Академический Документы

Профессиональный Документы

Культура Документы

Polyflow

Загружено:

angel gabriel perez valdezАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Polyflow

Загружено:

angel gabriel perez valdezАвторское право:

Доступные форматы

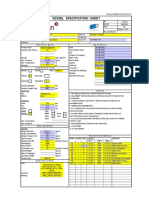

Outside Internal Min.

Short-term Minimum Bend Weight Reel Length per Loaded Reel

PRODUCT Diameter (in.) Diameter (in.) Liner Max. Pressure (psi) Burst Pressure (psi) Max Temp. (°F) Radius (ft.) (lbs./ft.) Size (ft.) Reel (ft.) Weight (lbs.)

THERMOFLEX ® PIPE A Nylon 6 polyphenylene liner makes Thermoflex pipe the ideal choice for a broad spectrum of applications.

STRONG AS STEEL — AND MORE DURABLE Thermoflex ® 2.375 2.35 1.90 Nylon PA6 2,000 5,389 150° 3.92 0.67 10.3 5,100 3,726

Thermoflex® pipe is a spoolable, reliable solution for hydrocarbon transportation, delivering the Thermoflex ® 3.0 3.05 2.52 Nylon PA6 1,800 5,018 150° 5.08 1.04 12 4,800 5,968

greatest strength-to-weight ratio, chemical compatibility and paraffin build-up resistance in Thermoflex ® 3.5 3.50 2.89 Nylon PA6 1,500 4,145 150° 5.83 1.35 12 3,900 6,279

reinforced thermoplastic pipes. The proprietary five-layer construction of Thermoflex pipe goes

beyond conventional pipe options, standing up to high pressure and extreme corrosive environments. Thermoflex ® 4.0 4.04 3.36 Nylon PA6 1,500 3,462 150° 6.73 1.74 12 1,850 4,217

Thermoflex ® 4.5 4.55 3.81 Nylon PA6 1,000 2,719 150° 7.58 2.13 12 1,600 4,402

Thermoflex ® 5.0 5.12 4.25 Nylon PA6 1,000 2,587 150° 8.53 2.77 14.5 1,400 4,882

Thermoflex ® 6.0 6.06 5.03 Nylon PA6 750 1,892 150° 10.1 3.84 14.5 600 3,304

THERMOFLEX ® PLUS PIPE A polyphenylene sulfide (PPS) liner makes Thermoflex Plus pipe ideal for transporting highly corrosive fluid with high H2S content.

For Sour-Gas, Corrosive For Extreme Temperatures, Chemicals

and Bacterial Environments and Conditions Thermoflex ® 2.375 Plus 2.35 1.90 PPS 2,000 5,886 150° 3.92 0.69 10.3 5,100 3,834

With an inner Polyphenylene Sulfide (PPS) PE-RT material, combined with a Nylon PA12 liner Thermoflex ® 3.0 Plus 3.05 2.52 PPS 1,800 5,267 150° 5.08 1.07 12 4,800 6,121

layer, Thermoflex Plus resists harsh chemicals makes Thermoflex RT ideal for extreme conditions,

Thermoflex ® 3.5 Plus 3.50 2.89 PPS 1,500 4,543 150° 5.83 1.39 12 3,900 6,438

and is a superior choice for extremely including high temperatures, aggressive chemicals,

corrosive environments. high oxidation and certain hydrocarbons. Thermoflex ® 4.0 Plus 4.04 3.36 PPS 1,500 3,830 150° 6.73 1.79 12 1,850 4,314

Thermoflex ® 4.5 Plus 4.55 3.81 PPS 1,000 3,091 150° 7.58 2.2 12 1,600 4,517

Thermoflex ® 5.0 Plus 5.12 4.25 PPS 1,000 2,867 150° 8.53 2.84 14.5 1,400 4,976

Five Layers of Reinforcement Thermoflex ® 6.0 Plus 6.06 5.03 PPS 750 2,013 150° 10.1 3.92 14.5 600 3,352

PE-RT material with a Nylon 12 liner makes Thermoflex RT pipe ideal for challenging operating conditions - high temperature, aggressive chemicals,

THERMOFLEX ® RT PIPE crude oil (aromatics) and paraffin build up.

