Академический Документы

Профессиональный Документы

Культура Документы

Pipelines Design Philosophy Overview

Загружено:

Daniel DamboИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Pipelines Design Philosophy Overview

Загружено:

Daniel DamboАвторское право:

Доступные форматы

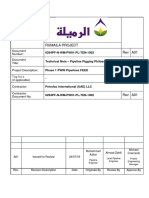

ADDITIONAL AGREEMENT / APPROVAL RECORD

Party Ref Ind Name Sign Date

REVISION PHILOSOPHY

All revisions for review will be issued at R01, with subsequent R02, R03, etc as required.

All revisions approved for issue or design will be issued at A01, with subsequent A02, A03, etc as

required.

Documents approved for Construction will be issued at C01, C02 , and C03 respectively.

Documents or drawings revised as ―As built‖ will be issued as Z01, Z02 Z03 etc.

Narrative sections revised from previous approved issues are to be noted in the table below and/or

highlighted in the RH margin (using the appropriate revision status) thus: | A02

Previous revision highlighting to be removed at subsequent issues.

Drawings/diagrams revised from previous approved issues are highlighted by 'clouding' the affected

areas and by the use of a triangle containing the revision status.

REVISION HISTORY

Revision Date Reason for Change

SSG-TPEF-GEN-LA-5507-00001-A01 Page 2 of 29 Pipelines Design Philosophy

This document is controlled electronically and is uncontrolled when printed

Table of Contents

DEFINITIONS AND ABBREVIATIONS .......................................................................................................... 4

1.0 INTRODUCTION........................................................................................................................ 6

1.1Objective ............................................................................................................................... 6

1.2Background ........................................................................................................................... 6

1.3Change Control ..................................................................................................................... 7

1.4Units and Coordinates .......................................................................................................... 7

2.0 REGULATIONS, CODES AND STANDARDS ........................................................................... 9

2.1General 9

2.2Regulations ........................................................................................................................... 9

2.3Codes and Standards ........................................................................................................... 9

2.4Order of Precedence ............................................................................................................. 9

3.0 PROJECT SUMMARY ............................................................................................................. 11

3.1Project Workscope .............................................................................................................. 11

3.2Location and Interfaces ....................................................................................................... 12

3.3Pipeline Design Life ............................................................................................................ 12

4.0 ROUTE SELECTION, PERMITS AND ACQUISITION .............................................................. 13

4.1Route Selection ................................................................................................................... 13

4.2Permits 13

4.3Land Acquisition .................................................................................................................. 14

5.0 DESIGN DATA ......................................................................................................................... 15

5.1Material Data ....................................................................................................................... 15

5.3Feed Composition ............................................................................................................... 15

5.4Feed Pressure and Temperature Data ............................................................................... 15

6.0 DESIGN PHILOSOPHY ........................................................................................................... 17

6.1Flow Assurance................................................................................................................... 17

6.2Pipeline Loading Cases ...................................................................................................... 17

6.3Pipeline Expansion and Flexibility....................................................................................... 18

6.4Pipeline Wall Thickness ...................................................................................................... 19

6.5River and Swamp Crossings............................................................................................... 19

6.6Landfall and Shore Approach ............................................................................................. 19

6.7Subsea Pipeline Crossing Design ....................................................................................... 20

6.8Pipeline Branches Connections .......................................................................................... 20

6.9ESD and Blowdown ............................................................................................................ 20

6.10 Subsea Valves ...................................................................................................... 20

6.11 Sectionalising Valves ............................................................................................ 20

6.12 Corrosion Control ................................................................................................. 21

6.13 Hydrotest, Pre-Commissioning and Commissioning ............................................ 22

6.14 Pipeline Leak Detection ........................................................................................ 22

6.15 Drains ................................................................................................................... 22

6.16 Instrument Air ....................................................................................................... 22

6.17 Safeguarding Philosophy...................................................................................... 22

6.18 Pipeline Risk Analysis .......................................................................................... 22

7.0 OPERATIONAL REQUIREMENTS .......................................................................................... 23

7.1Start Up 23

7.2Maintenance and Inspection ............................................................................................... 23

7.3Isolation / Locked Valve Philosophy ................................................................................... 23

