Академический Документы

Профессиональный Документы

Культура Документы

Safe Work Method Statement: Excavation, Trenching and Underground Services

Загружено:

Morhne RufinОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Safe Work Method Statement: Excavation, Trenching and Underground Services

Загружено:

Morhne RufinАвторское право:

Доступные форматы

SAFE WORK METHOD

STATEMENT

DOC DOC

SWMS5 VERSION 5 Dave Cowan

EXCAVATION, TRENCHING AND UNDERGROUND ID OWNER

SERVICES ACTIVE DATE 6/3/2018 REVIEW DATE 6/3/2020

INTRODUCTION

This Safe Work Method Statement details how specific risks associated with excavation, trenching and the location of underground services are to be

managed. It outlines the common risks and dangers associated with this work and how to best control them based on the Hierarchy of Controls.

The control measures listed in this SWMS must be implemented on site.

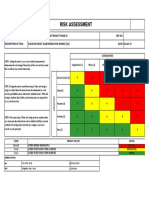

If other hazards are identified that are not identified in this SWMS a Risk Assessment for the new hazard must be completed on the WRAP.

CONSULTATION AND REVIEW OF SAFE WORK METHOD STATEMENT (SWMS)

This SWMS has been developed in consultation with Subject Matter Experts. Reviews will be conducted two years, in the event an incident occurs, if there

is a change in operational practices and if there is a change in legislation. It will also be reviewed in conjunction with any review of associated

procedures and/or training programs. Effectiveness of control measures will be monitored by on site supervisors.

REFERENCE DOCUMENTS - OCCUPATIONS/HIGH RISK WORK

Relevant Workplace Health & Safety / Environmental Legislation References

QLD Work Health & Safety Act 2011 QUU Trenching, Excavation and Underground Services Standard

QLD Work Health & Safety Regulations 2011 Safe Work Method Statement – Working on or adjacent to a Road or Railway

Electrical Safety Act 2002 Safe Work Method Statement – Confined Space Entry

Electrical Safety Regulations 2002 Safe Work Method Statement – Operating Mobile Plant

Hazardous Manual Tasks Code of Practice Safe Work Method Statement – Working at Heights

Traffic Management Code of Practice (MUTCD) 2010

How to Manage Work Health & Safety Risks Code of Practice

ABN: 86 673 835 011

Confidential

SWMS5 1

Environmental Protection Act 1994

Environmental Protection Regulation1996

In the event of a collapse:

Immediately contact Emergency Services by telephone (000) your supervisor and the WH&S Team. (07 3855 6418)

Try and locate the victim looking for signs such as tools or a shovel, but do not put yourself at risk.

Clear all unnecessary employees and others on QUU worksite away from the area.

If possible, batter the sides of the trench in the collapsed area or insert shoring where possible to protect victim(s) and rescuers.

Remove the collapsed soil with shovels, or if it is a very deep trench, with a machine.

If a machine is used, take extreme care to avoid further injury to a victim!

Do not allow anyone on top of the collapsed soil (this will increase the pressure on a victim).

If the excavation is over 1.5 m deep, rescuers must wear safety harnesses and life lines that extend to the surface.

When rescuers are near a victim, hands should be used to remove the soil if possible. If shovels have to be used, these must be used with extreme

caution.

When a victim is located, clear soil from head and chest, and check for breathing and a pulse. If no signs of life are present, start Cardio-

Pulmonary Resuscitation (CPR).

If a victim’s chin is pressed onto their chest, tilt the head back as soon as possible so as to open up the airway to the lungs. This can be done while

other rescuers are freeing the soil from the upper part of their body and before starting CPR.

Check for injuries and apply first aid where necessary.

DO NOT attempt to remove a victim by tying a rope around him/her and pulling on the rope.

Where possible, once a victim has been freed from the soil, leave them in the trench until the ambulance or qualified medical person arrives. This

minimises unnecessary movement of the victim.