ABRASION-RESISTANT PROPRIETARY ARAMID Thermoflex ® 2.375 RT 2.35 1.87 Nylon PA12 2,000 5,473 180° 3.92 0.8 10.3 5,100 4,375

HDPE OUTER JACKET FIBER REINFORCEMENT

Thermoflex ® 3.0 RT 3.05 2.53 Nylon PA12 1,800 4,848 180° 5.08 1.13 12 4,800 6,404

Thermoflex ® 3.5 RT 3.50 2.92 Nylon PA12 1,500 4,010 180° 5.83 1.41 12 3,900 6,507

Thermoflex ® 4.0 RT 4.04 3.37 Nylon PA12 1,500 3,743 180° 6.73 1.86 12 1,850 4,449

Thermoflex ® 4.5 RT 4.55 3.82 Nylon PA12 1,000 2,527 180° 7.58 2.22 12 1,800 5,002

TYBOND LAYER

Thermoflex ® 5.0 RT 5.12 4.26 Nylon PA12 1,000 2,560 180° 8.53 3.02 14.5 1,400 5,230

Thermoflex ® 6.0 RT 6.06 5.01 Nylon PA12 750 1,874 180° 10.1 4.02 14.5 700 3,811

Thermoflex Couplings & Fittings

đŏ No welding required or makeup needed for flanges

PROPRIETARY INERT or thread joints

HYDROCARBON- đŏ Coupling options include NPT or BSPT threads, weld end,

RESISTANT LINER and API 6A/ASME B16.5 flange—all can mate with standard

or custom pipe sizes

CENTER LAYER FOR HIGH-

TEMPERATURE STRENGTH

đŏ Termination fittings connect to common oilfield infrastructure Contact us at (432) 686-2001

đŏ Available in carbon steel, 316 stainless steel, 2205 duplex

stainless steel or Polyphenylene Sulfide (PPS) coated or sales@thermoflexpipe.com

ThermoflexPipe.com © 2018 Polyflow, LLC. All rights reserved. Thermoflex is a registered trademark of Polyflow, LLC.

Minimum ThermoflexPipe.com

Outside Internal Maximum Short-term Burst Minimum Bend Weight Length per Loaded Reel

LOW-PRESSURE FLUID PRODUCT Diameter (in.) Diameter (in.) Pressure (psi) pressure (psi) Max Temp. °F Radius (ft.) (lbs./ft.) Reel (ft.) Weight (lbs.) Reel Size (ft.)

TRANSPORT, WITH PE FLEX™ PLUS PIPE A Nylon PA6 liner and a high density polyethylene backer make PE Flex Plus superior for continuous runs transporting fluids below 300 psi.

HYDROCARBON AND PE Flex Plus 2.0 2.375 1.729 4 0.88 8,850 8,810 12

240 >600

PARAFFIN RESISTANCE PE Flex Plus 3.0 3.5 2.600 (70°F) (70°F) 5.8 1.82 3,600 7,540 12

140°

PE Flex Plus 4.0 4.5 3.372 150 >375 7.5 2.93 2,300 7,740 12

Providing major advantages over conventional

(140°F) (140°F)

HDPE pipe, PE Flex® Plus is the best choice for

long, continuous runs transporting fluids below

PE Flex Plus 6.0 6.625 5.013 11 6.17 915 8,250 14.5 HIGH PRESSURES.

300 psi. Featuring a nylon liner for protection

against hydrocarbon contamination, it requires

PE FLEX™ PLUS RT PIPE A Nylon liner and a PE-RT backer make PE Flex RT excellent for transporting fluids up to 180°F. HIGHER TEMPERATURES.

no pressure derating for hydrocarbons, even at

higher temperatures.

PE Flex RT 2.0 2.375 1.729

240 >600

4 0.88 8,850 8,810 12 UNMATCHED DURABILITY.

PE Flex RT 3.0 3.5 2.600 (70°F) (70°F) 5.8 1.82 3,600 7,540 12

BRING IT ON.

180°

PE Flex RT 4.0 4.5 3.372 120 >300 7.5 2.93 2,300 7,740 12

LOW-PRESSURE TRANSPORT (180°F) (180°F)

PE Flex RT 6.0 6.625 5.013 11 6.17 915 8,250 14.5

OF FLUIDS UP TO 180°F

PE Flex® Plus RT features all benefits of PE Flex Coupling Options

Plus, along with a nylon liner with a PE-RT backer

to withstand higher temperatures.