7.4Spares 23

8.0 CONSTRUCTABILITY / CONSTRUCTION INTERFACES...................................................... 25

9.0 REFERENCES ......................................................................................................................... 26

SHELL DESIGN AND ENGINEERING PRACTICE (DEPS)............................................................................ 27

SPDC PIPELINE ENGINEERING CONSTRUCTION SPECIFICATION............................................................. 27

INTERNATIONAL CODES AND STANDARDS .............................................................................................. 28

SSG-TPEF-GEN-LA-5507-00001-A01 Page 3 of 29 Pipelines Design Philosophy

This document is controlled electronically and is uncontrolled when printed

Definitions and Abbreviations

The following definitions and abbreviations are used in this document

Definitions

Pipeline – General A system of pipes and other components used to transport

hydrocarbon between plants. A pipeline includes pig traps and

extends from pig trap to pig trap, or, if no pig trap is fitted, to the first

isolation valve within the plant.

Pipeline – Specific A pipeline transporting processed hydrocarbon from the processing

plant. A flowline is a pipeline that transports un-processed

hydrocarbon from a well head to a remote gathering point (manifold)

or a processing plant. A Bulkline is a pipeline which transports un-

processed hydrocarbon from a remote gathering point (manifold) to a

processing plant

Company/Shell/SPDC Shell Petroleum Development Company of Nigeria Limited

Principal Party (Usually SPDC), that initiates the project and ultimately pays

for its design and construction. The Principal will generally specify

the technical requirements. The Principal may also include an agent

or consultant authorised to act for and on behalf of, the Principal.

Contractor Party, which carries out all or part of the detail design. The Principal

may undertake all or part of the duties of the Contractor.

Manufacturer/Supplier Party, which manufactures or supplies equipment and services to

perform the duties specified by the Contractor.

The word ‗shall‘ indicates a mandatory requirement.

The word ‗should‘ indicates a recommendation.

Abbreviations

AG Associated Gas

API American Petroleum Institute

API RP American Petroleum Institute – Recommended Practice

ASNT American Society for Non-Destructive Testing

ASTM American Society for Testing of Materials

BDEP Basic Design and Engineering Package

BfD SSAGS Project Basis for Design, SSG-TPD-GEN-AA-7704-00001

BP Business Plan

CAPEX Capital Expenditure

CCP Central Compressor Plant

CP Cathodic Protection

DEP Shell Standard for Design and Engineering Practice

DPR Department of Petroleum Resources

D/t Diameter to thickness ratio

EIA Environmental Impact Assessment

ELPS Escravos-Lagos Pipeline System

ESD Emergency Shutdown

FBE Fusion Bonded Epoxy

FYIP Forcados Yokri Integrated Project

SSG-TPEF-GEN-LA-5507-00001-A01 Page 4 of 29 Pipelines Design Philosophy

This document is controlled electronically and is uncontrolled when printed

HSLA High-strength low-alloy steel

CPF Central Processing Facility

ISO International Standards Organisation

LLWS Low Low Water Surface

MAOP Maximum Allowable Operating Pressure

MMscfd Million Standard Cubic Feet Per Day

NAG Non Associated Gas

NFA No Further Activity

NLNG Nigeria Liquefied Natural Gas

OGGS Offshore Gas Gathering System

OML Oil Mining Lease

OPL Oil Pipeline License

PTS Permit to Survey

QRA Quantitative Risk Analysis

RoW Right of Way

RP-A Riser Platform – A

SCS SPDC Standard Construction Specification

SIOGP Southern Swamp Integrated Oil and Gas Project

SMYS Specified Minimum Yield Strength

SPDC The Shell Petroleum Development Company of Nigeria Limited

SSAGS Southern Swamp Associated Gas

SSG-TPEF-GEN-LA-5507-00001-A01 Page 5 of 29 Pipelines Design Philosophy

This document is controlled electronically and is uncontrolled when printed

1.0 INTRODUCTION

1.1 Objective

The objective of this document is to present the design philosophy for the SSAGS pipelines

as described in the SSAGS Project Basis for Design (Ref 1).

This document should be read in conjunction with the BfD which details the project

engineering system requirements to meet the company‘s business case objectives.

