Академический Документы

Профессиональный Документы

Культура Документы

Dover DMC REM. Message PDF

Загружено:

kenОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Dover DMC REM. Message PDF

Загружено:

kenАвторское право:

Доступные форматы

Issued: April 2003

Re f e r e n c e Ma n ua l

REM® Messages for

Dover® DMC

RF - 11

NONDISCLOSURE WARNING

This work contains proprietary information and is the property of

Otis Elevator Company. It is distributed only to those employees

with a need to know the information and may not be reproduced,

disclosed, or distributed to any person outside the employ of

Otis Elevator Company without written authorization from an

officer thereof. Otis competitors, customers, former employees,

retirees, members of the general public, and consultants not

bound by a written nondisclosure agreement are among those

outside the employ of Otis. In the event that an employee in the

possession of this work no longer needs the information, retires,

resigns, is terminated or laid off from Otis, or in the event that

a person outside the employ of Otis comes into possession of

this work, such employee or person should destroy the work

or return it to Otis.

Any unauthorized reproduction, disclosure, or distribution by

any person of any portion of this work may be a breach of a

duty owed by such person to Otis Elevator Company and could

result in damages actionable at law.

PROHIBITION ON COPYING

Any unauthorized reproduction, disclosure, or distribution of

copies by any person of any portion of this work may be a

violation of Copyright Law of the United States of America

and other countries, could result in the awarding of Statutory

Damages of up to $250,000 (17 USC 504) for infringement,

and may result in further civil and criminal penalties. All rights

reserved.

Unpublished Work – © Otis Elevator Company, 2003

Table of Contents

1-006: Condition Resolved.............................. 8

1-009: Low Tank Oil........................................ 9

1-014: Excessive Alerts................................ 11

1-047: Elevator Delayed................................ 12

1-102: Hoistway Door Close Failure

(UNOC2)............................................ 13

1-103: Elevator Failed to Run (UNOC3)........ 14

1-105: Car Doors Failed to Open

(UNOC5)............................................ 15

1-106: Run Too Long (UNOC6)..................... 16

1-116: Low Battery - Replace Battery........... 18

1-117: Low Battery........................................ 19

1-118: Battery Configuration Error................ 20

1-119: Dead Battery or No Battery............... 21

1-120: Unit Powered On But Not

Configured......................................... 22

1-121: Satellite-to-Main Communications

Failed................................................. 23

1-122: Satellite-to-Main Communications Re-

stored................................................. 25

1-123: REM® Unit Powered On.................... 27

1-124: Main-to-Local Communication Link Veri-

fied..................................................... 28

1-125: Elevator-to-REM® Communication Fail-

ure...................................................... 29

1-126: Elevator-to-REM® Communication Re-

stored................................................. 31

1-129: Controller Shutdown.......................... 32

1-130: Front Door Not Opening..................... 33

Unpublished Work – © Otis Elevator Company, 2003

Re f e r e n c e Ma n ua l

1-131: Rear Door Not Opening..................... 34

1-132: Front Door Safety Shoe Stuck On...... 35

1-133: Front Door Light Ray Stuck On.......... 36

1-134: Rear Door Safety Shoe Stuck On...... 37

1-135: Rear Door Light Ray Stuck On.......... 38

1-136: Front Door Communication Failure.... 39

1-137: Rear Door Communication Failure.... 40

1-138: Selector Board Communication

Failure................................................ 41

1-139: Car Shutdown on Stall Protection...... 42

1-140: Car Not Releveling............................. 44

1-141: CLC Battery Failed............................ 45

1-142: CLC Ignoring Requests..................... 46

2-100: Miscellaneous REM® 5 Message Re-

Dover® DMC

ceived................................................. 47

2-101: Service Mode Entered....................... 48

2-102: Service Mode Exited.......................... 49

2-103: Doors Blocked Multiple Times............ 50

2-106: Run Took Too Long............................ 51

2-195: Selector Detected Pulse Count

Problem............................................. 52

for

2-196: Terminal Switch Not Active When Ex-

pected................................................ 53

REM® M e s s a g e s

2-197: Target Floor Sequence Error ............ 54

2-198: Front Door Pulse Count Failure......... 55

2-199: Rear Door Pulse Count Failure.......... 56

2-201: Front Door Loss of 150 Volts.............. 57

2-202: Front Door Light Ray Stuck................ 58

2-203: Front Door Safety Shoe Stuck On...... 59

2-204: Rear Door Light Ray Stuck On.......... 60

2-205: Rear Door Safety Shoe Stuck On...... 61

2-206: Slowdown Interrupt Fault................... 62

Unpublished Work – © Otis Elevator Company, 2003

Table of Contents (continued)

2-207: Rear Door Loss of 150 Volts.............. 63

2-208: Front Door Open Button Stuck On..... 64

2-209: Stuck Hall Button Detected................ 65

2-210: Front Door Limit Problem................... 66

2-211: Overshoot In Up Direction.................. 70

2-212: Overshoot In Down Direction............. 71

2-213: Unknown CLC Fault Logged.............. 72

2-214: Unknown Mode Detected.................. 73

2-215: Overheat During Oil Heating.............. 74

2-216: Oil Heating on Too Long.................... 75

2-217: Rear Door Limit Problem................... 76

2-218: Stuck Car Button................................ 80

2-219: Rear Door Open Button Stuck On..... 81

2-220: Front Door Communication Failure

Detected............................................ 82

2-221: Selector Communication Failure De-

tected................................................. 83

2-222: Rear Door Communication

Detected............................................ 84

2-223: Hoistway Lock Open During Flight..... 85

2-224: Group Communication Failure........... 86

2-225: CLC Communication Failure

Logged............................................... 87

2-226: Front DR Off When Doors Closed...... 88

2-227: Rear DR Off When Doors Closed...... 89

2-228: Front Door Overspeed on Close........ 90

2-229: Rear Door Overspeed on Close......... 91

2-230: DZR on Outside of Door Zone........... 92

2-231: Sensor Missed................................... 93

Unpublished Work – © Otis Elevator Company, 2003

Re f e r e n c e Ma n ua l

2-232: Unknown Front Door Fault

Detected............................................ 94

2-233: Unknown Rear Door Fault

Detected............................................ 95

2-234: Unknown Selector Fault Detected..... 96

2-235: Front DCB Stuck On.......................... 97

2-236: Front DR Open During Flight............. 98

2-237: 120-Volt Chain Open.......................... 99

2-238: Switch Tree Open............................. 100

2-239: Position Fault................................... 101

2-240: Inductor Sequence Error Due

to DZ................................................ 102

2-241: DZ Missing....................................... 103

2-242: LU and LD Stuck On........................ 104

Dover® DMC

2-243: Front Door Voltage Spike or

Armature Problem............................ 105

2-244: Rear Door Voltage Spike or

Armature Problem............................ 106

2-245: CLC Not Responding to

Commands...................................... 107

2-246: 24-Volt Power Supply Failed............ 108

for

2-247: Configuration Table Corrupted......... 109

2-248: Rear DCB Stuck On......................... 110

REM® M e s s a g e s

2-249: Rear DR Open During Flight............ 111

2-250: Front Door Speed Exceeded

While Opening................................. 112

2-251: Rear Door Speed Exceeded

While Opening................................. 113

2-252: DR and DOL Active at the

Same Time....................................... 114

2-253: Rear DR and DOL Active at the

Same Time....................................... 115

Unpublished Work – © Otis Elevator Company, 2003

REM® Messages for

DMC

Otis is a registered trademark of Otis Elevator Company

of Connecticut

Dover is a registered trademark of Dover Corporation

of New York, New York

Freedom Tool is a registered trademark of World

Electronics Sales and Service, Inc. of Reading,

Pennsylvania.

Unpublished Work – © Otis Elevator Company, 2003

Re f e r e n c e Ma n ua l

INTRODUCTION

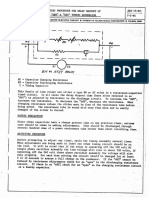

The message code number is made up of

two segments that identify the message

type subtype.

Example: Message 2-132

Message Type = 2. Type 2 messages

do not necessarily warrant a service call.