ABN: 86 673 835 011

Confidential

SWMS5 2

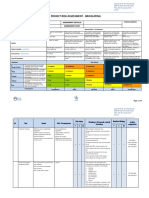

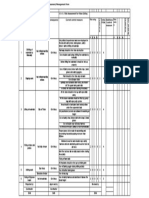

HAZARD ANALYSIS AND CONTROL MEASURES

Inherent Residual Hierarchy PICOW’s

Task/Activity Hazard/Risk Control Measures

Risk Risk of Initials

Rating Rating Controls

1. 1. E 1. Obtain DBYD prescribed information. L Admin

Planning of Hazard: 2. Contact relevant authorities for information about the service (location, type, depth Admin

site, not identifying and restrictions to be followed) including maps and information from QUU.

identificatio some 3. All relevant prescribed information in writing and keep on site for the duration of the Admin

n and underground task.

location of services

4. The relevant person must consider the information supplied, follow any reasonable Admin

undergroun

restrictions and implement the necessary control measures. The information shall be

d services

kept on site at all times.

Risk:

Disconnecting 5. Carry out a detailed site inspection considering all possible services such as phone Admin

a service, and optical cables, water and sewerage, gas, electricity, stormwater drainage,

electrocution irrigation and indirect services, survey marks and street lighting electric cables. and

review the site against prescribed information and plans by scanning the site with a

cable avoidance tool (CAT), if available.

6. Pothole using hand tools, shovels, trowels, etc. (insulated equipment must be used if Admin

working near electrical services) must be conducted.

7. Exclusion Zones must be identified and marked prior to any excavation starting, this Isolation

includes Potholing.

8. All onsite workers must be advised of the location of the services, in particular the Admin

operator(s) of any plant working on the worksite.

9. Mark all exposed services with flags or devices that can be readily seen. Admin

H 1. Setup site so that runoff from sediment pile or Trench/Excavation does not enter L Engineering

2. 1.

waterways

Planning of Hazard: site

site and site setup results in Engineering

2. Install Sediment/Erosion controls as required

setup erosion or

sediment

runoff

E 1. Only use plant once you have identified where the relevant services are located M Engineering

3. 1.

(e.g. electricity, gas, telephone).

Excavating Hazard:

around the Gas lines, 2. Work around identified service(s), use caution at all times. Admin

ABN: 86 673 835 011

Confidential

SWMS5 3

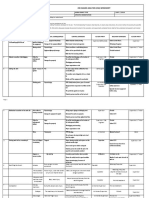

Inherent Residual Hierarchy PICOW’s

Task/Activity Hazard/Risk Control Measures

Risk Risk of Initials

Rating Rating Controls

located electricity 3. Use an “Authorised Person” (observer) to assist the plant operator(s) by maintaining sight Admin

services Risk: of the service(s).

Contact with

4. Support exposed services (seek advice from the service authority if required). Admin

services,

electrocution, 5. Ensure all marked services continue to be visible for the duration of the work. Admin

explosion,

struck by plant

6. NO WORKERS (apart from operator) are to be in physical contact with any excavating Admin

machine or plant at any time whilst it is operating. (Do not touch plant!)

4. 1. E 1. No one is to be in the excavation whilst any plant/equipment is in operation within the L Admin

excavation.

Trenching Hazard: 2. A ‘Record of Excavation Inspection’ form must be completed by a competent person Admin

loose soil, when the trench or excavation reaches a depth of 1m and other occasions outlined on

excavation; the form.

Risk: 3. Approval in writing by a geo-technical engineer must be obtained, for trenches > 3 m Admin

Trench deep, stating that the trench is safe to work in. The approval must be kept on site at all

collapse, times and All nominated controls followed.

falling objects, 4. Ascertain if the excavation and/or trench is a confined space. If so, Admin

refer to the SWMS2 – Confined Space Entry.

