Академический Документы

Профессиональный Документы

Культура Документы

500-275 Megablock Installation Instructions

Загружено:

Mohammed Mubashir AffaniАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

500-275 Megablock Installation Instructions

Загружено:

Mohammed Mubashir AffaniАвторское право:

Доступные форматы

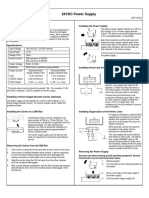

Installation Megablock

Instructions Series

1010.1 Equipment Information

Equipment Class II, Pollution Degree 2, Installation Category II

Maximum Altitude: 2000m

Humidity: 0 to 90% (non-condensing)

Operating Temperature: -45°C to 70°C

For Indoor Use Only (IP40 minimum enclosure)

Electrical Ratings (see Drawing for connection information and certified devices)

Area Classification Ratings Drawing

General Purpose; Class I, Div 2 (Ex nA) 32VDC, 1.5A MB-0107

Class I, Div 1 (Ex ia, ib IIC) 24VDC, 250mA MB-020108

Class I, Div 1 (Ex ia, ib IIC) FISCO 17.5VDC, 380mA MB-020109

Non-Incendive Outputs (Ex nA [nL]) 32VDC, 1.5A MB-020116

Installation

Refer to the drawing that is appropriate for the area in which the Megablock series device will be installed. These

drawings represent typical installations and are intended to address the safety aspects of the area for which they

are drawn. Actual segment connections may vary depending on factors such as the required number of Fieldbus

devices to be connected to the segment (determines the specific models and quantities of Megablocks used).

IMPORTANT: For SpurGuards to work properly, the Fieldbus Segment MUST be isolated from ground.

Mounting

Megablocks are designed to be mounted on 35 mm DIN rail using the clip mechanism on the back of each unit.

Mounting can be vertical or horizontal. Use of DIN rail end stops is recommended.

Megablocks must be installed inside of an enclosure with a minimum rating of IP40.

Once all wiring connections have been made, the retaining screws on each pluggable cable connector should be

securely fastened.

Testing/Troubleshooting

Once DC power has been connected to the Fieldbus segment, the green power LED on the Megablock should be lit,

indicating that a minimum of 9.2VDC is present on the segment trunk. If the green LED is not lit, verify the

integrity and polarity of the trunk cable connections to the Megablock, that the voltage measured at the trunk

connection to the Megablock is greater than 9.2VDC, that there are no shorts in the trunk cable, and that the

power supply is operating properly.

On Megablock models with SpurGuard™ current limiters (-SG models), verify that none of the red short circuit

LED’s are lit. If any of the red LED’s are lit, remove the three-conductor plug from the affected spur connection.

Locate and repair the short circuit on the spur cable before reconnecting.

Operation

During normal operation, the green power LED should be lit. If the green LED is not lit, follow the instructions in

the testing/troubleshooting section above.

A lit red LED indicates a short in a spur cable or in the Fieldbus device connected to the spur cable. The LED will

cease to be lit once the short has been repaired.

Some versions have a Switchable Terminator. This is indicated by a large “T” with a dashed border. Use a small

screwdriver to turn the Terminator On or Off as indicated on the label.

Some versions have an Internal Terminator. This is indicated by a large “T” with a solid border.

Maintenance Requirements

Megablocks contain no user serviceable parts. Non-functioning units should be returned to the manufacturer for

replacement or repair.

For Further Information

Contact your local MTL representative or Relcom Inc. as listed at the bottom of this page.

2221 Yew Street

Forest Grove, Oregon 97116 USA

(503) 357-5607 or (800) 382-3765

Fax (503) 357-0491

Page 1 of 4 www.relcominc.com

500-275 Rev. C

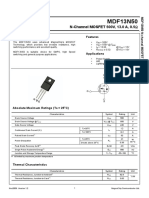

MB-0107: Class I, Div 2 (Zone 2) Installation

HAZARDOUS (CLASSIFIED) LOCATION NONHAZARDOUS LOCATION

Class I, Division 2, Groups A, B, C, D, T4 Galvanic Isolation Must be Provided by the Power Conditioner or Power Source

Class I, Zone 2, Groups IIC, T4

Ex nA, IIC, T4 (CSA and CENELEC only)

