Академический Документы

Профессиональный Документы

Культура Документы

Technological Aspects of Low-Alloyed Cast Steel Massive Casting Manufacturing

Загружено:

Rajkumar MuthumanickamОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Technological Aspects of Low-Alloyed Cast Steel Massive Casting Manufacturing

Загружено:

Rajkumar MuthumanickamАвторское право:

Доступные форматы

ISSN (1897-3310)

ARCHIVES Volume 13

Issue 4/2013

of

97 – 102

FOUNDRY ENGINEERING

18/4

Published quarterly as the organ of the Foundry Commission of the Polish Academy of Sciences

Technological Aspects of Low-Alloyed Cast

Steel Massive Casting Manufacturing

J. Szajnar a, A. Studnicki a, *, J. Głownia b, M. Kondracki a, J. Suchoń a, T. Wróbel a

a

Department of Foundry, Silesian University of Technology, Towarowa 7, 44-100 Gliwice, Poland

b

AGH University of Science and Technology, Department of Engineering of Cast Alloys and Composites,

Reymonta 23, 30-059 Cracow, Poland

* Corresponding author. E-mail address: andrzej.studnicki@polsl.pl

Received 15.06.2013; accepted in revised form 02.09.2013

Abstract

In the paper authors have undertaken the attempt of explaining the causes of cracks net occurrence on a massive 3-ton cast steel casting

with complex geometry. Material used for casting manufacturing was the low-alloyed cast steel with increased wear resistance modified

with vanadium and titanium. The studies included the primary and secondary crystallization analysis with use of TDA and the qualitative

and quantitative analysis of non-metallic inclusions.

Keywords: Low-alloyed cast steel, Crystallization, Modification, Non-metallic inclusions, TDA method

In the work selected results were presented, which were

1. Introduction registered during the massive casting manufacturing. Analysis of

results was aimed on describing the causes of cracking observed

Low-alloyed cast steels with increased wear resistance belong

on some surfaces of the casting.

to the group of materials often used for heavy-duty machinery

elements, such as: mining combines, loaders, mills etc [1-5]. The

representative material of the entire group mentioned above, is the

L20HGSNM cast steel according to PN-88/H-83160 standard [6], 2. Cast steel, technology of melting and

characterised by the highest mechanical properties (Rm >

1300MPa and Re> 1100 MPa) among all cast steel grades

casting

included in Polish Standards. In some cases of application such

Analysed low-alloyed cast steel with increased wear

mechanical characteristics are insufficient and need to be

resistance, modified with vanadium and titanium was used for

improved. This premise initiated the studies undertaken in

massive casting manufacturing with complex geometry with mass

Department of Foundry of Silesian University of Technology on

of 3 tons.

elaboration of new low-alloyed cast steel with high mechanical

The alloy was prepared in an electric-arc furnace with basic

and operational properties. Laboratory studies enabled obtainment

lining with full process of oxygen refining. Liquid metal was

of cast steel with tensile strength higher than 1450MPa.

deoxidised with use of Al and Ti according to elastic wire method

Encouraging results influenced the decision of massive casting

and modified with ferrovanadium and ferrotitanium. After

manufacturing, using the elaborated cast steel, in one of the Polish

modification the liquid melt was purified by argon bubbling. The

foundries.

mould was poured with cast steel at temperature of 1640oC with

bottom-tap ladle through two tap holes at the same time.

ARC HI VE S of F OUN DR Y EN GI NE ER ING V ol u me 1 3 , Iss u e 4 / 2 01 3 , 9 7 - 10 2 97

In Table 1 the chemical composition of obtained low-alloyed crystallization process of the prepared low-alloyed cast steel [8-

cast steel (marked with K) was presented. 11]. Testers construction as well as the moulding materials

applied enabled diversification of cooling rate for specimen

Table 1. castings. For applied testers two different cooling rate were

Chemical composition of (K) low-alloyed cast steel in %wt. obtained: for ATD-C tester - 100 K/min and ATD-Is - 50 K/min.

C Mn Si P S Cr Temperature registration during the analysis was conducted with

0,23 0,85 0,58 0,013 0,006 0,81 use of TDA stand, shown schematically in Fig. 2.

