Академический Документы

Профессиональный Документы

Культура Документы

Drawing

Загружено:

ahmedОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Drawing

Загружено:

ahmedАвторское право:

Доступные форматы

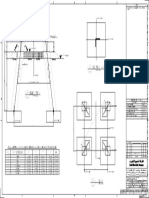

00 01

WA-401413 MK238 Q 4400005604

NOTES

REV. NO. SHEET NO. DRAWING NUMBER PLANT NO. INDEX JOB ORDER NO. CONTRACT NO.

1. ALL DIMENSIONS ARE IN MILLIMETERS UNLESS OTHERWISE

NOTED.

OW NER.

2. CONCRETE COMPRESSIVE STRENGTH SHALL CONFORM WITH

REQUIREMENTS OF 70-TMSS-03 REV.0 AND SHALL HAVE

MINIMUM COMPRESSIVE STRENGTH OF 38Mpa FOR SEVERE

UNFACTORED

EFFECTIVE REBAR LIST FOR PEDESTAL REBAR LIST FOR FOOTING BARS FOUNDATION DATA EXPOSURE SOIL AND 28Mpa FOR MODERATE EXPOSURE SOIL

FOUNDATION LOADS CONDITION.

TS

SOIL PARAMETERS

OF I

LONGITUDINAL BARS (BAR B) TIES (BAR A) TOP BARS BOTTOM BARS FOOTING PEDESTAL [kgf] 3. YIELD STRENGTH OF DEFORMED STEEL REINFORCEMENT,

DESIGN

fy = 420 MPa.

TOWER NO. OVERALL CALCULATION#

BEARING UNIT NOS. NOS. DEPTH 4. THE MINIMUM CONCRETE COVER TO REINFORCEMENT STEEL

NOS. NOS. CUTTING CUTTING SIZE H

CONSENT

C2 C3 SIZE L x B DEPTH DEPTH SHALL BE 75mm.

CAPACITY WEIGHT SIZE A1 B1 LENGTH SIZE LENGTH a1 REQ’D IN C1 C3 REQ’D IN "OL" Pu Pd

(DEG) REQ’D REQ’D SIZE LENGTH (LTB) SIZE LENGTH (LBB) (a x a)

2 3

EACH DIR. EACH DIR. "Fd" "h" PHX PHY 5. PROVIDE (2) TWO LAYERS OF 150 MICRON THICK POLYETHYLENE

kN/m kN/m

SHEET UNDER 75mm THICK LEAN CONCRETE AS PER SEC

STANDARD TCS-Q-113.03 SEC: 7.3.7.

S1, S3, 1A, 1B & 1C 30.0 350 17.044 {25 40 5226 300 5526 {12 2900 22 650 {20 29 4600 425 5450 {20 29 4600 425 5450 4800 x 4800 800 800 x 800 3700 5250 294582 349575 74512 82028 06-P-916F-PA-HA-DE-R0

6. TOP SURFACE OF CONCRETE SHALL BE CROWNED AND GIVEN

TTEN

A SMOOTH STEEL TROWEL FINISH.

7. BACKFILLING SHALL BE DONE WITH APPROVED BACKFILLING

THE W RI

MATERIALS AND COMPACTION SHALL BE CARRIED OUT TO

ACHIEVE A MIN. 95% OF STANDARD PROCTOR DENSITY IN

LAYERS NOT MORE THAN 200mm THICK.

| OF FOUNDATION

8. ALL EXPOSED CONCRETE SURFACES SHALL BE DRY &

CLEANED AT THE TIME OF APPLICATION AND IT SHALL BE

STUB ANGLE COATED WITH POLYURETHANE WATER PROOFING MEMBRANE.

THOUT

SEE NOTE #10 9. ALL CONCRETE SURFACES BELOW GRADE LEVEL SHALL BE

| OF FOOTING COATED WITH A MINIMUM OF (2) COATS OF COAL TAR EPOXY.

PUNCH MARK

WI

| OF PEDESTAL 10. FOR STUB & STUB SETTING DETAILS AND TOWER GROUNDING

FOR CONCRETE LEVEL

DETAILS SEE REFERENCE DRAWINGS.

