Академический Документы

Профессиональный Документы

Культура Документы

Section 6: Specification Classification

Загружено:

Dimas Wisnu WardanaОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Section 6: Specification Classification

Загружено:

Dimas Wisnu WardanaАвторское право:

Доступные форматы

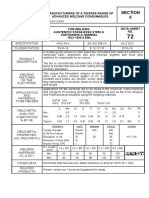

MANUFACTURERS OF A DIVERSE RANGE OF SECTION

ADVANCED WELDING CONSUMABLES 6

WI-0304 DS75 NSB-318 Rev. 1, Date 10.11.2010

DATA SHEET

FOR WELDING AUSTENITIC STAINLESSS STEELS NO.

NSB-318 CONTAINING A NOMINAL

18Cr-12Ni-2.7Mo-Nb 75

SPECIFICATION AWS A5.4 BS EN 1600 JIS Z 3221

CLASSIFICATION E318-16 E19 12 3 Nb R D318-16

A metallurgically advanced rutile based flux formulated with balanced additions of

chemically basic, amphoteric and acid minerals, together with small alloy additions

to compensate for arc losses.

PRODUCT

DESCRIPTION The flux is concentrically extruded onto a fully alloyed core wire and bound by a

blend of silicates that assures both coating strength and resistance to subsequent

moisture absorption.

WELDING This unique flux formulation ensures excellent arc stability, ease of initial arc strike

FEATURES and re-strike minimal spatter on AC and virtually none on DC+. The resultant weld

OF THE seams are smooth, evenly rippled and free from undercut while slag detachability is

ELECTRODE excellent. Metal recovery is some 103% with respect to core wire weight.

Applications for the electrode are to be found in the Chemical, Petro-Chemical and

Cryogenic Processing and Storage Industries as well as the Food, Brewery and

Pharmaceutical Industries using the following materials:

APPLICATIONS

AND ASTM/ASMC 316Ti 316Cb CF10MC 318C17

MATERIALS UNS S31635 S316640

TO BE WELDED NSB-318 is designed to weld Nb- or Ti-stabilised grades of Mo containing

Austenitic Stainless Steels when good corrosion resistance is needed. Max service

temperature is 400ºC.

C Mn Si S P Cr Ni Mo Cu Nb FN

WELD METAL

ANALYSIS MIN - 0.5 - - - 17 11 2.0 - 6xC 6

COMPOSITION MAX 0.08 2.5 1.0 0.03 0.03 20 14 3.0 0.75 1.0 13

% BY Wt.

TYPICAL 0.02 1.2 0.7 0.01 0.02 19 13.5 2.6 0.3 0.6 8

PROPERTY UNITS MINIMUM TYPICAL OTHERS

Tensile strength N/mm 2

550 660

WELD METAL 0.2% Proof stress N/mm2 - 500 H.V. 215

PROPERTIES

Elongation on 4d % 25 30

(ALL WELD METAL)

Reduction of Area (RA) % - 50

Impact energy 20 C o

J - 70

Ø (mm) 2.0 2.6 3.2 4.0 5.0

WELDING

AMPERAGE MIN 35 65 80 120 160

AC or DC+

MAX 80 100 125 170 210

OTHER DATA Electrodes that have become damp should be re-dried at 150oC for 1 hour.

RELATED

Please contact our Technical Department for detail.

PRODUCTS

Вам также может понравиться

- Itinerary SatishДокумент3 страницыItinerary SatishGreetsОценок пока нет

- Ninjatrader Futures Contract Details PDFДокумент3 страницыNinjatrader Futures Contract Details PDFMustapha El HamzaouiОценок пока нет

- Fujitsu Asya07lgc-Aoyr07lgc Asya09lgc-Aoyr09lgc Asya12lgc-Aoyr12lgcДокумент22 страницыFujitsu Asya07lgc-Aoyr07lgc Asya09lgc-Aoyr09lgc Asya12lgc-Aoyr12lgcmadalin9001Оценок пока нет

- iMAP User Guide 9 0 Issue1Документ872 страницыiMAP User Guide 9 0 Issue1vasilacheaОценок пока нет

- Bang Mau KCC 2021Документ5 страницBang Mau KCC 2021Trường NguyenОценок пока нет

- Catalog of RBS DAIHATSUДокумент8 страницCatalog of RBS DAIHATSUcbaautoparts197Оценок пока нет