Ni Mo Al Cu V Ti

1,13 0,31 0,032 0,09 0,06 0,04

The mould was prepared with use of furan resin. Due to

complex geometry and diverse wall thickness of the casting, a

large number of risers and feeders was applied. The casting mass

together with the entire gating and feeding system was about 8 Fig. 2. Scheme of TDA stand

tons.

After pouring the casting cooled down in the mould about five In Fig. 3 the TDA curves in function of time were presented for

days. Then it was knocked out and the gating system together low-alloyed cast steel, in range of primary and secondary

with feeders was cut off using the gas burner. The raw casting crystallization, for both testers used during the analysis.

was machined. After machining the casting was visually

inspected; during the inspection the shrinkage cavities and

porosity were discovered in regions close to side feeders. These

flaws were eliminated with welding techniques according to PN-

EN ISO 11970:2009 standard. Next the casting was subjected to

penetrant inspection. Extensive net of cracks was revealed in

regions of top risers. In regions of casting with no feeders such

net of cracks did not occur. Depth of cracks was in range of 5-

8mm. In Fig. 1 casting surface with cracks was shown.

I – primary crystallization II – secondary crystallization

Fig. 3. TDA curves registered with use of ATD-C and ATD-Is

testers for low-alloyed cast steel during primary and secondary

crystallization

Based on Fe-C binary equilibrium system and TDA curves the

path of primary crystallization was established; during the

Fig. 1. Net of cracks on test casting surface

primary crystallization the peritectic transformation takes place

(Fig. 4).

The region of cracks was removed with use of machining.

Crucial regions of the test casting was also subjected to ultrasonic

a)

inspection, which did not show any other flaws. After elimination

of discovered defects and inspection the test casting was

transferred to heat treatment.

Although the shrinkage defects were hard to avoid (and easy

to predict) for such geometry of the cast steel casting, the cracks

net was a bit of surprise, especially when considered the earlier

experiences with similar cast steel grades in the foundry, which

did not revealed such cracking tendencies. The aspect of crackin

was further explored using different methods.

3. Analysis of primary and secondary

crystallization

primary crystallization path L → L+α (δ) → L+γ → γ

During the test casting manufacturing the Thermal and

Derivative Analysis (TDA) was employed to analyse the

98 ARC HI VE S of F OUN DR Y EN GI NE ER ING V ol u me 1 3 , Iss u e 4 / 2 01 3 , 9 7 - 10 2

b)

In Fig. 4a the probable path of primary crystallization for

analysed cast steel was shown, in fragment of Fe-C binary system.

The characteristic temperature points were defined, based on

TDA curves registered during the experimental studies (Fig 4b

and 4c) at different cooling rates. The crystallization starts in TA,

registered in maximum thermal effect of the α (δ) phase

crystallization. Next temperature point which is registered is

marked as TB and indicates the peritectic transformation

temperature. The primary crystallization of studied cast steel ends

in temperature TH. Conducted studies showed that changes in

cooling rate influenced the characteristic temperature points

c) position.

Phase transformations during the secondary crystallization are

also indicated in TDA curves diagrams. In Fig. 5 the considered

TDA curves together with as-cast structure were presented.

Registered characteristic temperature points indicated that during

the crystallization the baintic transformation takes place. The

microstructure of low-alloyed cast steel consists of bainite and

ferrite (Widmanstatten structure) together with non-metallic

inclusions (Fig. 5c and Fig. 5d).

Fig. 4. Analysis of primary crystallization of (K) low-alloyed cast

steel (a – path of crystallization in stable conditions, according to

Fe-C binary system, b – TDA curves for higher cooling rate of

sample casting, c – TDA curves for lower cooling rate of sample

casting

a) b)

c) d)

Fig. 5. Analysis of secondary crystallization for (K) low-alloyed cast steel (a –TDA curves at higher cooling rate, b –TDA curves at lower

cooling rate, c – as-cast microstructure of sample casting observed for higher cooling rate, d – as-cast microstructure of sample casting

observed for lower cooling rate)

ARC HI VE S of F OUN DR Y EN GI NE ER ING V ol u me 1 3 , Iss u e 4 / 2 01 3 , 9 7 - 10 2 99

a)