1.2 Background

The Southern Swamp area comprises fields within Oil Mining License (OML) 35 and OML 46

in the coastal swamp area, sixty-five kilometer (65km) South of Warri. There are ten (10) fully

appraised, Ten (10) partially appraised and four (4) un-appraised fields within the node, with

expectation oil ‗Ultimate Recovery‘ (UR) of 1,636 million stock tank barrel (MMstb) and 2,138

billion standard cubic feet (Bscf) of Associated Gas (AG) (‗Gas Initially In Place‘ - GIIP UR of

4 Tcf, 53% Recovery Factor (RF)) out of which 792 MMstb and 444 Bscf has been produced

by end 2010. All existing production in the area is gathered into four flow stations at Tunu,

Ogbotobo, Benisede and Opukushi. The produced oil is evacuated via Trans Ramos pipeline

to Forcados Terminal whilst the associated gas is currently flared.

The project to end routine flaring and re-develop the fields in the southern swamp catchment

area started in 1999 as Southern Swamp Integrated Oil and Gas Project (SIOGP). This

project stalled at the Define phase in 2006 due to among other things funding challenges. In

2009 the project was re-invigorated as an AG solution project with provision for mini

development. The latest project concept now called Southern Swamp AG Solutions (SSAGS)

primarily aimed at providing AG solutions to cover ‗No further Activity‘ (NFA) production (141

million barrel (MMbbl) + 98 Bscf AG) while maximising use of existing flowstation assets in

order to reduce Capex. It also includes a reduced well scope of 21 oil wells and 2 NAG wells

to develop additional 125 MMbbl new oil and 347 Bscf of gas (AG+NAG). NAG development

is to support the sustenance of circa 100MMScf/d gas supply to the domestic market for at

least 10 years. This development will also provide anchor infrastructure to support future

development of significant discovered and undiscovered potentials within the node (presently

about 820 MMboe).

Gas will be exported to Escravos Lagos Pipeline System (ELPS) via the existing 24‖ Offshore

Gas Gathering System (OGGS) line from EA Riser Platform (RP-A) to Forcados Yokri

(reverse flow) and the existing 16‖line from Forcados Yokri Integrated Project (FYIP) central

processing facility (CPF) to Odidi. A new pipeline will be installed from Tunu to EA RP-A. In

order to allow gas from Southern Swamp to reverse flow through OGGS to FYIP.

SSG-TPEF-GEN-LA-5507-00001-A01 Page 6 of 29 Pipelines Design Philosophy

This document is controlled electronically and is uncontrolled when printed

SSAGG proposed Process Schematic

Export

Ogbotobo Benisede

ELPS 10 MMscf /d 20 MMscf /d

AG

FYIP Phase 1 & 2 Facility AG AG Opukushi

CCP 30 MMscf /d

H2O HC

230 MMscf/d

usm

NAG Plant CPF

40 MMscf/d 110 MMscf/d

1NAG Wells + 12 estuary Oil well + AG AG

CCP H2O HC usm

16‘x32km Tunu CPF Tunu

EARP 160 MMscfd 2x35 MMscf/d AG 15 MMscf /d

NAG Slug catcher

120 MMscf/d 2 NAG Wells 120bar

To OGGS TUNU Facility

FYIP CCP by-pass line

USM - Ultrasonic-Flow •Uptime for new gas facilities 90%

Meter •Deferment for oil facilities 18-24%

Figure 1 – Southern Swamp Development Schematic

1.3 Change Control

This document is a controlled document and falls under the SPDC Corporate Change Control

Procedure (Ref 2).

1.4 Units and Coordinates

Except where otherwise noted, SI units shall be used in all reports and calculations. The size

of the unit shall be appropriate to the value being measured.

Units Preferred Units (Allowable Alternatives)

Mass Flow kg/hr (kg/s, tonnes/hr)

Liquid Volume Flow std. m³/hr (m³/s, kbpd)

Gas Volume Flow normal m³/hr (m³/s, MMscfd)

Level m or % full (mm)

Pressure barg (bara)

Temperature ºC

Length m, km

Diameter mm

Wall thickness mm

Area m²

SSG-TPEF-GEN-LA-5507-00001-A01 Page 7 of 29 Pipelines Design Philosophy

This document is controlled electronically and is uncontrolled when printed

Volume m³

Weight kg, tonne

Force N, kN, MN

Density kg/m³

Velocity m/s

Power W, kW, MW

Dynamic Viscosity cP

Kinematic Viscosity cSt

Energy J, kW, MW

Entropy kJ/kg.K

Heat transfer coefficient W/ m².K

Specific Heat Capacity kJ/kg.K

Thermal Conductivity W/m.K

Calorific Value MJ/ m³ (BTU/scf)

The co-ordinate system shall be based on the Nigerian Transverse Mercator Projection Mid-

Belt (Minna Datum).