DOCUMENT

11. TOWER SHALL NOT BE ERECTED/INSTALLED UNTIL AT LEAST

a

| OF FOUNDATION CHAMFERED STUB ANGLE

(25x25) 150x150x15H 10 DAYS AFTER POURING THE CONCRETE FOUNDATIONS AS PER

CLAUSE 4.3 OF TCS-P-122.06, REV.01.

ELASTOMERIC PU 12. NO LOAD TO BE APPLIED TO TOWER UNTIL THE CONCRETE

PUNCH MARK COATING HAS REACHED 28 DAYS STRENGTH AS PER CLAUSE 4.3 OF

C

S

(SEE NOTE #8) TCS-P-122.06, REV.01.

THI

FOR CONCRETE LEVEL

C 13. CONSTRUCTION JOINT IF REQUIRED, SHALL BE PROVIDED AT

450

1.5 - 2% 300mm BELOW THE STUB ANGLE. BEFORE APPLICATION OF

1.5 - 2%

FROM

TOP OF SLOPE NEXT CONCRETE POURING APPROVED BONDING AGENT SHALL

1

SLOPE

0

BE USEDAS PER 11.3.1 OF TCS-P-122.05, REV.1.

.7

a STRUCTURE PAD

4

14. EXPOSED FOUNDATIONS SHALL BE CURED IN MOIST CONDITION

5

300

SEE NOTE#15

NED

10

2

NATURAL

00

FOR 21 DAYS FOLLOWING CLAUSE 8.3.5 OF TCS-Q-133.03, REV.0.

.4

SECTION C-C

1000.

GROUND LEVEL

S OBTAI

12

15. STUB ANGLES SHALL BE CONNECTED BY (7#5 OR 7#7, AS

500

10

)

APPLICABLE) COPPER CLAD GROUNDING CONDUCTOR THROUGH

TYP.

500

COMPRESSION CONNECTOR AND REBARS EXOTHERMALLY WELDED

(

AT LEAST TWO (2) LOCATIONS ON EACH TOWER LEG AS PER

2 COATS (MIN.)

I

| OF FOOTING CLAUSE 6.3 OF TCS-Q-122.10, REV.0.

EPOXY COATING

PART

(SEE NOTE #9) 16. DE-SHUTTERING AND REMOVAL OF TEMPLATES SHALL BE CARRIED

15

8. OUT AFTER (72 HOURS) 3 DAYS OF CONCRETE CURING FOLLOWING

8000 13

3 CLAUSE 10.3 OF TCS-P-122.03, REV.0.

(TYP.) 158.133

N

I

TWO COATS OF

17. EXCAVATION MUST BE CLOSELY MONITORED TO MAKE SURE

COAL TAR EPOXY

FULL OR

PEDESTAL THE SOIL/ROCK PARAMETERS USED IN THIS DESIGN ARE IN

AGREEMENT WITH THE ACTUAL SITE CONDITION. IF THERE ARE

ANY DIFFERENCES, DESIGN OFFICE SHALL BE INFORMED FOR

TIES @ 200mm

RECTIFICATION AND REDESIGN IF NEEDED.

OL

18. THE REINFORCEMENT DETAILS SHOWN IN THE DRAWING AND THE

LONGITUDINAL BARS

N

I

SCALES ARE REPRESENTATIVE ONLY. THE ACTUAL DIMENSION

A1

ON

AND NUMBER OF BAR SHALL BE OBTAINED FROM THE SCHEDULE

h

REPRODUCTI

A A SHOWN IN THE TABLE.

SELECTED

EXCAVATI0N

BACKFILL

a

LINE

B

| OF FOOTING SEE NOTE #7

75mm COVER

REFERENCE DRAWINGS

(TYP)

ANGLE AS PER DRAWING TITLE DRAWING NO.

