for the alloys and

properties after repeated loading is an important investments. Heat treatment of the alloys was done

consideration in metal selection for framework based on the manufacturer’s specifications.

©INTERNATIONAL JOURNAL OF DENTAL CLINICS VOLUME 3 ISSUE 4 2011 20

ISSN 0975-8437 INTERNATIONAL JOURNAL OF DENTAL CLINICS 2011:3(4):20-22

Alloys Manufacturer Composition Investment specimens was less to the second generation than

Yellow Metallor Au-41% Phosphate the first generation alloys for all the groups, third

special dental, Ag-44.9% bonded

Switzerland Pd-1.7% investment generation alloys require less cycles than the first

Cu-11% and second generation alloys for all the alloys

<1% - studied, and it is not affected by heat treatment

Pt,Ru,Sn,Zn also. The 100% new alloy used for casting requires

Pontor Metallor Au-72% Phosphate

MPF dental, Ag-13.7% bonded

more number of cycles to undergo fracture than the

Switzerland Pt-3.6% investment 50% as cast and 75% as cast new alloy used to

Cu-9.8% obtain the castings. The mean values were

<1%- Zn,Ir compared and statistical analysis was done. There

Ceradelta Metallor Pd-57.5% Phosphate

dental, Ag-32% bonded

was no statistical difference between the groups at

Switzerland In-6% investment 95% confidence level.

Sn-2% Discussion

Ga-1.5% For decades gold has been used to

Zn-1%

fabricate cast dental prosthesis. In an attempt to

Metalloy Metallor Co-61.5% Phosphate

CC dental, Cr-27.5% bonded reduce the expenses of these restorations gold

Switzerland W-8.6% investment alloys could be recast. Over time for economic

Si-1.3% reasons base metal alloys have become widely used

<1%- as cast materials. Base metal alloys are prone to

Mn,N,Nb

Table -1 Alloys studied various types of corrosion depending on alloy

Recovered castings were cleaned with composition and the oral environment. To further

airborne particle abrasion using 80 micron decrease the cost, previously used base metal

aluminum oxide particles. The dimensions of the alloys may be combined with new metal to produce

specimens were measured by a digital micrometer restorations. Manufacturer product information on

[with an accuracy of 0.001mm] supplemented with casting alloys typically states that scrap metals can

a profile projector [Model 6 c; Nikon corps, Tokyo, be remelted to fabricate clinically acceptable

Japan]. Specimens with defects [macropores and castings providing that at least 50% new metal is

metal protrusions] were rejected and repeated. used. The basis for this empiric guideline is that

Incomplete and deformed castings were also certain important secondary elements present in

discarded. No polishing procedures were small percentages in the original alloy

performed to ensure uniformity. Only nodules were compositions may be lost during melting, through

carefully removed under magnification. volatization or oxidization. The best example is

zinc which act as an oxygen scavenger during

Alloys Vicker hardness Modulus of elasticity melting to minimize the oxygen of other elements

hvs Mpa in the alloy. Some studies concluded that amount

Yellow special 160 80,000 of noble metals and other major elements in the

Pontor MPF 220 1,00,000 alloy composition remained stable during

Ceradelta 270 122,000

Metalloy CC 290 2,00,000

remelting. This was concluded from the results of

Table-2 Physical properties of alloys studied the present study also. However some studies

Fatigue test: A one way constant proved the poor surface texture of the remelted

deflection fatigue test was used with the pneumatic castings, this is probably because of some alloy

testing machine used by the previous studies.(5) components like tin, and indium was volatilized

The specimens were deflected with a 0.6 mm one due to their low melting point.(6)

way constant amplitude force at intervals of 300 Fatigue which is the process of

milli seconds. The maximum deflection force, time progressive localized permanent structural change

and number of loading cycles were registered. The in a material subjected to cyclic loading is

loading frequency used in this test was 3.3 Hz; the responsible for 90% of all service failures due to

loading waveform was square and R-5% [load mechanical causes. Fatigue fracture develops from

ratio-ratio of minimum and maximum fatigue small cracks presented on the surface and

force]. The test was carried out until fracture of the propagates through the grains of the material. The

specimen. The number of loading cycles required causes of cyclic fatigue in the material are its

to fracture each specimen was recorded inhomogeneity and anisotropy. Metallurgical

automatically. concentrators, such as superficial defects and

Results notches, poor surface polishing, inclusions and

From the results it is revealed that the porosity are particularly dangerous and can lead to

number of cycles required to fracture the catastrophic failure and the reduced number of

