Академический Документы

Профессиональный Документы

Культура Документы

Uha 32-2

Загружено:

Lipika GayenОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Uha 32-2

Загружено:

Lipika GayenАвторское право:

Доступные форматы

ASME BPVC.VIII.

1-2017 UHA-33 – UHA-42

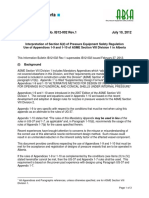

Table UHA-32-2

Postweld Heat Treatment Requirements for High Alloy Steels — P-No. 7

Normal Holding Minimum Holding Time at Normal Temperature for Nominal Thickness [See UHA-32(d)]

Temperature, °F (°C), Over 2 in. to 5 in.

Material Minimum Up to 2 in. (50 mm) (50 mm to 125 mm) Over 5 in. (125 mm)

P‐No. 7 Gr. Nos. 1, 2 1,350 (730) 1 hr/in. (25 mm), 15 min 2 hr plus 15 min for each additional 2 hr plus 15 min for each

minimum inch (25 mm) over 2 in. (50 mm) additional inch (25 mm) over

2 in. (50 mm)

GENERAL NOTES:

(a) Postweld heat treatment is not required for vessels constructed of SA-1010 UNS S41003 Type 405, Type 410S, or Type 430 Ti materials for

SA-240 and SA-268 with carbon content not to exceed 0.08%, welded with electrodes that produce an austenitic–chromium–nickel weld

deposit or a non‐air‐hardening nickel–chromium–iron weld deposit, provided the nominal thickness does not exceed 3/8 in. (10 mm) and

for thicknesses over 3/8 in. (10 mm) to 11/2 in. (38 mm) provided a preheat of 450°F (230°C) is maintained during welding and that the

joints are completely radiographed.

(b) Postweld heat treatment shall be performed as prescribed in UW-40 and UCS-56(e) except that the cooling rate shall be a maximum of

100°F/hr (56°C/h) in the range above 1,200°F (650°C) after which the cooling rate shall be sufficiently rapid to prevent embrittlement.

(c) Postweld heat treatment is not required for vessels constructed of Grade TP XM-8 material for SA-268 and SA-479 or of Grade TP

18Cr–2Mo for SA-240 and SA-268.

UHA-33 RADIOGRAPHIC EXAMINATION in UW-40(f), shall be examined for the detection of cracks

by the liquid penetrant method. This examination shall be

(a) The requirements for radiographing prescribed in

made following heat treatment if heat treatment is per-

UW-11, UW-51, and UW-52 shall apply in high alloy ves-

formed. All cracks shall be eliminated.

sels, except as provided in (b) below. (See UHA-21.)

(b) Butt-welded joints in vessels constructed of materi-

als conforming to Type 405 welded with straight chro-

mium electrodes, and to Types 410, 429, and 430 FABRICATION

welded with any electrode, shall be radiographed in all UHA-40 GENERAL

thicknesses. The final radiographs of all straight chro-

The rules in the following paragraphs apply specifically

mium ferritic welds including major repairs to these

to the fabrication of pressure vessels and vessel parts that

welds shall be made after postweld heat treatment has

are constructed of high alloy steel and shall be used in

been performed.

conjunction with the general requirements for Fabrica-

(c) Butt-welded joints in vessels constructed of auste-

tion in Subsection A, and with the specific requirements

nitic chromium–nickel stainless steels which are radio-

for Fabrication in Subsection B that pertain to the method

graphed because of the thickness requirements of

of fabrication used.

UW-11, or for lesser thicknesses where the joint efficiency

reflects the credit for radiographic examination of Table

UW-12, shall be radiographed following post heating if UHA-42 WELD METAL COMPOSITION

such is performed. Welds that are exposed to the corrosive action of the

contents of the vessel should have a resistance to corro-

UHA-34 LIQUID PENETRANT EXAMINATION sion that is not substantially less than that of the base me-

All austenitic chromium–nickel alloy steel and austeni- tal. The use of filler metal that will deposit weld metal

tic/ferritic duplex steel welds, both groove and fillet, with practically the same composition as the material

which exceed a nominal size of 3/4 in. (19 mm), as defined joined is recommended. When the manufacturer is of

Table UHA-32-3 ð17Þ

Postweld Heat Treatment Requirements for High Alloy Steels — P-No. 8

Normal Holding Minimum Holding Time at Normal Temperature for Nominal Thickness [See UHA-32(d)]

Temperature, °F (°C), Over 2 in. to 5 in.