SSG-TPEF-GEN-LA-5507-00001-A01 Page 8 of 29 Pipelines Design Philosophy

This document is controlled electronically and is uncontrolled when printed

2.0 REGULATIONS, CODES AND STANDARDS

2.1 General

The regulations, codes and standards to be applied shall always be the latest revision thereof

and any amendment or supplement thereto in effect as at the contract date with contractor,

manufacturer or supplier.

Design, fabrication and installation work will be governed by the following regulations, codes

and standards.

2.2 Regulations

Local laws regulating the oil and gas industry shall be strictly adhered to. Guidance on the

statutory requirements for pipelines design, construction and operation should be obtained

from the following documents:

Regulation Function

Petroleum Act, CAP P10, Laws of This is the principal statute regulating the oil industry.

the Federation of Nigeria, LFN The following regulations relevant to this project are

2004, as amended issued pursuant to the Act.

Mineral Oil (Safety) Regulations These regulations, in so far as they apply to pipelines,

1963, as amended. require compliance with the IP, API and ASME codes

and standards.

Oil Pipelines Act, 1956. CAP. 145 Provides for licenses to be granted for the

(Amended 1965, CAP. 338, LFN establishment and maintenance of pipelines incidental

1990) and supplementary to oilfields and oil mining, and for

purposes ancillary to such pipelines.

Oil and Gas Pipelines Regulations, Detailed regulations for the design, construction and

1995 maintenance of oil and gas pipelines

Environmental Impact Assessment Makes the conduct of an EIA mandatory prior to the

Act, CAP E12, LFN 2004. development of any project or activity likely to have a

significant effect on the environment

Federal Environment Protection Provides for the protection of the environment and

Agency Act, CAP F13, LFN 2004. sustainable development of Nigeria‘s natural

resources.

Environmental Guidelines and Document is issued by the DPR and provides

Standards For The Petroleum guidelines on pollution abatement and relevant

Industry In Nigeria, 1991. legislation.

2.3 Codes and Standards

Applicable codes and standards for the project fall under the following broad categories:

SPDC Standard Construction Specifications (SCS)

Shell Design and Engineering Practice (DEPs)

ASME Codes and Standards

International Codes and Standards

The detailed list of applicable codes and standards are listed in section 9.0.

2.4 Order of Precedence

Should any conflict occur as a result of applying this philosophy document, the order of

preference shall be as follows:

SSG-TPEF-GEN-LA-5507-00001-A01 Page 9 of 29 Pipelines Design Philosophy

This document is controlled electronically and is uncontrolled when printed

Nigerian National Standards.

This philosophy document / project functional specifications.

SPDC Standard Construction Specifications.

SPDC Engineering Specifications.

DEPs.

International Standards.

Where there are conflicts of interpretation, the principal will review to determine what should

apply.

2.4 Pipeline Design Codes

The primary pipeline design code prescribed by the Nigerian national Standard is:

a) ASME B31.8: Pipeline Gas Transmission.

In addition to the codes above, the current Shell DEP prescribes the following design code:

a) ISO 13623 Petroleum and natural gas Industries – Pipeline Transportation Systems

Since the Nigerian design code mandates the use of ASME B31.8, the use of ISO

13623 shall be by exception only.

SSG-TPEF-GEN-LA-5507-00001-A01 Page 10 of 29 Pipelines Design Philosophy

This document is controlled electronically and is uncontrolled when printed

3.0 PROJECT SUMMARY

3.1 Project Work scope

The Southern Swamp Associated Gas Gathering project aims to gather all associated gas

from the Tunu, Ogbotobo, Benisede and Opukushi Flowstations and non associated gas from

two Dodo North field NAG wells to a new Gas Processing Facility at Tunu and export the

treated gas to the domestic market. The figure below provides an overview of the pipeline

scope:

Figure 2 – Southern Swamp Pipelines Schematic

The project work scope consists of:

Identification of optimum AG pipeline route between the Flowstations and Tunu CPF.