They indicate a condition that should be

investigated during the next maintenance

visit. Type 1 messages sent to the mechanic

report alarm conditions and do warrant a

service call. (Some Type 1 messages, such

Dover® DMC

as 1-126 and 1-127, do not warrant service

calls; these are filtered by the REM® Center

and not sent to the mechanic.)

Message Subtype = 132. See the message

description for a detailed description of the

symptom and possible root cause(s).

for

REM® M e s s a g e s

Unpublished Work – © Otis Elevator Company, 2003

Type 1 Messages

1-006: Condition Resolved

Explanation:

A previously received Type 1 shutdown

message (usually the last one received) has

been resolved. Expect running on arrival.

NOTE: Does not denote which Type 1 event

was resolved. Rarely, this applies

to an earlier Type 1 event, rather

than the current/active event.

Unpublished Work – © Otis Elevator Company, 2003

Re f e r e n c e Ma n ua l

1-009: Low Tank Oil

Explanation:

The oil level input signal is low when the

car is at the bottom landing. The oil level

sensor will detect oil loss at approximately

4.5 gallons. Oil loss is usually due to leaking

cylinder or cylinder packing.

Causes:

• Leaking Oil – Verify location of missing

Dover® DMC

oil; reclaim/recover if possible. If location

cannot be determined, unit must remain

shut down until missing oil has been

conclusively located.

Empty pit can. If can needs to be emptied

more than once every three months,

for

replace packing and correct leakage.

Report problem to your Supervisor.

REM® M e s s a g e s

Check for leaking cylinder packing and

check cylinder for leaks.

• False Message – If a false oil level

message occurred, check (in order of

probability):

o Oil Level Sensor Float – Is float

(see next page)

Unpublished Work – © Otis Elevator Company, 2003

1-009: Low Tank Oil (continued)

restricted from moving freely? Hidden

floating tank debris may obstruct

proper float operation, or debris

between float and brass shaft may

cause intermittent false messages.

o Oil Temperature – Extremely high

oil temperature can cause float to

lose buoyancy; may require float

replacement and/or better cooling of

hydraulic oil.

o Float Sensor Assembly – Replacement

of float sensor assembly sometimes

stops false messages (use upgraded

assembly p/n 177BH4).

o Improper Sensor Wiring to REM®

Unit – Verify oil level sensor wire is

connected RMH DI-2 (+) and HL1 is

connected to RMH DI-2 (-).

• Oil Level Sensor Adjustment/Failure

– Ensure sensor has ground return to

G24 and P24 (HL1 and 30-volt feed, in

Otis terminology).

• REM® PC – REM® main or satellite board

failed.

Unpublished Work – © Otis Elevator Company, 2003

Re f e r e n c e Ma n ua l

1-014: Excessive Alerts

Explanation:

An excessive number of the same Type 2

message was detected in a 24-hour period.

The default setting in the Alert Threshold

REM® parameter is 10 events in 24 hours.

This parameter can be configured for the

REM® unit from 5 to 99 occurrences.

IMPORTANT NOTE: This setting affects

all Type 2 messages.

Dover® DMC

Causes:

• Refer to the Type 2 message included

in the 1-014 message.

for

REM® M e s s a g e s

Unpublished Work – © Otis Elevator Company, 2003

1-047: Elevator Delayed

Explanation:

The elevator was delayed from responding

to demand for a period longer than the “Car

Delayed” REM® timer value.

Causes:

• Refer to accompanying Type 2

message.

• Safety Chain – Reverse phase relay,

pit safety switch, bottom final limit, top

final limit, car top switch, emergency

exit contact. SC0–SC6 points (switch

tree).

Unpublished Work – © Otis Elevator Company, 2003

Re f e r e n c e Ma n ua l

1-102: Hoistway Door Close Failure

(UNOC2)

Explanation:

Hall or car demand was established and the

doors failed to close within the “INOP2 to

UNOC2” REM® configuration timer.

Causes:

• Door System – Something is blocking the

doors or causing them not to close.

Dover® DMC

• Door Lock – Lock is not making. Early

versions of Dover® software will cycle

doors six times then keep them open;

car will not enter shutdown mode as in

later versions of Dover® software.

for

• Stuck Car Button – Button is stuck in the

active state.

REM® M e s s a g e s

• Gate Switch – Switch is not making.

• 150 V – Voltage supply to door operator

failed. Will also generate Type 2 door

fault indicating loss of 150 volts.

• Relay Board – HWP, HW1, HW2,

HW3. Relay failed or associated wiring

problem.

• Door Control Board – Failed.

Unpublished Work – © Otis Elevator Company, 2003

1-103: Elevator Failed to Run

(UNOC3)

Explanation:

Hall or car demand was established, the

hoistway doors were closed (HWP=1), but

the car failed to run within the “INOP3 to

UNOCC3” REM® configuration timer.

Causes:

• Gate Switch – A car with rear doors may

be at a floor with one opening, with an

open gate switch on the rear doors.

• TBD – Other causes of this error message

are currently under investigation.

Unpublished Work – © Otis Elevator Company, 2003

Re f e r e n c e Ma n ua l

1-105: Car Doors Failed to Open

(UNOC5)

Explanation:

A run was completed but the doors failed to

open within the “INOP5 to UNOCC5” REM®

configuration timer.

Causes:

• Door System – Doors not opening.

Dover® DMC

• Door Control Board – Door control board

is not allowing doors to open. A Type 2

door fault may also be logged.

for

REM® M e s s a g e s

Unpublished Work – © Otis Elevator Company, 2003

1-106: Run Too Long (UNOC6)

Explanation:

A run was started, but the car failed to

complete the run within the “INOP6 to

UNOCC6” REM® configuration timer. Some

of the early versions of Dover® software did

not provide down stall protection.

Causes:

• Run Circuit – Check down run circuit

relay contacts on relay board.

• Valves – Valves failed; start with down

valve.

• Relay Board – HW2, HW3, CST, DN1,

DN2, VMR, or UP2 relays.

• Switch Tree – Bottom directional limit

(BDL).

• Door Lock – Door lock opened in flight

and did not close.

• LD Sensor – LD sensor is missing or there

is a wiring error. Car will not complete

a down run.

Unpublished Work – © Otis Elevator Company, 2003

Re f e r e n c e Ma n ua l

• Emergency Stop Button – Emergency

stop button or switch was activated.

Dover® does not remove run command

when switch is active.

Dover® DMC

for

REM® M e s s a g e s

Unpublished Work – © Otis Elevator Company, 2003

1-116: Low Battery - Replace

Battery

Explanation:

The REM® main unit detected low backup

battery voltage and the battery cannot be

recharged. This message is indicative of

future problems with the REM® unit failing

to report problems when expected.

Causes:

• Connections - Verify battery terminals

are clean, tight, and free from corrosion.

Check for battery leakage and case

swelling.

• Battery – Replace REM® backup battery

at next regular visit or sooner (REM® 5

battery p/n AAA718E3).

Unpublished Work – © Otis Elevator Company, 2003

Re f e r e n c e Ma n ua l

1-117: Low Battery

Explanation:

The REM® main unit detected low backup

battery voltage. Main AC power has

probably been removed and the battery is

discharged. No mechanic action normally

required unless this message continues to

be dispatched. May also indicate the backup

battery is failing.

Dover® DMC

for

REM® M e s s a g e s

Unpublished Work – © Otis Elevator Company, 2003

1-118: Battery Configuration Error

Explanation:

The REM® main unit detected an error in

the configuration parameter that indicates

presence or absence of a battery backup.

This is a REM® installation message and

normally does not require field attention. If

this message continues to be generated,

notify a REM® Center engineer.

Unpublished Work – © Otis Elevator Company, 2003

Re f e r e n c e Ma n ua l

1-119: Dead Battery or No Battery

Explanation:

The REM® main unit detected its battery is

dead or not installed.

Cause:

• REM ® Battery – Replace battery.

Check battery connection. Check

configuration information for proper

battery configuration.

Dover® DMC

for

REM® M e s s a g e s

Unpublished Work – © Otis Elevator Company, 2003

1-120: Unit Powered On But Not

Configured

Explanation:

A main or satellite unit was powered on but

not configured. This is a REM® installation

message that normally occurs when the

REM® Center CSR is configuring the unit.