©INTERNATIONAL JOURNAL OF DENTAL CLINICS VOLUME 3 ISSUE 4 2011 21

ISSN 0975-8437 INTERNATIONAL JOURNAL OF DENTAL CLINICS 2011:3(4):20-22

cycles. These imperfections lead first to the Authors Affiliations: 1. Dr. Abdul Aziz Al Kheraif ,

development of micro cracks, which coalesce and Ph.D., Chairman, Dept. of Oral Health Sciences,

ultimately to a microscopic crack and failure. College of Applied Medical Sciences, King Saud

The testing method in this study used a University, K.S.A 2. Dr. Murali Ramamoorthi, MDS,

Reader, Dept. of Prosthodontics,Sinhgad Dental College

deflection of 0.6 mm. obviously; the magnitude of and Hospital, India.

deflection is greater than the retention undercut of References

the tooth used clinically. It has been suggested that 1. Tuccillo JJ. Composition and functional

for an RPD with wrought-wire clasps, an undercut characteristics of precious metal alloys for dental

of 0.25 mm provides adequate retention. Later, restorations. In: Valega TM, editor. Alternatives to

after testing wrought-metal wire clasps, Ikebe et al. gold alloys in dentistry. Bethesda (MD): US

reported undercuts greater than 0.5 mm are too Department of Health, Education, and Welfare,

large for base metal wires.(7) Because of relatively Publication No. (NIH) 77-1227; 1977. p. 40-67.

high modulus of elasticity, the cobalt-chromium 2. Hong JM, Razzoog ME, Lang BR. The effect of

recasting on the oxidation layer of a palladium-

alloy clasp should, according to the literature, be silver porcelain alloy. J Prosthet Dent 1988;59:420-

used in retentive undercuts of less than 0.5 mm.(6) 5.

It can be roughly estimated that the clasp of the 3. Reisbick MH, Brantley WA. Mechanical property

RPD bends 10 times per day from insertion and and microstructural variations for recast low-gold

removal of the RPD, which means that the clasp is alloy. Int J Prosthodont 1995;8:346-50.

affected by 3600 deflections per year.(7-10) 4. Lewis AJ. The effects of remelting on the

Furthermore mastication affects bending of the mechanical properties of a nickel base partial

clasps and should also be considered. If no wearing denture casting alloy. Aust Dent J 1975;20:89-93.

of the retentive undercuts of the tooth is seen, 5. Vallittu PK, Kokkonen M. Deflection fatigue of

cobalt-chromium, titanium, and gold alloy cast

metal fatigue may fracture the yellow special alloy denture clasp. J Prosthet Dent 1995;74:412–9.

after 11 years, Pontor mpf alloys after 18.5 years, 6. Ayad MF. Compositional stability and marginal

ceradelta after 20 years and metalloy cc after 12.4 accuracy of complete cast crowns made with as-

years. This hypothesis, however, requires further received and recast type III gold alloy. J Prosthet

verification. An important factor that affects the Dent 2002;87:162-6

strength of an alloy is its grain structure. Biffar and 7. Ikebe K, Nokubi T, Kibi M, Ono T, Okuno Y.

Appel examined the grain size of cobalt-chromium Influence of dimensional factors and heat treatment

alloy at different locations on the RPD and found on permanent deformation of wrought wire clasps. J

that the grain count decreased continuously from Osaka Univ Dent Sch 1992;32:75–83.

