Академический Документы

Профессиональный Документы

Культура Документы

Welder Responsibilits: S.MOHAN (Welding Supervisor)

Загружено:

Mohan Shanmugam0 оценок0% нашли этот документ полезным (0 голосов)

12 просмотров1 страницаwelder responsibilities

Оригинальное название

Welder Responsibilits

Авторское право

© © All Rights Reserved

Доступные форматы

DOCX, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документwelder responsibilities

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

12 просмотров1 страницаWelder Responsibilits: S.MOHAN (Welding Supervisor)

Загружено:

Mohan Shanmugamwelder responsibilities

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 1

WELDER RESPONSIBILITS

MUST CHECK THE FIT UP OK SIGNATURE FROM THE QC INSPECTOR

DON’T START THE WELDING UNTIL YOU GOT THE SIGNATURE FROM YOUR QC INSPECTOR

EVEN THOUGH SIGNATURE THE FIT UP IS STILL BAD FOR YOUR VIEW, DOES NOT START THE WORK.

ASK THE RESPONSIBLE PERSON

MUST CHECK WELDING PARAMETERS AND APPLICABLE SPECIFICATION

CHECK THE JOINT LOCATIONS AND CLEARANCE FOR BETTER PERFORMANCE

CHECK THE WIND SHIELDS WHETHER THAT ARE ADEQUATE TO MAKE A SOUND WELD

CHECK THE PORTABLE OVENS TEMPRATURE BEFORE FILLING THE ELECTRODE TO ENSURE THE

CONTAMINATION FREE WELDING AND CHECK IN THE FIELD IT IS PLUG IN PROPERLY

CHECK THE CONSUMABLES FOR ANY CONTAMINATION

ROOT PASS IS THE VITAL STRENGTH ONEVERY JOINT TO TAKE CAUTIONS ON IT

CLEAN EVERY PASS TO AVOID INCLUTIONS

AVIOD FATIGUE MISTAKES

GOOD HOUSE KEEPING NEED FOR EFFECTIVE WELDING

TO ACHIEVE QUALITY YOU SHOULD FOLLOW THE RESPONSIBILITIES

Prepared by,

S.MOHAN (welding supervisor)

Вам также может понравиться

- Turnover Punchlist GuidelinesДокумент3 страницыTurnover Punchlist GuidelinesAnonymous lApm6PsfОценок пока нет

- Arpool Linear Recessed Housing 000Документ3 страницыArpool Linear Recessed Housing 000Aljohn AmbatОценок пока нет

- Welding Inspection Technology: Module 7 - Visual Inspection WorkshopДокумент20 страницWelding Inspection Technology: Module 7 - Visual Inspection Workshoprex valenciaОценок пока нет

- ZahoorДокумент1 страницаZahoorzahoorrehman505Оценок пока нет

- PAF RSC System Form 2 Motorcycle Inspection ReportДокумент1 страницаPAF RSC System Form 2 Motorcycle Inspection ReportMorris LandichoОценок пока нет

- Ind Mwide 002 69 Report TC 57Документ6 страницInd Mwide 002 69 Report TC 57Daryl HernandezОценок пока нет

- Manual: Instant Recovery Gas Fryer SERIES PRE-2000Документ32 страницыManual: Instant Recovery Gas Fryer SERIES PRE-2000chjunaidchОценок пока нет

- Auto Processor at Xray EquipДокумент8 страницAuto Processor at Xray EquipNER CARLO SANTOSОценок пока нет

- Quality Control: A Brief Introduction About QUALITY SYSTEMS in M/s. AADHIRA CNC Product PVT LTDДокумент25 страницQuality Control: A Brief Introduction About QUALITY SYSTEMS in M/s. AADHIRA CNC Product PVT LTDsridharanОценок пока нет

- Watersoftner UltraSoft 400 - ManualДокумент36 страницWatersoftner UltraSoft 400 - Manualbece13Оценок пока нет

- Quadratec QRC Front Bumper Install Instructions JKДокумент8 страницQuadratec QRC Front Bumper Install Instructions JKCamilo ArenasОценок пока нет

- Company Profile Print UrutДокумент20 страницCompany Profile Print Urutari supriyantoОценок пока нет