The message indicates that configuration has

succeeded far enough for the REM® unit to

know how to call the REM® Center, but not

far enough to know what kind of equipment

it is talking to.

Cause:

• Incomplete Configuration – Typically

caused by an incomplete site

configuration. Ask REM® Center to

reconfigure unit if no messages are

received from controller after this one.

Unpublished Work – © Otis Elevator Company, 2003

Re f e r e n c e Ma n ua l

1-121: Satellite-to-Main

Communications Failed

Explanation:

Communication failed between the main

REM® unit and a satellite unit. If failed and

restored messages occur excessively or

unexpectedly, closer examination of the

REM® system is recommended, as the REM®

system has become unreliable.

Causes:

• RF Interference – Verify RMH-RMH Dover® DMC

communications cable is not routed next

to any high frequency RF source (e.g.,

motor leads on VF sites or incoming

building power leads).

for

• Line Terminators – Verify RMH-RMH

horizontal bus cable line terminators are

REM® M e s s a g e s

installed only at far ends of cable run for

this group of REM® units. Line terminators

should be placed from “R” terminal to

“-” terminal.

• Address Conflicts – Check REM ®

addressing for conflicts. No two REM®

units in the group may use the same

(see next page)

Unpublished Work – © Otis Elevator Company, 2003

1-121: Satellite-to-Main

Communications Failed

(continued)

address (dip switches 1–4 on REM®

5).

• Power – Verify power feed to all REM®

5 units is 105–125 VAC.

• Replace REM® Unit – Not a common

solution for this problem.

Unpublished Work – © Otis Elevator Company, 2003

Re f e r e n c e Ma n ua l

1-122: Satellite-to-Main

Communications Restored

Explanation:

Communication restored between the main

REM® unit and a REM® satellite unit. If this

error message appears often, it may indicate

a communication problem.

Causes:

• No action necessary if message was

Dover® DMC

expected.

• Communications Link – Check REM®

Online web site and check for excessive

occurrences of this message. If message

appears random or unexplained,

for

troubleshoot RMH-to-RMH communi-

cations link:

REM® M e s s a g e s

1. Check for loose wires, transient

voltages.

2. Ensure routing communications cable

is not next to motor leads or incoming

building power.

(see next page)

Unpublished Work – © Otis Elevator Company, 2003

1-122: Satellite-to-Main

Communications Restored

(continued)

NOTE: On some sites, communications

cable must be run in separate conduit

to be fully isolated from effects of

induced EMF interference and

eliminate problem completely.

• Power – Check REM® unit 110 VAC

supply, wiring, and fuses.

Unpublished Work – © Otis Elevator Company, 2003

Re f e r e n c e Ma n ua l

1-123: REM® Unit Powered On

Explanation:

AC power was restored to the REM® main

box. If the cause is known, no mechanic

action is normally required. If the message

appears excessively or unexpectedly, check

the unit for a bad backup battery and/or poor

or intermittent 110 VAC power source.

Causes:

Dover® DMC

• No action necessary if message was

expected.

• Backup Battery – Bad, dead, or

disconnected backup battery when

110 VAC power removed and then

returned.

for

• POR – Mechanic PORed REM® unit.

REM® M e s s a g e s

• Power – Low voltage supply. Measure

110 VAC input voltage at REM® unit and

verify it is greater than 105 VAC.

Unpublished Work – © Otis Elevator Company, 2003

1-124: Main-to-Local Communication

Link Verified

Explanation:

Periodically the REM® main units will call the

local to verify that an outgoing call can be

completed. This message is confirmation

that the call was completed. For controllers

with little to no message activity this message

enables the REM® Center to periodically

verify that the REM® main unit and phone lines

are working properly and can successfully

report any recorded faults if they do occur.

Cause:

• No action necessary. This message

is generated to help track noncom-

municating units that have bad phone

lines or bad REM® unit. If this message

is obtained, it verifies that the REM® unit,

line share device, and telephone service

are all working properly for an outbound

call. This message is only seen on REM®

main unit machine numbers—satellite

units will not generate this message.

Unpublished Work – © Otis Elevator Company, 2003

Re f e r e n c e Ma n ua l

1-125: Elevator-to-REM®

Communication Failure

Explanation:

The REM ® box is no longer able to

communicate with the elevator-enhanced

diagnostics via the serial link. This message

is only generated once unless the REM® unit

is PORed or the problem is corrected and

then occurs again.

Causes:

• Building Power Loss – When building Dover® DMC

power is lost, REM® unit will run on

battery backup but controller will not be

powered up.

for

• Fuse – Fuse F1 caused the loss of AC

voltage.

REM® M e s s a g e s

• System Power Supply – 5-volt or 12-volt

side of system power supply (located

in car operating panel) failed. There

are two adjustment pots on the board.

Verify that it was not vandalized. Output 1

should be 5 volts and output 2 should be

12 volts. If REM® can talk to CLC but CLC

is generating communication failures

(see next page)

Unpublished Work – © Otis Elevator Company, 2003

1-125: Elevator-to-REM®

Communication Failure

(continued)

with all devices in system (door boards

and selector), check 12-volt side.

• REM® Box PC – Check REM® box

processor and associated wiring.

Replace board if communication wiring

to controller is OK.

• Dover® Converter (REM® - CLC Serial

Link Converter) – Check loose wire,

check power feed, replace converter.

• CLC Board – Communication line

locked up or failed. Check Dover®

communication line termination.

Unpublished Work – © Otis Elevator Company, 2003

Re f e r e n c e Ma n ua l

1-126: Elevator-to-REM®

Communication Restored

Explanation:

Communication was re-established between

the REM® unit and the controller.

Causes:

• No action required if message was

expected

Dover® DMC

• Dover® Converter (REM® - CLC Serial

Link Converter) – Troubleshoot REM®-

to-CLC serial communications cable

and converter box. Elevator controller

processor may be failing and need to be

replaced.

for

REM® M e s s a g e s

Unpublished Work – © Otis Elevator Company, 2003

1-129: Controller Shutdown

Explanation:

The CLC entered shutdown mode 0.

Cause:

• Other Type 2 Fault – Refer to the last

Type 2 fault listed by the message.

Unpublished Work – © Otis Elevator Company, 2003

Re f e r e n c e Ma n ua l

1-130: Front Door Not Opening

Explanation:

The doors were commanded to open but did

not begin to open.

Causes:

• Door System – Door unable to open.

• Power – 150-volt supply to door failed.

Message 2-219 will also be generated.

Dover® DMC

• Door Fault – Type 2 fault reported by

door board.

• Door Control Board – Front door control

board failed.

for

REM® M e s s a g e s

Unpublished Work – © Otis Elevator Company, 2003

1-131: Rear Door Not Opening

Explanation

The doors were commanded to open but

never started to open.

Causes:

• Door System – Door unable to open.

• Power – 150-volt supply to door failed.

Message 2-220 will also be generated.

• Door Fault – Type 2 fault reported by

rear door board.

• Door Control Board – Rear door control

board failed.

Unpublished Work – © Otis Elevator Company, 2003

Re f e r e n c e Ma n ua l

1-132: Front Door Safety Shoe

Stuck On

Explanation:

The Dover® system will label a reversal

stuck if a reversal device sticks on for a

configurable period of time (the default

time is four minutes). Once detected, the

device is disabled and the doors are nudged

closed. The device is disabled until the signal

provides a zero reading (off). This message

is generated if the device is stuck on for

Dover® DMC

a consecutive number of door operations

specified by the REM® configuration timer

“Excessive door closings”.

Causes:

for

• Reversal – Safety shoe stuck on.

• Door System – Blocked doors, failure of

REM® M e s s a g e s

door control board.

Unpublished Work – © Otis Elevator Company, 2003

1-133: Front Door Light Ray

Stuck On

Explanation:

The Dover® system will label a reversal

stuck if a reversal device sticks on for a

configurable period of time (the default

time is four minutes). Once detected, the

device is disabled and the doors are nudged

closed. The device is disabled until the signal

provides a zero reading (off). This message

is generated if the device stays stuck on for

a consecutive number of door operations

specified by the REM® configuration timer

“Excessive door closings”.