5. Proximity of plant (including vehicles/trucks) to the top of the trench or excavation shall Admin

be determined through a risk assessment. (The risk assessment should take into account

the weight of the plant or vehicle involved as well as the type of soil and weather

conditions.)

6. Minimise plant and equipment movement near trench or excavations. Admin

7. Keep spoil further than 1 m from the excavation edge and keep spoil piles to a Isolation

maximum of 600mm.

8. Monitor gas continuously if working in the vicinity of known gas lines or near a high traffic Admin

flow area.

9. Use an industrial strength rated ladder to enter and exit the trench. (Ladders must not PPE

be more than 9 m apart and at least 1 m of the ladder must extend out of the trench.)

10. No petrol driven machinery is to be used in or near the trench. Isolation

ABN: 86 673 835 011

Confidential

SWMS5 4

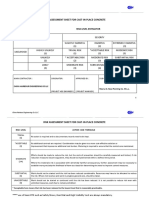

Inherent Residual Hierarchy PICOW’s

Task/Activity Hazard/Risk Control Measures

Risk Risk of Initials

Rating Rating Controls

11. All tools and equipment shall be placed so that they cannot fall into the trench or Isolation

excavation.

12. Minimise the length of open trench by back-filling the trench or excavation as soon as Engineering

possible.

13. Work only from inside shored areas or from on top of stable backfill. Isolation

14. All workers must constantly monitor the stability of the trench or excavation walls. Admin

15. If a change of shift is required, the site supervisor will hold a handover meeting with Admin

incoming staff and supervisor to discuss the workplace and indicate any known

hazards.

5. 1. H L Engineering

1. Ensure all equipment has been removed and site is restored to a high standard, safe

Site Manual and clean, posing no risk to the public or environment.

restoration handling,

obstructions,

public safety,

falling,

6. 1. H L Engineering

1. Remove all loose material

Site Erosion of soil,

restoration movement of Isolation

sediment 2. Ensure any exposed areas are stabilised (to prevent possible later runoff)

offsite

END OF SAFE WORK METHOD STATEMENT

ABN: 86 673 835 011

Confidential

SWMS5 5

Вам также может понравиться

- (Potential/existing) (Permits, Safety Precautions, Equipment, PPE, Recommended Actions)Документ3 страницы(Potential/existing) (Permits, Safety Precautions, Equipment, PPE, Recommended Actions)krisОценок пока нет

- L Risk Assessment Code (RAC) MatrixДокумент6 страницL Risk Assessment Code (RAC) MatrixMario Marasigan50% (2)

- Manhole Construction SafetyДокумент13 страницManhole Construction SafetyTaiwo Oshin100% (1)

- Risk Assessment For Elevator Shaft Slab Demolition (C01, S10)Документ1 страницаRisk Assessment For Elevator Shaft Slab Demolition (C01, S10)rayОценок пока нет

- F5B-BMJV-0001-AHA-HSE 00 AHA For Precast Storm Drain and Subdrain Uty.Документ13 страницF5B-BMJV-0001-AHA-HSE 00 AHA For Precast Storm Drain and Subdrain Uty.Taiwo Oshin100% (1)

- Risk assessment for 300MW Masinloc coal-fired power plant plumbing worksДокумент8 страницRisk assessment for 300MW Masinloc coal-fired power plant plumbing worksResearcherОценок пока нет

- Risk Assesment Form ScaffoldДокумент10 страницRisk Assesment Form ScaffoldRejin PradeepОценок пока нет

- Installing Cladding Risk AssessmentДокумент3 страницыInstalling Cladding Risk AssessmentAhmed Tarek67% (3)

- Risk Assesment Installation Testing For Fire Fighting Piping System and AccessoriesДокумент8 страницRisk Assesment Installation Testing For Fire Fighting Piping System and AccessoriesGopinath SekarОценок пока нет

- Sealcoating /crack Repair Parking Lots: Job Safety AnalysisДокумент3 страницыSealcoating /crack Repair Parking Lots: Job Safety AnalysisRetselisitsoe0% (1)