4. Analysis of non-metallic inclusions

To describe the stereological parameters on non-metallic

inclusions, the metallographic specimens were prepared from

TDA sample castings. Quantitative analysis was performed on

non-etched specimens and 400x magnification, for ten measuring

fields using the NIS ELEMENTS BR 3.10 software. The

measuring system consists of two applications; first one (NIS

ELEMETS F) is used for image capture and the second one (NIS

ELEMETS BR 3.10) is used for image analysis (inclusion

counting, area, capacity, shape ratio etc.). In Figs. 6 and 7

histograms of non-metallic inclusions distributions of its quantity

and fraction were shown, for sample casting ATD-C (Fig. 6) and

ATD-Is (Fig. 7), respectively. For analysed cast steel, at higher b)

cooling rate, the non-metallic inclusions fraction was 0,21% and

their quantity for 1mm2 is 1960. For lower cooling rate the

parameters were: 0,24% and 1540, respectively.

a)

c)

b)

Fig. 7. Non-metallic inclusions in sample casting ATD-Is (lower

cooling rate); a- example image of inclusions, b-distribution of

inclusion size according to size class, c- distribution of volumetric

c) fraction according to size class

Qualitative analysis of non-metallic inclusions consisted of

scanning microscopy of fracture and inclusions identification with

use of roentgen microanalysis. In Fig. 8 the fracture of as-cast

sample after KCV Charpy impact testing was shown. Specimens

was taken from sample casting designated to mechanical testing.

On specimens fracture porosity and different inclusions were

observed eg. the manganese sulphides and titanium carbides.

Fig. 6. Non-metallic inclusions in sample casting ATD-C (higher

cooling rate); a- example image of inclusions, b-distribution of

inclusion size according to size class, c- distribution of volumetric

fraction according to size class

100 ARC HI VE S of F OUN DR Y EN GI NE ER ING V ol u me 1 3 , Iss u e 4 / 2 01 3 , 9 7 - 10 2

a) a)

b) b)

c)

c)

d)

Fig. 9. Sulphide inclusions on low-alloyed cast steel fracture (a –

inclusions 1 and 2 in interdendritic spaces, b and c –

microanalysis of inclusions chemical composition

Fig. 8. Specimen fracture for low-alloyed cast steel investigated;

(a- microporosity, b- hollow interdendritic spaces,

c, d- titanium carbon inclusions on dendrites surface)

ARC HI VE S of F OUN DR Y EN GI NE ER ING V ol u me 1 3 , Iss u e 4 / 2 01 3 , 9 7 - 10 2 101

a) containing Fe, Mn and Si. In case of studied cast steel some

titanium carbides and carbide-nitrides can be treated as impurities,

regarding the fact that this element was used as a deoxidant and

modifier. All indicated phases can occur in the final stage of the

primary crystallization, in regions under the top risers, which

solidifies the last. The phases are pushed out by the moving front

of solidifying dendrites towards the top risers. Difference in

cooling rate of different casting regions causes stress exceeding

the material strength at elevated temperature, resulting in

deterioration of bounding between structural components and

finally in cracking occurrence.

Acknowledgement

b)

This work was prepared under the Scientific Development Project

N R507 0054 10 financed by Polish Ministry of Science and

Higher Education

References

[1] Kniaginin, G. (1972). Cast steel. Metallurgy and Founding.

Katowice: Śląsk.

[2] Lis, T. (2000). Present methods receives steel. Gliwice:

Publisher Politechnika Śląska.

[3] Sakwa, W., Jura, S., Sakwa, J. (1980). Wear resistance iron

Fig. 10. Probable inclusion of titanium carbide on low-alloyed alloys. Part II Cast steel. Kraków: ZG STOP.

cast steel fracture (a – inclusion 1, b – microanalysis of the [4] Dobrzański, L.A. (2004). Metal engineering materials.

inclusion) Warszawa: WNT.

[5] Głownia, J. (2002). Castings from alloyed cast steel;

application. Kraków: Publisher Fotobit.

[6] PN-88/H-83160 Wear resistant cast steel.