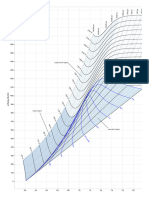

PE Flex Plus and PE Flex RT Pipe Pressure Ratings

Mechanical Versus Temperature Service with Crude Oil

With 10-times faster 500

installation in any weather,

PE Flex Plus DR9

Triple-Layer Protection this reliable method 450

requires no special tools PE Flex RT DR9

or extra time for heating 400

or cooling. It’s suitable for Regular PE Pipe DR9

348

new, used or dirty pipe, 350

Pressure rating (psi)

329

ABRASION-RESISTANT

311

HDPE OUTER JACKET providing connections

293

that meet or exceed pipe 300 276

pressure ratings. 260

240

NYLON LINER 250 230

215

201

Electrofusion 188

200 175

162

Featuring a lower per-unit 150

cost, this method joins 150 174

pipes by melting surfaces 165

155

147 143

together. Suitable for 138 135

100 130

120 115 127 120

all fluid types, it offers 108 101

94

GPS traceability, superior 87

50 81 75

TYBOND LAYER corrosion resistance and

fusion consistency with no

loss of pipe ID or joint strength.

0

0 50 100 150 200

Temperature (°F)

ThermoflexPipe.com Pressure ratings for regular single-wall Polyethylene pipe are calculated in accordance with PPI TR-9 and Handbook for PE pipe.

Вам также может понравиться

- Choosing The Right Teflon Fluoropolymer Resin: Comparison Chart Summary and AnalysisДокумент1 страницаChoosing The Right Teflon Fluoropolymer Resin: Comparison Chart Summary and AnalysisXarly Polite Jr.Оценок пока нет

- CORROSION RESISTANCE Durco 2 PDFДокумент8 страницCORROSION RESISTANCE Durco 2 PDFJUAN ANTONIO HERNANDEZ SOSAОценок пока нет

- Gasket Corrosion Guide Page 1Документ1 страницаGasket Corrosion Guide Page 1KiranОценок пока нет

- Gasket Corrosion Resistance Guide Page-1Документ1 страницаGasket Corrosion Resistance Guide Page-1KiranОценок пока нет

- Rubber FaberДокумент10 страницRubber FabersoldatechОценок пока нет

- Hi Temp 1000 HaДокумент2 страницыHi Temp 1000 HaMarleo MorenoОценок пока нет

- Comparison of Thermolon Vs PTFEДокумент33 страницыComparison of Thermolon Vs PTFERené, soluciones para un hogar saludables y eficientesОценок пока нет

- PFA Vs PTFE in InstrumentationДокумент5 страницPFA Vs PTFE in InstrumentationArif HakimОценок пока нет

- Shashi Fluoroplastiks E-BrochureДокумент6 страницShashi Fluoroplastiks E-BrochureYogesh LadolaОценок пока нет

- TFM 1600 Ptfe Seats: Properties Benefi TsДокумент2 страницыTFM 1600 Ptfe Seats: Properties Benefi TsagrovadoОценок пока нет

- Lineplus PF 150-P - TDSДокумент2 страницыLineplus PF 150-P - TDSSAURAVENDRA TOMARОценок пока нет

- Teflon Ptfe NXT 85 Product InfoДокумент2 страницыTeflon Ptfe NXT 85 Product InfocvfОценок пока нет

- Teflon Tubing: What You Absolutely Need To KnowДокумент4 страницыTeflon Tubing: What You Absolutely Need To Knowdarsh2001patelОценок пока нет

- Dupont Teflon Ptfe 3859Документ4 страницыDupont Teflon Ptfe 3859hermioneОценок пока нет

- Teflon Ptfe Disp 30 Product InfoДокумент2 страницыTeflon Ptfe Disp 30 Product InfoThusith WijayawardenaОценок пока нет

- TFM 1600Документ1 страницаTFM 1600Rendi MulyadiОценок пока нет

- DEGALAN® For Intumescence Coatings (English)Документ2 страницыDEGALAN® For Intumescence Coatings (English)slantsyhimОценок пока нет

- Loctite Ea 934na Aero (Known As Hysol Ea 934na) - TdsДокумент5 страницLoctite Ea 934na Aero (Known As Hysol Ea 934na) - TdspokleОценок пока нет

- Gore UPG Gasket Style 800 Specs PDFДокумент2 страницыGore UPG Gasket Style 800 Specs PDFprateekmuleОценок пока нет

- Loctite Ea 9394.2 Aero-EnДокумент5 страницLoctite Ea 9394.2 Aero-EnOzgur CimenОценок пока нет

- PCRS9309-QT TDSДокумент5 страницPCRS9309-QT TDSDaniele CatacchioОценок пока нет