- PMP Question AnswersДокумент12 страницPMP Question AnswersRashid Mahamood100% (1)

- PAN African e-Network Project PGDIT Software Engineering Semester - 1 Session - 6Документ115 страницPAN African e-Network Project PGDIT Software Engineering Semester - 1 Session - 6Morhne RufinОценок пока нет

- JC 7Документ20 страницJC 7Alexander S. Garcia Jr.Оценок пока нет

- Pamstrong - Week 1 LegsДокумент2 страницыPamstrong - Week 1 LegsSondosОценок пока нет

- APVS 2005 Proceedings More On PigsДокумент258 страницAPVS 2005 Proceedings More On PigsDulce AmorОценок пока нет

- Risk Assessment For Excavation Works Prior To Installation of Signage Gantry at Road A3Документ6 страницRisk Assessment For Excavation Works Prior To Installation of Signage Gantry at Road A3Muideen OyedeleОценок пока нет

- 01 Loading, Unloading & Transportation of Heavy Equipment (Well Head)Документ11 страниц01 Loading, Unloading & Transportation of Heavy Equipment (Well Head)Pangky AbasoloОценок пока нет

- Risk Assessment What Work Excavation Work With Help of JCB Location PM Warehouse Area Contractor Company-Aalanna Project PVT LTDДокумент2 страницыRisk Assessment What Work Excavation Work With Help of JCB Location PM Warehouse Area Contractor Company-Aalanna Project PVT LTDhemant yadav0% (1)

- Job Safety Analysis For Pump Installation in Ts3 Area: Hcu & Lobs Revamp ProjectДокумент5 страницJob Safety Analysis For Pump Installation in Ts3 Area: Hcu & Lobs Revamp ProjectShilpiengg SafetyОценок пока нет

- RA - For Precast ChambersДокумент5 страницRA - For Precast ChambersKallem RajashekarОценок пока нет

- JSA For Pipe Installation TS 3Документ8 страницJSA For Pipe Installation TS 3Shilpiengg SafetyОценок пока нет

- Risk Assessment for Overhead Line Relocation ProjectДокумент5 страницRisk Assessment for Overhead Line Relocation Projectghada gattouchОценок пока нет

- Job Safety Analysis: 10.06.2017 Page 1 of 7Документ7 страницJob Safety Analysis: 10.06.2017 Page 1 of 7Raghava RichhuОценок пока нет

- F5B-BMJV-0001-AHA-HSE 00 AHA For Foul Sewer - Manhole ConstructionДокумент11 страницF5B-BMJV-0001-AHA-HSE 00 AHA For Foul Sewer - Manhole ConstructionTaiwo OshinОценок пока нет

- Diesel Filling JSAДокумент6 страницDiesel Filling JSAMohammed Ali QaziОценок пока нет

- Risk AssessmentДокумент3 страницыRisk AssessmentAkinbami Olorunnifemi100% (1)

- RA-for Glass Installation 30-04-2022Документ6 страницRA-for Glass Installation 30-04-2022Muideen Oyedele100% (2)

- Job Safety Analysis: Shaybah NGL Recovery Plant DepartmentДокумент4 страницыJob Safety Analysis: Shaybah NGL Recovery Plant DepartmentMadhan KannanОценок пока нет

- Risk Assessment - Site Establishment - 2021Документ6 страницRisk Assessment - Site Establishment - 2021Asakundwi MukhwaОценок пока нет

- Block Work (Unit Masonary) RISK ASSESSMENTДокумент8 страницBlock Work (Unit Masonary) RISK ASSESSMENTVimal ViswanathОценок пока нет

- Risk Assessment - PlantingДокумент5 страницRisk Assessment - PlantingJunaid Mir100% (1)

- Job Hazard Analysis: Rohan Builders (I) PVT LTDДокумент4 страницыJob Hazard Analysis: Rohan Builders (I) PVT LTDsoubhagyaОценок пока нет