Causes:

• Reversal – Light ray stuck on.

• Door System – Blocked doors, door

control board failure.

Unpublished Work – © Otis Elevator Company, 2003

Re f e r e n c e Ma n ua l

1-134: Rear Door Safety Shoe

Stuck On

Explanation:

The Dover® system will label a reversal

stuck if a reversal device sticks on for a

configurable period of time (the default

time is four minutes). Once detected, the

device is disabled and the doors are nudged

closed. The device is disabled until the signal

provides a zero reading (off). This message

is generated if the device stays stuck on for

Dover® DMC

a consecutive number of door operations

specified by the REM® configuration timer

“Excessive door closings”.

Causes:

for

• Reversal – Safety shoe stuck on.

• Door System – Blocked doors, door

REM® M e s s a g e s

control board failure.

Unpublished Work – © Otis Elevator Company, 2003

1-135: Rear Door Light Ray

Stuck On

Explanation:

The Dover® system will label a reversal

stuck if a reversal device sticks on for a

configurable period of time (the default

time is four minutes). Once detected, the

device is disabled and the doors are nudged

closed. The device is disabled until the signal

provides a zero reading (off). This message

is generated if the device stays stuck on for

a consecutive number of door operations

specified by the REM® configuration timer

“Excessive door closings”.

Causes:

• Reversal – Safety shoe stuck on.

• Door System – Blocked doors, door

control board failure.

Unpublished Work – © Otis Elevator Company, 2003

Re f e r e n c e Ma n ua l

1-136: Front Door

Communication Failure

Explanation:

The front door control board can no longer

communicate with the CLC.

Causes:

• Door Control Board – Front door control

board failed or lost power.

Dover® DMC

• System Power Supply – 5-volt or 12-volt

side of system power supply (located in

car operating panel) failed. There are two

adjustment pots on the board. Verify that

it was not vandalized. Output 1 should

be 5 volts and output 2 should be 12

for

volts. If REM® can talk to CLC but CLC

is generating communication failures

with all devices in system (door boards

REM® M e s s a g e s

and selector), check 12-volt side.

• Line Termination – Improper termination

of RS-485 communication line. Shields

of the two communication lines at DOC1

connection should be tied together.

Unpublished Work – © Otis Elevator Company, 2003

1-137: Rear Door

Communication Failure

Explanation:

The rear door control board can no longer

communicate with the CLC.

Causes:

• Door Control Board – Rear door control

board failed or lost power.

• System Power Supply – 5-volt or 12-volt

side of system power supply (located in

car operating panel) failed. There are

two adjustment pots on board. Verify that

it was not vandalized. Output 1 should

be 5 volts and output 2 should be 12

volts. If REM® can talk to CLC but CLC

is generating communication failures

with all devices in system (door boards

and selector), check 12-volt side.

• Line Termination – Improper termination

of RS-485 communication line. Shields

of the two communication lines at DOC1

connection should be tied together.

Unpublished Work – © Otis Elevator Company, 2003

Re f e r e n c e Ma n ua l

1-138: Selector Board

Communication Failure

Explanation:

The CLC cannot communicate with the

selector. A call to the elevator will cause

it to run to a terminal limit and eventually

shutdown at 1 on stall protection.

Causes:

• Selector Board – Control board failed or

Dover® DMC

lost power.

• System Power Supply – 5-volt or 12-volt

side of system power supply (located in

car operating panel) failed. There are

2 adjustment pots on the board. Verify

for

that it was not vandalized. Output 1

should be 5 volts and output 2 should

be 12 volts. If REM® can talk to CLC

REM® M e s s a g e s

but CLC is generating communi-cation

failures with all devices in system

(door boards and selector), check

12-volt side.

• Line Termination – Improper termination

of RS-485 communication line. Shields

of the two communication lines at CS1

connection should be tied together.

Unpublished Work – © Otis Elevator Company, 2003

1-139: Car Shutdown on

Stall Protection

Explanation:

An up stall protection was detected and

the car returned to the bottom landing and

shut down.

Causes:

• Up Valves – Up valve failed or needs

adjustment. Check/replace small filter

in valve, which tends to clog.

• Relay Board – FST relay. Car will run

up at leveling speed.

• Switch Tree – UTS, TSL, or associated

wiring. If car fails to run at all, check up

terminal slowdown and terminal speed

limiting switches.

• Relay Board – HW3, HW2, CST, VMR or

UMD relays or associated wiring. CLC

will energize UMD (up motion disable)

relay during down runs. Make sure signal

is not active if event buffer shows no car

motion (DZ off signal not seen after start

of run).

Unpublished Work – © Otis Elevator Company, 2003

Re f e r e n c e Ma n ua l

• Selector Board – Circuit board failure.

• Leveling Problem – Car may have trouble

leveling when oil gets cold. Adjust for

firmer up start. Add tank heater or enable

oil heating with Freedom Tool®.

• Pump – Failed to start.

• Thermal Overload Contact – Check

overload contacts.

• Temperature Sensors – OTS1 failed,

causing oil to overheat during heating

operation.

Dover® DMC

• Door Locks – Door lock opened during run

(2-223 message) and never closed.

• LU Sensor – LU not seen on type 1A

controller.

• Terminal Direction Limit – Car was parked

for

at top landing, sagged to LU and could

not level because terminal direction limit

(TDL) was open. Check event buffer.

REM® M e s s a g e s

• CLC Board – UMD or RUM output wiring

or board failed.

Unpublished Work – © Otis Elevator Company, 2003

1-140: Car Not Releveling

Explanation:

The elevator is stopped on LU or LD and not

releveling to the floor for a period specified

by the REM® configuration value “Rear Door

Cycle”.

Causes:

• CLC Board – LE output or associated

wiring.

• Relay Board – FST, LU, LD, or DZ

relays.

• Terminal Direction Limit – Car is at

terminal floor and directional limit is

open.

Unpublished Work – © Otis Elevator Company, 2003

Re f e r e n c e Ma n ua l

1-141: CLC Battery Failed

Explanation:

The battery on the CLC failed. All RAM data

was lost, so RAM needs to be reloaded.

Causes:

• Battery – Battery is defective.

• CLC Board – Board failed.

Dover® DMC

for

REM® M e s s a g e s

Unpublished Work – © Otis Elevator Company, 2003

1-142: CLC Ignoring Requests

Explanation:

The Dover® CLC is not responding to requests

from the REM® unit.

Causes:

• Dover® Converter – RS-422 to RS-485

REM® converter failed. REM® wiring to

converter is incorrect. Notify Engineering

if converter is not the problem.

Unpublished Work – © Otis Elevator Company, 2003

Re f e r e n c e Ma n ua l

Type 2 Messages

2-100: Miscellaneous REM® 5

Message Received

Explanation:

A REM® 5 message used by European REM®

was received. No action is normally required

unless this message occurs excessively.

Dover® DMC

for

REM® M e s s a g e s

Unpublished Work – © Otis Elevator Company, 2003

2-101: Service Mode Entered

Explanation:

The REM® main or satellite service button

was activated.

Unpublished Work – © Otis Elevator Company, 2003

Re f e r e n c e Ma n ua l

2-102: Service Mode Exited

Explanation:

The REM® main or satellite service button

was deactivated.

Dover® DMC

for

REM® M e s s a g e s

Unpublished Work – © Otis Elevator Company, 2003

2-103: Doors Blocked

Multiple Times

Explanation:

The doors were blocked for more than the

time-out period specified by the REM®

configuration value “INOP2 blocked doors”

(default time is 2 minutes) and this occurred

a specified number of times (default

occurrences is twice) in a 1-hour period.

Note that the car had further demand when

the doors were held open.

Causes:

• Reversal – Sticking or false firing.

• Hall Button – Sticking.

• Car Button – Sticking.

• Door System – Motion inhibited.

Unpublished Work – © Otis Elevator Company, 2003

Re f e r e n c e Ma n ua l

2-106: Run Took Too Long

Explanation:

A run started but did not complete within the

time-out period (REM® timer 16).

Causes:

• Run Circuit – Check down run circuit

relay contacts on relay board.

