Академический Документы

Профессиональный Документы

Культура Документы

Aisc Manual 13th Part7

Загружено:

Raditya Purnamahadi0 оценок0% нашли этот документ полезным (0 голосов)

594 просмотров90 страницAisc Manual 13th Part7

Авторское право

© © All Rights Reserved

Доступные форматы

PDF или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документAisc Manual 13th Part7

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

594 просмотров90 страницAisc Manual 13th Part7

Загружено:

Raditya PurnamahadiAisc Manual 13th Part7

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

Вы находитесь на странице: 1из 90

PART 7

DESIGN CONSIDERATIONS FOR BOLTS

SCOPE eer anncboce oe

GENERAL REQUIREMENTS FOR BOLTED JOINTS ..........-

Fastener Components :

Proper Selection of Bolt Length...

Washer Requirements

Nut Requirements. .

Bolted Parts Gonesbsoseeeno

PROPER SPECIFICATION OF JOINT TYPE .

Snug-Tightened Joints ...........

Pretensioned Joints .......

Slip-Critical Joints

DESIGN REQUIREMENTS

Shear

Tension

Combined Shear and Tension

Bearing Strength at Bolt Holes

Slip Resistance 0.00... eeeceeeeeeeeeeees

ECCENTRICALLY LOADED BOLT GROUPS ......

Eccentricity in the Plane of the Faying Surface

Instantaneous Center of Rotation Method ........

Elastic Method .

Eecentricity Normal to the Plane of the Faying Surface cee

SPECIAL CONSIDERATIONS FOR HOLLOW STRUCTURAL SECTIONS

Throwgh-Bolting to HSS ...........

Blind Bolts.

Flow-Drilling ..

‘Threaded Studs to HSS...

Nailing OHSS ....0....e eee oe

Screwing to HSS

AMERICAN INSTITUTE OF StEEL, CONSTRUCTION, INC.

73

7-3

7-3

-73

1-6

12 DESIGN CONSIDERATIONS FOR BOLTS

OTHER SPECIFICATION REQUIREMENTS AND.

DESIGN CONSIDERATIONS . coven ee

Placement of Bolt Groups ...

Bolts in Combination with Welds or Rivets

Galvanizing High-Strength Bolts and Nuts

Reuse of Bolts... 00... 0.000

Fatigue Applications

Entering and Tightening Clearances

Fully Threaded ASTM A325 Bolts

ASTM A307 Bolts

ASTM A449 Bolts

DESIGN TABLES

Table 7-1. Available Shear Strength of Bolts

Table 7-2. Available Tensile Strength of Bolts .

Tables 7-3 and 74. Available Resistance to Slip

Tables 7-5 and 7-6. Available Bearing Strength at Bolt Holes

‘Tables 7-7 through 7-14. Coefficients C for Eccentrically Loaded Bolt Groups

Table 7-15. Dimensions of High-Strength Fasteners

‘Tables 7-16 and 7-17. Entering and Tightening Clearances . .

Table 7-18. Threading Dimensions for High Strength

and Non-High-Strength Bolts, cece

Table 7-19. Weights of High-Strength Fasteners

Table 7-20. Dimensions of Non-High-Strength Fasteners

Tables 7-21, 7-22, and 7-23, Weights of Non-High-Strength Fasteners

PART 7 REFERENCES

AMERICAN INSTITUTE OF STEEL CONSTRUCTION, INC.

- 7-16

7-16

7-16

I-16

7-16

7-16

716

IAT

7-17

717

7-17

AT

7-17

77

TAT

718

-TA9

719

719

7-20

7-20

7-20

7-21

GENERAL REQUIREMENTS FOR BOLTED JOINTS. 13

SCOPE

‘The specification requirements and other design considerations summatized in this Part apply

to the design of bolts in stee!-to-steel structural connections. Additional guidance on bolt design

isavailable in AISC Design Guide 17, High Strength Bols~A Primer for Structural Engineers,

(Kulak, 2002). For the design of steel-to-concrete anchorage, see Part 14. For the design of con-

nection elements, see Part 9. For the design of simple shear, moment, bracing, and other

connections, see Parts 10 through 15. For bolted joints that are part of a seismic force resisting

system in which the seismic response modification factor, R, is taken greater than 3, the require-

‘ments in the AISC Seismic Provisions for Structural Steel Buildings also apply. The AISC

Seismic Provisions for Structural Steel Buildings is available in Part 6 of the AISC Seismic

Design Manual from the American Institute of Steel Construction, Inc. at www.aise.org.

GENERAL REQUIREMENTS FOR BOLTED JOINTS

Fastener Components

‘The applicable material specifications for fastener components are as given in Part 2.

Material and storage requirements fastener components are as given in AISC Specification

Section A3.3 and RCSC Specification Section 2. The compatibility of ASTM A563 nuts and

F436 washers with ASTM A325, F1852, and A490 bolts is as given in RCSC Specification

Table 2.1. These products are given identifying marks, as illustrated in RCSC Specification

Figure C-2.1. Alerative-design fasteners, including twist-off-type tension-control bolt

assemblies with a strength level matching that of ASTM A490 bolts, and alternative washer-

type indicating devices are permitted, subject to the requirements in RCSC Specification

Sections 2.8 and 2.6.2, respectively.

Mixing grades of fasteners raises inventory and quality control issues associated with the

‘use of multiple fastener grades. When both ASTM A325 and A490 bolts are used on a proj-

ect, different diameters can be specified for each to help ensure that the ASTM A490 bolts

are installed in the proper location.