8. Bridgeport DA, Brantley WA, Herman PF. Cobalt-

the clasp tip towards the sprue.(11) The grain count chromium and nickel-chromium alloys for

in a clasp cross-section has been reported to be as removable prosthodontics. Part 1: mechanical

low as two or three. On the other hand, in a cross- properties. J Prosthod 1993;2:144–50.

section of a gold alloy clasp there can be as many 9. Ghani F, Mahood M. A laboratory examination of

as 100 grains.(8) Further investigations should be the behavior of cast cobalt-chromium clasps. J Oral

conducted to determine the cytotoxicity, surface Rehabil 1990;17:229–37.

roughness of recasted alloy. Specimens were 10. VandenBrink JP, Wolfaardt JF, Faulkner MG. A

subjected only to vertical directed forces, clinically comparison of various removable partial denture

the forces are multidirectional. Hence the influence clasp materials and fabrication procedure for

placing clasps on canine and premolar teeth. J

of these factors should be considered in future Prosthet Dent 1993;70:180–8.

experiments before a more accurate evaluation can 11. Yli-Urpo A, Lappalainen R, Huuskonen O.

be made. Frequency of damage to and need for repairs of

Conclusion removable dentures. Proc Finn Dent Soc

Within the limitations of the study the 1985;81:151–5.

following points were concluded; Address for Correspondence

1. The fatigue resistance of recasted alloy is less Dr. Murali Ramamoorthi,MDS,

compared to the fresh alloy. Reader,

2. The one way deflection fatigue test is a useful tool to Dept. of Prosthodontics,

study the fatigue behaviour of an alloy. Sinhgad Dental College and Hospital

3. Noble alloys shows better fatigue resistance than base India

metal alloy. Email:muralee.dr@gmail.com

Source of Support: This study was funded by King Saud University, Riyadh, K.S.A, Conflict of Interest: None Declared

©INTERNATIONAL JOURNAL OF DENTAL CLINICS VOLUME 3 ISSUE 4 2011 22

Вам также может понравиться

- Api 510 Q&aДокумент13 страницApi 510 Q&aShaikh Aftab100% (2)

- Manual RapID NF Plus System5Документ25 страницManual RapID NF Plus System5Eduardo Josue Tuesta MoyohuaraОценок пока нет

- Florafelt Vertical Garden GuideДокумент27 страницFlorafelt Vertical Garden Guidelarguedas100% (1)

- Metallic Denture Base Materials-New1Документ57 страницMetallic Denture Base Materials-New1DRNIRBANMITRA100% (9)

- Casting PlatinumДокумент8 страницCasting PlatinumCarlos Mario Agudelo CastrillonОценок пока нет

- NAAMM NOMMA Finishes Manual PDFДокумент116 страницNAAMM NOMMA Finishes Manual PDFMichaelTorresОценок пока нет

- Grain Refinement of Permanent Mold Cast Copper Base AlloysДокумент124 страницыGrain Refinement of Permanent Mold Cast Copper Base Alloyschris nelson100% (1)

- Dennis Hendershot SACHE Inherently Safer DesignДокумент87 страницDennis Hendershot SACHE Inherently Safer Designanon-196321100% (3)

- Tarnish & CorrosionДокумент48 страницTarnish & CorrosionmujtabaОценок пока нет

- Practical Guidelines For The Fabrication of High Performance Austenitic SSДокумент72 страницыPractical Guidelines For The Fabrication of High Performance Austenitic SSlram70Оценок пока нет

- Precipitation in The Ni-Cu-Base Alloy Monel K-500Документ13 страницPrecipitation in The Ni-Cu-Base Alloy Monel K-500farhadeeОценок пока нет

- IMMUNOASSAYS Powerpoint PresentaionДокумент29 страницIMMUNOASSAYS Powerpoint PresentaionAloo DenishОценок пока нет

- Cu, Ni & Co ExtractionДокумент30 страницCu, Ni & Co Extractionapi-26141882Оценок пока нет

- There Are Three Main Groups of Resin:: Polyester ResinsДокумент1 страницаThere Are Three Main Groups of Resin:: Polyester ResinsmukeshОценок пока нет

- Coordination ChemistryДокумент43 страницыCoordination ChemistryvictorОценок пока нет

- Die Casting Metallurgy: Butterworths Monographs in MaterialsОт EverandDie Casting Metallurgy: Butterworths Monographs in MaterialsРейтинг: 3.5 из 5 звезд3.5/5 (2)

- Refractories IP PDFДокумент52 страницыRefractories IP PDFJarlys ZaniОценок пока нет