24 Power Source (Typical)

45 C <= Tamb <= 70 C

TO BE INSTALLED IN AN IP40 OR BETTER ENCLOSURE

Gray Spur Connections

FIELDBUS POWER CONDITIONER

Vout (max) <= 32V

Iout (max) <= 1.5A Host Connection

Megablock Fieldbus Connection Block

(Typical)

(FCS-MB8, 8-spur series shown) Install According to Power Conditioner

Instructions to Ensure Maximum

Vmax = 32V Voltage and Current Output is not

Imax = 1.5A Black Trunk Connections

Exceeded

Fusing of the Power Source is Recommended

Wire Requirements:

Insulation Displacement: 18 - 20 AWG

Gray Spur Connections Screw Terminal: 12 - 24 AWG

Spring Clamp: 12 - 24 AWG

Cables will connect Fieldbus Devices

to the Gray Spur Connections

WARNING:

Megablock FCS-MBT or EXPLOSION HAZARD - DO NOT DISCONNECT

Terminator F100 EQUIPMENT UNLESS POWER HAS BEEN SWITCHED

with Surge

Protection Vmax = 32V

OFF OR THE AREA IS KNOWN TO BE NON-HAZARDOUS.

Megablock Part Numbers:

FCS-MB2 FCS-MB2-SG

FCS-MB2-T FCS-MB2-SG-T

F200 AVERTISSEMENT:

FCS-MB4 FCS-MB4-SG

RISQUE D'EXPLOSION - AVANT DE DECONNECTER

Connect either Ground Terminal to L'EQUIPEMENT, COUPER LE COURANT OU S'ASSURER

FCS-MB4-T FCS-MB4-SG-T

Local Earth for Surge Protection

F201, F202 F203 QUE L'EMPLACEMENT EST DESEGNE NON DANGEREUX.

FCS-MB8 FCS-MB8-SG

FCS-MB8-T FCS-MB8-SG-T

F205, F206 F207

FCS-MB10 FCS-MB10-SG

FCS-MB10-T FCS-MB10-SG-T

F209, F210 F211, F118

2221 Yew Street, Forest Grove, Oregon 97116 USA

May include suffixes '-PC' or '-PD'.

CONTROL DRAWING FOR MEGABLOCK

The FCS-MBT, or F100 may be omitted if the Megablock includes a built-in Terminator. SERIES FIELDBUS CONNECTION BLOCKS

CLASS I, DIV 2 (ZONE 2)

Installation must be in accordance with the National Electrical Code HAZARDOUS LOCATIONS

(NFPA 70, Article 504), ANSI/ISA-RP12.6, and CEC Part 1, or any other

Approved by: Mike Strauser Date: 8/06/04

applicable local electrical requirements.

Drawing Number: MB-0107 Rev.:

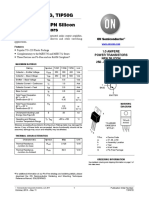

MB-020116: Non-Incendive Outputs Installation

HAZARDOUS (CLASSIFIED) LOCATION NONHAZARDOUS LOCATION

Class I, Division 2, Groups A, B, C, D, T4 Galvanic Isolation Must be Provided by the Power Conditioner or Power Source

Class I, Zone 2, Groups IIC, T4 (CSA and CENELEC only)

Ex nA [nL], IIC, T4 (CSA and CENELEC only)

45 C <= Tamb <= 70 C 24 Power Source (Typical)

TO BE INSTALLED IN AN IP40 OR BETTER ENCLOSURE

Gray Spur Connections

ASSOCIATED APPARATUS

WITH ENTITY PARAMETERS

Megablock Fieldbus Connection Block

(FCS-MB8, 8-spur series shown) Vout (max) <= 32V

Iout (max) <= 1.5A Host Connection

Gray Spur Connections are (Typical)

Current Limited to 59mA (nominal) Install According to Power Conditioner

Instructions to Ensure Maximum

Voc = 32V Black Trunk Connections Voltage and Current Output is not

Isc = 60mA Exceeded

Gas Groups A,B (IIC) C (IIB) D (IIA) Fusing of the Power Source is Recommended

Ca 170nF 1.22 F 4.59 F Wire Requirements:

La 1.2mH 3.4mH 6.3mH

Insulation Displacement: 18 - 20 AWG

Screw Terminal: 12 - 24 AWG

Spring Clamp: 12 - 24 AWG

Gray Spur Connections

Cables will connect Fieldbus Devices WARNING:

to the Gray Spur Connections EXPLOSION HAZARD - DO NOT DISCONNECT

Megablock FCS-MBT or

Only the Gray Spur Connections may

Terminator F100 EQUIPMENT UNLESS POWER HAS BEEN SWITCHED

with Surge

be connected and disconnected while

Protection

OFF OR THE AREA IS KNOWN TO BE NON-HAZARDOUS.

circuit is live. EXCEPT IN CANADA Vmax = 32V

Megablock Part Numbers:

AVERTISSEMENT:

FCS-MB2-SG FCS-MB4-SG RISQUE D'EXPLOSION - AVANT DE DECONNECTER

FCS-MB2-SG-T FCS-MB4-SG-T Connect either Ground Terminal to

F203

L'EQUIPEMENT, COUPER LE COURANT OU S'ASSURER

Local Earth for Surge Protection

QUE L'EMPLACEMENT EST DESEGNE NON DANGEREUX.

FCS-MB8-SG FCS-MB10-SG

FCS-MB8-SG-T FCS-MB10-SG-T

F207 F211, F118

May include suffixes '-PC' or '-PD'.

The FCS-MBT, or F100 may be omitted if the Megablock includes a built-in Terminator.

2221 Yew Street, Forest Grove, Oregon 97116 USA

CONTROL DRAWING FOR MEGABLOCK

SERIES FIELDBUS CONNECTION BLOCKS

Installation must be in accordance with the National Electrical Code

NON-INCENDIVE OUTPUTS APPLICATION

(NFPA 70, Article 504), ANSI/ISA-RP12.6, and CEC Part 1, or any other

applicable local electrical requirements. Approved by: Mike Strauser Date: 8/06/04

Drawing Number: MB-020116 Rev.:

2221 Yew Street

Forest Grove, Oregon 97116 USA

(503) 357-5607 or (800) 382-3765

Fax (503) 357-0491

Page 2 of 4 www.relcominc.com

500-275 Rev. C

MB-020108: Intrinsically Safe (IS) Installation – (CSA and CENELEC only)

HAZARDOUS (CLASSIFIED) LOCATION NONHAZARDOUS LOCATION

Class I, Division 1, 2, Groups A, B, C, D, T4

Class I, Zone 0, Groups IIC, T4

Ex ia, ib, IIC, T4 (CSA and CENELEC only)

45 C <= Tamb <= 70 C 24 Power Source (Typical)

TO BE INSTALLED IN AN IP40 OR BETTER ENCLOSURE

Gray Spur Connections

ASSOCIATED APPARATUS

WITH ENTITY PARAMETERS

Megablock Fieldbus Connection Block Host Connection

(FCS-MB8, 8-spur series shown) Voc <= 24V (Typical)

Isc <= 250mA

Vmax = 24V

Imax = 250mA Black Trunk Connections

Ci = 0

Li = 0 H

Pi = 1.2W

Shield is grounded for reasons other than Intrinsic Safety

Fusing of the Power Source is Recommended

Gray Spur Connections

Wire Requirements:

Insulation Displacement: 18 - 20 AWG

Cables will connect IS rated Devices Screw Terminal: 12 - 24 AWG

to the Gray Spur Connections FCS-MBT Vmax = 24V Spring Clamp: 12 - 24 AWG

Imax = 250mA

Megablock Ci = 0

Terminator Li = 0 H

with Surge Pi = 1.2W

Protection WARNING:

SUBSTITUTION OF COMPONENTS

Megablock Part Numbers:

MAY IMPAIR INTRINSIC SAFETY

FCS-MB2

FCS-MB2-T

Connect either Ground Terminal to

FCS-MB4 F204 Local Earth for Surge Protection

FCS-MB4-T

FCS-MB8 F208

FCS-MB8-T

FCS-MB10 F212

FCS-MB10-T

May include suffixes '-PC' or '-PD'. 2221 Yew Street, Forest Grove, Oregon 97116 USA

The FCS-MBT may be omitted if the Megablock includes a built-in Terminator.