Material Minimum Up to 2 in. (50 mm) (50 mm to 125 mm) Over 5 in. (125 mm)

P‐No. 8 Gr. Nos. 1, 2, 3, 4 … … … …

GENERAL NOTE: Postweld heat treatment is neither required nor prohibited for joints between austenitic stainless steels of the P‐No. 8

group. See Nonmandatory Appendix UHA-A.

213

Вам также может понравиться

- 02 Samss 006Документ17 страниц02 Samss 006inatt101Оценок пока нет

- ASME B16 Welding EndsДокумент2 страницыASME B16 Welding Endsf_riseОценок пока нет

- A494Документ7 страницA494Prakash MakadiaОценок пока нет

- QCF312 WPQRДокумент2 страницыQCF312 WPQRminhnnОценок пока нет

- ASTM A733 Standard Specification For Welded and Seamless Carbon Steel and Austenitic Stainless Steel Pipe NipplesДокумент5 страницASTM A733 Standard Specification For Welded and Seamless Carbon Steel and Austenitic Stainless Steel Pipe NipplesYaser Mohamed AbasОценок пока нет

- VESV1003 - Fabrication of Welded Vessels and Tanks To Be LinedДокумент6 страницVESV1003 - Fabrication of Welded Vessels and Tanks To Be LinedMuhammad Farukh ManzoorОценок пока нет

- Triple Eccentric Metal Seated ValvesДокумент4 страницыTriple Eccentric Metal Seated ValvesFelipe Gamboa GálvezОценок пока нет

- Ref SA 515Документ5 страницRef SA 515nachoircОценок пока нет

- ASME B1.20.1 (ANSI B2.1 Pipe Threads)Документ32 страницыASME B1.20.1 (ANSI B2.1 Pipe Threads)Lean_HerediaОценок пока нет

- Case 2864 9Cr–1Mo–VДокумент1 страницаCase 2864 9Cr–1Mo–VAlevj Db100% (1)

- Pwps 06Документ1 страницаPwps 06eldobie3Оценок пока нет

- Asme Section II A Sa-263Документ8 страницAsme Section II A Sa-263Anonymous GhPzn1xОценок пока нет

- ASME Section V Article 5 (2019)Документ7 страницASME Section V Article 5 (2019)Baguz SaputraОценок пока нет

- Astm A 450Документ10 страницAstm A 450Telmo VianaОценок пока нет

- SURIA ENGINEERING WELDING PROCEDURE SPECIFICATION (WPS) FOR GTAW & SMAWДокумент1 страницаSURIA ENGINEERING WELDING PROCEDURE SPECIFICATION (WPS) FOR GTAW & SMAWsuria qaqcОценок пока нет

- En ASME ComparisonДокумент18 страницEn ASME ComparisonPeterWay100% (1)

- En 764-4-2002Документ44 страницыEn 764-4-2002Marija IvanovskaОценок пока нет

- ASME B16.47!75!300# Series B Flanges With FLEXSEAL Spiral Wound GasketsДокумент5 страницASME B16.47!75!300# Series B Flanges With FLEXSEAL Spiral Wound Gasketserik aranaОценок пока нет

- ET de TubulacaoДокумент214 страницET de TubulacaoClarisse MendoncaОценок пока нет

- ES 22 Color Coding of Piping MaterialsДокумент3 страницыES 22 Color Coding of Piping MaterialsjojeecaresОценок пока нет

- Astm D2517 (2000)Документ5 страницAstm D2517 (2000)SANKARAN.KОценок пока нет

- Valve Material ApplicationДокумент16 страницValve Material Applicationswapneel_kulkarniОценок пока нет

- ASME Section VIII Nozzle Reinforcement RulesДокумент3 страницыASME Section VIII Nozzle Reinforcement RulesSachinОценок пока нет

- Standard Specification FOR High Frequency Welded (HFW) Line Pipe (Onshore)Документ31 страницаStandard Specification FOR High Frequency Welded (HFW) Line Pipe (Onshore)Agniva DuttaОценок пока нет

- Asme - HeaderДокумент3 страницыAsme - HeaderReadersmoОценок пока нет

- Astm e 428 Rev A 2005 PDFДокумент7 страницAstm e 428 Rev A 2005 PDFJORGE ARTURO TORIBIO HUERTAОценок пока нет

