Академический Документы

Профессиональный Документы

Культура Документы

Section 05530

Загружено:

shacoolhameedАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Section 05530

Загружено:

shacoolhameedАвторское право:

Доступные форматы

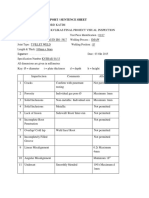

CONTENTS

SECTION 05530

GRATINGS

PART 1 GENERAL

1.1 Related Documents

1.2 Summary

1.3 Performance Requirements

1.4 Submittals

1.5 Submit For Approval:

1.6 Quality Assurance

1.7 Project Conditions

1.8 Coordination

PART 2 PRODUCTS

2.1 Ferrous Metals

2.2 Fasteners

2.3 Paint

2.4 Fabrication

2.5 Grating Frames And Supports

2.6 Gratings

PART 3 EXECUTION

3.1 Preparation

3.2 Installation, General

3.3 Installing Metal Bar Gratings

Gratings Section 05530

Headquarters Buildings of Civil Services Employees Pension Fund (Prj. 765) Page 1 of 10

SECTION 05530

GRATINGS

PART 1 GENERAL

1.1 RELATED DOCUMENTS

1.1.1 Drawings and general provisions of the Contract, including General and

Supplementary Conditions and Division 1 Specification Sections, apply to

this Section.

1.2 SUMMARY

1.2.1 This Section includes the following:

− Ductile cast iron grating for drain channels including metal frames and

supports for gratings over drain channels.

1.3 PERFORMANCE REQUIREMENTS

1.3.1 Structural Performance: Provide gratings capable of withstanding the

following structural loads without exceeding the allowable design working

stress of the materials involved, including anchors and connections:

− Limit deflection to L/360 or 6.4 mm, whichever is less.

− Thermal Movements: Provide gratings that allow for thermal movements

U U

resulting from the following maximum change in ambient and surface

temperatures by preventing buckling, opening of joints, overstressing of

components, failure of connections, and other detrimental effects. Base

engineering calculation on surface temperature of materials due to both

solar heat gain and nighttime-sky heat loss

• Temperature Change: 35 deg C, ambient 65 deg C materials

U U

surfaces

− Control of Corrosion: Prevent galvanic action and other forms of

U U

corrosion by insulting metals and materials from direct contact with

incompatible

1.4 SUBMITTALS

1.4.1 Product Data: For the following:

− Metal gratings.

− Clips and anchorage devices for gratings.

− Paint products.

Gratings Section 05530

Headquarters Buildings of Civil Services Employees Pension Fund (Prj. 765) Page 2 of 10

1.5 Submit for approval:

Manufacturers cataloged and data detailing all items to be finish under this

section

1.5.1 Shop Drawings: Show fabrication and installation details for gratings.

Include plans, elevations, sections, and details of connections. Show

anchorage and accessory items. Provide templates for anchors and bolts

specified for installation under other Sections.

− For installed products indicated to comply with design loads, include

structural analysis data signed and sealed by the qualified professional

engineer responsible for their preparation.

1.6 QUALITY ASSURANCE

1.6.1 Engineering Responsibility: Engage a fabricator who utilizes a qualified

structural engineer to prepare design calculations, shop drawings, and

other structural data.

1.6.2 Consulting Engineer Qualifications: A structural consulting engineer

who is legally qualified to practice locally in and who is experienced in

providing engineering services of the kind indicated. Engineering services

are defined as those performed for installations of gratings that are similar

to those indicated for this Project in material, design, and extent.

1.6.3 Fabricator Qualifications: A firm experienced in producing gratings

similar to those indicated for this Project and with a record of successful in-

service performance, as well as sufficient production capacity to produce

required units.

1.6.4 Metal Bar Grating Standards: Comply with applicable requirements of

the following:

− Non-Heavy-Duty Metal Bar Gratings: Comply with NAAMM MBG 531,

U U

"Metal Bar Grating Manual for Steel Gratings and Stair Treads."