CONTROL DRAWING FOR MEGABLOCK

SERIES FIELDBUS CONNECTION BLOCKS

Installation must be in accordance with the National Electrical Code INTRINSICALLY SAFE (IS) INSTALLATIONS

(NFPA 70, Article 504), ANSI/ISA-RP12.6, and CEC Part 1, or any other

Approved by: Mike Strauser Date: 8/06/04

applicable local electrical requirements.

Drawing Number: MB-020108 Rev.:

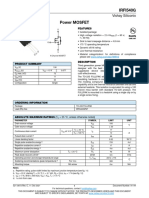

MB-020109: FISCO Installation – (CSA and CENELEC only)

HAZARDOUS (CLASSIFIED) LOCATION NONHAZARDOUS LOCATION

Class I, Division 1, 2, Groups A, B, C, D, T4

Class I, Zone 0, Groups IIC, T4

Ex ia, ib, IIC, T4 (CSA and CENELEC only)

45 C <= Tamb <= 70 C 24 Power Source (Typical)

TO BE INSTALLED IN AN IP40 OR BETTER ENCLOSURE

Gray Spur Connections

ASSOCIATED APPARATUS

WITH ENTITY PARAMETERS

Megablock Fieldbus Connection Block Host Connection

(FCS-MB8, 8-spur series shown) Voc <= 17.5V (Typical)

Isc <= 380mA

Vmax = 17.5V

Imax = 380mA Black Trunk Connections

Ci = 0

Li = 0 H

Pi = 5.32W

Shield is grounded for reasons other than Intrinsic Safety

Fusing of the Power Source is Recommended

Gray Spur Connections

Wire Requirements:

Insulation Displacement: 18 - 20 AWG

Cables will connect IS rated Devices Screw Terminal: 12 - 24 AWG

to the Gray Spur Connections FCS-MBT Vmax = 17.5V Spring Clamp: 12 - 24 AWG

Imax = 380mA

Megablock Ci = 0

Terminator Li = 0 H

with Surge Pi = 5.32W

Protection WARNING:

SUBSTITUTION OF COMPONENTS

Megablock Part Numbers:

MAY IMPAIR INTRINSIC SAFETY

FCS-MB2

FCS-MB2-T

Connect either Ground Terminal to

FCS-MB4 F204 Local Earth for Surge Protection

FCS-MB4-T

FCS-MB8 F208

FCS-MB8-T

FCS-MB10 F212

FCS-MB10-T

May include suffixes '-PC' or '-PD'. 2221 Yew Street, Forest Grove, Oregon 97116 USA

The FCS-MBT may be omitted if the Megablock includes a built-in Terminator.

CONTROL DRAWING FOR MEGABLOCK

SERIES FIELDBUS CONNECTION BLOCKS

Installation must be in accordance with the National Electrical Code FISCO INSTALLATIONS

(NFPA 70, Article 504), ANSI/ISA-RP12.6, and CEC Part 1, or any other

Approved by: Mike Strauser Date: 8/06/04

applicable local electrical requirements.

Drawing Number: MB-020109 Rev.:

2221 Yew Street

Forest Grove, Oregon 97116 USA

(503) 357-5607 or (800) 382-3765

Fax (503) 357-0491

Page 3 of 4 www.relcominc.com

500-275 Rev. C

Megablock

EMC Summary

Series

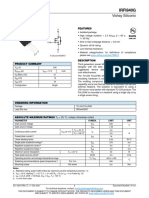

Megablock Series EMC Summary

European Union EMC Tests in accordance with EN61326 EMC Product Family Standard for measurement, control

and laboratory equipment.

Test Items: FCS-MB8-SG, FCS-MBT

Other products conforming based on these test results include:

FCS-MB2 F200 FCS-MB2-T

FCS-MB2-SG FCS-MB2-SG-T

FCS-MB4 F201, F202 FCS-MB4-T F203, F204

FCS-MB4-SG FCS-MB4-SG-T

FCS-MB8 F205, F206 FCS-MB8-T F207, F208

FCS-MB8-SG FCS-MB8-SG-T

FCS-MB10 F209, F210 FCS-MB10-T F211, F212

FCS-MB10-SG FCS-MB10-SG-T F118

F100

European Union Electromagnetic Compatibility (EMC) Tests

in accordance with EC Council Directive 89/336/EEC

Emissions Tests per EN61326

Result Standard Description Port Comments

N/A EN61326 Radiated Emissions Enclosure Test Not Required

N/A EN61326 Conducted Emissions AC Mains Test Not Required

Immunity Tests per EN61326 Annex A

Result Standard Description Port Criteria

Pass EN61000-4-2 Electrostatic Discharge Immunity Enclosure B

Pass EN61000-4-3 RF Electromagnetic Field Immunity Enclosure A

Pass EN61000-4-4 Electrical Fast Transient/Burst Immunity DC / IO Port B

Pass EN61000-4-5 Electrical Slow Transient Immunity DC / IO Port B

Pass EN61000-4-6 RF Conducted Immunity DC / IO Port A

N/A EN61000-4-8 Magnetic Field Immunity N/A N/A

N/A EN61000-4-11 Voltage Dips/Short Interruptions Imm. N/A N/A

I, Mike Strauser, representative for Relcom Inc., verify that the product tested is representative of production

products to be sold.

2221 Yew Street

Forest Grove, Oregon 97116 USA

(503) 357-5607 or (800) 382-3765

Fax (503) 357-0491

Page 4 of 4 www.relcominc.com

500-275 Rev. C

Вам также может понравиться

- Book of Lost Spells (Necromancer Games)Документ137 страницBook of Lost Spells (Necromancer Games)Rodrigo Hky91% (22)

- Audio IC Projects: A Collection of Useful Circuits Based on Readily Available ChipsОт EverandAudio IC Projects: A Collection of Useful Circuits Based on Readily Available ChipsОценок пока нет

- MB0042-MBA-1st Sem 2011 Assignment Managerial EconomicsДокумент11 страницMB0042-MBA-1st Sem 2011 Assignment Managerial EconomicsAli Asharaf Khan100% (3)

- 04 LimeДокумент32 страницы04 LimeGoogle user100% (1)

- Telegra Manual - DatasheetДокумент79 страницTelegra Manual - DatasheetNilanjan Chakravortty100% (1)

- Quality Control QuestionerДокумент31 страницаQuality Control QuestionerKaukab Imam88% (42)

- History of English Prose PDFДокумент21 страницаHistory of English Prose PDFMeisyita QothrunnadaОценок пока нет

- Judges - God's War Against HumanismДокумент347 страницJudges - God's War Against HumanismgypsylanternОценок пока нет

- Academic Writing & IdentityДокумент218 страницAcademic Writing & IdentityGustavo RegesОценок пока нет

- Figures of Speech ExplainedДокумент5 страницFigures of Speech ExplainedDarenJayBalboa100% (1)

- Manual de Instruções Iveco Eurocargo Euro 6Документ226 страницManual de Instruções Iveco Eurocargo Euro 6rsp filmes100% (1)

- Management and Breeding of Game BirdsДокумент18 страницManagement and Breeding of Game BirdsAgustinNachoAnzóateguiОценок пока нет

- Process Control Fundamentals 2Документ73 страницыProcess Control Fundamentals 2Otuekong Ukpong100% (2)

- Organizing and Delivering A Memorized SpeechДокумент9 страницOrganizing and Delivering A Memorized SpeechJanice L. Langit100% (4)

- The Pathogenic Basis of Malaria: InsightДокумент7 страницThe Pathogenic Basis of Malaria: InsightRaena SepryanaОценок пока нет

- SK-Relay: Installation and Maintenance InstructionsДокумент2 страницыSK-Relay: Installation and Maintenance InstructionsAbhishek ChakrabortyОценок пока нет

- Lm2825n Datasheet PDF AipcbaДокумент21 страницаLm2825n Datasheet PDF AipcbaBarth XaosОценок пока нет

- DatasheetДокумент3 страницыDatasheetJorge VieiraОценок пока нет

- 11 - Alimentation Versamax IoДокумент2 страницы11 - Alimentation Versamax IoZouhair IguerhzifenОценок пока нет

- 02 40058 02 enДокумент4 страницы02 40058 02 enShirin AzadiОценок пока нет

- Takedo - 3VF: Instruction ManualДокумент19 страницTakedo - 3VF: Instruction ManualMohd Abu AjajОценок пока нет