- Flange Leakage 6Документ2 страницыFlange Leakage 6hamid sobirinОценок пока нет

- Material Selection GuideДокумент12 страницMaterial Selection Guideaajmsae*Оценок пока нет

- Radiography Cheat SheetДокумент1 страницаRadiography Cheat SheetbplturnerОценок пока нет

- Is 210Документ16 страницIs 210Debopriyo GhoshОценок пока нет

- SP-P-001 - Specification For StrainerДокумент30 страницSP-P-001 - Specification For Strainervishal bhamreОценок пока нет

- A-23 WB36 Rev 03 15NiCuMoNb5 MicrostructureДокумент4 страницыA-23 WB36 Rev 03 15NiCuMoNb5 Microstructuremavis16Оценок пока нет

- Ug-116 - RT4Документ3 страницыUg-116 - RT4miteshpatel191Оценок пока нет

- Inspection and Test Plan: Rev Created by Checked by Approved by Date Issue StatusДокумент18 страницInspection and Test Plan: Rev Created by Checked by Approved by Date Issue StatusoberaiОценок пока нет

- Tube-To-Tube Sheet Joint RequirementsДокумент2 страницыTube-To-Tube Sheet Joint RequirementsWaqas WaqasОценок пока нет

- Main Check Points API 660Документ3 страницыMain Check Points API 660vm153748763Оценок пока нет

- Public-: Rev. D E English 03 / 2014Документ33 страницыPublic-: Rev. D E English 03 / 2014xaviereduardoОценок пока нет

- EIL - Specification Sheet123Документ1 страницаEIL - Specification Sheet123Dinesh ChouguleОценок пока нет

- SB 111-SB 111MДокумент14 страницSB 111-SB 111MRoberto Faustino FaustinoОценок пока нет

- JIS Standard ValveДокумент8 страницJIS Standard ValveJong JavaОценок пока нет

- ASME/ANSI B18.2.2 SAE GR.2 THREAD UNF 1/4-28; 1-12 INDEXДокумент2 страницыASME/ANSI B18.2.2 SAE GR.2 THREAD UNF 1/4-28; 1-12 INDEXCharan Kumar100% (1)

- Shell and Tube Heat Exchangers (API 660 vsTEMA)Документ3 страницыShell and Tube Heat Exchangers (API 660 vsTEMA)Aravind MadhuОценок пока нет

- Bleed or Drip RingДокумент2 страницыBleed or Drip RingAnonymous 6ZWS6IG2J9Оценок пока нет

- Nioec SP 90 02Документ77 страницNioec SP 90 02aminОценок пока нет

- Sa 450/sa 450MДокумент13 страницSa 450/sa 450MSaravana VelОценок пока нет

- Pipe Fittings To BS1740 150lbДокумент7 страницPipe Fittings To BS1740 150lbKiko Ruiz AhedoОценок пока нет

- Ucs 66Документ17 страницUcs 66Pratik DhuriОценок пока нет

- Equivalent MaterialsДокумент1 страницаEquivalent Materialsvaisakp7770% (1)

- Safety ValvesДокумент3 страницыSafety ValvesGiovanni LerasОценок пока нет

- Autopipe Asme NB ExampleДокумент31 страницаAutopipe Asme NB ExampleEl riza annamlОценок пока нет

- Wps GT 9b Cvn90 Rev 1 PDFДокумент6 страницWps GT 9b Cvn90 Rev 1 PDFM. Zaki RahmaniОценок пока нет

- Sa 480Документ25 страницSa 480gasolineandoilОценок пока нет

- How To Weld 254 SMOДокумент12 страницHow To Weld 254 SMOsateesh chand100% (7)

- Asme Section II A Sa-358 Sa-358mДокумент10 страницAsme Section II A Sa-358 Sa-358mAnonymous GhPzn1xОценок пока нет

- Asme Section Ii A-2 Sa-814 Sa-814mДокумент8 страницAsme Section Ii A-2 Sa-814 Sa-814mdavid perezОценок пока нет

- Asme-803 Specification For Welded Ferritic Stainless Steel Feedwater Heater TubesДокумент10 страницAsme-803 Specification For Welded Ferritic Stainless Steel Feedwater Heater Tubeslucecita1902Оценок пока нет

- Technical Specification of Lattice Steel PolesДокумент9 страницTechnical Specification of Lattice Steel PolesCalinB.ACОценок пока нет