• Valves – Valves failed; start with down

Dover® DMC

valve.

• Relay Board – HW2, HW3, CST, DN1,

DN2, VMR, or UP2 relays.

• Switch Tree – Bottom directional limit

(BDL).

for

• Door Lock – Opened in flight, on down

run, and failed to close.

REM® M e s s a g e s

Unpublished Work – © Otis Elevator Company, 2003

2-195: Selector Detected Pulse

Count Problem

Explanation:

The selector board detected a problem with

the pulse counts received.

Causes:

• Selector Tape – Check tape tension and

adjust or replace guides.

NOTE: Guides can be reversed one

time.

• Main Sensor Board – Main selector

sensor board failed.

• Selector Board

Unpublished Work – © Otis Elevator Company, 2003

Re f e r e n c e Ma n ua l

2-196: Terminal Switch Not Active

When Expected

Explanation:

The elevator stopped at a terminal landing

and the terminal limit UTS or DTS did not

activate when expected.

Causes:

• Switch Tree – UTS or DTS (refer to

message). Contact was not activated

Dover® DMC

when expected.

• Selector Board – Check inputs and

wiring.

for

REM® M e s s a g e s

Unpublished Work – © Otis Elevator Company, 2003

2-197: Target Floor

Sequence Error

Explanation:

The CLC generated a target fault error

07 00. The selector detected an invalid

change in position, at the reported floor.

Causes:

• Selector Tape – Check tape tension and

adjust or replace guides and magnet

alignment.

• Rails – Check lubrication cans on top of

car. Check ride for smoothness.

• Selector Board – Selector board or main

sensor board failed.

Unpublished Work – © Otis Elevator Company, 2003

Re f e r e n c e Ma n ua l

2-198: Front Door Pulse

Count Failure

Explanation:

The front door board generated a pulse

count failure.

Cause:

• Door Control Board – Check DOC2

connections and motor sensor or replace

board.

Dover® DMC

for

REM® M e s s a g e s

Unpublished Work – © Otis Elevator Company, 2003

2-199: Rear Door Pulse

Count Failure

Explanation:

The rear door board generated a pulse

count failure.

Cause:

• Door Control Board – Check DOC2

connections and motor sensor or replace

board.

Unpublished Work – © Otis Elevator Company, 2003

Re f e r e n c e Ma n ua l

2-201: Front Door Loss of

150 Volts

Explanation:

The front door board detected a loss of 150

volts.

Causes:

• 150 Volt Door Power Supply – Check 150-

volt door power supply and associated

wiring and fuse F6 on relay board. Power

Dover® DMC

circuit is on relay board.

• Door Control Board – Fuse F1 on front

door board or board itself failed.

• Traveling Cable Wire – Check for possible

break in TC wire or loose connection.

for

REM® M e s s a g e s

Unpublished Work – © Otis Elevator Company, 2003

2-202: Front Door Light Ray Stuck

Explanation:

The front door light ray has been on for a

period of time that is Dover®-configurable

(the CLC timer “Stuck door sensor device

timer” default is four minutes). The reversal

device is disabled until the signal clears and

the doors are nudged closed.

Causes:

• Door System – Someone is blocking

door.

• Light Ray – Light ray is stuck on or there

is a wiring problem.

• Configuration Parameter – CLC

configuration parameter # 14 (not

available for three-chip CLC) “stuck door

sensor device timer” is set too short.

Should be set to at least 60 seconds.

• Door Control Board – Front door control

board failed.

Unpublished Work – © Otis Elevator Company, 2003

Re f e r e n c e Ma n ua l

2-203: Front Door Safety Shoe

Stuck On

Explanation:

The front door safety shoe has been on for

a period of time that is Dover®-configurable

(the CLC timer “Stuck door sensor device

timer” default is four minutes). The reversal

device is disabled until the signal clears and

the doors are nudged closed.

Causes:

• Door System – Someone is blocking Dover® DMC

door.

• Safety Shoe – Safety shoe is stuck on

or there is a wiring problem.

for

• Configuration Parameter – CLC

configuration parameter # 14 (not

REM® M e s s a g e s

available for three-chip CLC) “stuck door

sensor device timer” is set too short.

Should be set to at least 60 seconds.

• Door Control Board – Front door control

board failed.

Unpublished Work – © Otis Elevator Company, 2003

2-204: Rear Door Light Ray

Stuck On

Explanation:

The rear door light ray has been on for a

period of time that is Dover®-configurable

(the CLC timer “Stuck door sensor device

timer” default is four minutes). The reversal

device is disabled until the signal clears and

the doors are nudged closed.

Causes:

• Door System – Someone is blocking

door.

• Light Ray – Light ray is stuck on or there

is a wiring problem.

• Configuration Parameter – CLC

configuration parameter # 14 (not

available for three-chip CLC) “stuck door

sensor device timer” is set too short.

Should be set to at least 60 seconds.

• Door Control Board – Front door control

board failed.

Unpublished Work – © Otis Elevator Company, 2003

Re f e r e n c e Ma n ua l

2-205: Rear Door Safety Shoe

Stuck On

Explanation:

The rear door safety shoe has been on for

a period of time that is Dover®-configurable

(the CLC timer “Stuck door sensor device

timer” default is four minutes). The reversal

device is disabled until the signal clears and

the doors are nudged closed.

Causes:

• Door System – Someone is blocking Dover® DMC

door.

• Safety Shoe – Safety shoe is stuck on

or there is a wiring problem.

for

• Configuration Parameter – CLC

configuration parameter # 14 (not

REM® M e s s a g e s

available for three-chip CLC) “stuck door

sensor device timer” is set too short.

Should be set to at least 60 seconds.

• Door Control Board – Front door control

board failed.

Unpublished Work – © Otis Elevator Company, 2003

2-206: Slowdown Interrupt Fault

Explanation:

As the car activates the SI signal, this

message indicates that it is time to slow down

into a floor. The message is sent from the

selector to the CLC at the slowdown point.

This 24-volt signal originates at connector

CS9, pin 3, of the selector then goes to

terminal block CSX2, pin 7, then to the CLC

connector LCC11, pin 18. If the selector

board is mounted on the side of the controller

where the wires are run with door signals or

through the door operator, noise may cause

intermittent faults.

Causes:

• DC Power – Current setting for starter

may be too high, causing 24-volts to drop

when car starts.

• CLC Board – Check connector at LCC11,

pin 18. Replace board.

• Selector Board – Check wiring CS9, pin

3, through to CLC board. Move wire

away from door control signals if noise

is indicated. If interrupt is indicated as

failed, transistor Q5 on selector board

may have failed.

Unpublished Work – © Otis Elevator Company, 2003

Re f e r e n c e Ma n ua l

2-207: Rear Door Loss of

150 Volts

Explanation:

The rear door board detected a loss of 150

volts.

Causes:

• 150 Volts – The 150-volt door power

supply or associated wiring. Fuse F6

on relay board. The power circuit is on

Dover® DMC

the relay board.

• Door Control Board – Fuse F1 on rear

door board—or board itself—failed.

• Traveling Cable Wire – Break in wire or

loose connection.

for

REM® M e s s a g e s

Unpublished Work – © Otis Elevator Company, 2003

2-208: Front Door Open Button

Stuck On

Explanation:

The front door-open button was held in for a

period of time that can be Dover®-configured

(the CLC timer “Door open time—stuck

button” default is one minute). The DOB will

be disabled until the signal reads 0 (off).

Causes:

• DOB – Door-open button stuck on or

failed, or there is a wiring problem.

• Configuration Parameter – CLC

configuration parameter 7 (6 for three-

chip CLC), “Door open time—stuck

button”, set too short. Value should be

at least 60 seconds.

• CLC Board – Board failed.

Unpublished Work – © Otis Elevator Company, 2003

Re f e r e n c e Ma n ua l

2-209: Stuck Hall Button Detected

Explanation:

A hall button was held in for a period of time

that can be Dover®-configured (the CLC timer

“Door open time—stuck button” default is

one minute).

Causes:

• Hall Button – Hall button stuck, or there

is a wiring problem.