- MAX20328/MAX20328A/ MAX20328B MUX Switch For USB Type-C Audio Adapter AccessoriesДокумент43 страницыMAX20328/MAX20328A/ MAX20328B MUX Switch For USB Type-C Audio Adapter AccessoriesMumu MuserzОценок пока нет

- Fzm-1 Interface Module: Installation and Maintenance InstructionsДокумент2 страницыFzm-1 Interface Module: Installation and Maintenance InstructionsRobel MTОценок пока нет

- Type 2 PV surge protector protects photovoltaic systemsДокумент1 страницаType 2 PV surge protector protects photovoltaic systemsilhamОценок пока нет

- MJD340 (NPN), MJD350 (PNP) High Voltage Power Transistors: DPAK For Surface Mount ApplicationsДокумент8 страницMJD340 (NPN), MJD350 (PNP) High Voltage Power Transistors: DPAK For Surface Mount Applicationshalil ibrahim soysalОценок пока нет

- CMF 300 ManualДокумент2 страницыCMF 300 ManualCristhian Monasterio HuertasОценок пока нет

- Max20050-Max20053 2A Synchronous-Buck Led Drivers With Integrated MosfetsДокумент23 страницыMax20050-Max20053 2A Synchronous-Buck Led Drivers With Integrated MosfetsAdrian WongОценок пока нет

- DatasheetДокумент3 страницыDatasheetJorge VieiraОценок пока нет

- Notifier FCM 1 Supervised Control ModuleДокумент2 страницыNotifier FCM 1 Supervised Control ModuleAhmedОценок пока нет

- SmartX IP Controller - RP-C-16A Model Installation SheetДокумент4 страницыSmartX IP Controller - RP-C-16A Model Installation SheetWalter BarbaОценок пока нет

- DatasheetДокумент3 страницыDatasheetJorge VieiraОценок пока нет

- SBL2030PT, SBL2040PT: Vishay General SemiconductorДокумент4 страницыSBL2030PT, SBL2040PT: Vishay General SemiconductortallertecuОценок пока нет

- Voltagedrop PDFДокумент2 страницыVoltagedrop PDFOsama ElhadadОценок пока нет

- DEHN Supresor de Impulsos DG MU 3PY 480 3W+G (908314) - Hoja TécnicaДокумент1 страницаDEHN Supresor de Impulsos DG MU 3PY 480 3W+G (908314) - Hoja TécnicaRotsen AltuveОценок пока нет

- Horizon Compact Quick Reference Installation GuideДокумент2 страницыHorizon Compact Quick Reference Installation Guidegk234Оценок пока нет

- Takedo 3VF ManualДокумент19 страницTakedo 3VF ManualAllan AgustinОценок пока нет

- Datasheet for 5A 240KHz 36V PWM Buck DC/DC Converter TD7590Документ13 страницDatasheet for 5A 240KHz 36V PWM Buck DC/DC Converter TD7590andibdgОценок пока нет

- MDF9N50F MagnaChipДокумент6 страницMDF9N50F MagnaChipchokОценок пока нет

- LP339 Ultra-Low Power Quad Comparator: General DescriptionДокумент10 страницLP339 Ultra-Low Power Quad Comparator: General DescriptionahmedОценок пока нет

- Compact Dual-Band Combiner for 698-960MHz and 1710-2700MHz BandsДокумент3 страницыCompact Dual-Band Combiner for 698-960MHz and 1710-2700MHz BandsMuhammad NoorОценок пока нет

- Datasheet 12A 300Khz 32V Buck DC To DC Converter Xl4012Документ9 страницDatasheet 12A 300Khz 32V Buck DC To DC Converter Xl4012yb3hgf2222Оценок пока нет

- 300KHz 32V 12A DC-DC converter datasheetДокумент9 страниц300KHz 32V 12A DC-DC converter datasheetJose M PeresОценок пока нет

- CRF-300 ManualДокумент2 страницыCRF-300 ManualGONZALO FLORES LOPEZОценок пока нет

- Acomd2h18 PDFДокумент3 страницыAcomd2h18 PDFJoao SilvaОценок пока нет

- Citel 2CP 202302en Pl24-Cat6Документ1 страницаCitel 2CP 202302en Pl24-Cat6vish2008 anandОценок пока нет