- Lab 7 - BioeactorДокумент43 страницыLab 7 - Bioeactornur athilahОценок пока нет

- Exp7 Metal CorrosionДокумент21 страницаExp7 Metal CorrosionArisha Ruzalani100% (1)

- MelamineДокумент18 страницMelamineSurjendu MaityОценок пока нет

- Biogas Production SystemsДокумент22 страницыBiogas Production SystemsEmiliano Rodriguez TellezОценок пока нет

- Investigation On Corrosion Behaviour of Copper Brazed JointsДокумент7 страницInvestigation On Corrosion Behaviour of Copper Brazed JointsAyuni Hadiatur RahmanОценок пока нет

- 12101-Article Text PDF-36993-2-10-20190815Документ7 страниц12101-Article Text PDF-36993-2-10-20190815Shakeel MohmandОценок пока нет

- Research Article: Evaluation On The Corrosion of The Three Ni-Cr Alloys With Different CompositionДокумент5 страницResearch Article: Evaluation On The Corrosion of The Three Ni-Cr Alloys With Different CompositionEfy NagОценок пока нет

- Moskalyk 1999Документ9 страницMoskalyk 1999Cristian Cornejo AguileraОценок пока нет

- Microstructure and Corrosion Behaviour in Biological Environments of The New Forged Low-Ni Co-Cr-Mo AlloysДокумент12 страницMicrostructure and Corrosion Behaviour in Biological Environments of The New Forged Low-Ni Co-Cr-Mo AlloysshameekaОценок пока нет

- EDX Al2O3 InclusionsДокумент18 страницEDX Al2O3 InclusionsmadyeОценок пока нет

- Electrochemical Corrosion Behavior of Magnesium and Titanium Alloys in Simulated Body UidДокумент6 страницElectrochemical Corrosion Behavior of Magnesium and Titanium Alloys in Simulated Body UidBellanira HerreraОценок пока нет

- Selection of Stainless Steel For Cathode Plate in Hydrometallurgical ProcessДокумент6 страницSelection of Stainless Steel For Cathode Plate in Hydrometallurgical ProcessIbnu AndriОценок пока нет

- An Overview of Orthodontic Material Degradation in Oral CavityДокумент10 страницAn Overview of Orthodontic Material Degradation in Oral CavitySai KrupaОценок пока нет

- JCDR ArticleДокумент6 страницJCDR ArticleAnupama PathakОценок пока нет

- Base Metal Alloys Used in Fixed and RemoveableДокумент72 страницыBase Metal Alloys Used in Fixed and RemoveableKhushi DesaiОценок пока нет

- Structural and Spectroscopic Characterisations of The Surface Oxide Scales and Inclusions Present On Edge-Burst Hot-Rolled Steel CoilsДокумент8 страницStructural and Spectroscopic Characterisations of The Surface Oxide Scales and Inclusions Present On Edge-Burst Hot-Rolled Steel CoilsmusonlyОценок пока нет

- Corrosion Behavior of Fe-Ni-Al Alloy Inert Anode in Cryolite MeltsДокумент13 страницCorrosion Behavior of Fe-Ni-Al Alloy Inert Anode in Cryolite MeltsdinambrosОценок пока нет

- Is Metal Recycling Sustainable?: by Steven Wright, Sharif Jahanshahi, Frank Jorgensen and David BrennanДокумент22 страницыIs Metal Recycling Sustainable?: by Steven Wright, Sharif Jahanshahi, Frank Jorgensen and David BrennanNguyễn Vĩnh MạnhОценок пока нет

- The Electrodeposition of Ternary Fe-Cr-Ni AlloysДокумент28 страницThe Electrodeposition of Ternary Fe-Cr-Ni AlloysMariianiita SalvatoreОценок пока нет

- Study of Constituents of An AlloyДокумент18 страницStudy of Constituents of An AlloyMohammed Anis RahmanОценок пока нет

- Alam 2021Документ4 страницыAlam 2021FergiawanОценок пока нет

- 2003-Pint - Optimization of Reactive-Element Additions To Improve Oxidation Performance of Alumina-Forming AlloysДокумент10 страниц2003-Pint - Optimization of Reactive-Element Additions To Improve Oxidation Performance of Alumina-Forming AlloysDavid Hernández EscobarОценок пока нет