Dover® DMC

• CLC Board – Board failed.

for

REM® M e s s a g e s

Unpublished Work – © Otis Elevator Company, 2003

2-210: Front Door Limit Problem

Explanation:

The doors were commanded to open or close

but failed to reach the limit (DOL or DCL)

within the time specified by CLC configuration

parameter “door fail time”. The signals that

contribute to this fault are gate switch (DR),

door close limit (DCL) or hoistway lock (HWP)

for the closing direction, and door open limit

(DOL) for the opening direction. The event

buffer and the second line of the message

will be very helpful.

DR is the gate switch, HWP is the hoistway

locks, DCL is the door close limit on the

door motor shaft, and FDOL is the status

of front door open limit. The gate switch,

DR, should energize 1.5–2 inches from fully

closed. The hoistway lock should follow

DR and energize before DCL. DCL should

energize about 0.375 inch from the final stop

and should remain energized once the doors

have stopped. If DOL or DCL are moved,

you must run the door setup sequence on

the Freedom Tool®, which will restore the

default door parameters, then re-enter the

values last adjusted.

Unpublished Work – © Otis Elevator Company, 2003

Re f e r e n c e Ma n ua l

The spirator plays an important role in the

door profile. Tension should be equal on

all floors.

A Dover® software bug may cause this

message if the door system has a light ray.

The CLC may command the doors to close

when the light ray is active, but the doors will

not honor the command. When a door limit

problem is determined, the CLC commands

the doors to override the light ray signal.

More recent versions of door software honor

this and close the doors at normal speed,

relying on the safety shoe. Older versions

of door software will cause the car to lock

Dover® DMC

up as long as the light ray is active.

NOTE: If the gate switch or door lock do not

make after six attempts, the car will

shut down with the door open.

for

Causes:

REM® M e s s a g e s

• Door Lock – Door lock not making. If lock

doesn’t make when there is no demand,

linkage may have slipped. Fix and pin

linkage.

• Door System – Doors blocked or motion

inhibited. Door power is removed when

there is no demand, allowing doors to

(see next page)

Unpublished Work – © Otis Elevator Company, 2003

2-210: Front Door Limit Problem

(continued)

sag. This may be enough to break DCL,

gate switch, or hoistway lock. Make sure

spirator tension is consistent on all floors.

Opening hoistway door with drop key

may also generate this message.

• Door Gib – Door gib is inhibiting motion,

so doors could not reach fully open

position.

• Light Ray – Old door software and stuck

light ray causing software bug.

• Configuration Parameter – Current CLC

configuration parameters related to door

operation may be contributing to this

fault. If nudging is enabled (“nudging

operation” = 1), adjust CLC configura-tion

parameter “door fail time” to 7 seconds

longer than “nudging time”. Low values

yield short delayed car and door retry if

door lock fails to make. High values yield

longer time before delayed car and door

retry operations.

To test for this as the cause, stall doors

when almost fully closed and check

whether door configuration parameter

9 (close speed manual) can make

Unpublished Work – © Otis Elevator Company, 2003

Re f e r e n c e Ma n ua l

DCL, DR, and hoistway lock. Increase

parameter if necessary, which may

require additional door parameter

adjustments. For example, parameter

7 (close high speed), may need to be

reduced if doors close too hard during

normal close. Verify spirator tension is

consistent on all floors.

Dover® DMC

for

REM® M e s s a g e s

Unpublished Work – © Otis Elevator Company, 2003

2-211: Overshoot In Up Direction

Explanation:

The car ended an up run on the level down

inductor.

Causes:

• Magnet Alignment – Adjust magnets at

landing of reported problem.

• Run Adjustment – Adjust run in up

direction.

Unpublished Work – © Otis Elevator Company, 2003

Re f e r e n c e Ma n ua l

2-212: Overshoot In Down Direction

Explanation:

The car ended a down run on the level up

inductor.

Causes:

• Magnet Alignment – Adjust magnets at

landing of reported problem.

• Run Adjustment – Adjust run in down

Dover® DMC

direction.

for

REM® M e s s a g e s

Unpublished Work – © Otis Elevator Company, 2003

2-213: Unknown CLC Fault Logged

Explanation:

An unknown fault was logged by the CLC.

Cause:

• Unknown – Contact REM® Center to

investigate message source.

Unpublished Work – © Otis Elevator Company, 2003

Re f e r e n c e Ma n ua l

2-214: Unknown Mode Detected

Explanation:

The CLC entered a mode that has not yet

been documented.

Cause:

• Unknown – Contact REM® Center to

investigate message source.

Dover® DMC

for

REM® M e s s a g e s

Unpublished Work – © Otis Elevator Company, 2003

2-215: Overheat During Oil Heating

Explanation:

The over-temperature sensor OTS2 indicated

oil overheating during the oil heating

operation.

Causes:

• Temperature Sensor – Sensor OTS1

failed indicating cold oil.

• CLC Board – Failed input or temperature

input wiring error.

Unpublished Work – © Otis Elevator Company, 2003

Re f e r e n c e Ma n ua l

2-216: Oil Heating on Too Long

Explanation:

The elevator returned to the bottom landing

and attempted to heat the oil, staying on

too long.

Causes:

• Relay Board – VMR relay not

energizing.

Dover® DMC

• CLC Board – Failed output or VMR output

wiring problem.

• Temperature Sensor – OTS1 failed while

stuck on.

for

REM® M e s s a g e s

Unpublished Work – © Otis Elevator Company, 2003

2-217: Rear Door Limit Problem

Explanation:

The doors were commanded to open or close

but failed to reach the limit (RDOL or RDCL)

within the time specified by CLC configuration

parameter “door fail time”. The signals that

contribute to this fault are gate switch (DR),

rear door close limit (RDCL) or hoistway lock

(HWP) for the closing direction, and rear door

open limit (RDOL) for the opening direction.

The event buffer and the second line of the

message will be very helpful.

DR is the gate switch, HWP is the hoistway

locks, RDCL is the door close limit on the

door motor shaft, and RDOL is the status

of rear door open limit. The gate switch,

DR, should energize 1.5–2 inches from fully

closed. The hoistway lock should follow DR

and energize before RDCL. RDCL should

energize about 0.375 inch from the final stop

and should remain energized once the doors

have stopped. If RDOL or RDCL are moved,

you must run the door setup sequence on

the Freedom Tool®, which will restore the

default door parameters, then re-enter the

values last adjusted.

Unpublished Work – © Otis Elevator Company, 2003

Re f e r e n c e Ma n ua l

The spirator plays an important role in the

door profile. Tension should be equal on all

floors.

A Dover® software bug can cause this

message if the door system has a light ray.

The CLC may command the doors to close

when the light ray is active and the doors will

not honor the command. When a door limit

problem is determined, the CLC commands

the doors to override the light ray signal.

More recent versions of door software honor

this and close the doors at normal speed,

relying on the safety shoe. Older versions

of door software cause the car to lock up as

Dover® DMC

long as the light ray is active.

NOTE: If the gate switch or door lock do

not make after six attempts, the car

shuts down with the doors open.

for

Causes:

REM® M e s s a g e s

• Door Lock – Lock not making. If lock

doesn’t make when there is no demand,

linkage may have slipped. Fix and pin

linkage.

• Door System – Doors blocked or motion

inhibited. Door power is removed when

there is no demand, allowing doors to

(see next page)

Unpublished Work – © Otis Elevator Company, 2003

2-217: Rear Door Limit Problem

(continued)

sag. This may be enough to break DCL,

gate switch, or hoistway lock. Make

sure spirator tension is consistent on all

floors.

• Door Gib – Inhibiting motion, doors could

not reach fully open.

• Light Ray – Software bug in old door

software caused by stuck light ray.

• Gate Switch – Gate switch signal DR

failed to make. Check adjustment and

for loose wire.

• Configuration Parameter – Current CLC

configuration parameters related to door

operation may be contributing to this

fault. If nudging is enabled (“nudging

operation” = 1), adjust CLC configuration

parameter “door fail time” to 7 seconds

longer than “nudging time”. Low values

yield short delayed car and door retry if

door lock fails to make. High values yield

longer time before delayed car and door

retry operations.