- Loctite Ea 9396 AeroДокумент4 страницыLoctite Ea 9396 AerobenОценок пока нет

- Hysol EA 9394Документ4 страницыHysol EA 9394aswampОценок пока нет

- Technical Data Sheet: EPIKURE™ Curing Agent 3046Документ4 страницыTechnical Data Sheet: EPIKURE™ Curing Agent 3046Maha MuflehОценок пока нет

- PFA - HandbookДокумент16 страницPFA - HandbookFelipe GustavoОценок пока нет

- Teflon 200731103643Документ22 страницыTeflon 200731103643Diwas GhimireОценок пока нет

- Material Description: PolyvinylsДокумент13 страницMaterial Description: Polyvinylsyuvaraja.dhanabalОценок пока нет

- Disp 40Документ2 страницыDisp 40RajanSharmaОценок пока нет

- Hysol Ea 9395 PDFДокумент4 страницыHysol Ea 9395 PDFedgmtОценок пока нет

- Fluolion BrochureДокумент7 страницFluolion Brochurekyn jessОценок пока нет

- Dupont Teflon VlinexДокумент2 страницыDupont Teflon Vlinexsowmiya bОценок пока нет

- Magnetic Flowmeter Material Selection Guide: Technical Data SheetДокумент24 страницыMagnetic Flowmeter Material Selection Guide: Technical Data SheetGILBERTОценок пока нет

- Chapter 1 (Introduction)Документ26 страницChapter 1 (Introduction)aimanrslnОценок пока нет

- Supaflex Rubber InsДокумент12 страницSupaflex Rubber InssenghouОценок пока нет

- Valves Eat Seal Materials and Service TypesДокумент3 страницыValves Eat Seal Materials and Service Typess.mladinОценок пока нет

- Loctite Ea 9395 Aero: Epoxy Paste AdhesiveДокумент5 страницLoctite Ea 9395 Aero: Epoxy Paste AdhesiveFernando GarzonОценок пока нет

- Engineering Bulletin: Rev. 10/07 Page 1 of 4Документ5 страницEngineering Bulletin: Rev. 10/07 Page 1 of 4Iván López PavezОценок пока нет

- Hcs2407 141 Henkel Resin Kit Loctite Ea 9394 AeroДокумент6 страницHcs2407 141 Henkel Resin Kit Loctite Ea 9394 AeroTimmyОценок пока нет

- Isolasi ArmaflexДокумент5 страницIsolasi ArmaflexjatakompОценок пока нет

- Magnetic Flowmeter Material Selection Guide: Technical Data Sheet TDS 3033 June 1993Документ27 страницMagnetic Flowmeter Material Selection Guide: Technical Data Sheet TDS 3033 June 1993mealysrОценок пока нет

- Flange Insulation Kits - WebДокумент1 страницаFlange Insulation Kits - WebabhishekОценок пока нет

- Tekapur Firestop Hand Held TD - V2 - GB - 06 20Документ2 страницыTekapur Firestop Hand Held TD - V2 - GB - 06 20sacdawoodОценок пока нет

- TEFLON FPДокумент3 страницыTEFLON FPcamilsoftОценок пока нет

- Free Flow Granular Modified PTFEДокумент8 страницFree Flow Granular Modified PTFEharsh421Оценок пока нет

- Allseals Web LowДокумент6 страницAllseals Web LowjmartinezmoОценок пока нет

- Elastomers Properties PDFДокумент5 страницElastomers Properties PDFhadeОценок пока нет

- Loctite Ea 9309.3naДокумент5 страницLoctite Ea 9309.3naechobravo1Оценок пока нет

- Nylatron® 4.6 - BoedekerДокумент6 страницNylatron® 4.6 - BoedekerMas ZuhadОценок пока нет

- FOAMULAR 400 Product Data 2077961Документ2 страницыFOAMULAR 400 Product Data 2077961dinko19Оценок пока нет

- International Cement Review - Too Hot To Handle. Heat Resistant Belt ArticleДокумент3 страницыInternational Cement Review - Too Hot To Handle. Heat Resistant Belt ArticleawfahОценок пока нет

- Hysol EA9395 Data SheetДокумент4 страницыHysol EA9395 Data SheetenjeeОценок пока нет

- Elastomers For Energy, Oil & Gas SealingДокумент2 страницыElastomers For Energy, Oil & Gas SealingDanialОценок пока нет

- Armaflex Pipa AcДокумент6 страницArmaflex Pipa Acmedtsl.cppОценок пока нет

- Armaflex Class 1: Engineered To Prevent CondensationДокумент6 страницArmaflex Class 1: Engineered To Prevent CondensationSalamet TeguhОценок пока нет