Identification of optimum route for the NAG flowlines between the wells and CPF.

Design and installation of the following AG pipelines:

o 12‖ x 16km pipeline from the Benisede flowstation to the Tunu CPF.

o 12‖ x 24km pipeline from the Opukushi flowstation to the Tunu CPF

o 8‖ x 16km pipeline from the Ogbotobo flowstation to the Tunu CPF

Design and installation of two 10‖ x 150m NAG flowlines, to transport:

o 100 MMscfd of gas from the Dodo North well 1 and

o 60 MMscfd of gas from the Dodo North well 2 to a new NAG Bulkline M/F

Design and installation of a 10‖ x 10km NAG Pipeline, to transport Dodo North well 1

and 2 well fluid from new NAG Bulkline M/F to Tunu CPF.

Design and installation of a 16‖ x 32km gas export pipeline, to ship a maximum of 160

MMscfd of gas, from the Tunu CPF to the EA RP-A riser platform and onwards via

existing facilities to the ELPS manifold at Odidi.

Provision of pig launching / receiving facilities at either end of the AG / NAG lines.

SSG-TPEF-GEN-LA-5507-00001-A01 Page 11 of 29 Pipelines Design Philosophy

This document is controlled electronically and is uncontrolled when printed

Revalidation of operating conditions in the existing pipelines downstream of the 16‖ x

32km Tunu – EA RP-A pipeline and the impact on operations at the Bonny NLNG, EA

RP-A, North Bank CCP and the Odidi ELPS manifold.

Provision of control and monitoring systems for the pipelines.

Design and installation of corrosion protection measures for the pipelines

Provision of tie-ins for future NAG flowlines at the CPF.

3.2 Location and Interfaces

The pipelines have physical interfaces with the following facilities:

Proposed Ogbotobo flowstation AG module

Proposed Benisede flowstation AG module

Proposed Opukushi flowstation AG module

Proposed Dodo North NAG well 1

Proposed Dodo North NAG well 2

Proposed Tunu CPF

EA RP-A

Pipeline approach, landfall and offshore locations

The scope of the SSAGS Pipeline project shall be as stated under ―Definitions and

Abbreviations‖ and figure 5A in the DEP for Pipeline Pig Trap Systems (Ref 3).

Utilities and services for any pipeline shall be provided at the facility to which the line is tied. A

16‖ diameter riser is installed at the EA RP-A. An hydraulic analysis shall be conducted to

confirm the adequacy of the line size and it‘s integrity confirmed prior to BDEP completion.

Documents and drawings addressing all pipeline interfaces at the above locations shall be

developed during the BDEP, Detail Design, Construction and Commissioning of the pipelines.

3.3 Pipeline Design Life

The Southern Swamp Associated Gas Gathering facilities are to be designed for a 25 year

service life in line with the project BfD. Consequently, the design life of the pipelines shall be

consistent with this service life and shall not be less than 25 years. Corrosion protection and

material selection shall be based on a target design life of 25 years.

SSG-TPEF-GEN-LA-5507-00001-A01 Page 12 of 29 Pipelines Design Philosophy

This document is controlled electronically and is uncontrolled when printed

4.0 ROUTE SELECTION, PERMITS and ACQUISITION

4.1 Route Selection

Routes for the pipelines were earlier selected. Refer to:

Route Selection Study for Gathering Lines (Ref 4).

Dodo Flowlines Route Selection Report (Ref 5) and

Tunu – OGGS RP-A Pipeline Route Survey Report (Ref 6).

A Routing Study should be carried out to confirm the adequacy of the selected routes.

In executing the study, it should be noted that the lines should be routed along existing SPDC

RoW and within common RoW‘s in order to minimise land take with consideration for

acquisition of additional strips where existing corridor is insufficient. Temporary acquisition

may be required for laydown and pipelay activities.