- FSW of Ti-Al Alloys ChinaДокумент12 страницFSW of Ti-Al Alloys ChinaKrishnaОценок пока нет

- JD Hanawalt, "Corrosion Studies of Magnesium and Its Alloys" (1942)Документ28 страницJD Hanawalt, "Corrosion Studies of Magnesium and Its Alloys" (1942)Patrick Bowen100% (2)

- Based Noble: Electrodes MetalsДокумент10 страницBased Noble: Electrodes MetalsSumedh WaradeОценок пока нет

- Alloy Recovery and Control in Steel MeltingДокумент14 страницAlloy Recovery and Control in Steel MeltingArjun KoduriОценок пока нет

- 30prasad EtalДокумент7 страниц30prasad EtaleditorijmrhsОценок пока нет

- Inhibition of X80 Steel Corrosion in Oilfield Acidizing Environment PDFДокумент9 страницInhibition of X80 Steel Corrosion in Oilfield Acidizing Environment PDFLê CôngОценок пока нет

- Chemical Reactions and Metal Flow in WeldingДокумент40 страницChemical Reactions and Metal Flow in WeldingJim GrayОценок пока нет

- EurJProsthodontRestDent2007v15p33 Co-Ni CorrosДокумент8 страницEurJProsthodontRestDent2007v15p33 Co-Ni CorrosGraziella TurdeanОценок пока нет

- Role of Second-Phase Particles in Chip Breakability in Aluminum AlloysДокумент10 страницRole of Second-Phase Particles in Chip Breakability in Aluminum AlloysbangjjОценок пока нет

- Jurnal SMA (1) RajeshДокумент6 страницJurnal SMA (1) RajeshMuhammad Falqi YusufОценок пока нет

- CAD/CAM Cobalt-Chromium Alloy Single Crowns in Posterior Regions: 4-Year Prospective Clinical StudyДокумент7 страницCAD/CAM Cobalt-Chromium Alloy Single Crowns in Posterior Regions: 4-Year Prospective Clinical StudySudip SinhaОценок пока нет

- Effect of Silicon On Corrosion Behaviour of Al-ZnДокумент10 страницEffect of Silicon On Corrosion Behaviour of Al-ZnNew NSskinОценок пока нет

- Segregation Effects Iii Welded Stairless Steels: Pinstech/Npd-121Документ26 страницSegregation Effects Iii Welded Stairless Steels: Pinstech/Npd-121Lenin CórdovaОценок пока нет

- LuckenederДокумент10 страницLuckenederTúlio NogueiraОценок пока нет

- Chemical Analysis of Dental Alloys: Name: Mahmoud Mohamed Owais ID:200043957 Subject: Prof. Dr. El-Zeiny Mousa EbeidДокумент12 страницChemical Analysis of Dental Alloys: Name: Mahmoud Mohamed Owais ID:200043957 Subject: Prof. Dr. El-Zeiny Mousa Ebeid3bdallah.mseОценок пока нет

- Piis0109564104000429 PDFДокумент8 страницPiis0109564104000429 PDFMartin AdriazolaОценок пока нет

- Comparing Castability of Nickel-Chromium, Cobalt-Chromium, and NonPrecious Gold Color AlloysДокумент7 страницComparing Castability of Nickel-Chromium, Cobalt-Chromium, and NonPrecious Gold Color AlloysPao JanacetОценок пока нет

- Optimization of Tin Recovery From Concentrates Through A Model For Prediction of Slag CompositionДокумент11 страницOptimization of Tin Recovery From Concentrates Through A Model For Prediction of Slag CompositionDiego Aguirre MuñozОценок пока нет

- TMP ED08Документ11 страницTMP ED08FrontiersОценок пока нет

- Tozalti Crushed FluxДокумент5 страницTozalti Crushed FluxSuphi YükselОценок пока нет

- Corrosion Rate of Low Carbon Steel ForДокумент7 страницCorrosion Rate of Low Carbon Steel ForGustavo M.Оценок пока нет