5. Summary [7] Głownia, J. & Huebner, K. (1997). Morphology of nitrides

during deoxidation of steel. Solidification of Metals and

Occurrence of cracks net on upper surface of the test casting, Alloys. 31.

located under risers would indicate that the causes of such state [8] Gawroński, J. (2004). Professor Stanisław Jura the creator of

need to be searched for in final stage of the primary crystallization theory and the industrial uses of diagnostics and the wear of

or during the gating and feeding system removal. The foundry metals and alloys. Archive of Founding. 4(spec. 16).

stated that, the removal process was performed according to [9] Cholewa, M., Jura, Z., Studnicki, A. (2009). The

standards applied to L20HGSNM and similar cast steel massive development of thermal analysis and derivative method in

castings and that such flaws did not occur in the past. The size and Department of Foundry Silesian University of Technology,

geometry of applied risers and feeders were verified using the Progresses Theory and The Casting practice, Publisher PAN

MAGMA software. Sufficient range of feeding system action was Katowice, (pp. 49-70).

in that way theoretically confirmed. Nevertheless, small shrinkage [10] Studnicki, A., Kondracki, M., Szajnar, J. (2013). Primary

cavities and porosity were indicated in regions near to side Crystallization of Chromium Cast Steel in Metastable

feeders, what can indicate, that the designed chemical Conditions, Metal 2013 Conference Proceedings, Brno.

composition of low-alloyed cast steel with increased wear [11] Studnicki, A., Kondracki, M., Szajnar, J. & Wróbel, T.

resistance needs different feeding model to be applied. In case of (2013). Crystallization of Low-alloyed Construction Cast

top risers its size was in agreement with the theory. Thus, the Steel Modified with V and Ti, Archive of Foundry

remaining solution of the problem is the low quality of the liquid Engineering. 13(3).

metal, represented by high quantity of non-metallic inclusions,

exceeding 0,2%. During the primary crystallization the inclusions

locate themselves at grain boundaries. Different sulphides occur,

not necessary manganese sulphides and complex oxides,

102 ARC HI VE S of F OUN DR Y EN GI NE ER ING V ol u me 1 3 , Iss u e 4 / 2 01 3 , 9 7 - 10 2

Вам также может понравиться

- Investigation and Application of High Strength Low Alloy Wear Resistant Cast SteelДокумент4 страницыInvestigation and Application of High Strength Low Alloy Wear Resistant Cast Steelz2aliОценок пока нет

- Efecto de Los Parámetros de Tratamiento Térmico en Las Características de La Fundición de Hierro Dúctil Austemperizado de Pared Delgada."Документ7 страницEfecto de Los Parámetros de Tratamiento Térmico en Las Características de La Fundición de Hierro Dúctil Austemperizado de Pared Delgada."Orlando RangelОценок пока нет

- Microstructure and Properties of Quenched-and-Aged Plates Produced From A Copper-Bearing HSLA SteelДокумент7 страницMicrostructure and Properties of Quenched-and-Aged Plates Produced From A Copper-Bearing HSLA Steelardeshir yarakzadehОценок пока нет

- SSC DWДокумент4 страницыSSC DWsanketpavi21Оценок пока нет

- 28 Pezda Effect of t6 1s 2013Документ4 страницы28 Pezda Effect of t6 1s 2013evelynОценок пока нет

- Effects of ZR, Ti, and Al Additions On Impact ToughnessДокумент12 страницEffects of ZR, Ti, and Al Additions On Impact ToughnessDo Tuan DatОценок пока нет

- Analysis On Clogging of Submerged Entry Nozzle in Continuous Casting of High Strength Steel With Rare EarthДокумент10 страницAnalysis On Clogging of Submerged Entry Nozzle in Continuous Casting of High Strength Steel With Rare EarthEvren ÇaprazОценок пока нет

- Shreya S 2019Документ8 страницShreya S 2019Ilmal YaqinОценок пока нет

- Rana2007 PDFДокумент4 страницыRana2007 PDFjohn paulОценок пока нет

- WJ - 1986 - 08 - s213 - TVT Reaquecido - Gráficos LegaisДокумент14 страницWJ - 1986 - 08 - s213 - TVT Reaquecido - Gráficos LegaisRafaella SilvaОценок пока нет

- Coatings 10 01265Документ15 страницCoatings 10 01265Mani RameshОценок пока нет

- Demarque 2018Документ9 страницDemarque 2018Jose G. Cueva CardeñaОценок пока нет

- Welding Metallurgy of Stainless Steels During Resistance Spot Welding Part I - Fusion Zone PDFДокумент11 страницWelding Metallurgy of Stainless Steels During Resistance Spot Welding Part I - Fusion Zone PDFKhalid HafezОценок пока нет