The optimal route should impose minimal impact on the environment. Route selection will be

subjected to the statutory requirement for ESHIA. Considerations to improve access and re-

routing to avoid areas where there may be difficulties with the pipeline construction shall be

made during the detail design phase. The following points should be considered:

Rivers and ravines should be crossed at right angles and in a straight run of the river

away from caving banks, if possible. A safe distance of at least 60m shall be

maintained between new and existing crossing(s) to avoid damage to existing

pipelines during construction activities.

Areas with potential for communities to expand beyond the current limits should be

detailed, while areas with a high potential for community encroachment should be

avoided. However, where pipelines must traverse these areas design factors shall be

applied as advised by the project QRA or other major risk assessment.

Pipeline building proximity distances and design factors shall be in line with section

6.2.1.2 of the DEP for Pipeline Engineering (Ref 7).

Pipelines should not be routed parallel and adjacent to power lines where reasonable

alternatives are available.

Land ownership may require the re-routing of the pipeline.

The pipeline end points and preliminary route should be finalised using a combination of

satellite imagery, state maps, field reconnaissance, aerial photography and helicopter overfly.

After preliminary determination of the route, an ownership search and preliminary survey

should be made to determine actual conditions along the route. Based on the survey and

related information, the route should be finalized and re-surveyed as required.

4.2 Permits

Environmental permits will be required for the new pipeline facilities. These permits shall

comply with the statutory Nigerian regulations listed in section 2.1.

Land use permits shall be required where the pipelines crosses state lands, roads, rivers etc.

and the design/installation of the pipeline must be in compliance with the specific permit

requirements. Any conditions or special requirements should be indicated on the design

drawings, or in the contract documents.

The required statutory permits, PTS/OPL/EIA etc., shall be secured as part of project

execution.

SSG-TPEF-GEN-LA-5507-00001-A01 Page 13 of 29 Pipelines Design Philosophy

This document is controlled electronically and is uncontrolled when printed

4.3 Land Acquisition

Generally, permanent RoW shall be 15m wide with the minimum separation distance between

lines in the same trench in line with section 25.8.2 of SPDC‘s SCS and the separation

distance between new and existing lines designed to section 6.2.1.7 of the DEP for Pipeline

Engineering (Ref 7).

Temporary RoW acquisition will be required to cater for equipment workspace, linepipe

laydown areas and excavated spoil management. These shall be acquired during the

acquisition of the mainline RoW and ownership will be relinquished on construction

completion.

SSG-TPEF-GEN-LA-5507-00001-A01 Page 14 of 29 Pipelines Design Philosophy

This document is controlled electronically and is uncontrolled when printed

5.0 DESIGN DATA

5.1 Material Data

Selection of materials shall take into account the maximum and minimum process conditions,

the high strain capacity requirements, the extremes of ambient temperatures and any and all

other conditions that are likely to affect the performance of the material. Particular attention

shall be given to minimise the potential for brittle fracture of materials due to the low ambient

temperatures.

The linepipe material shall be carbon steel and 450MPa steel grade is recommended to

reduce steel/construction cost and construction duration. Induction bends shall be 5D for all

pipelines. Other material data shall be as detailed in the Materials Selection Report (Ref 11).

Corrosion mitigation shall include any or a combination of coatings, corrosion inhibitors,

linings, cathodic protection, use of corrosion allowance or corrosion resistant materials, in

order to provide the facilities with a safe, reliable and cost effective material solution.

Any material or corrosion data or guidelines issued for BDEP and detail design shall be

treated as provisional and checked and verified for consistency with a safe, technically

appropriate and cost effective design for the design life of the facilities.

5.2 Production Forecast

The production forecast is detailed in section 3.2 of the BfD and is based on SPDC BP-2010.

The production from the Tunu CPF is made up of AG and NAG. The Tunu CPF will be

designed for a normal sales gas throughput rate of 160MMscfd based on 2 x 80MMscfd

export compression trains.

5.3 Feed Composition

The AG and NAG composition are detailed in section 3.4 of the BfD. The production is not

anticipated to contain significant levels of sulphur compounds such as H 2S, carbonyl sulphide,

etc. Consequently, the pipelines will not be designed to NACE specifications to

accommodate sour service.