THE TOWER LEG

DRAWING CONTROL SHEET WE-401392

NO

CONSTRUCTION SLOPE ANGLE

a

JOINT PROJECT TECHNICAL SPECIFICATIONS PTS-14WO141

TWO COATS OF STUB AND CLEAT DRAWING WA-400863

B1

COAL TAR EPOXY TOP BARS

d SA

100 (TYP.) STUB SETTING TEMPLATE DRAWING WA-400863

(BOTH WAYS)

ALL SIDES

onalGri

TOWER / MONOPOLE GROUNDING DETAILS WA-400863

WA-294555

LONGITUDINAL BARS

Fd

ONG

ON PEDESTAL

0 L

OF Nati

L

349

905

STUB ANGLE

..

L + 200

75

0x35

LEAN CONCRETE BOTTOM BARS 250x250x35H

B1 B1 PUNCH MARK FOR

SEE NOTE-5 (BOTH WAYS)

0x25

ARE THE SOLE PROPERTY

100 L 100 CONCRETE LEVEL

P L A N

L25

51

REBAR CHAIRS (IF REQUIRE)

SECTION A-A

11

2

512

461

VARIES

EARTHING CLAMP

| OF FOOTING | OF STRUCTURE G.L/TSP G.L/TSP

| OF FOOTING &

PEDESTAL AT BASE PUNCH MARK FOR AS-BUILT BY DATE

GROUND LEVEL a1

N

HEREI

3413

BOTTOM BARS

LENGTH)

TIES

NED

75mm CLEAR COVER

MBEDDED

00 13/11/17 AZ ISSUED FOR APPROVAL FNK

CONTAI

TYP. ALL AROUND

REV. DATE BY CHKD. CERT. APPD.

DESCRIPTION

ES

| OF STRUCTURE NO.

(

}

2050

} /2

} /2

CLEAT

VARI

PEDESTAL

BARS

BARS

2400

C1 DRAWING COMPLETION CERTIFICATE (DCC):

200x200x20H

ON

B

NFORMATI

| OF FOOTING & TOP BARS

BOTTOM

a

TOP

| OF T/L | O PEDESTAL AT BASE

F T ADDITIONAL

/L

TIES @ 400MM

C3

THE I

| OF FOOTING a AZ/TE MNK

DRAWN BY CHECKED BY SCALE: N.T.S

10/04/2015 _________

BOTTOM BARS DATE STARTED DATE COMPLETED

AND

OPR’G. DEPT. ENG. DEPT.

C2

TOP BARS

THIS DRAWING IS NOT TO BE USED FOR CERTIFIED

NG

FOUNDATION PLAN (TYP) CONSTRUCTION OR FOR ORDERING

DRAW I

MATERIAL UNTIL CERTIFIED AND DATED BY DATE

L

FOOTING BARS

CONSTRUCTION OF 110 kV D/C OHTL FOR

S

THI

TYPICAL STUB AND CLEAT ANGLE FOR ’HA-DE’ WALLI AL AHAD-2 S/S WITH NETWORK

REINFORCEMENT DETAILS MAKKA SAUDI ARABIA

(FOR DETAILS SEE STUB ANGLE REF. DWG.)

CONTRACT NO. JOB ORDER NO. INDEX PLANT NO. DRAWING NUMBER SHEET NO. REV. NO.

4400005604 Q MK238 WA-401413 01 00

NG-A (2012/01)

DMS VECTOR NGA00

Вам также может понравиться

- BOQ - Method of Measurement and BOQ PDFДокумент176 страницBOQ - Method of Measurement and BOQ PDFyousef100% (1)

- S-Curve Rev.2 Due To Eot No. 1Документ1 страницаS-Curve Rev.2 Due To Eot No. 1Budi DermawanОценок пока нет

- Civil Works Technical SpecificationsДокумент33 страницыCivil Works Technical SpecificationsAsim KhanОценок пока нет

- TSF Shop Drawing For ReviewДокумент8 страницTSF Shop Drawing For ReviewMahmoud ShakerОценок пока нет

- Specifications: FoundationДокумент6 страницSpecifications: FoundationRichu PaliОценок пока нет

- Option 3 FenceДокумент1 страницаOption 3 FenceAYSON N. DELA CRUZОценок пока нет

- Tray DrawingДокумент1 страницаTray DrawingFareethAbdullahОценок пока нет

- Flow For Construction Works: Field Check ListДокумент1 страницаFlow For Construction Works: Field Check ListAsepGPОценок пока нет