- MGDD 21Документ18 страницMGDD 21baldiwala aliabbasОценок пока нет

- CDDFN10-2574N - Surface Mount TVS Diode Array: Features ApplicationsДокумент6 страницCDDFN10-2574N - Surface Mount TVS Diode Array: Features ApplicationsAlexОценок пока нет

- MDF13N50: N-Channel MOSFET 500V, 13.0 A, 0.5Документ6 страницMDF13N50: N-Channel MOSFET 500V, 13.0 A, 0.5Moroșan CristiОценок пока нет

- TIP47G, TIP48G, TIP50G High Voltage NPN Silicon Power TransistorsДокумент6 страницTIP47G, TIP48G, TIP50G High Voltage NPN Silicon Power TransistorsAhmed Sherif CupoОценок пока нет

- MOSFET POWER TRANSISTOR Vs Fa40sa50lc-1769355Документ11 страницMOSFET POWER TRANSISTOR Vs Fa40sa50lc-1769355Ramón MartinezОценок пока нет

- IRFI540G: Vishay SiliconixДокумент10 страницIRFI540G: Vishay SiliconixKiril JordanovОценок пока нет

- Citel 2CP 202301en Pl12-Cat6Документ1 страницаCitel 2CP 202301en Pl12-Cat6vish2008 anandОценок пока нет

- Citel 2CP 202301en Pl12-Cat6Документ1 страницаCitel 2CP 202301en Pl12-Cat6vish2008 anandОценок пока нет

- MMBZXXVXL, SZMMBZXXVXL Series 40 Watt Peak Power Zener Transient Voltage SuppressorsДокумент5 страницMMBZXXVXL, SZMMBZXXVXL Series 40 Watt Peak Power Zener Transient Voltage SuppressorsEsquisofОценок пока нет

- IRFI840G: Vishay SiliconixДокумент10 страницIRFI840G: Vishay SiliconixFarhad FalahatparvarОценок пока нет

- LM392 Low Power Operational Amplifier/Voltage Comparator: General DescriptionДокумент7 страницLM392 Low Power Operational Amplifier/Voltage Comparator: General DescriptionAndrés Cely AgudeloОценок пока нет

- Design Example Report: TitleДокумент19 страницDesign Example Report: TitleJose BenavidesОценок пока нет

- Voltage Regulators: MC7800, MC7800A, MC7800AE, NCV7800 - PositiveДокумент34 страницыVoltage Regulators: MC7800, MC7800A, MC7800AE, NCV7800 - PositiveJorge CarranzaОценок пока нет

- Voltage Regulators: MC7800, MC7800A, MC7800AE, NCV7800 - PositiveДокумент32 страницыVoltage Regulators: MC7800, MC7800A, MC7800AE, NCV7800 - PositiveRudyXPОценок пока нет

- Sboa 290 CSHXGHDCXCFXDDCGДокумент6 страницSboa 290 CSHXGHDCXCFXDDCGKarthik SuryaОценок пока нет

- Max 253Документ18 страницMax 253Muhammad Abdullah ButtОценок пока нет

- SQM48T20025 NBB0Документ33 страницыSQM48T20025 NBB0Gabriel RacovskyОценок пока нет

- L 020MXxx CCДокумент1 страницаL 020MXxx CCZeroОценок пока нет

- FCB20N60F D 1805582 PDFДокумент11 страницFCB20N60F D 1805582 PDFEo GpОценок пока нет

- Iifn400x220 G02NДокумент4 страницыIifn400x220 G02NMarco GaliassiОценок пока нет

- STB12NM50T4, STP12NM50, STP12NM50FPДокумент20 страницSTB12NM50T4, STP12NM50, STP12NM50FPinformagicОценок пока нет

- EtherWAN EX35080-00B User ManualДокумент21 страницаEtherWAN EX35080-00B User ManualJMAC SupplyОценок пока нет

- LA4282 Audio Power Amplifier Class AB, 10W × 2-Channel: Specification Absolute Maximum Ratings at Ta 25Документ7 страницLA4282 Audio Power Amplifier Class AB, 10W × 2-Channel: Specification Absolute Maximum Ratings at Ta 25GilbertoAdonayGutierrezОценок пока нет

- GE Power ManagemenДокумент21 страницаGE Power ManagemeningguedezandresОценок пока нет