- Development and Application of Amorphous Core-Distribution Transformers in QudbecДокумент5 страницDevelopment and Application of Amorphous Core-Distribution Transformers in QudbecAdeel ZafarОценок пока нет

- Aziz Et Al. - 2014 - Characterisation and Utilisation of Steel Slag For The Construction of Roads and HighwaysДокумент5 страницAziz Et Al. - 2014 - Characterisation and Utilisation of Steel Slag For The Construction of Roads and Highwayslahcen essОценок пока нет

- Reuse of Heavy Metal-Containing Sludges in Cement ProductionДокумент6 страницReuse of Heavy Metal-Containing Sludges in Cement ProductionMarita M. OrbegosoОценок пока нет

- Journal of Alloys and Compounds: C. Salvo, C. Aguilar, R. Cardoso-Gil, A. Medina, L. Bejar, R.V. MangalarajaДокумент10 страницJournal of Alloys and Compounds: C. Salvo, C. Aguilar, R. Cardoso-Gil, A. Medina, L. Bejar, R.V. MangalarajanadhirahОценок пока нет

- The Effect of Adding Different Percentages of Copper On Corrosion of Pure AluminumДокумент6 страницThe Effect of Adding Different Percentages of Copper On Corrosion of Pure AluminumLilian Jefferson MalavaziОценок пока нет

- D 819Документ56 страницD 819ksvinyk7193Оценок пока нет

- 2011 Wear Assement PN h11Документ9 страниц2011 Wear Assement PN h11pank1987_inОценок пока нет

- Ecap PF SteelsДокумент7 страницEcap PF SteelsJoselo HRОценок пока нет

- Gold Plating in The Electronics Industry: F. H. ReidДокумент5 страницGold Plating in The Electronics Industry: F. H. ReidCicero Gomes de SouzaОценок пока нет

- BT Crops - Review PaperДокумент12 страницBT Crops - Review Paperrajiv pathakОценок пока нет

- PresentationДокумент14 страницPresentationshu-sunanОценок пока нет

- New List of GLP Approved LabsДокумент15 страницNew List of GLP Approved LabsMulayam Singh YadavОценок пока нет

- Hoffman Chemical Resistant EnclosuresДокумент4 страницыHoffman Chemical Resistant Enclosuresmora287Оценок пока нет

- 3100 P TДокумент196 страниц3100 P TTim FowlerОценок пока нет

- Sgs Port Klang Ann Joo Integrated Steel 03653-03731 (79samples)Документ8 страницSgs Port Klang Ann Joo Integrated Steel 03653-03731 (79samples)Jasni JalaludinОценок пока нет

- Gliesse Plant PresentationДокумент20 страницGliesse Plant PresentationNeel Gliesse PharmaОценок пока нет

- ReagentGuide 8th SynthesticOrganicChemistry MaterialsChemistryДокумент396 страницReagentGuide 8th SynthesticOrganicChemistry MaterialsChemistryyulliarperezОценок пока нет

- Amol Raj PDFДокумент10 страницAmol Raj PDFGaurav SinghОценок пока нет

- Efficacy and Safety of Diabecon (D-400), A Herbal Formulation, in Diabetic PatientsДокумент5 страницEfficacy and Safety of Diabecon (D-400), A Herbal Formulation, in Diabetic PatientsrawanОценок пока нет

- Coa CaprillycДокумент2 страницыCoa Caprillycptcahaya kemilaupratamaОценок пока нет

- Catalogue Product M-Plus FilterДокумент40 страницCatalogue Product M-Plus FilterAdrian Samuel ThenochОценок пока нет

- Complex Carbohydrates in Foods Marcel Dekker 1999Документ655 страницComplex Carbohydrates in Foods Marcel Dekker 1999Dekel PolivaОценок пока нет

- 2021 Raptor CatalogДокумент12 страниц2021 Raptor CatalogLoc BuiОценок пока нет

- Worksheet - Experiment 9 MilkДокумент2 страницыWorksheet - Experiment 9 MilkYuraОценок пока нет

- Clariant SDS AddWorks IBC 760 Australia EnglishДокумент10 страницClariant SDS AddWorks IBC 760 Australia EnglishRafi UdeenОценок пока нет