- Risk-Assessment Ducts & AccessoriesДокумент13 страницRisk-Assessment Ducts & AccessoriesMohammed Amer PashaОценок пока нет

- Lifting and Removing Using The Forklift or Telescopic Loader in SiteДокумент3 страницыLifting and Removing Using The Forklift or Telescopic Loader in SiteAMINОценок пока нет

- HAZARD IDENTIFICATION AND RISK ASSESSMENT FOR SUSPENDED CEILING WORKSДокумент4 страницыHAZARD IDENTIFICATION AND RISK ASSESSMENT FOR SUSPENDED CEILING WORKSfaizan khanОценок пока нет

- Metal Bollards Installation Risk AssessmentДокумент7 страницMetal Bollards Installation Risk AssessmentEldhose VargheseОценок пока нет

- Installation of Diesel GeneratorДокумент12 страницInstallation of Diesel Generatoramal100% (1)

- C/M or P Excavation SafetyДокумент1 страницаC/M or P Excavation SafetyHafiz SabriОценок пока нет

- Job Hazard Analysis (Jha) WorksheetДокумент4 страницыJob Hazard Analysis (Jha) WorksheetSamer AlsumaryОценок пока нет

- Jsa Fueling Equipment On DeckДокумент2 страницыJsa Fueling Equipment On DeckIlya BordonosovОценок пока нет

- Construction Safety: Page 1 of 4Документ4 страницыConstruction Safety: Page 1 of 4ryan.aniceteОценок пока нет

- MANAGEMENT OF TEMP WORKSДокумент14 страницMANAGEMENT OF TEMP WORKSezzularab100% (1)

- 23 JSA For Block WorkДокумент2 страницы23 JSA For Block WorkWakil AhmadОценок пока нет

- Concrete Pouring JSaДокумент12 страницConcrete Pouring JSaTheo Vidallon BautistaОценок пока нет

- RC Pipes Installation SafetyДокумент15 страницRC Pipes Installation SafetyTaiwo Oshin100% (1)

- Risk Assessment - Cutting and Chipping of Concrete StructureДокумент7 страницRisk Assessment - Cutting and Chipping of Concrete StructureHasham KhanОценок пока нет

- HAZARD IDENTIFICATION AND RISK ASSESSMENTДокумент31 страницаHAZARD IDENTIFICATION AND RISK ASSESSMENTNikhil ManjrekarОценок пока нет

- Risk Assessment For Anti Termite WorksДокумент7 страницRisk Assessment For Anti Termite WorksSaeed Ahmad100% (1)

- Painting Work Method StatementДокумент8 страницPainting Work Method StatementNisanth Thulasidas100% (1)

- Risk Assessment for Canal Construction WorksДокумент9 страницRisk Assessment for Canal Construction WorksAshoka Indunil WickramapalaОценок пока нет

- jsa-for-electrical-conduit-installationdocx - compress-đã chuyển đổiДокумент6 страницjsa-for-electrical-conduit-installationdocx - compress-đã chuyển đổiMon Trang NguyễnОценок пока нет

- JSA Gathering Tent: Basic Job Step Potential Hazards Controls Action PartyДокумент4 страницыJSA Gathering Tent: Basic Job Step Potential Hazards Controls Action PartyMuhammad TariqОценок пока нет

- Cast-In Place Concrete - Risk Assessment SheetДокумент3 страницыCast-In Place Concrete - Risk Assessment SheetYash SharmaОценок пока нет

- Fencing Installation Risk AssessmentДокумент6 страницFencing Installation Risk AssessmentVictorОценок пока нет

- Ra For Night PDFДокумент23 страницыRa For Night PDFsoliman fathyОценок пока нет

- Bricks Messonary Work Job Hazard AnalysisДокумент2 страницыBricks Messonary Work Job Hazard AnalysisMc Evans Magallanes100% (1)