- BOQ Full Unpriced.Документ118 страницBOQ Full Unpriced.JettSoriano100% (1)

- Roof Plan Roof Framing Plan: C A D B C A D BДокумент1 страницаRoof Plan Roof Framing Plan: C A D B C A D BmjfprgcОценок пока нет

- KnaufДокумент28 страницKnaufprokaОценок пока нет

- List of DrawingsДокумент6 страницList of DrawingsAhmed medhatОценок пока нет

- 377c Site Construction ReportsДокумент11 страниц377c Site Construction Reportsalikajbaf67% (3)

- Price ListДокумент11 страницPrice ListJacy Maricor Reabad100% (1)

- LO1. Prepare-Stake Out Building Lines - Copy 1Документ13 страницLO1. Prepare-Stake Out Building Lines - Copy 1Lloyd Bryan Deric100% (1)

- Complete Church Planning GuideДокумент72 страницыComplete Church Planning Guidereotan gulmatz100% (1)

- General Construction Notes:: Notes On Beams and GirdersДокумент1 страницаGeneral Construction Notes:: Notes On Beams and GirdersJaycee RollanОценок пока нет

- Bid Documents PDFДокумент133 страницыBid Documents PDFCaitlin Elise O. CornelОценок пока нет

- Manhole Detail Grease Trap Detail: Sanitary EngineerДокумент1 страницаManhole Detail Grease Trap Detail: Sanitary Engineer3Crow BuildersОценок пока нет

- Terms & Condition For A Residential BuildingДокумент17 страницTerms & Condition For A Residential BuildingJayachandranОценок пока нет

- S2 - Demolition (Jan 2013)Документ17 страницS2 - Demolition (Jan 2013)msyan1965100% (1)

- BOQ Housing - MyCitiHomesДокумент4 страницыBOQ Housing - MyCitiHomesAnjo BalucasОценок пока нет

- Appendix B Standard Construction DrawingsДокумент98 страницAppendix B Standard Construction DrawingsSubashini JaganathanОценок пока нет

- S 1 Structural NotesДокумент1 страницаS 1 Structural NotesJBFPОценок пока нет

- Rev.5 - IRAK Mossul Airport - BOQ Shell & Core 25082021Документ3 страницыRev.5 - IRAK Mossul Airport - BOQ Shell & Core 25082021Sara AhmedОценок пока нет

- S001 (1) - Drawing List - Drawing TransmittalДокумент1 страницаS001 (1) - Drawing List - Drawing TransmittalScott McCallum100% (1)

- Project Engineer Duties and ResponsibilitiesДокумент2 страницыProject Engineer Duties and ResponsibilitiesSalama ShurrabОценок пока нет

- Building Drawings Approval Process and DetailsДокумент15 страницBuilding Drawings Approval Process and DetailsrkssОценок пока нет

- A-VA06-105 Ground Floor Ceiling PlanДокумент1 страницаA-VA06-105 Ground Floor Ceiling PlanNgai TranОценок пока нет

- Program of Works For The Construction of Mobile Equipment Parking Area and Non Revenue StoresДокумент1 страницаProgram of Works For The Construction of Mobile Equipment Parking Area and Non Revenue StoresZachОценок пока нет

- General and Technical Specification Section 1.0-GeneralДокумент3 страницыGeneral and Technical Specification Section 1.0-GeneralTarhata KalimОценок пока нет

- Documents - MX - Bec 402 Estimating ContractДокумент228 страницDocuments - MX - Bec 402 Estimating ContractNg Zhe ShengОценок пока нет

- Leon Engineerng SiloWeigh Presentation Installation Procedures ExamplesДокумент50 страницLeon Engineerng SiloWeigh Presentation Installation Procedures ExamplesjokoОценок пока нет

- TYPICAL DETAIL DRAWING - SYABAS PC SLab PDFДокумент20 страницTYPICAL DETAIL DRAWING - SYABAS PC SLab PDFBMZОценок пока нет