Regardless of the bolt type selected, the typical sizes of ¥4-in., ’/s-in., 1-in. and 1'¥s-in,

diameter are usually preferred. Diameters above | in. require special consideration for avail-

ability as well as installation, when pretensioned installation is required, Special equipment

may be required to pretension large-diameter ASTM A490 bolts.

Proper Selection of Bolt Length

Per RCSC Specification Section 2.3.2, adequate thread engagement is developed when the

‘end of the bolt is at least flush with or projects beyond the face of the nut. To provide for

this, the ordered length of ASTM A325, F1852, and A490 bolts should be calculated as the

arip (see Figure 7-1) plus the nominal thickness of washers and/or direet-tension indicators

if used, plus the allowance from Table 7-15, with the total rounded to the next higher inere-

ment of '/4 in, up to a5 in. length and the next higher 2 in. over a 5 in. length. Note that

bolts longer than five inches are generally available only in '2-in, increments, except by spe-

cial arrangement with the manufacturer or vendor. While longer lengths may be ordered, an

8-in. length is generally the maximum stock length available. Requirements for a minimum

stick-through greater than zero are discouraged because of the risk of jamming the nut on

the thread runout, particularly in the bolt length range available only in 'V2-in, increments.

See Carter (1996) for further information.

AMERICAN INSTITUTE oF STEEL CONSTRUCTION, INC.

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- TL - Vol. IV - Tower ErectionДокумент155 страницTL - Vol. IV - Tower Erectionobayapalli100% (8)

- PIP STE05121 - Anchor Bolt Design GuideДокумент55 страницPIP STE05121 - Anchor Bolt Design Guidenistiana100% (4)

- Aisc Manual 13th Part8Документ114 страницAisc Manual 13th Part8Raditya PurnamahadiОценок пока нет

- Storage Tanks CalculationsДокумент21 страницаStorage Tanks Calculationsjimallen21288% (26)

- Storage Tank Design Calculations - Seismic Design & Overturning Moment - by Abdel Halim GalalaДокумент10 страницStorage Tank Design Calculations - Seismic Design & Overturning Moment - by Abdel Halim Galalamarkfgt57% (7)

- AISC13th - Bolt Edge Distance PDFДокумент1 страницаAISC13th - Bolt Edge Distance PDFRaditya PurnamahadiОценок пока нет

- Aplikasi 49Документ5 страницAplikasi 49Raditya PurnamahadiОценок пока нет

- Comparison Steel ShapeДокумент80 страницComparison Steel ShapeRaditya PurnamahadiОценок пока нет

- Aplikasi 2Документ7 страницAplikasi 2ANGGY MAULANA JOHN WINARAОценок пока нет

- Hilti Stock BoltsДокумент38 страницHilti Stock BoltsmaniaxpdfОценок пока нет

- Aplikasi 2Документ7 страницAplikasi 2ANGGY MAULANA JOHN WINARAОценок пока нет

- 2011 UscДокумент907 страниц2011 UscRaditya PurnamahadiОценок пока нет

- Office Building Lumen CalculationДокумент6 страницOffice Building Lumen CalculationRaditya PurnamahadiОценок пока нет

- Daya Dukung - Pondasi DangkalДокумент34 страницыDaya Dukung - Pondasi DangkalRaditya PurnamahadiОценок пока нет

- Spec NovДокумент3 страницыSpec NovSEDDIGHI55Оценок пока нет

- Drawing Retaining Wall Scope UIP XIДокумент4 страницыDrawing Retaining Wall Scope UIP XIRaditya PurnamahadiОценок пока нет

- Kebutuhan Material LightingДокумент2 страницыKebutuhan Material LightingRaditya PurnamahadiОценок пока нет

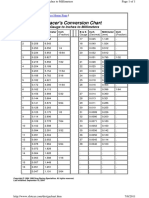

- Racer's Conversion Chart: Gauge To Inches To MillimetersДокумент1 страницаRacer's Conversion Chart: Gauge To Inches To MillimetersRaditya PurnamahadiОценок пока нет

- Aisc Manual 13th Part6Документ96 страницAisc Manual 13th Part6Raditya PurnamahadiОценок пока нет

- Anchor Bolt Design CriteriaДокумент42 страницыAnchor Bolt Design CriteriaRaditya Purnamahadi100% (2)

- 39 Excel 2003 MacrosДокумент63 страницы39 Excel 2003 Macrosstjon1954Оценок пока нет

- T/L TowersДокумент72 страницыT/L TowersEngr Imtiaz Hussain Gilani100% (1)

- Tank FoundationsДокумент83 страницыTank Foundationsdroates100% (17)

- Tank FoundationsДокумент83 страницыTank Foundationsdroates100% (17)

- Design of Retaining Wall: S.No W, LB X, FT M W XДокумент1 страницаDesign of Retaining Wall: S.No W, LB X, FT M W XYOSEMITEROCKОценок пока нет

- AISC13th - Bolt Edge DistanceДокумент1 страницаAISC13th - Bolt Edge DistanceRaditya PurnamahadiОценок пока нет

- LRFD TablasДокумент3 страницыLRFD TablasFlorencio SandovalОценок пока нет

- Astm F436M PDFДокумент1 страницаAstm F436M PDFRaditya PurnamahadiОценок пока нет