- EA9395Документ4 страницыEA9395lacsmm982Оценок пока нет

- MultiTherm OG-1® Tech DataДокумент2 страницыMultiTherm OG-1® Tech DataSteranskoОценок пока нет

- Zeus FocusPTFEДокумент6 страницZeus FocusPTFESelva BabuОценок пока нет

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesОт EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesРейтинг: 3.5 из 5 звезд3.5/5 (3)

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsОт EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsРейтинг: 5 из 5 звезд5/5 (1)

- Laboratory Manual of Glass-BlowingОт EverandLaboratory Manual of Glass-BlowingРейтинг: 5 из 5 звезд5/5 (1)

- Dragon Ball - Bilingual Discussion and Activities Lesson Plan Chapter 1 +Документ8 страницDragon Ball - Bilingual Discussion and Activities Lesson Plan Chapter 1 +angel gabriel perez valdezОценок пока нет

- The I-Configure InterfaceДокумент51 страницаThe I-Configure Interfacecasaean100% (1)

- Valves Piping and Pipelines Handbook PDFДокумент694 страницыValves Piping and Pipelines Handbook PDFangel gabriel perez valdez100% (1)

- Elded EF Elded EF OДокумент5 страницElded EF Elded EF Oangel gabriel perez valdezОценок пока нет

- Vibration Analysis: A) Modal AnalysisДокумент5 страницVibration Analysis: A) Modal Analysisangel gabriel perez valdezОценок пока нет

- Adding 3D Pipe Supports To A Specification Using The CADWorx Specification Editor PDFДокумент19 страницAdding 3D Pipe Supports To A Specification Using The CADWorx Specification Editor PDFangel gabriel perez valdez100% (1)

- J54-100 Parte2Документ45 страницJ54-100 Parte2angel gabriel perez valdezОценок пока нет

- Delivery: Properties:: Se AnexaДокумент3 страницыDelivery: Properties:: Se Anexaangel gabriel perez valdezОценок пока нет

- Soliii-N800-P04-51-R0 (E-0821.01)Документ2 страницыSoliii-N800-P04-51-R0 (E-0821.01)angel gabriel perez valdezОценок пока нет

- J54-100 Parte1Документ45 страницJ54-100 Parte1angel gabriel perez valdezОценок пока нет

- Exchanger Specification Sheet: Service Date of Purchase Order No Location Serial No. Supplier Kcal/hr 1,183,330Документ4 страницыExchanger Specification Sheet: Service Date of Purchase Order No Location Serial No. Supplier Kcal/hr 1,183,330angel gabriel perez valdezОценок пока нет

- Soliii-N800-P04-15-R0 (E-0811.01)Документ2 страницыSoliii-N800-P04-15-R0 (E-0811.01)angel gabriel perez valdezОценок пока нет

- Filtro Y Griega StrainerДокумент48 страницFiltro Y Griega Strainerangel gabriel perez valdezОценок пока нет

- D 52156Документ45 страницD 52156angel gabriel perez valdezОценок пока нет

- Exchanger Specification Sheet: Service Date of Purchase Order No Location Serial No. Supplier 389,450Документ9 страницExchanger Specification Sheet: Service Date of Purchase Order No Location Serial No. Supplier 389,450angel gabriel perez valdezОценок пока нет

- Exchanger Specification Sheet: Process Conditions Tube Side Shell SideДокумент2 страницыExchanger Specification Sheet: Process Conditions Tube Side Shell Sideangel gabriel perez valdezОценок пока нет

- Vessel Specification SheetДокумент2 страницыVessel Specification Sheetangel gabriel perez valdezОценок пока нет

- Pipe Hangers and SupportДокумент120 страницPipe Hangers and Supportangel gabriel perez valdezОценок пока нет

- Pipe Fittings: S# Description No Size Unit Rate (RS/FT) Cost Rs. Dia (Rs/No)Документ20 страницPipe Fittings: S# Description No Size Unit Rate (RS/FT) Cost Rs. Dia (Rs/No)angel gabriel perez valdezОценок пока нет

- CH 12 Review Solutions PDFДокумент11 страницCH 12 Review Solutions PDFOyinkansola OsiboduОценок пока нет

- Geared Motors Power Distribution: V V V VДокумент2 страницыGeared Motors Power Distribution: V V V VShamim Ahsan ParvezОценок пока нет