- PTW272 - Asphalt Paving 17-01-2023Документ22 страницыPTW272 - Asphalt Paving 17-01-2023Shah Muzzamil0% (1)

- JSA 150 Trench Excavation Backfilling Berming & Sand Removal KRT-2 KM 104 - 108Документ10 страницJSA 150 Trench Excavation Backfilling Berming & Sand Removal KRT-2 KM 104 - 108Zubair Khan100% (1)

- Risk Assessment For Acrylic Rubber Filled CoatingДокумент6 страницRisk Assessment For Acrylic Rubber Filled CoatingKalid Jmal100% (1)

- Jsa For Manual Backfiling Usin Hand Roller CompactorДокумент5 страницJsa For Manual Backfiling Usin Hand Roller CompactorAbdus SamadОценок пока нет

- Exacavation Job Safety AnalysisДокумент1 страницаExacavation Job Safety AnalysisNeelakantamОценок пока нет

- Ref: Section / Dept: Civil Activity: Risk Assessment For False CeilingДокумент1 страницаRef: Section / Dept: Civil Activity: Risk Assessment For False CeilingJack P100% (2)

- Daily JSA - Diesel FillingДокумент3 страницыDaily JSA - Diesel Fillingshoaib akhtarОценок пока нет

- SWMS2 Confined Space EntryДокумент9 страницSWMS2 Confined Space EntryIslam Sarhan100% (1)

- Tech Sup StatДокумент1 страницаTech Sup StatMorhne RufinОценок пока нет

- Service Vehicle (Pickup) - Maintenance RequestДокумент4 страницыService Vehicle (Pickup) - Maintenance RequestMorhne RufinОценок пока нет

- 05-2013-MTCNA M5 Network Management en v2Документ70 страниц05-2013-MTCNA M5 Network Management en v2alessandroОценок пока нет

- Rocket M5Документ10 страницRocket M5Juan Manuel Avila FariñaОценок пока нет

- End-User License Agreement Papercut Software Pty. LTDДокумент1 страницаEnd-User License Agreement Papercut Software Pty. LTDCarlosCoñacaQuispeОценок пока нет

- airMAX - Training - Guide 10 15 12 PDFДокумент84 страницыairMAX - Training - Guide 10 15 12 PDFMorhne RufinОценок пока нет

- Ubiquiti DocumentationДокумент50 страницUbiquiti DocumentationMorhne RufinОценок пока нет

- 06-2013-Mtcna m6 Firewall en v3Документ61 страница06-2013-Mtcna m6 Firewall en v3alessandroОценок пока нет

- Latest Dump Compiled by Genius PDFДокумент127 страницLatest Dump Compiled by Genius PDFMateus Gerboni100% (1)

- MN Cdm625aДокумент756 страницMN Cdm625aMorhne Rufin100% (1)

- JET + RW2000D+ Overview and Key BenefitsДокумент36 страницJET + RW2000D+ Overview and Key BenefitsMorhne RufinОценок пока нет

- Pan African Enetwork Project: Course Name: PgditДокумент69 страницPan African Enetwork Project: Course Name: PgditMorhne RufinОценок пока нет

- Chap56 Cycle-6 SE Session8Документ118 страницChap56 Cycle-6 SE Session8Morhne RufinОценок пока нет

- Pan African Enetwork Project: Post Graduate Diploma (It)Документ68 страницPan African Enetwork Project: Post Graduate Diploma (It)Morhne RufinОценок пока нет

- Canopy AP ManualДокумент102 страницыCanopy AP ManualJose Yesid BocanegraОценок пока нет

- Introduction For ComputerДокумент88 страницIntroduction For ComputerMorhne RufinОценок пока нет

- Canopy BU ManualДокумент53 страницыCanopy BU ManualJorge Alfredo Cortes HuertaОценок пока нет

- 1 PBДокумент21 страница1 PBDewi Puspita SariОценок пока нет

- Seminar on Concepts and Foundations of RehabilitationДокумент13 страницSeminar on Concepts and Foundations of Rehabilitationamitesh_mpthОценок пока нет