- Script of Cca Eim EditedДокумент4 страницыScript of Cca Eim EditedMhen Maugan100% (1)

- Evaporator Manual IM50.202 ISS 4 0814Документ55 страницEvaporator Manual IM50.202 ISS 4 0814Mikhail YudhiantaraОценок пока нет

- Fe-Gen-St-Xxxxx-Welder Qualification and Control Procedure-R1Документ10 страницFe-Gen-St-Xxxxx-Welder Qualification and Control Procedure-R1Parag WadekarОценок пока нет

- SuperVent and SuperPro Instructions SPR JSC USДокумент50 страницSuperVent and SuperPro Instructions SPR JSC USLucas AlОценок пока нет

- Ind Mwide 002 82 Report PB 04Документ4 страницыInd Mwide 002 82 Report PB 04Daryl HernandezОценок пока нет

- Checklist For Installation of Chemical Fire Suppression SystemДокумент1 страницаChecklist For Installation of Chemical Fire Suppression Systembeho2000100% (1)

- 8.safety Plan - SS 7914Документ3 страницы8.safety Plan - SS 7914GANESH KОценок пока нет

- Rce329a Home Installation GuideДокумент28 страницRce329a Home Installation GuideengrfahadkhanОценок пока нет

- Sgs Cbe Rbs Quality Infographic enДокумент1 страницаSgs Cbe Rbs Quality Infographic enMadawa MaduwanthaОценок пока нет

- Invenio Presentation - Quality ControlДокумент16 страницInvenio Presentation - Quality ControlPavleОценок пока нет

- Job Safety Analysis Worksheet: Yes NoДокумент8 страницJob Safety Analysis Worksheet: Yes NoBorislav VulićОценок пока нет

- Installation Instructions - Fluid Hammer Arrestors - PPP Precision Plumbing ProductsДокумент2 страницыInstallation Instructions - Fluid Hammer Arrestors - PPP Precision Plumbing ProductsChase GietterОценок пока нет

- Value Proposition: Customer SegmentДокумент2 страницыValue Proposition: Customer SegmentOtis MelbournОценок пока нет

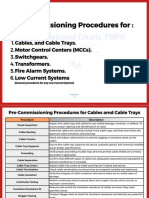

- Pre-Commissioning ProceduresДокумент9 страницPre-Commissioning ProceduresDede IskandarОценок пока нет

- Mechanical QC ProceduresДокумент3 страницыMechanical QC ProceduresricosanojuanОценок пока нет

- Fab&inst Methodology.. Balcony, Hallway RailingsДокумент22 страницыFab&inst Methodology.. Balcony, Hallway RailingsNanette LagundayОценок пока нет

- Safety Manual VNSДокумент58 страницSafety Manual VNSDesh Raj GauttamОценок пока нет

- YES NO: Supplier To CompleteДокумент1 страницаYES NO: Supplier To CompleteSudhaОценок пока нет

- Observation The Corrective Action Work by Authorised Officer Review by Expertice EngineerДокумент2 страницыObservation The Corrective Action Work by Authorised Officer Review by Expertice EngineerDineth LakshanОценок пока нет

- Cutting & Grinding & WeldingДокумент2 страницыCutting & Grinding & Weldingghazi kallelОценок пока нет

- WaterSoftner UltraSoft 425 480 - Manual PDFДокумент36 страницWaterSoftner UltraSoft 425 480 - Manual PDFbece13Оценок пока нет

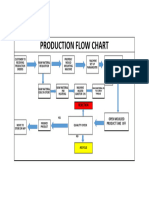

- Production Flow ChartДокумент1 страницаProduction Flow ChartNandha KumarОценок пока нет

- Adindu Nathan Rosemary Siwes Report FullДокумент45 страницAdindu Nathan Rosemary Siwes Report FullPiuskylala PiuskyОценок пока нет

- Ervices AIM Control Provide... : The Viet-Nhan Agriculture - Industry - Marine Control Inspection CorporationДокумент9 страницErvices AIM Control Provide... : The Viet-Nhan Agriculture - Industry - Marine Control Inspection CorporationInspection0% (2)