- Sa 312 PDFДокумент14 страницSa 312 PDFAnilОценок пока нет

- T-721 For MPTДокумент1 страницаT-721 For MPTLipika GayenОценок пока нет

- How Does A Steam Boiler Work?Документ11 страницHow Does A Steam Boiler Work?Lipika GayenОценок пока нет

- Table T-233.1 For RTДокумент1 страницаTable T-233.1 For RTLipika GayenОценок пока нет

- Table T-233.1 For RTДокумент1 страницаTable T-233.1 For RTLipika GayenОценок пока нет

- Axial Flow For Industry 1Документ9 страницAxial Flow For Industry 1Lipika GayenОценок пока нет

- CompressorДокумент17 страницCompressorLipika GayenОценок пока нет

- Impact Test Machine CalculationsДокумент6 страницImpact Test Machine CalculationsSoumadipta SenОценок пока нет

- Quality (1) Min. Yield Point (2) Tensile Strenght (3) Impact Strenght (4) Reh N/MM RM N/MM Temp °C Charpy VДокумент1 страницаQuality (1) Min. Yield Point (2) Tensile Strenght (3) Impact Strenght (4) Reh N/MM RM N/MM Temp °C Charpy VLipika Gayen100% (1)

- Ductile Pipe MFG ProcessДокумент1 страницаDuctile Pipe MFG ProcessLipika GayenОценок пока нет

- CompressorДокумент17 страницCompressorLipika GayenОценок пока нет

- Acceptance Criteria For Pipeline & WQT: South Pars Gas Field Development 9&10 Pipe Line Connecting Phase 1 To Phases 9&10Документ4 страницыAcceptance Criteria For Pipeline & WQT: South Pars Gas Field Development 9&10 Pipe Line Connecting Phase 1 To Phases 9&10Lipika Gayen100% (1)

- API 650 Tank Design CalculationДокумент8 страницAPI 650 Tank Design Calculationmail_younes659283% (29)

- Welding Procedure Specification: WPS For Low Yeild Streght Carbon Steel With PWHT (SMAW)Документ1 страницаWelding Procedure Specification: WPS For Low Yeild Streght Carbon Steel With PWHT (SMAW)Lipika GayenОценок пока нет

- Tee JointsДокумент1 страницаTee JointsLipika GayenОценок пока нет

- CompressorДокумент6 страницCompressorLipika GayenОценок пока нет

- CompressorДокумент17 страницCompressorLipika GayenОценок пока нет

- Test ConditionДокумент1 страницаTest ConditionLipika GayenОценок пока нет

- Third Party Inspection For Reciprocating Compressor - ProcedureДокумент12 страницThird Party Inspection For Reciprocating Compressor - ProcedureLipika GayenОценок пока нет

- Code for Gas Welding Process and ParametersДокумент1 страницаCode for Gas Welding Process and ParametersLipika GayenОценок пока нет

- Work permit details for IPDC project constructionДокумент1 страницаWork permit details for IPDC project constructionLipika GayenОценок пока нет

- Wa0000Документ9 страницWa0000Lipika GayenОценок пока нет

- Test ConditionДокумент1 страницаTest ConditionLipika GayenОценок пока нет

- Technical Tank Inspection Report TemplateДокумент1 страницаTechnical Tank Inspection Report TemplateLipika GayenОценок пока нет

- S.No. Hospital Code Hospital NameДокумент20 страницS.No. Hospital Code Hospital NameLipika GayenОценок пока нет

- API 650, 5.6.4, Calculation of Shell ThicknessДокумент31 страницаAPI 650, 5.6.4, Calculation of Shell ThicknessalokbdasОценок пока нет

- Flange Dimensions and Pressure Ratings ChartДокумент24 страницыFlange Dimensions and Pressure Ratings Chartgateauxboy100% (2)

- Tank Shell DesignДокумент4 страницыTank Shell Designgon972001Оценок пока нет

- API 650 Datasheet 1Документ16 страницAPI 650 Datasheet 1alwacsОценок пока нет

- Tank Shell DesignДокумент4 страницыTank Shell Designgon972001Оценок пока нет

- Standard Pipe Sizes and PropertiesДокумент64 страницыStandard Pipe Sizes and PropertiesLipika GayenОценок пока нет

- Non Chip FormingДокумент33 страницыNon Chip FormingNur AmirahОценок пока нет

- Rr322105-High Speed AerodynamicsДокумент8 страницRr322105-High Speed AerodynamicsSRINIVASA RAO GANTAОценок пока нет