- Monorail PDFДокумент7 страницMonorail PDFhizemОценок пока нет

- SL - No Location/Area Work DescriptionДокумент2 страницыSL - No Location/Area Work Descriptionshyamsundar_ceОценок пока нет

- Architecture: Schedule of Finishes 1 Schedule of Finishes 2Документ10 страницArchitecture: Schedule of Finishes 1 Schedule of Finishes 2Eunice RosarioОценок пока нет

- Structural FujiДокумент6 страницStructural Fujichris100% (1)

- Structural CommentsДокумент3 страницыStructural CommentsMusherib KhanОценок пока нет

- Construction of Moiben Sub-County Office BlockДокумент152 страницыConstruction of Moiben Sub-County Office Blockapi-258641606Оценок пока нет

- Shop Drawing of Status SummaryДокумент2 страницыShop Drawing of Status SummaryANJellHwanОценок пока нет

- Material Tracking ListДокумент2 страницыMaterial Tracking Listsmart_onyx17Оценок пока нет

- Kest 5th Septic Tank & Soak Away MT 1Документ166 страницKest 5th Septic Tank & Soak Away MT 1EphremHailuОценок пока нет

- KBrown Course Project Week 1Документ3 страницыKBrown Course Project Week 1Kyle BrownОценок пока нет

- Isolated FootingДокумент15 страницIsolated FootingMark Christian Esguerra100% (1)

- Shop Drawing, Sample and SubmittalsДокумент6 страницShop Drawing, Sample and SubmittalsPhilip Yap100% (2)

- De Tablan, Dan Alfonso (Boq)Документ10 страницDe Tablan, Dan Alfonso (Boq)Dan Alfonso de TablanОценок пока нет

- Division 2Документ10 страницDivision 2Luis Gabriel BautistaОценок пока нет

- General Notes: Kennesaw, GA Kennesaw, GAДокумент11 страницGeneral Notes: Kennesaw, GA Kennesaw, GAJulie Ann CedoОценок пока нет

- Excel Bill of Materials Bom TemplateДокумент8 страницExcel Bill of Materials Bom TemplateRavi ChhawdiОценок пока нет

- CFLHD Production RatesДокумент7 страницCFLHD Production RatesabhiazadОценок пока нет

- Electrical SpecificationsДокумент4 страницыElectrical Specificationsjoe rommel riveraОценок пока нет

- BOQ Site Devpt.Документ15 страницBOQ Site Devpt.Angelica PonceОценок пока нет

- General Specification: B. Plans and SpecificationsДокумент5 страницGeneral Specification: B. Plans and Specificationsmichael nabusОценок пока нет

- mcc2 PDFДокумент1 страницаmcc2 PDFSravyaSree100% (2)

- Ea-679798 001 0000Документ1 страницаEa-679798 001 0000engrabbas75Оценок пока нет

- Sa128563 0002 0004Документ1 страницаSa128563 0002 0004Gavriel NgОценок пока нет

- Wa-532012 0002 0002Документ1 страницаWa-532012 0002 0002khawarОценок пока нет

- GA & Rebar Detail of StaircaseДокумент1 страницаGA & Rebar Detail of Staircasedebu1985Оценок пока нет

- Road "01" Profile: ROAD 01 C STATION 1+000.000 TO 1+500.000 LДокумент1 страницаRoad "01" Profile: ROAD 01 C STATION 1+000.000 TO 1+500.000 LtogireeshОценок пока нет

- Project Quality Manual TL Projects: 3.1 Quality Is Every Employee's ResponsibilityДокумент1 страницаProject Quality Manual TL Projects: 3.1 Quality Is Every Employee's ResponsibilityahmedОценок пока нет

- Inspection and Test Plan For Power CableДокумент5 страницInspection and Test Plan For Power Cablesamuraivicky100% (1)

- Project Quality Manual TL Projects: System ImprovementДокумент1 страницаProject Quality Manual TL Projects: System ImprovementahmedОценок пока нет

- Calibration Certificate LogsheetДокумент1 страницаCalibration Certificate LogsheetahmedОценок пока нет

- Monthly Quality Report SampleДокумент1 страницаMonthly Quality Report SampleahmedОценок пока нет