1.6.5 Welding: Qualify procedures according to relevant codes of Authorities

having jurisdiction.

− Certify that each welder has satisfactorily passed qualification tests by

Authorities having jurisdiction for welding processes involved and, if

pertinent, has undergone recertification.

− AWS D1.1, "Structural Welding Code--Steel."

1.7 PROJECT CONDITIONS

1.7.1 Field Measurements: Where gratings are indicated to fit to other

construction, verify dimensions of other construction by field measurements

before fabrication and indicate measurements on Shop Drawings.

Coordinate fabrication schedule with construction progress to avoid

delaying the Work.

Gratings Section 05530

Headquarters Buildings of Civil Services Employees Pension Fund (Prj. 765) Page 3 of 10

1.8 COORDINATION

1.8.1 Coordinate installation of anchorages for gratings, grating frames, and

supports. Furnish setting drawings, templates, and directions for installing

anchorages, including sleeves, concrete inserts, anchor bolts, and items

with integral anchors, that are to be embedded in concrete or masonry.

Deliver such items to Project site in time for installation.

PART 2 PRODUCTS

Covers gratings and farm shall be (gray cast iron castings , grey cast iron

shall confirm to or exceed the requirements ASTM A48

2.1 FERROUS METALS

2.1.1 Steel Plates, Shapes, and Bars: ASTM A 36/A 36M.

2.1.2 Wire Rod for Grating Crossbars: ASTM A 510M.

2.1.3 Welding Rods and Bare Electrodes: Select according to AWS

specifications for metal alloy to be welded.

2.1.4 Steel Bars for Gratings: ASTM A 569M or ASTM A 36M.

2.2 FASTENERS

2.2.1 General: Provide Type 316 stainless steel fasteners.

2.3 PAINT

2.3.1 Galvanizing Repair Paint: High-zinc-dust-content paint for regalvanizing

welds in steel, complying with SSPC-Paint 20.

2.3.2 Polyurethane Based Coating System shall be Aliphatic Polyurethane to

produce excellent and color retention coating, applied on epoxy primer and

high molecular-weight epoxy intermediate coat.

− Appearance: Gloss, semi –gloss or matt as directed by the Engineer

U U

2.4 FABRICATION

2.4.1 Shop Assembly: Fabricate grating sections in shop to greatest extent

possible to minimize field splicing and assembly. Disassemble units only

as necessary for shipping and handling limitations. Use connections that

maintain structural value of joined pieces. Clearly mark units for

reassembly and coordinated installation.

2.4.2 Form from materials of size, thickness, and shapes indicated, but not less

than that needed to support indicated loads.

2.4.3 Shear and punch metals cleanly and accurately. Remove burrs.

2.4.4 Ease exposed edges to a radius of approximately 1 mm, unless otherwise

Gratings Section 05530

Headquarters Buildings of Civil Services Employees Pension Fund (Prj. 765) Page 4 of 10

indicated.

2.4.5 Fit exposed connections accurately together to form hairline joints.

2.4.6 Welding: Comply with AWS recommendations and the following:

− Use materials and methods that minimize distortion and develop

strength and corrosion resistance of base metals.

− Obtain fusion without undercut or overlap.

− Remove welding flux immediately.

2.4.7 Provide for anchorage of type indicated; coordinate with supporting

structure. Fabricate and space anchoring devices to secure gratings,

frames, and supports rigidly in place and to support indicated loads.

2.5 GRATING FRAMES AND SUPPORTS

2.5.1 General: Provide steel frames and supports, where indicated.

2.5.2 Frames and Supports: Fabricate from metal shapes, plates, and bars of

welded construction to sizes, shapes, and profiles indicated and as

necessary to receive gratings. Miter and weld connections for perimeter

angle frames. Cut, drill, and tap units to receive hardware and similar

items.

− Unless otherwise indicated, fabricate from same basic metal as gratings.

2.5.3 Equip units with integrally welded anchors for casting into concrete or

building into masonry.