- V1 N2 1980 RabenhorstДокумент6 страницV1 N2 1980 Rabenhorstraa2010Оценок пока нет

- 15Документ20 страниц15Allen Rey YeclaОценок пока нет

- Virgil Ionescu Eforie 2016Документ99 страницVirgil Ionescu Eforie 2016Andreea CimpoiОценок пока нет

- Demag KBK Alu Enclosed Track SystemДокумент2 страницыDemag KBK Alu Enclosed Track SystemMAGSTОценок пока нет

- Low Temperature Plastics - EnsingerДокумент4 страницыLow Temperature Plastics - EnsingerAnonymous r3MoX2ZMTОценок пока нет

- UNIT 14 - On-Screen DigitizingДокумент6 страницUNIT 14 - On-Screen DigitizingResti KharismaОценок пока нет

- Physics Lab - Detailed - Answer KeyДокумент6 страницPhysics Lab - Detailed - Answer KeyJasdeepSinghОценок пока нет

- Mathematical Analysisand Optimizationfor EconomistsДокумент4 страницыMathematical Analysisand Optimizationfor EconomistsGuillermo GómezОценок пока нет

- 86-Article Text-596-1-10-20211030Документ7 страниц86-Article Text-596-1-10-20211030adel bbОценок пока нет

- Mollier Enthalpy Entropy Chart For Steam - US UnitsДокумент1 страницаMollier Enthalpy Entropy Chart For Steam - US Unitslin tongОценок пока нет

- Organic Chemistry - Some Basic Principles and Techniques-1Документ195 страницOrganic Chemistry - Some Basic Principles and Techniques-1aditya kumar Agarwal100% (1)

- Day 3 Polygons Lesson PlanДокумент6 страницDay 3 Polygons Lesson PlanBA RTОценок пока нет

- Fundamentals of Physics Sixth Edition: Halliday Resnick WalkerДокумент4 страницыFundamentals of Physics Sixth Edition: Halliday Resnick WalkerAhmar KhanОценок пока нет

- OODBMSДокумент19 страницOODBMSashimsarkar2006Оценок пока нет

- QPT Charts BarДокумент8 страницQPT Charts BarKacak BergayaОценок пока нет

- W.R. Klemm (Auth.) - Atoms of Mind - The - Ghost in The Machine - Materializes-Springer Netherlands (2011)Документ371 страницаW.R. Klemm (Auth.) - Atoms of Mind - The - Ghost in The Machine - Materializes-Springer Netherlands (2011)El equipo de Genesis ProjectОценок пока нет

- MA201 Mechanical Vertical Machining Center 133-134Документ2 страницыMA201 Mechanical Vertical Machining Center 133-134Ali HashmiОценок пока нет

- API ISCAN-LITE ScannerДокумент4 страницыAPI ISCAN-LITE Scannergrg_greОценок пока нет

- 3AP1 DTC en - V9 - Epost PDFДокумент8 страниц3AP1 DTC en - V9 - Epost PDFjoan75Оценок пока нет

- Integrals - Integral Calculus - Math - Khan Academy PDFДокумент7 страницIntegrals - Integral Calculus - Math - Khan Academy PDFroberteleeroyОценок пока нет

- Nav 2000Документ4 страницыNav 2000Balaji TriplantОценок пока нет

- Ugc Model Curriculum Statistics: Submitted To The University Grants Commission in April 2001Документ101 страницаUgc Model Curriculum Statistics: Submitted To The University Grants Commission in April 2001Alok ThakkarОценок пока нет

- FP 3000 PDFДокумент1 страницаFP 3000 PDFClaudio Godoy ZepedaОценок пока нет

- HPC168 Passenger CounterДокумент9 страницHPC168 Passenger CounterRommel GómezОценок пока нет

- Ap Unit 1 NotesДокумент42 страницыAp Unit 1 NotesDhruv GoyalОценок пока нет

- Pre Calculus MIdTermsДокумент5 страницPre Calculus MIdTermsLamette Austria Ayong0% (1)

- Put Call ParityДокумент37 страницPut Call ParityVaidyanathan Ravichandran100% (1)

- Test Bank For Chemistry An Atoms Focused Approach 3rd Edition Thomas R Gilbert Rein V Kirss Stacey Lowery Bretz Natalie FosterДокумент38 страницTest Bank For Chemistry An Atoms Focused Approach 3rd Edition Thomas R Gilbert Rein V Kirss Stacey Lowery Bretz Natalie Fosterauntyprosperim1ru100% (10)