- Antenatal & Postnatal Care: 1. General InformationДокумент7 страницAntenatal & Postnatal Care: 1. General InformationanishnithaОценок пока нет

- DAFTAR PUSTAKA SarkomaДокумент2 страницыDAFTAR PUSTAKA SarkomaantaniaaaОценок пока нет

- Islamic Relaxation and OutcomeДокумент14 страницIslamic Relaxation and OutcomeMardiyonoОценок пока нет

- Treating Gout Uric Acid Tibb e NabwiДокумент11 страницTreating Gout Uric Acid Tibb e Nabwinadeem uddinОценок пока нет

- Coating of Pellets With Micronized Ethylcellulose Particles by A Dry Powder Coating TechniqueДокумент11 страницCoating of Pellets With Micronized Ethylcellulose Particles by A Dry Powder Coating TechniqueFaizОценок пока нет

- TH THДокумент11 страницTH THFista Divi AmesiaОценок пока нет

- Bls - Fbao - First AidДокумент172 страницыBls - Fbao - First AidMaria Regina Castro Gabriel100% (1)

- Seminar Molar DistalizationДокумент130 страницSeminar Molar DistalizationMuhsina EyyanathilОценок пока нет

- CAE-UOE Part1Документ4 страницыCAE-UOE Part1nikitsaОценок пока нет

- Balcom Rebecca Functional ResumeДокумент2 страницыBalcom Rebecca Functional Resumeapi-360266135Оценок пока нет

- Genetic Counseling: A Study and SuggestionsДокумент10 страницGenetic Counseling: A Study and SuggestionsraphynjОценок пока нет

- Influence of Anthropometric Parameters On Aerobic Capacity Among DancersДокумент7 страницInfluence of Anthropometric Parameters On Aerobic Capacity Among DancersAnonymous izrFWiQОценок пока нет

- Act 342 Prevention and Control of Infectious Diseases Act 1988Документ26 страницAct 342 Prevention and Control of Infectious Diseases Act 1988Adam Haida & Co100% (1)

- District: Rajkot Name of Institute: P.D.U. Medical CollegeДокумент9 страницDistrict: Rajkot Name of Institute: P.D.U. Medical CollegeManas K. TrivediОценок пока нет

- Case Study: MYXEDEMATOUS COMAДокумент5 страницCase Study: MYXEDEMATOUS COMAjisooОценок пока нет

- Perioperative Nursing (1) 2007Документ14 страницPerioperative Nursing (1) 2007Lorraine BuelvaОценок пока нет

- Pediatric PerfectionismДокумент20 страницPediatric Perfectionismapi-438212931Оценок пока нет

- Concrete MSDS 1 PDFДокумент5 страницConcrete MSDS 1 PDFmanil_5100% (1)

- IP Sterility TestingДокумент6 страницIP Sterility TestingVarghese100% (3)

- EEG ArtifactsДокумент18 страницEEG ArtifactsNazwan Hassa100% (1)

- Case Study - MyomaДокумент54 страницыCase Study - Myomauvinr100% (1)

- TEMPLATE-B-Master-list-of-Learners-for-the-Pilot-Implementation-of-F2F-Classes-for-S.Y.-2021-2022Документ7 страницTEMPLATE-B-Master-list-of-Learners-for-the-Pilot-Implementation-of-F2F-Classes-for-S.Y.-2021-2022Resa Consigna MagusaraОценок пока нет

- Bradford Assay To Detect Melamine ConcentrationsДокумент3 страницыBradford Assay To Detect Melamine ConcentrationsVibhav SinghОценок пока нет

- HEX Character Generation Cheat Sheet Version 3Документ20 страницHEX Character Generation Cheat Sheet Version 3NestorDRod100% (1)

- Rangkuman by Yulia VionitaДокумент21 страницаRangkuman by Yulia VionitaRizqi AkbarОценок пока нет