- CHEM123 Experiment #9 Write UpДокумент4 страницыCHEM123 Experiment #9 Write UpKamil KrawczykОценок пока нет

- Surface Preparation and Coating Inspection Report for Tasiast Tailings ThickenerДокумент2 страницыSurface Preparation and Coating Inspection Report for Tasiast Tailings ThickenerRekhis OussamaОценок пока нет

- GEAS 1 - Chemistry - 2Документ4 страницыGEAS 1 - Chemistry - 2Leoneil Angelo AbreuОценок пока нет

- IIT JEE Laws of Motion PhysicsДокумент32 страницыIIT JEE Laws of Motion PhysicsShakil Khan100% (1)

- Wireline Logging GuidelinesДокумент3 страницыWireline Logging GuidelinesHamdan HamzahОценок пока нет

- CaseStudy2 WindmillДокумент8 страницCaseStudy2 WindmillAnthony BergemannОценок пока нет

- Macroetch Testing of Tool Steel Bars: Standard Practice ForДокумент2 страницыMacroetch Testing of Tool Steel Bars: Standard Practice ForAmir AlikhaniОценок пока нет

- Mp501e PDFДокумент8 страницMp501e PDFEdgar CanelasОценок пока нет

- Optical Balance Procedure For The Unbalanced Diode Error On The G1362A Refractive Index DetectorДокумент4 страницыOptical Balance Procedure For The Unbalanced Diode Error On The G1362A Refractive Index DetectorAhmad IbrahemОценок пока нет

- Characterisation of Polymer With GCДокумент104 страницыCharacterisation of Polymer With GCAmit KumarОценок пока нет

- Is 2190.2010 Selection, Installation & Maintenance of Portable Fire ExtinguishersДокумент26 страницIs 2190.2010 Selection, Installation & Maintenance of Portable Fire ExtinguishersShivakumara ArehalliОценок пока нет

- Venturi EffectДокумент21 страницаVenturi Effectmuhammad ridОценок пока нет

- Direct Energy Conversion Methods for Improving Fusion Reactor EfficiencyДокумент4 страницыDirect Energy Conversion Methods for Improving Fusion Reactor EfficiencyPavan Kumar BittuОценок пока нет

- Alloy 286Документ6 страницAlloy 286shivam.kumarОценок пока нет

- Basic Hydraulics Bench: Page 1/3 05/2008Документ3 страницыBasic Hydraulics Bench: Page 1/3 05/2008brianlaksonoОценок пока нет

- Statistical Treatment of Some Properties of Beans: Chemistry 3225 K. PierceДокумент2 страницыStatistical Treatment of Some Properties of Beans: Chemistry 3225 K. Piercespiff spacemanОценок пока нет

- Winch DesignДокумент132 страницыWinch DesignShreyas Raut100% (2)

- Iesc 103Документ12 страницIesc 103Debasish DeyОценок пока нет

- Half Yearly - Syllabus Class - XiiДокумент2 страницыHalf Yearly - Syllabus Class - XiiSky SirОценок пока нет

- Catálogo SKODAДокумент14 страницCatálogo SKODAruben colqueОценок пока нет

- Stoich AnsДокумент23 страницыStoich AnsNaze TamarayОценок пока нет

- FormulaДокумент6 страницFormulaLars RembrandtОценок пока нет

- 91988v00 Modeling Industrial Chemical Processes With Matlab and Simulink 04 PPДокумент4 страницы91988v00 Modeling Industrial Chemical Processes With Matlab and Simulink 04 PPEdenson Flores TrujilloОценок пока нет

- 05.lecture110120 GGE2012 PrecisionLeveling ByAhn 2pagesДокумент14 страниц05.lecture110120 GGE2012 PrecisionLeveling ByAhn 2pagesGirma FikreОценок пока нет

- Jee Mains Force and Newton Laws of Motion Ezyexamsolution Sol-03Документ6 страницJee Mains Force and Newton Laws of Motion Ezyexamsolution Sol-03Oyas DubeyОценок пока нет

- PHYS 1220 Coulomb's Law and Electric Fields SolutionsДокумент20 страницPHYS 1220 Coulomb's Law and Electric Fields SolutionsHüthâifâ AbdérahmânОценок пока нет

- Class 12 Biology ProjectДокумент14 страницClass 12 Biology ProjectDhruv Shah100% (3)

- Hello - Bioclad ASTMДокумент4 страницыHello - Bioclad ASTMgrrcОценок пока нет