- SunFields Specification NAF121-128-135GK ENGДокумент2 страницыSunFields Specification NAF121-128-135GK ENGkhemrajmahadewОценок пока нет

- CRN 7458470848Документ3 страницыCRN 7458470848ANUSHAОценок пока нет

- 12420/gomti Express Second Sitting (2S) : WL WLДокумент2 страницы12420/gomti Express Second Sitting (2S) : WL WLMohd HashimОценок пока нет

- Sartorius Entris Series Product BrochureДокумент8 страницSartorius Entris Series Product BrochureJhon David VillanuevaОценок пока нет

- JW1782BДокумент13 страницJW1782BGustavo AlonsoОценок пока нет

- Polycab Pricelist Oct 2018Документ5 страницPolycab Pricelist Oct 2018Pranit RasailyОценок пока нет

- Vdocuments - MX Sony HCD Shake33 HCD Shake77 Ver10 SMДокумент120 страницVdocuments - MX Sony HCD Shake33 HCD Shake77 Ver10 SMmemepiОценок пока нет

- Mesh Inch Micron Conversion ChartДокумент1 страницаMesh Inch Micron Conversion ChartAhmed IsmailОценок пока нет

- Ultraconductor ReportДокумент25 страницUltraconductor Reportamit patilОценок пока нет

- J Renene 2019 11 157Документ70 страницJ Renene 2019 11 157hamza malikОценок пока нет

- Saldo Per Barang: Nama Barang Kode Barangbatch No. Exp. Datesaldo Batch Otal BarangДокумент34 страницыSaldo Per Barang: Nama Barang Kode Barangbatch No. Exp. Datesaldo Batch Otal BarangimansariОценок пока нет

- Iwk 219019 Esm HarnessДокумент1 страницаIwk 219019 Esm HarnessJoão Pedro MoreiraОценок пока нет

- Polycab Cables PricelistДокумент4 страницыPolycab Cables PricelistSwapnil BorasteОценок пока нет

- FRONX BrochureДокумент16 страницFRONX BrochureMK AutoОценок пока нет

- Design of Ladle Shroud For Minimum Turbulence in Tundish Surface During Continuous Casting of SteelДокумент5 страницDesign of Ladle Shroud For Minimum Turbulence in Tundish Surface During Continuous Casting of SteelInternational Journal of Technology and Emerging Sciences (IJTES)Оценок пока нет

- Cambridge International AS & A Level: CHEMISTRY 9701/22Документ16 страницCambridge International AS & A Level: CHEMISTRY 9701/22The ImmortalОценок пока нет

- Motor Catalogue 2018Документ48 страницMotor Catalogue 2018Pandu BirumakovelaОценок пока нет

- SILICONE SPRAY (SDS - UK) Rev5.0Документ8 страницSILICONE SPRAY (SDS - UK) Rev5.0Hoàng Minh ĐứcОценок пока нет

- ALR1 Data SheetДокумент6 страницALR1 Data SheetUsmani Haman DhellОценок пока нет

- Updated Product List As On 18.03.2023Документ252 страницыUpdated Product List As On 18.03.2023Jas AyyapakkamОценок пока нет

- Im 03247Документ8 страницIm 03247jefersonОценок пока нет

- PS/Consolidated Premium Statement /ver 2.1/jan 2021: A Reliance Capital CompanyДокумент1 страницаPS/Consolidated Premium Statement /ver 2.1/jan 2021: A Reliance Capital CompanyJhansi RokatiОценок пока нет

- Akkaya Katalog EN 2019Документ66 страницAkkaya Katalog EN 2019Juan MendozaОценок пока нет

- MK HoneyWellДокумент56 страницMK HoneyWellKevin MaldeОценок пока нет

- NEXO Sliding SleeveДокумент3 страницыNEXO Sliding SleevetongsabaiОценок пока нет

- Acme CV Valve LiteratureДокумент8 страницAcme CV Valve LiteratureBhuvanaОценок пока нет

- Aib Journal Ijarbn2020Документ56 страницAib Journal Ijarbn2020ijarbn editorОценок пока нет

- 12V 150AH Quanta-12AL150Документ2 страницы12V 150AH Quanta-12AL150Satheesh Kumar NatarajanОценок пока нет

- Parts List Xrv750yДокумент61 страницаParts List Xrv750yGiorgos KoretsisОценок пока нет