- Method Statement For PILING WorkДокумент1 страницаMethod Statement For PILING WorkahmedОценок пока нет

- Monthly Quality Report SampleДокумент1 страницаMonthly Quality Report SampleahmedОценок пока нет

- Calibration FlowДокумент1 страницаCalibration FlowahmedОценок пока нет

- 01-P-916b-Pa-Fdn Plans-Tt-R0 PDFДокумент1 страница01-P-916b-Pa-Fdn Plans-Tt-R0 PDFahmedОценок пока нет

- Logbook SampleДокумент1 страницаLogbook SampleahmedОценок пока нет

- Butter Slope CalculationДокумент1 страницаButter Slope CalculationahmedОценок пока нет

- ASG-QAQC-PROC-005 Pmo & Technical Affairs Department - Sheq Equipement Testing ProcedureДокумент1 страницаASG-QAQC-PROC-005 Pmo & Technical Affairs Department - Sheq Equipement Testing ProcedureahmedОценок пока нет

- Calculation For Butter SlopeДокумент1 страницаCalculation For Butter SlopeahmedОценок пока нет

- 1Документ1 страница1ahmedОценок пока нет

- Calibration Process Flow (Lab Eq.) : Issued byДокумент1 страницаCalibration Process Flow (Lab Eq.) : Issued byahmedОценок пока нет

- List of ManfucДокумент1 страницаList of ManfucahmedОценок пока нет

- Calibration FlowДокумент1 страницаCalibration FlowahmedОценок пока нет

- Construction of 110 KV D/C Ohtl For Al Kamel S/S Makkah, Saudi Arabia Foundation Setting PlanДокумент1 страницаConstruction of 110 KV D/C Ohtl For Al Kamel S/S Makkah, Saudi Arabia Foundation Setting PlanahmedОценок пока нет

- Construction of 110 KV D/C Ohtl For Al Kamel S/S Makkah, Saudi Arabia Foundation Setting PlanДокумент1 страницаConstruction of 110 KV D/C Ohtl For Al Kamel S/S Makkah, Saudi Arabia Foundation Setting PlanahmedОценок пока нет

- Islam GuideДокумент80 страницIslam Guideaaghamdi100% (17)

- Foundation Layout For Star TWRДокумент1 страницаFoundation Layout For Star TWRahmed100% (1)

- Installation of 110 KV D/C Ohtl From 380/110 KV Khulais BSP To 110/13.8Kv S/S Gulf Salman Jeddah, Saudi Arabia Foundation Setting PlanДокумент1 страницаInstallation of 110 KV D/C Ohtl From 380/110 KV Khulais BSP To 110/13.8Kv S/S Gulf Salman Jeddah, Saudi Arabia Foundation Setting PlanahmedОценок пока нет

- Foundation Layout For Star TWRДокумент1 страницаFoundation Layout For Star TWRahmed100% (1)

- Installation of 110 KV D/C Ohtl From 380/110 KV Khulais BSP To 110/13.8Kv S/S Gulf Salman Jeddah, Saudi Arabia Foundation Setting PlanДокумент1 страницаInstallation of 110 KV D/C Ohtl From 380/110 KV Khulais BSP To 110/13.8Kv S/S Gulf Salman Jeddah, Saudi Arabia Foundation Setting PlanahmedОценок пока нет

- Manhole Handhole Accessories For CommunicationsДокумент2 страницыManhole Handhole Accessories For CommunicationsahmedОценок пока нет

- Foundation Layout For Star TWRДокумент1 страницаFoundation Layout For Star TWRahmed100% (1)

- SEC Standards PDFДокумент10 страницSEC Standards PDFahmedОценок пока нет

- Islam GuideДокумент80 страницIslam Guideaaghamdi100% (17)

- Foundation Layout For Star TWRДокумент1 страницаFoundation Layout For Star TWRahmed100% (1)

- Ap Chem Lab Formula of A HydrateДокумент5 страницAp Chem Lab Formula of A Hydrateapi-2598549080% (1)