− Unless otherwise indicated, space anchors 600 mm o.c. and provide

minimum anchor units in the form of steel straps 32 mm wide by 6 mm

thick by 200 mm long.

2.6 GRATINGS

2.6.1 Ductile Cast Iron Bar Grating: Heavy duty gratings, manufactured from

ductile cast iron to ASTM A 536.

− Bearing Bar Spacing: 30 mm, unless otherwise indicated

U U

− Bearing Bar Depth: As required to comply with structural performance

U U

requirements.

− Bearing

U Bar Thickness: As required to comply with structural

U

performance requirements.

− Traffic Surface: Plain.

U U

− Finish: Hot Dip galvanized with a coating of not less than 550 g/sq.m of

U U

coated surface.

− All castings shall be free from blowholes, shrinkage defects, swells,

cracks and other defects.

Gratings Section 05530

Headquarters Buildings of Civil Services Employees Pension Fund (Prj. 765) Page 5 of 10

− Fabricate removable grating sections with banding bars attached by

welding to entire perimeter of each section. Include anchors of type

indicated for attaching to supports.

• Provide not less than four weld lugs for each heavy-duty grating

section, with each lug shop welded to two bearing bars.

• Pads are to be from solid neoprene.

PART 3 EXECUTION

3.1 PREPARATION

3.1.1 Coordinate and furnish anchorages, setting drawings, diagrams, templates,

instructions, and directions for installation of anchorages, including sleeves,

anchor bolts, and miscellaneous items having integral anchors. Coordinate

delivery of such items to Project site.

3.2 INSTALLATION, GENERAL

− Install the covers and frames strictly in accordance with the

manufactures instructions and recommendations and to the details

shown on drawing and schedules.

− Don’t subject covers gratings and frames to any loads until such time the

bedding hunching materials have adequately cured .

− Bed and level all covers to prevent rocking and lateral movements of the

frame

− Set cover level with surrounding finishes and square with joints

surrounding finishes or with the building.

3.2.1 Fastening to In-Place Construction: Provide anchorage devices and

fasteners where necessary for securing gratings to in-place construction.

3.2.2 Cutting, Fitting, and Placement: Perform cutting, drilling, and fitting

required for installing gratings. Set units accurately in location, alignment,

and elevation; measured from established lines and levels and free from

rack.

3.2.3 Fit exposed connections accurately together to form hairline joints. Do not

weld, cut, or abrade the surfaces of units that have been finished after

fabrication and are for bolted or screwed field connections.

3.2.4 Attach toe plates to gratings by welding at locations indicated.

3.3 INSTALLING METAL BAR GRATINGS

3.3.1 General: Install gratings to comply with recommendations of referenced

metal bar grating standards that apply to grating types and bar sizes

indicated, including installation clearances and standard anchoring details.

3.3.2 Attach units to supporting members with type and size of clips and

Gratings Section 05530

Headquarters Buildings of Civil Services Employees Pension Fund (Prj. 765) Page 6 of 10

fasteners indicated or, if not indicated, as recommended by grating

manufacturer for type of installation conditions shown.

3.3.3 Attach non removable units to supporting members by welding where both

materials are same; otherwise, fasten by bolting as indicated above.

4. References

1- American society for testing and materials

2- ASTMA 48 standard specification for grey iron castings

3 - ASTMA 536 Ductile iron casting

END OF SECTION 05530

Gratings Section 05530

Headquarters Buildings of Civil Services Employees Pension Fund (Prj. 765) Page 7 of 10

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- QC General NotesДокумент21 страницаQC General NotesBilly Kurniawan100% (2)

- 733Документ17 страниц733Subhajit DasОценок пока нет

- Oxy Laundry Company ProfileДокумент4 страницыOxy Laundry Company ProfilewildanОценок пока нет

- MSS SP 75 2019 High Strength, Wrought, Butt Welding FittingsДокумент42 страницыMSS SP 75 2019 High Strength, Wrought, Butt Welding FittingsJed Kevin MendozaОценок пока нет