- Islamic StudyДокумент3 страницыIslamic StudyArooj ImranОценок пока нет

- 54 KkksДокумент3 страницы54 KkksAndi YassaОценок пока нет

- English WorksheetДокумент4 страницыEnglish WorksheetALI Imran100% (1)

- Mini ProjectДокумент27 страницMini ProjectAnju MuthuОценок пока нет

- Iocl Proce BidДокумент63 страницыIocl Proce BidSankara Naga Srinivas NОценок пока нет

- 11-22 IRD Awarded $65 Million Agricultural Development Project in Afghanistan's Kandahar and Helmand ProvincesДокумент2 страницы11-22 IRD Awarded $65 Million Agricultural Development Project in Afghanistan's Kandahar and Helmand ProvincesInternational Relief and DevelopmentОценок пока нет

- JCZ Marine Axial Fan: Safety - High Quality - Professional - Fast Delivery - Reliable PartnerДокумент9 страницJCZ Marine Axial Fan: Safety - High Quality - Professional - Fast Delivery - Reliable PartnerSea Man MktОценок пока нет

- Term Paper ClaveriaДокумент10 страницTerm Paper ClaveriaMarc LxmnОценок пока нет

- Mnagement Fee InfoДокумент1 страницаMnagement Fee InfoOpik TamaОценок пока нет

- Howto Cisco External Web Authentication (EN)Документ12 страницHowto Cisco External Web Authentication (EN)karthikkumarkanniyappanОценок пока нет

- TN 73 T 6099 PolicyДокумент2 страницыTN 73 T 6099 PolicyLakshmipathy SubramaniОценок пока нет

- Profile 45 250 Sandwich Panel Techincal DatasheetДокумент2 страницыProfile 45 250 Sandwich Panel Techincal DatasheetEle SultanaОценок пока нет

- Baltra Catalogues 2022-23 FinalДокумент44 страницыBaltra Catalogues 2022-23 FinalRohit KumarОценок пока нет

- Lista Atlantic 09-03-23 PDFДокумент32 страницыLista Atlantic 09-03-23 PDFcorsetti33Оценок пока нет

- MYPNA SE G12 U1 Web PDFДокумент110 страницMYPNA SE G12 U1 Web PDFOtto VasquezОценок пока нет

- SERIE Pegasus PoseidonДокумент14 страницSERIE Pegasus PoseidonOlger Quintero TapiaОценок пока нет

- Chorus 826v-Specification SheetДокумент1 страницаChorus 826v-Specification SheetMoPo Zio MauriОценок пока нет

- InvoiceДокумент1 страницаInvoiceGolden RosesОценок пока нет

- KOGA Specifications WorldTraveller29 F13WT H UkДокумент2 страницыKOGA Specifications WorldTraveller29 F13WT H Uk2009bobОценок пока нет

- Maximum Retail Price: 2T Specification 20 40 60 250 500 1 5Документ2 страницыMaximum Retail Price: 2T Specification 20 40 60 250 500 1 5Nitansh GuptaОценок пока нет

- 11 AppendixДокумент19 страниц11 AppendixГеорги ПренчевОценок пока нет

- Date: 11 March 2021 MR Rahul Sharma Rze2 Mahavi Enclave New Delhi New Delhi 110045 Delhi Policy No.: 16811926 Mobile No.: Xxxxxx3693Документ6 страницDate: 11 March 2021 MR Rahul Sharma Rze2 Mahavi Enclave New Delhi New Delhi 110045 Delhi Policy No.: 16811926 Mobile No.: Xxxxxx3693Rahul SharmaОценок пока нет

- Logcat CSC Compare LogДокумент2 491 страницаLogcat CSC Compare LogCosmin TironОценок пока нет

- Fuelling: FreedomДокумент394 страницыFuelling: FreedomAssa ZhouОценок пока нет

- 3.26 & 3.27 Kawat Las Nikko Steel 316 2,6 X 350 MM & 3,2 X 350 MMДокумент1 страница3.26 & 3.27 Kawat Las Nikko Steel 316 2,6 X 350 MM & 3,2 X 350 MMumarОценок пока нет

- Low Alloy Steel - An OverviewДокумент10 страницLow Alloy Steel - An OverviewhaharameshОценок пока нет