- Taheri2020 - Article - CharacterizationsOfDissimilar DSS-316LДокумент9 страницTaheri2020 - Article - CharacterizationsOfDissimilar DSS-316Lkamal touilebОценок пока нет

- Weldability of Austenitic Manganese Steel: J. Mendez, M. Ghoreshy, W.B.F. Mackay, T.J.N. Smith, R.W. SmithДокумент7 страницWeldability of Austenitic Manganese Steel: J. Mendez, M. Ghoreshy, W.B.F. Mackay, T.J.N. Smith, R.W. Smithนรวิชญ์ กาญจนามัยОценок пока нет

- Microstructural Evolution in The Friction Stir Welded 6061to CuДокумент13 страницMicrostructural Evolution in The Friction Stir Welded 6061to CuOrlandoZeaQuinteroОценок пока нет

- Microstructural Evaluation and Property Change of 5 WT PCT Al-Zn Coating On Press Hardening Steel During AustenitizationДокумент14 страницMicrostructural Evaluation and Property Change of 5 WT PCT Al-Zn Coating On Press Hardening Steel During Austenitization張竣凱Оценок пока нет

- Effect of Alloying Elements On Thermal Wear 2006 Journal of Iron and Steel RДокумент7 страницEffect of Alloying Elements On Thermal Wear 2006 Journal of Iron and Steel RJesus ZilchОценок пока нет

- A Comparative Study Into The Fracture Toughness Properties of Duplex Stainless SteelsДокумент9 страницA Comparative Study Into The Fracture Toughness Properties of Duplex Stainless Steelscehamos882Оценок пока нет

- IJETR021817Документ3 страницыIJETR021817erpublicationОценок пока нет

- Elrefaey 2010Документ7 страницElrefaey 2010mojtaba nОценок пока нет

- Ling2017 Article MicrostructureAndFatigueBehavi PDFДокумент9 страницLing2017 Article MicrostructureAndFatigueBehavi PDFKhalid HafezОценок пока нет

- Corrosion of Stainless Steels of Cryogenic Hydrocarbon Flare Tips BurnersДокумент13 страницCorrosion of Stainless Steels of Cryogenic Hydrocarbon Flare Tips Burnersravikanth_rОценок пока нет

- Characterization of Titanium/Steel Joints Brazed in Vacuum: Welding ResearchДокумент6 страницCharacterization of Titanium/Steel Joints Brazed in Vacuum: Welding Researchmojtaba nОценок пока нет

- 47 4 KozuhДокумент10 страниц47 4 KozuhRobert NatasorpОценок пока нет

- Las JurnalДокумент8 страницLas JurnalEby Nugroho MeinsideОценок пока нет

- 10 1016@j Jeurceramsoc 2007 04 007Документ9 страниц10 1016@j Jeurceramsoc 2007 04 007gutierrezcamposd20Оценок пока нет

- Sliding Wear ConditionsДокумент8 страницSliding Wear ConditionsAnantharam GSОценок пока нет

- Volchok 22Документ4 страницыVolchok 22amitkkambleОценок пока нет

- Gold Jewellery Casting Technology Design and Defects EliminationДокумент7 страницGold Jewellery Casting Technology Design and Defects EliminationReinol Eko SianturiОценок пока нет

- Optimizing Hot Dip Galvanizing Operations of Steel Sheets For Better QualityДокумент7 страницOptimizing Hot Dip Galvanizing Operations of Steel Sheets For Better QualitykhurshedlakhoОценок пока нет

- Materials Today: Proceedings: Vamshi Manne, Singh S.K., Sateesh N., Subbiah RamДокумент4 страницыMaterials Today: Proceedings: Vamshi Manne, Singh S.K., Sateesh N., Subbiah RamBilal AlahmadОценок пока нет

- Sensitization of Weld Overlay 308 PDFДокумент12 страницSensitization of Weld Overlay 308 PDFShoaib AhmedОценок пока нет

- ArunДокумент14 страницArunAyanokoji kunОценок пока нет

- Failure Analysis at Deep Drawing of Low Carbon SteelsДокумент7 страницFailure Analysis at Deep Drawing of Low Carbon SteelsPaul RosiahОценок пока нет