5.4 Feed Pressure and Temperature Data

The delivery temperatures and pressures for the pipelines will depend on production rates

and operational factors at the production and reception facilities. The minimum pipeline inlet

pressures to ensure gas delivery at Tunu, North Bank CCP and at the Odidi ELPS tie-in shall

be calculated at the BDEP phase. Operating conditions for the pipelines are detailed below:

Operating Conditions – AG Pipelines

Benisede Ogbotobo Opukushi Tunu

Design Flow Rate 20 MMscfd 10 MMscfd 30 MMscfd 15 MMscfd

1

Design Pressure To be based on final material selection.

Min Landing Pressure @Tunu CPF 7 barg 7 barg 7 barg 7 barg

Max. Design Gas Temperature 80°C 80°C 80°C 80°C

2

Min. Design Gas Temperature 0°C 0°C 0°C 0°C

Operating Conditions – NAG Flowlines

Dodo North 1 Dodo North 2

Design Flow Rate 100 MMscfd 60 MMscfd

3

Design Pressure – Mainline 263 barg 263 barg

Min Landing Pressure @Tunu CPF 112 barg 112 barg

FTHP 150 barg 150 barg

SSG-TPEF-GEN-LA-5507-00001-A01 Page 15 of 29 Pipelines Design Philosophy

This document is controlled electronically and is uncontrolled when printed

CITHP 246 barg 263 barg

Max. Design Gas Temperature 110°C 110°C

2

Min. Design Gas Temperature -45°C -45°C

Future NAG pipelines routed to the Tunu CPF must conform to the design limits specified

above.

Operating Conditions – NAG Bulkline

Property Value

Design Pressure 150 barg

Max. Design Gas Temperature 110°C

2

Min. Design Gas Temperature -45°C (see previous page)

Operating Conditions – Export Pipeline

Property Value

Design Flow Rate 160 MMscfd

Design Pressure 150 barg

MAOP 147.5 barg

MOP 135 barg

Min. Landing Pressure @ ELPS 72 barg

Max. Design Gas Temperature 80°C

2

Min. Design Gas Temperature -45°C (see previous page)

1. The expected pipeline inlet pressure for the AG lines is less than 15 barg with corresponding wall thicknesses

less than 1mm for any of the likely HSLA material. Consequently, the maximum design pressure for the AG

lines shall be dictated by section 6.4.1.1 of DEP 31.40.00.10 Pipeline Engineering, which requires the pipe wall

thickness be not less than 4.8mm.

2. Transient temperatures during start up and blowdown could be lower due to J-T effects. This should be taken

into consideration during material selection.

3. In line with existing SPDC Gas Flowlines Design Pressure

SSG-TPEF-GEN-LA-5507-00001-A01 Page 16 of 29 Pipelines Design Philosophy

This document is controlled electronically and is uncontrolled when printed

6.0 DESIGN PHILOSOPHY

6.1 Flow Assurance

6.1.1 General

Flow requirements for the pipelines are detailed in section 5.4. A preliminary hydraulic study

has been carried out and the result detailed in section 2.1.1 of the BfD (Ref 1).

A 16‖ spare riser exists at the EA RP-A and is proposed for tie-in to the Tunu export pipeline.

The adequacy of this riser vis-à-vis the material type, grade and integrity shall be confirmed at

the BDEP phase. A static hydraulic analysis shall also be executed during the same phase to

determine the following using the best available terrain profiles for the pipelines:

Confirmation of the preliminary line sizes

Optimise design / operating pressures for the pipelines.

Establish expected flow regimes

Evaluate sensitivities to different compositions, temperatures, line pack, flow rate

ramp up / turn down and pigging operations to the domestic market and NLNG when

domestic gas demand is low.

The result of a transient hydraulic analysis during the detail design phase shall be

incorporated into the start-up, shutdown and normal operations narratives of the Pipelines

Operations and Maintenance Manual.

6.1.2 Slugging / Hold Up

The following slugging issues are to be determined from the hydraulic simulations:

Hydrodynamic slugs formed during normal operation in the slug flow regime due to

instability of the gas-liquid interface.

Terrain induced slugs due to liquid collection at low points in the pipelines.

Rate induced slugs due to change in flow rate.

Pig induced slugs due to liquids being swept out of the pipelines by pipeline pigs.