- Nickel and Cobalt MaterialsДокумент2 страницыNickel and Cobalt MaterialsshamsОценок пока нет

- The Iron-Iron Carbide (Fe-Fe C) Phase DiagramДокумент32 страницыThe Iron-Iron Carbide (Fe-Fe C) Phase DiagramNisaОценок пока нет

- Drawing 2Документ1 страницаDrawing 2Pradisa Radja LazuardiОценок пока нет

- Platuna - Alloy 1: Umicore Electroplating Decorative Precious MetalsДокумент21 страницаPlatuna - Alloy 1: Umicore Electroplating Decorative Precious MetalsIswanto AdeОценок пока нет

- En1.7225 42CrMo4Документ1 страницаEn1.7225 42CrMo4Ahmed El-sheshtawyОценок пока нет

- Range of Trim MaterialsДокумент1 страницаRange of Trim MaterialsAbu___AbdullahОценок пока нет

- Welding Chart The Complete Reference Guide To WeldingДокумент2 страницыWelding Chart The Complete Reference Guide To WeldingJitu JenaОценок пока нет

- ASTM Specifications - ASTM Specs and Standards For BoltsДокумент2 страницыASTM Specifications - ASTM Specs and Standards For BoltsskilachОценок пока нет

- Properteis Ofrefractory Metals and Metals PDFДокумент48 страницProperteis Ofrefractory Metals and Metals PDFBasavaraj N.CОценок пока нет

- Filler Wires LeafletДокумент2 страницыFiller Wires LeafletAshok RajОценок пока нет

- Reflex-Brochure Cologne 2020Документ15 страницReflex-Brochure Cologne 2020Phan MInh TriОценок пока нет

- Catalog of Hoop Earring-2-1Документ10 страницCatalog of Hoop Earring-2-1Jafeth VargasОценок пока нет

- Astm F468-2012Документ14 страницAstm F468-2012Svetlana PerekopskayaОценок пока нет

- Slickline Wire Supplier DataДокумент3 страницыSlickline Wire Supplier Datahoss mosafaОценок пока нет

- Product Form: Api 6A LT ASTM A694 F60Документ5 страницProduct Form: Api 6A LT ASTM A694 F60Ejaz KОценок пока нет

- Sae SymbolДокумент1 страницаSae Symbolnate anantathatОценок пока нет

- OKICAT11 04bДокумент26 страницOKICAT11 04bMohan SelvakumarОценок пока нет

- Cast Iron: Cast Iron Is A Group of Iron-Carbon Alloys With A Carbon Content Greater ThanДокумент8 страницCast Iron: Cast Iron Is A Group of Iron-Carbon Alloys With A Carbon Content Greater ThanspibluОценок пока нет

- 10-Low Alloy Steel PDFДокумент32 страницы10-Low Alloy Steel PDFIdes Trian100% (1)

- GalvalumeДокумент4 страницыGalvalumeSanel SarvagjnaОценок пока нет

- 2011sup1 PDFДокумент60 страниц2011sup1 PDFEka DavidОценок пока нет

- Steel NumbersДокумент3 страницыSteel NumbersAhmadiBinAhmadОценок пока нет

- Welding ConsumablesДокумент79 страницWelding Consumablesazam RazzaqОценок пока нет

- SteelMint Daily Report As On 27 Dec 2019 PDFДокумент13 страницSteelMint Daily Report As On 27 Dec 2019 PDFabhayОценок пока нет

- Excel Implementation of Schaeffler and Delong Diagrams PDFДокумент8 страницExcel Implementation of Schaeffler and Delong Diagrams PDFEmad A.AhmadОценок пока нет

- What Scrap Metal Is This? A Guide To Identifying Metals: The Magnet TestДокумент2 страницыWhat Scrap Metal Is This? A Guide To Identifying Metals: The Magnet TestRakesh Ranjan MishraОценок пока нет

- Brocas NachiДокумент83 страницыBrocas NachiconsultachОценок пока нет

- Howrah (Wire Drawing and Galvanising) Cluster: S.No. Name of Unit Address Contact Person Contact NoДокумент2 страницыHowrah (Wire Drawing and Galvanising) Cluster: S.No. Name of Unit Address Contact Person Contact NoVishal Kumar ShawОценок пока нет

- Jar Test Result ExcelДокумент11 страницJar Test Result ExcelMuhammad NuruddinОценок пока нет