- Jresv9n1p9 A2bДокумент19 страницJresv9n1p9 A2bMatteo CarusoОценок пока нет

- X. Y. LI - Surface Engineering 17 (2001) 147-152 - Low Temperature Plasma Nitriding of 316 SS-Nature of S Phase and Its Thermal StablityДокумент6 страницX. Y. LI - Surface Engineering 17 (2001) 147-152 - Low Temperature Plasma Nitriding of 316 SS-Nature of S Phase and Its Thermal StablityTania DanielОценок пока нет

- Post-Mortem Ladle Shroud Analysis From The Casting of Al-Killed Steel: Microstructures and Origin of Alumina Clogging DepositsДокумент15 страницPost-Mortem Ladle Shroud Analysis From The Casting of Al-Killed Steel: Microstructures and Origin of Alumina Clogging DepositsCan ERTANОценок пока нет

- Roqtuf PDFДокумент6 страницRoqtuf PDFLeonidio CamposОценок пока нет

- ATD and DSC Analyses of Nickel SuperalloysДокумент4 страницыATD and DSC Analyses of Nickel SuperalloysEnary SalernoОценок пока нет

- Surface Modification of 316L Stainless Steel With Plasma NitridingДокумент11 страницSurface Modification of 316L Stainless Steel With Plasma NitridingDavid ToroОценок пока нет

- Influence of Clad Metal Chemistry On Stress CorrosДокумент6 страницInfluence of Clad Metal Chemistry On Stress CorrosOwais MalikОценок пока нет

- Plasma Nitriding of AISI 52100 Ball Bearing Steel and Effect of Heat Treatment On Nitrided LayerДокумент7 страницPlasma Nitriding of AISI 52100 Ball Bearing Steel and Effect of Heat Treatment On Nitrided LayerSubodh RanjanОценок пока нет

- The Influence of Heat Treatment On Microstructure and Crack Resistance of Boron Microalloyed Steel PlatesДокумент8 страницThe Influence of Heat Treatment On Microstructure and Crack Resistance of Boron Microalloyed Steel PlatesNileshGawandeОценок пока нет

- CI Casting Failre AnalysisДокумент4 страницыCI Casting Failre Analysisdelta lab sangliОценок пока нет

- Hot Workability and Corrosion Behavior of EN31 Grade Steel-CompressedДокумент7 страницHot Workability and Corrosion Behavior of EN31 Grade Steel-CompressedJaggu TitlerОценок пока нет

- Metals 11 01121Документ18 страницMetals 11 01121Izod GetterОценок пока нет

- Cracks in High-Manganese Cast Steel: Archives of Foundry EngineeringДокумент6 страницCracks in High-Manganese Cast Steel: Archives of Foundry EngineeringSaif UllahОценок пока нет

- Cracks in High-Manganese Cast Steel: Archives of Foundry EngineeringДокумент6 страницCracks in High-Manganese Cast Steel: Archives of Foundry EngineeringAgil SetyawanОценок пока нет

- Austenitic Oxide Dispersion Strengthened Steels A ReviewДокумент7 страницAustenitic Oxide Dispersion Strengthened Steels A ReviewJuliana FortunatoОценок пока нет

- Materials Science & Engineering A: M. Sabzi, S.H. Mousavi Anijdan, A.R. Eivani, N. Park, H.R. JafarianДокумент13 страницMaterials Science & Engineering A: M. Sabzi, S.H. Mousavi Anijdan, A.R. Eivani, N. Park, H.R. JafarianRami GhorbelОценок пока нет

- AL Si CuДокумент7 страницAL Si CuRiedl LaurentiuОценок пока нет

- 1 s2.0 S1005030215002108 MainДокумент9 страниц1 s2.0 S1005030215002108 MainDr. Rachid djoudjouОценок пока нет

- Evolution of Carbide Precipitates in 2.25Cr-1Mo Steel During Long-Term Service in A Power PlantДокумент7 страницEvolution of Carbide Precipitates in 2.25Cr-1Mo Steel During Long-Term Service in A Power PlantRogger Asmat VasquezОценок пока нет

- Engineering Failure AnalysisДокумент9 страницEngineering Failure AnalysisFranco Faza ZamoraОценок пока нет