- Osmo RasocemДокумент2 страницыOsmo RasocemscorcdОценок пока нет

- Maharashtra Engineering Services (Civil), Gr. A & Gr. B (Main) ExamДокумент3 страницыMaharashtra Engineering Services (Civil), Gr. A & Gr. B (Main) ExamErRajivAmieОценок пока нет

- Befib 2020-Id 144Документ18 страницBefib 2020-Id 144Mehdi BakhshiОценок пока нет

- Staggered Truss Framing SystemsДокумент49 страницStaggered Truss Framing SystemsjorgeОценок пока нет

- Design of Pile FoundationsДокумент188 страницDesign of Pile FoundationsSiriveri Lakshmi KanthОценок пока нет

- A CASE STUDY ON AggregatesДокумент4 страницыA CASE STUDY ON AggregatesAritro Roy MitraОценок пока нет

- Rtu M.tech Dissertation GuidelinesДокумент4 страницыRtu M.tech Dissertation GuidelinesFinishedCustomWritingPaperCanada100% (1)

- QCS 2010 Section 5 Part 11 ReinforcementДокумент10 страницQCS 2010 Section 5 Part 11 Reinforcementbryanpastor106Оценок пока нет

- Variation in Cement Properties and Its Effect On Quality of Concrete PDFДокумент7 страницVariation in Cement Properties and Its Effect On Quality of Concrete PDFTran Huynh NamОценок пока нет

- Tower Construction Detailed ProceduresДокумент13 страницTower Construction Detailed ProceduresboomarОценок пока нет

- Whole GardnerMarkAlan2004 ThesisДокумент380 страницWhole GardnerMarkAlan2004 ThesisAnil kumar RОценок пока нет

- Construction Proposal For Casting of Bored PileДокумент8 страницConstruction Proposal For Casting of Bored PileGold HavenОценок пока нет

- Nitomortar ELДокумент4 страницыNitomortar ELmilanbrasinaОценок пока нет

- Ritemix Pcr300 Tds 0Документ2 страницыRitemix Pcr300 Tds 0Joy Oco MañiboОценок пока нет

- Flexural StrengthДокумент2 страницыFlexural StrengthMrcoke SeieОценок пока нет

- Samsung NotesДокумент9 страницSamsung NotesheshamОценок пока нет

- Sika Plast 257Документ3 страницыSika Plast 257HasithaОценок пока нет

- DSR 2016 (Vol.1) PDFДокумент234 страницыDSR 2016 (Vol.1) PDFJoe78% (54)

- Request For Inspection ReportДокумент8 страницRequest For Inspection ReportArchie Joseph LlanaОценок пока нет

- EZ03-02 Standard SpecificationsДокумент28 страницEZ03-02 Standard SpecificationsXanti Zabala Da RosaОценок пока нет

- Design and Simulation of Engineering ProblemsДокумент10 страницDesign and Simulation of Engineering ProblemspronobОценок пока нет

- Highly Durable Cement Products Containing Siliceous AshesДокумент15 страницHighly Durable Cement Products Containing Siliceous Asheskiwaallan3Оценок пока нет

- 201.1R-08 PreviewДокумент6 страниц201.1R-08 PreviewGhulam Qadir WaqarОценок пока нет

- Behaviour of Paver Blocks With Partial Replacement of Sand Using Quarry DustДокумент6 страницBehaviour of Paver Blocks With Partial Replacement of Sand Using Quarry Dustgerar ramirezОценок пока нет

- BoqДокумент9 страницBoqdeshpande KingОценок пока нет

- Cement Chemistry: Oxide Common Name Abbreviation Approx. Amount (%)Документ6 страницCement Chemistry: Oxide Common Name Abbreviation Approx. Amount (%)AJAY KUMAR T.MОценок пока нет

- 33 05 13 Manholes and Structures 10Документ4 страницы33 05 13 Manholes and Structures 10salamОценок пока нет

- Estimate 2Документ82 страницыEstimate 2shashirajhans2140Оценок пока нет

- Basf-Masterrheobuild 2000 Oct - 2016 enДокумент2 страницыBasf-Masterrheobuild 2000 Oct - 2016 enKonax Lihysd MandeОценок пока нет