- D 0 - 2 4 Buf2: 24V/20A DIN Rail Type Buffer ModuleДокумент7 страницD 0 - 2 4 Buf2: 24V/20A DIN Rail Type Buffer ModuleadrianioantomaОценок пока нет

- I/A Series Hardware 240 V Ac Input/Output Interface Module (FBM11) and 240 V Ac Expansion Input/Output Interface Module (FBM16)Документ4 страницыI/A Series Hardware 240 V Ac Input/Output Interface Module (FBM11) and 240 V Ac Expansion Input/Output Interface Module (FBM16)CHRISTIANABGОценок пока нет

- Control InterviewДокумент2 страницыControl InterviewMohammed Mubashir AffaniОценок пока нет

- 500-275 Megablock Installation InstructionsДокумент4 страницы500-275 Megablock Installation InstructionsMohammed Mubashir AffaniОценок пока нет

- Instrumentation Training Tutorial Part2Документ25 страницInstrumentation Training Tutorial Part2Gary8100% (1)

- Pacsystems™ Rx3I: Redundancy CpuДокумент11 страницPacsystems™ Rx3I: Redundancy CpuMohammed Mubashir AffaniОценок пока нет

- About Psig and PsiДокумент1 страницаAbout Psig and PsiMohammed Mubashir AffaniОценок пока нет

- Flowmeter Product Line Overview PDFДокумент4 страницыFlowmeter Product Line Overview PDFVisal ChengОценок пока нет

- Guided Vs Unguided MediaДокумент20 страницGuided Vs Unguided MediaMohammed Mubashir AffaniОценок пока нет

- Basic InstrumentationДокумент59 страницBasic Instrumentationjudegj100% (1)

- Asian Studies For Filipinos The Philippines in The Asian CenturyДокумент15 страницAsian Studies For Filipinos The Philippines in The Asian CenturyGlaizza QuintonОценок пока нет

- GBM Auction Versus English Auction A Large-Scale Empirical Study - E. Bessire, K. Elhadji Tchiambou (October 2021)Документ18 страницGBM Auction Versus English Auction A Large-Scale Empirical Study - E. Bessire, K. Elhadji Tchiambou (October 2021)Guillaume GonnaudОценок пока нет

- Strata KT Office OpportunityДокумент41 страницаStrata KT Office OpportunitySanskar SurekaОценок пока нет

- EINC ChecklistДокумент3 страницыEINC ChecklistMARK JEFTE BRIONESОценок пока нет

- Food Science, Technology & Nutitions - Woodhead - FoodДокумент64 страницыFood Science, Technology & Nutitions - Woodhead - FoodEduardo EstradaОценок пока нет

- Security Testing MatДокумент9 страницSecurity Testing MatLias JassiОценок пока нет

- Examples of IELTS Speaking Part 1 QuestionsДокумент15 страницExamples of IELTS Speaking Part 1 QuestionsThanh TrầnОценок пока нет

- Loverpreet Chapterv 1Документ16 страницLoverpreet Chapterv 1Sheikh SiddiquiОценок пока нет

- Template - Time in ManufacturingДокумент2 страницыTemplate - Time in ManufacturingVero RoaОценок пока нет

- XYZ Company Asset Inventory ReportДокумент1 страницаXYZ Company Asset Inventory ReportNini KitsОценок пока нет

- Air Con LouvresДокумент1 страницаAir Con LouvresChung May LynnОценок пока нет

- Nutritional support through feeding tubesДокумент76 страницNutritional support through feeding tubesKryzza LeizellОценок пока нет

- WBC Study Reveals God's NatureДокумент11 страницWBC Study Reveals God's NatureSherwin Castillo DelgadoОценок пока нет

- ComputerДокумент26 страницComputer29.Kritika SinghОценок пока нет

- Types of Stress: Turdalieva Daria HL 2-19 AДокумент9 страницTypes of Stress: Turdalieva Daria HL 2-19 ADaria TurdalievaОценок пока нет

- Beyond VaR OfficialДокумент76 страницBeyond VaR OfficialmaleckicoaОценок пока нет

- IntuitionДокумент10 страницIntuitionmailsonОценок пока нет

- 4 Exploring Your Personality Q and Scoring Key (Transaction Analysis)Документ3 страницы4 Exploring Your Personality Q and Scoring Key (Transaction Analysis)Tarannum Yogesh DobriyalОценок пока нет