- P65 Adc12 Ac4chДокумент13 страницP65 Adc12 Ac4chdevkumarvangarОценок пока нет

- Ijeit1412201305 43Документ7 страницIjeit1412201305 43Yamid NúñezОценок пока нет

- Dissimilar Welding of AISI 309 Stainless Steel To AISI 1020 Carbon Steel Using Arc Stud WeldingДокумент6 страницDissimilar Welding of AISI 309 Stainless Steel To AISI 1020 Carbon Steel Using Arc Stud WeldingFiras RocktОценок пока нет

- Resistance Spot Welding of Martensitic Stainless Steel (Ss420) - Part IДокумент12 страницResistance Spot Welding of Martensitic Stainless Steel (Ss420) - Part IJoel BrasilBorgesОценок пока нет

- Grain Boundary Chemistry and Intergranular Corrosion in Alloy 825Документ52 страницыGrain Boundary Chemistry and Intergranular Corrosion in Alloy 825Rajkumar MuthumanickamОценок пока нет

- TN VNR-DGL I 1905 08891Документ2 страницыTN VNR-DGL I 1905 08891Rajkumar MuthumanickamОценок пока нет

- Comparative Study of Slurry Erosion Behaviour On SS304 and SS202 in A Slurry Erosion Test Pot Rig Under Different Operating ParametersДокумент6 страницComparative Study of Slurry Erosion Behaviour On SS304 and SS202 in A Slurry Erosion Test Pot Rig Under Different Operating ParametersRajkumar MuthumanickamОценок пока нет

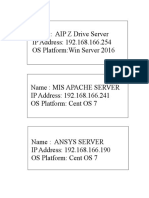

- Name: AIP Z Drive Server IP Address: 192.168.166.254 OS Platform:Win Server 2016Документ1 страницаName: AIP Z Drive Server IP Address: 192.168.166.254 OS Platform:Win Server 2016Rajkumar MuthumanickamОценок пока нет

- No. of Persons: No. of Laddus:: Special Entry Darshan Receipt ( .300/-)Документ1 страницаNo. of Persons: No. of Laddus:: Special Entry Darshan Receipt ( .300/-)Rajkumar MuthumanickamОценок пока нет

- Martensitic SS Alloy Materials PDFДокумент1 страницаMartensitic SS Alloy Materials PDFRajkumar MuthumanickamОценок пока нет

- 04 PotentialДокумент6 страниц04 PotentialRajkumar MuthumanickamОценок пока нет

- Green Gates Resort: A/C Cottage INR 6250 Couple / DayДокумент3 страницыGreen Gates Resort: A/C Cottage INR 6250 Couple / DayRajkumar MuthumanickamОценок пока нет

- 04 Method of Separation of VariablesДокумент15 страниц04 Method of Separation of VariablesRajkumar MuthumanickamОценок пока нет

- Workshop Inspection Checklist October 2010Документ11 страницWorkshop Inspection Checklist October 2010Rajkumar MuthumanickamОценок пока нет

- Ch5 - Rotation SpectraДокумент13 страницCh5 - Rotation SpectraRajkumar MuthumanickamОценок пока нет

- 2003-4.5 Feeding and RiseringДокумент48 страниц2003-4.5 Feeding and RiseringlalitlakshyОценок пока нет

- NMD Atm Brochure 2012Документ9 страницNMD Atm Brochure 2012Rajkumar MuthumanickamОценок пока нет

- Syllabus: ENGINEERING MATHEMATICS (Common To All Candidates)Документ3 страницыSyllabus: ENGINEERING MATHEMATICS (Common To All Candidates)Rajkumar MuthumanickamОценок пока нет

- The Grass Rink Summer Final 2019Документ9 страницThe Grass Rink Summer Final 2019api-241553699Оценок пока нет

- IPM GuidelinesДокумент6 страницIPM GuidelinesHittesh SolankiОценок пока нет

- PreviewpdfДокумент83 страницыPreviewpdfJohana GavilanesОценок пока нет

- A - PAGE 1 - MergedДокумент73 страницыA - PAGE 1 - MergedGenalyn DomantayОценок пока нет

- Linear Dynamic Analysis of Free-Piston Stirling Engines OnДокумент21 страницаLinear Dynamic Analysis of Free-Piston Stirling Engines OnCh Sameer AhmedОценок пока нет