Unpublished Work – © Otis Elevator Company, 2003

Re f e r e n c e Ma n ua l

To test for this as the cause, stall doors

when almost fully closed and check

whether door configuration parameter

9 (close speed manual) can make

RDCL, DR, and hoistway lock. Increase

parameter if necessary, which may

require additional door parameter

adjustments. For example, parameter

7 (close high speed), may need to be

reduced if doors close too hard during

normal close. Verify spirator tension is

consistent on all floors.

Dover® DMC

for

REM® M e s s a g e s

Unpublished Work – © Otis Elevator Company, 2003

2-218: Stuck Car Button

Explanation:

A car button was held for a period of time

that is Dover®-configurable (the CLC timer

“Door open time—stuck button” default is

one minute). With early versions of Dover®

software a 0 is reported instead of the number

of the car button that failed. Use the event

buffer to identify the landing.

Causes:

• Car Button – Button stuck or someone

holding button.

• CLC Board – Input or wiring to board

failed.

Unpublished Work – © Otis Elevator Company, 2003

Re f e r e n c e Ma n ua l

2-219: Rear Door Open Button

Stuck On

Explanation:

The rear door-open button was held in for a

period of time that is Dover®-configurable (the

CLC timer “Door open time—stuck button”

default is one minute). The rear DOB will be

disabled until the signal reads 0 (off).

Causes:

Dover® DMC

• DOB – Rear door open button stuck on,

failed, or there is a wiring problem.

• CLC Board – Board failed.

for

REM® M e s s a g e s

Unpublished Work – © Otis Elevator Company, 2003

2-220: Front Door Communication

Failure Detected

Explanation:

Communication failed between the CLC and

the front door.

Causes:

• Door Control Board – Front door control

board failed or lost power.

• Line Termination – Improper termination

of RS-485 communication line.

Unpublished Work – © Otis Elevator Company, 2003

Re f e r e n c e Ma n ua l

2-221: Selector Communication

Failure Detected

Explanation:

Communication failed between the CLC and

the selector.

Causes:

• Selector Board – Selector control board

failed or lost power.

Dover® DMC

• Line Termination – Improper termination

of RS- 485 communications line. for

REM® M e s s a g e s

Unpublished Work – © Otis Elevator Company, 2003

2-222: Rear Door Communication

Detected

Explanation:

Communication failed between the CLC and

the rear door.

Causes:

• Door Control Board – Rear door control

board failed or lost power.

• Line Termination – Improper termination

of RS-485 communications line.

Unpublished Work – © Otis Elevator Company, 2003

Re f e r e n c e Ma n ua l

2-223: Hoistway Lock Open During

Flight

Explanation:

The hoistway lock (signal HWP) opened

during a run.

Causes:

• Door Pickup – Door pickup clipped

hoistway lock during run. Doors bouncing

closed.

Dover® DMC

• Relay Board – HW1, HW2, and HW3

relays.

• Configuration Parameter– Make sure

CLC configuration parameter 15 (12

for three-chip CLCs), “Door fail time”, is

for

set to at least 30 seconds to allow doors

enough time to close once stalled. Stall

doors when almost fully closed and see if

REM® M e s s a g e s

the door configuration parameter 9 (close

speed manual), can make DCL, DR, and

hoistway lock. Increase if necessary,

which may require adjustment of other

door parameters. Reduce parameter 7

(close high speed) if doors close too hard

during normal close. Make sure spirator

tension is consistent on all floors.

Unpublished Work – © Otis Elevator Company, 2003

2-224: Group Communication Failure

Explanation:

The CLC lost communication with another

elevator.

Causes:

• Mechanic – Other elevator being

serviced.

• Line Termination – Improper termination

of group serial line GPSC or GPSN. See

Area 55–57 of wiring diagram.

• CLC Board – CLC board in one of the

cars failed.

• Communication Wiring – Loose

connection.

Unpublished Work – © Otis Elevator Company, 2003

Re f e r e n c e Ma n ua l

2-225: CLC Communication Failure

Logged

Explanation:

The CLC detected intermittent communication

failures with the service tool (REM® box).

Causes:

• Wiring – Check REM® box wiring through

RS-422 to 485 converter to serial port

on controller.

• Line Termination – Check CLC line Dover® DMC

termination PSC, NSC area 55–57.

for

REM® M e s s a g e s

Unpublished Work – © Otis Elevator Company, 2003

2-226: Front DR Off

When Doors Closed

Explanation:

The front door control board sensed the gate

switch signal (DR) was off when the doors

were closed.

Causes:

• Gate Switch – Gate switch contact bad,

gate switch out of adjustment (must be

active before DCL), or wiring error.

• Door Control Board – Front door board

failed.

Unpublished Work – © Otis Elevator Company, 2003

Re f e r e n c e Ma n ua l

2-227: Rear DR Off

When Doors Closed

Explanation:

The rear door control board sensed the gate

switch signal (DR) was off when the doors

were closed.

Causes:

• Gate Switch – Gate switch contact bad,

gate switch out of adjustment (must be

Dover® DMC

active before DCL), or wiring error.

• Door Control Board – Rear door board

failed.

for

REM® M e s s a g e s

Unpublished Work – © Otis Elevator Company, 2003

2-228: Front Door

Overspeed on Close

Explanation:

The front doors oversped while closing.

Causes:

• Configuration Parameter – Adjustment

13 on Freedom Tool® may be incorrect.

Adjust item 13 downward from high

value until “close speed exceeded”

fault is generated, then set eight counts

higher.

• Door Control Board – Front door board

failed.

Unpublished Work – © Otis Elevator Company, 2003

Re f e r e n c e Ma n ua l

2-229: Rear Door

Overspeed on Close

Explanation:

The rear doors started to open and the DR

signal stayed active.

Causes:

• Configuration Parameter – Adjustment

13 on Freedom Tool® may be incorrect.

Adjust item 13 downward from high

Dover® DMC

value until “close speed exceeded”

fault is generated, then set eight counts

higher.

• Door Control Board – Rear door board

failed.

for

REM® M e s s a g e s

Unpublished Work – © Otis Elevator Company, 2003

2-230: DZR on Outside of

Door Zone

Explanation:

The door-zone read relay (DZR) signal is

on when the selector thinks the car is out of

the door zone.

Causes:

• DZR – Relay stuck on or wiring error

(CS8 of selector board).

• Selector Board – Board failed.

Unpublished Work – © Otis Elevator Company, 2003

Re f e r e n c e Ma n ua l

2-231: Sensor Missed

Explanation:

A leveling sensor (LU, LD, or DZR) was

missed at the end of a run.

Causes:

• DZR – Relay failed, wiring problem

(CS8 of selector board), or adjustment

problem.

Dover® DMC

• Magnet Alignment – Magnet missing

or not aligned. Make sure magnet has

correct polarity facing out.

• Main Sensor Board – Selector’s main

sensor board failed.

for

• Selector Board – Selector board failed.

• DC Power – Check 24 volts to selector

REM® M e s s a g e s

board.

Unpublished Work – © Otis Elevator Company, 2003

2-232: Unknown Front

Door Fault Detected

Explanation:

The front door board has logged a fault that

has not yet been mapped.

Causes:

• Belt Slippage – If code C reported, belt

may have slipped.

• Configuration Parameter – Readjust

and perform door learn with Freedom

Tool®.

• Unknown – Contact the REM® Center

to investigate message source if belt

slippage or configuration parameters

(mentioned above) are not source of

message.

Unpublished Work – © Otis Elevator Company, 2003

Re f e r e n c e Ma n ua l

2-233: Unknown Rear

Door Fault Detected

Explanation:

The rear door board logged a fault that has

not yet been mapped.

Causes:

• Belt Slippage – If code C reported, belt

may have slipped.

Dover® DMC

• Configuration Parameter – Readjust

and perform door learn with Freedom

Tool®.

• Unknown – Contact the REM® Center

to investigate message source if belt

slippage or configuration parameters

for

(mentioned above) are not source of

message.

REM® M e s s a g e s

Unpublished Work – © Otis Elevator Company, 2003

2-234: Unknown Selector

Fault Detected

Explanation:

The selector board logged a fault that has

not yet been mapped.

Causes:

• Unknown – Contact the REM® Center

to investigate message source.