- Air Compressor On Pick UpДокумент1 страницаAir Compressor On Pick Upengr.haseebbalochОценок пока нет

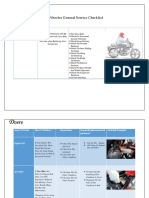

- General Service Checklist - BIKE PDFДокумент7 страницGeneral Service Checklist - BIKE PDFmanasОценок пока нет

- Construction Equipments Operations and MaintenanceДокумент1 страницаConstruction Equipments Operations and MaintenanceQueenie PerezОценок пока нет

- Duke Oven TSC-6-18Документ40 страницDuke Oven TSC-6-18Mua bán Đồ cũОценок пока нет

- FF Water Sprinkler Test ProcedureДокумент2 страницыFF Water Sprinkler Test ProcedureSalim Bakhsh100% (1)

- 4 Bed Rooms Villa Al Burj Al Thaki Mep Work QuoteДокумент3 страницы4 Bed Rooms Villa Al Burj Al Thaki Mep Work QuoteAL BURJ AL THAKIОценок пока нет

- UntitledДокумент8 страницUntitledShoaib ZafarОценок пока нет

- 1MC04-SCJ-QY-REV-SS05 - SL08-000002 - C01 (Signed)Документ4 страницы1MC04-SCJ-QY-REV-SS05 - SL08-000002 - C01 (Signed)sadiqОценок пока нет

- MEI Completion CertificateДокумент1 страницаMEI Completion CertificateMITHUN0% (1)

- Process Analysis For The Company Helados ZuliДокумент20 страницProcess Analysis For The Company Helados ZuliScribdTranslationsОценок пока нет

- Mobile Plant Checklist - ForkliftДокумент1 страницаMobile Plant Checklist - Forkliftosama F. MohamedОценок пока нет

- 1'sfsii: This Is To Certify That: From: Has Been Examined inДокумент5 страниц1'sfsii: This Is To Certify That: From: Has Been Examined inkazemi.rezzОценок пока нет

- Validation DharamshalaДокумент10 страницValidation Dharamshala172-MEET-18Оценок пока нет

- Flanges: Technical Conditions For Supply ofДокумент2 страницыFlanges: Technical Conditions For Supply ofradharaman_znaОценок пока нет

- Factory Compliance RequirementДокумент5 страницFactory Compliance RequirementShafiqulHasanОценок пока нет

- Quadratec QRC Rear Bumper JK 12057.0220 Install Instructions - 1Документ8 страницQuadratec QRC Rear Bumper JK 12057.0220 Install Instructions - 1Camilo ArenasОценок пока нет

- Bottle Jack ManualДокумент9 страницBottle Jack ManualjambomillerОценок пока нет

- Checklist For T&C of Chemical Fire Suppression SystemДокумент2 страницыChecklist For T&C of Chemical Fire Suppression Systembeho2000Оценок пока нет

- Risk Assessment (Electrical Supply) - 1Документ1 страницаRisk Assessment (Electrical Supply) - 1jafarrahimОценок пока нет

- Tamil Vowels 1Документ14 страницTamil Vowels 1Mohan Shanmugam0% (1)

- Reproduced, Without The Prior Consent of The Head of The DepartmentДокумент2 страницыReproduced, Without The Prior Consent of The Head of The DepartmentMohan ShanmugamОценок пока нет

- Tabs For The Song Malare Mounama PDFДокумент1 страницаTabs For The Song Malare Mounama PDFMohan ShanmugamОценок пока нет

- Ilaya Songs With RagaДокумент122 страницыIlaya Songs With RagaMohan ShanmugamОценок пока нет

- Cool Math For Hot Music - A First Introduction To Mathematics For Music Theorists PDFДокумент314 страницCool Math For Hot Music - A First Introduction To Mathematics For Music Theorists PDFMohan Shanmugam100% (7)

- Ilaya Songs With RagaДокумент122 страницыIlaya Songs With RagaMohan ShanmugamОценок пока нет

- Tabs For The Song Yedho Ninaivugal KanavugalДокумент1 страницаTabs For The Song Yedho Ninaivugal KanavugalMohan ShanmugamОценок пока нет