- Azolla ZS PDFДокумент1 страницаAzolla ZS PDFYQОценок пока нет

- Nutsche Filter ManufacturerДокумент3 страницыNutsche Filter Manufacturernany shahОценок пока нет

- A20X AlloyДокумент6 страницA20X AlloyWei WangОценок пока нет

- YC-300WY4: High End Models That Make Welding With High Quality For A Variety of MaterialsДокумент2 страницыYC-300WY4: High End Models That Make Welding With High Quality For A Variety of MaterialsvinodОценок пока нет

- Application of Cast Gamma TiAl For AutomobilesДокумент5 страницApplication of Cast Gamma TiAl For AutomobilesMuha KimОценок пока нет

- 01) Transformer Lecture - 140305Документ50 страниц01) Transformer Lecture - 140305robert_candra_tarunaОценок пока нет

- Sop For Cleaning of Ss Water Transfer PipeДокумент3 страницыSop For Cleaning of Ss Water Transfer PipeSolomonОценок пока нет

- Hose Couplings Quick Disconnect 10K To 20KДокумент3 страницыHose Couplings Quick Disconnect 10K To 20KemilianoОценок пока нет

- FCAW Consumables - Part 4 - TWIДокумент6 страницFCAW Consumables - Part 4 - TWIJlkKumarОценок пока нет

- Introduction To Nanoscience and NanotechnologyДокумент17 страницIntroduction To Nanoscience and NanotechnologybokumonОценок пока нет

- Heat Treatment of MetalsДокумент8 страницHeat Treatment of MetalsDr. L. Bhanuprakash ReddyОценок пока нет

- Parenteral PPT (Part-3)Документ27 страницParenteral PPT (Part-3)monoj5859100% (2)

- BYK® - 348 - Byk (Altana Group)Документ2 страницыBYK® - 348 - Byk (Altana Group)محمد عزتОценок пока нет

- Weld Inspection ReportДокумент5 страницWeld Inspection ReportFord Katim100% (2)

- LIFE CASTING SILICONEДокумент2 страницыLIFE CASTING SILICONEClaudia MolinaОценок пока нет

- Design of Screw FasteningДокумент37 страницDesign of Screw FasteningDhayane RedoquerioОценок пока нет

- 10 5923 J Mining 20120101 01Документ16 страниц10 5923 J Mining 20120101 01Karl Her ArtyomОценок пока нет

- Stress Corrosion Cracking and NACE (MR0103-2007) Scope and ApplicationДокумент24 страницыStress Corrosion Cracking and NACE (MR0103-2007) Scope and ApplicationMahendra PrabhuОценок пока нет

- TOPIC 4-Lithography PrintingДокумент20 страницTOPIC 4-Lithography PrintingGiha TardanОценок пока нет

- Brochure OTOMEC 2016Документ10 страницBrochure OTOMEC 2016Le LanОценок пока нет

- Neyriz Grey Cement Co.: Date: 02.05.30Документ1 страницаNeyriz Grey Cement Co.: Date: 02.05.30alishahsavarОценок пока нет

- Extractive Metallurgy of CopperДокумент12 страницExtractive Metallurgy of CopperBORUTO ANIMEZONEОценок пока нет

- DOWSIL™ 71 Additive: Features & BenefitsДокумент4 страницыDOWSIL™ 71 Additive: Features & BenefitsZhan FangОценок пока нет

- Emailing Chemical Kinetics (Class 12)Документ12 страницEmailing Chemical Kinetics (Class 12)roceniОценок пока нет

- Fabrication (Metal Joining) : Ravishankar M D 17EME14 Elements of Mechanical EngineeringДокумент18 страницFabrication (Metal Joining) : Ravishankar M D 17EME14 Elements of Mechanical EngineeringSatish HSОценок пока нет

- BlisterДокумент7 страницBlisterbharatsharmamechОценок пока нет