Unpublished Work – © Otis Elevator Company, 2003

Re f e r e n c e Ma n ua l

2-235: Front DCB Stuck On

Explanation:

The front door close button has been stuck

on for four minutes.

Causes:

• Door Close Button – Front door close

button stuck on or there is a wiring

error.

Dover® DMC

• CLC Board – Input failed.

for

REM® M e s s a g e s

Unpublished Work – © Otis Elevator Company, 2003

2-236: Front DR Open During Flight

Explanation:

The front gate switch (DR) opened during

flight.

Causes:

• Front Gate Switch – Switch defective

adjustment problem, or wiring problem.

Force to close doors increases on door

retry to close, which may cause doors

to bounce open at close limit. Review

event buffer associated with message.

• Door Control Board – Failed.

Unpublished Work – © Otis Elevator Company, 2003

Re f e r e n c e Ma n ua l

2-237: 120-Volt Chain Open

Explanation:

Signal SC6 at the selector board is 0 volts.

Causes:

• AC Voltage – AC1 missing. Check

fuse F1 and associated circuit on relay

board.

• Reverse-Phase Relay – If provided with

Dover® DMC

contract, reverse-phase relay may be

open.

• Safety Chain – Check connections

SC0–SC6, pit safety switch, car top

switch, final limit, and emergency exit

contact.

for

REM® M e s s a g e s

Unpublished Work – © Otis Elevator Company, 2003

2-238: Switch Tree Open

Explanation:

A contact in the switch tree is open.

Cause:

• Switch Tree – Check wiring and contacts

in switch. For 1A controller, check UTS

if up run, DTS if down run.

Unpublished Work – © Otis Elevator Company, 2003

Re f e r e n c e Ma n ua l

2-239: Position Fault

Explanation:

A position fault occurred. The second line of

the message will state that ISFL is missing

or that a signal sequence error occurred.

Causes:

• IFSL – Check switch and associated

wiring. Vane missing.

Dover® DMC

• Rail – Make sure lubrication cans on top

of car are full.

• CLC Board – Check input wiring of

IFSL, LU, LD, and DZ. Replace board

if necessary.

for

REM® M e s s a g e s

Unpublished Work – © Otis Elevator Company, 2003

2-240: Inductor Sequence

Error Due to DZ

Explanation:

The DZ signal is stuck in the active state or

LU/LD are stuck off.

Causes:

• LU Sensor – LU did not energize at end

of up run.

• LD Sensor – LD did not energize at end

of down run.

• DZ Sensor – Check wiring; replace

sensor.

• CLC Board – Check wiring to board;

replace board.

Unpublished Work – © Otis Elevator Company, 2003

Re f e r e n c e Ma n ua l

2-241: DZ Missing

Explanation:

The DZ signal is missing. The car transitioned

from LU to LD without seeing DZ.

Causes:

• DZ Sensor – Check wiring; replace

sensor.

• LU Sensor – Defective sensor or wiring

Dover® DMC

problem.

• LD Sensor – Defective sensor or wiring

error.

• CLC Board – Check wiring to board;

replace board.

for

REM® M e s s a g e s

Unpublished Work – © Otis Elevator Company, 2003

2-242: LU and LD Stuck On

Explanation:

The LU and LD signals were both active at

the same time.

Causes:

• LU Sensor – Check wiring; replace

sensor.

• LD Sensor – Check wiring; replace

sensor.

• CLC Board – Check wiring to board;

replace board.

Unpublished Work – © Otis Elevator Company, 2003

Re f e r e n c e Ma n ua l

2-243: Front Door Voltage Spike

or Armature Problem

Explanation:

A voltage spike could cause this message

on power-up. A grounded or shorted door

motor armature may also generate this

message.

Cause:

• Door Control Board – Replace board.

NOTE: You may see elevator shut down Dover® DMC

on every main line power cycle and

restart only by hitting reset switch

on door board.

for

REM® M e s s a g e s

Unpublished Work – © Otis Elevator Company, 2003

2-244: Rear Door Voltage Spike

or Armature Problem

Explanation:

A voltage spike could cause this message

on power-up. A grounded or shorted door

motor armature may also generate this

message.

Cause:

• Door Control Board – Replace board.

Unpublished Work – © Otis Elevator Company, 2003

Re f e r e n c e Ma n ua l

2-245: CLC Not Responding

to Commands

Explanation:

The CLC determined that another company

(not Dover®) is trying to access information.

Nothing can be done—this just allows us to

monitor this occurrence.

Dover® DMC

for

REM® M e s s a g e s

Unpublished Work – © Otis Elevator Company, 2003

2-246: 24-Volt Power Supply Failed

Explanation:

The 24-volt power circuit failed.

Causes:

• Fuse – F2 or F2 on the relay board.

• DC Power – 24-volt power supply failed.

See page 1 of drawing.

Unpublished Work – © Otis Elevator Company, 2003

Re f e r e n c e Ma n ua l

2-247: Configuration Table

Corrupted

Explanation:

The selector, front, or rear door parameter

table is empty or corrupt.

Causes:

• Learn Run – Contract data restored

without learning hoistway. Front or rear

doors not set up (requires Freedom

Dover® DMC

Tool®).

• Battery – Stored data corrupted due to

battery problem.

for

REM® M e s s a g e s

Unpublished Work – © Otis Elevator Company, 2003

2-248: Rear DCB Stuck On

Explanation:

The rear door-close button has been stuck

on for four minutes.

Causes:

• Door-Close Button – Rear door-close

button stuck on or wiring error.

• CLC Board – Input failed.

Unpublished Work – © Otis Elevator Company, 2003

Re f e r e n c e Ma n ua l

2-249: Rear DR Open During Flight

Explanation:

The rear DR signal opened during flight.

Causes:

• Rear Gate Switch – Switch defective,

adjustment problem, or wiring problem.

Force to close doors is increases on door

retry to close, which may cause doors

to bounce open at close limit. Review

Dover® DMC

event buffer associated with message.

• Door Control Board – Rear door control

board failed.

for

REM® M e s s a g e s

Unpublished Work – © Otis Elevator Company, 2003

2-250: Front Door Speed Exceeded

While Opening

Explanation:

The front doors oversped while opening.

Causes:

• Configuration Parameter – Adjustment

13 on Freedom Tool® may be incorrect.

Adjust item 13 down from high value until

open speed exceeded fault is generated,

then set eight counts higher.

• Door Control Board – Front door board

failed.

Unpublished Work – © Otis Elevator Company, 2003

Re f e r e n c e Ma n ua l

2-251: Rear Door Speed Exceeded

While Opening

Explanation:

The rear doors oversped while opening.

Causes:

• Configuration Parameter – Adjustment

13 on Freedom Tool® may be incorrect.

Adjust item 13 down from high value until

open speed exceeded fault is generated,

Dover® DMC

then set eight counts higher.

• Door Control Board – Rear door board

failed.

for

REM® M e s s a g e s

Unpublished Work – © Otis Elevator Company, 2003

2-252: DR and DOL Active

at the Same Time

Explanation:

The front door signal DR and DOL are active

at the same time.

Causes:

• Gate Switch – Stuck in or set

incorrectly.

• DOL Adjustment – Stuck on or adjusted

incorrectly.

• Door Control Board – Board failed input

stuck on.

Unpublished Work – © Otis Elevator Company, 2003

Re f e r e n c e Ma n ua l

2-253: Rear DR and DOL Active

at the Same Time

Explanation:

The front door signal DR and DOL are active

at the same time.

Causes:

• Gate Switch – Stuck in or set

incorrectly.

Dover® DMC

• DOL Adjustment – Stuck on or adjusted

incorrectly.

• Door Control Board – Board failed or

input stuck on.

for

REM® M e s s a g e s

Unpublished Work – © Otis Elevator Company, 2003

A d d i t i o n a l . I n f o r m at i o n :

Please address any comments,

questions, or suggestions pertaining to

REM® Messages for Dover® DMC

Reference Manual

RF - 11

to:

Otis Elevator Company

Manager, Maintenance Support

212 West Newberry Road

Bloomfield, CT 06002-1308

(860) 286-6318

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)