- Mark Magazine#65Документ196 страницMark Magazine#65AndrewKanischevОценок пока нет

- Lab 2 - Using Wireshark To Examine A UDP DNS Capture Nikola JagustinДокумент6 страницLab 2 - Using Wireshark To Examine A UDP DNS Capture Nikola Jagustinpoiuytrewq lkjhgfdsaОценок пока нет

- CEN and CENELEC Position Paper On The Proposal For CPR RevisionДокумент15 страницCEN and CENELEC Position Paper On The Proposal For CPR Revisionhalexing5957Оценок пока нет

- T-Tess Six Educator StandardsДокумент1 страницаT-Tess Six Educator Standardsapi-351054075100% (1)

- Asuhan Keperawatan Pada Klien Dengan Proses Penyembuhan Luka. Pengkajian Diagnosa Perencanaan Implementasi EvaluasiДокумент43 страницыAsuhan Keperawatan Pada Klien Dengan Proses Penyembuhan Luka. Pengkajian Diagnosa Perencanaan Implementasi EvaluasiCak FirmanОценок пока нет

- Vocations The New Midheaven Extension ProcessДокумент266 страницVocations The New Midheaven Extension ProcessMiss M.100% (24)

- List of Phrasal Verbs 1 ColumnДокумент12 страницList of Phrasal Verbs 1 ColumnmoiibdОценок пока нет

- IMC - BisleriДокумент8 страницIMC - BisleriVineetaОценок пока нет

- Toi Su20 Sat Epep ProposalДокумент7 страницToi Su20 Sat Epep ProposalTalha SiddiquiОценок пока нет

- Oracle SOA Suite 11g:buildДокумент372 страницыOracle SOA Suite 11g:buildMohsen Tavakkoli100% (1)

- BECIL Registration Portal: How To ApplyДокумент2 страницыBECIL Registration Portal: How To ApplySoul BeatsОценок пока нет

- Distribution BoardДокумент7 страницDistribution BoardmuralichandrasekarОценок пока нет

- III.A.1. University of Hawaii at Manoa Cancer Center Report and Business PlanДокумент35 страницIII.A.1. University of Hawaii at Manoa Cancer Center Report and Business Planurindo mars29Оценок пока нет

- The Minimum Means of Reprisal - China's S - Jeffrey G. LewisДокумент283 страницыThe Minimum Means of Reprisal - China's S - Jeffrey G. LewisrondfauxОценок пока нет

- Sistine Chapel Ceiling Lesson PlanДокумент28 страницSistine Chapel Ceiling Lesson PlannivamОценок пока нет

- Karthik ResumeДокумент2 страницыKarthik ResumeArun Raj AОценок пока нет

- REAL BABY FOOD: Easy All-Natural Recipes For Your Baby and Toddler by Jenna HelwigДокумент8 страницREAL BABY FOOD: Easy All-Natural Recipes For Your Baby and Toddler by Jenna HelwigHoughton Mifflin Harcourt Cookbooks50% (2)

- Eu Schengen Catalogue enДокумент54 страницыEu Schengen Catalogue enSorin din ConstanțaОценок пока нет

- 200150, 200155 & 200157 Accelerometers: DescriptionДокумент16 страниц200150, 200155 & 200157 Accelerometers: DescriptionJOSE MARIA DANIEL CANALESОценок пока нет

- CSEC SocStud CoverSheetForESBA Fillable Dec2019Документ1 страницаCSEC SocStud CoverSheetForESBA Fillable Dec2019chrissaineОценок пока нет

- Audi R8 Advert Analysis by Masum Ahmed 10PДокумент2 страницыAudi R8 Advert Analysis by Masum Ahmed 10PMasum95Оценок пока нет

- Research On Export Trade in BangladeshДокумент7 страницResearch On Export Trade in BangladeshFarjana AnwarОценок пока нет

- Why File A Ucc1Документ10 страницWhy File A Ucc1kbarn389100% (4)

- LDSD GodseДокумент24 страницыLDSD GodseKiranmai SrinivasuluОценок пока нет

- Information Technology Project Management: by Jack T. MarchewkaДокумент44 страницыInformation Technology Project Management: by Jack T. Marchewkadeeps0705Оценок пока нет