6.1.3 Pigging

All SSAGS pipelines shall be designed for sphere, foam, cup and intelligent pigs. The pigging

facilities shall be designed to handle standard inspection tools in line with DEP for Pipeline

Pig Trap Systems (Ref 3). The pig trap code breaks shall be as stated in figure 5A of

aforementioned DEP.

A suitable pigging philosophy should be developed during the BDEP phase.

6.2 Pipeline Loading Cases

6.2.1 General

The pipeline design shall conform to ISO 13623:2009 (Ref 8) as amended by the Shell DEP

for Pipeline Engineering (Ref 7).

Evaluation of combined stresses on the pipelines shall be carried out for the assurance of

mechanical strength. A preliminary stress analysis, to be carried out during the BDEP phase

shall be confirmed during detail design stage using Caesar II software or any other software

approved by the principal.

In analysing the pipeline systems, the following loads will be taken into consideration as a

minimum:

Internal pressure loads (hoop stress).

Sustained Loads (soil loads, soil frictional force, self weight)

SSG-TPEF-GEN-LA-5507-00001-A01 Page 17 of 29 Pipelines Design Philosophy

This document is controlled electronically and is uncontrolled when printed

Live (axial) Loads (vehicle traffic)

Thermal Loads (changes in operating/installation temperatures)

Test Loads (hydrostatic testing)

Equivalent Stresses

Collapse load in the offshore section of the export pipeline.

Offshore section buckling, propagation and control analysis

Fishing Trawler and dropped object interactions

6.2.2 Stress Conditions

The following stress conditions shall be considered for the design of the pipelines:

Circumferential stresses due to internal pressure and external sustained and live

loads.

Expansion stresses for restrained and unrestrained portions of the system due to

internal pressure and thermal loads.

Longitudinal stresses for unrestrained pipeline sections, due to pressure, weight and

other sustained loadings.

Longitudinal stresses for restrained pipeline sections, due to pressure, weight and

other sustained loadings, considering the frictional restraint of the soil.

Longitudinal stresses produced by internal pressure, live and dead loads.

Circumferential and longitudinal stresses induced during hydrostatic testing.

6.2.3 Hydrotest Loads

A hydrotest and pre-commissioning philosophy (Ref 9) shall be developed during the BDP

phase. The philosophy shall detail hydrotest induced loads and methods to keep the stresses

within limits.

6.2.4 Above-Ground Loading Cases

The above-ground pipe work at pipeline ends shall be designed for a number of loading

cases, ensuring the stress limits are not exceeded. Loading cases include spanning,

expansion, buckling and interaction with wellheads and pipelines.

The load cases shall be analysed for installation, hydrotest and operating conditions to

determine the governing design case. An analysis of the forces imposed on monolithic

isolation joints shall be carried out as part of the detailed stress analysis during the detail

design.

6.3 Pipeline Expansion and Flexibility

Pipeline expansion should be fully considered in pipe lay stress analysis to guide pipe

handling, ditch contour and lowering operation in order to avoid unacceptable stresses.

Pipeline expansion before ditching will be analysed to ensure that unacceptable stresses are

avoided during construction.

Anchor blocks may be installed at the end of the buried pipeline in order to limit expansion

and prevent the pipe being overstressed at end or branch connections to piping. In calculating

maximum allowable thermal stress, both the short-term expansion immediately after start up

and the long-term friction relaxation shall be considered.

SSG-TPEF-GEN-LA-5507-00001-A01 Page 18 of 29 Pipelines Design Philosophy

This document is controlled electronically and is uncontrolled when printed

6.4 Pipeline Wall Thickness

The wall thickness selection for the pipelines and bends, including bend thinning, shall be

calculated with consideration to the pipeline loading cases in section 6.2 and flexural factors

in section 6.3. Such calculations should take account of the Location Classes based on

pipeline routing and recommendation for corrosion allowance contained in the Materials

Selection Report (Ref 11).

Additionally, the export pipeline wall thickness calculation shall take into account water depth,

on-bottom stability, allowable span analysis, vortex shedding analysis, buckling analysis and

pipe collapse checks.

The nominal pipe wall thickness shall not be less than 4.8mm and the diameter to wall

thickness ratio shall not exceed 60 for the export pipeline and 96 (Ref 7) for the AG and NAG

lines. Pipeline wall thickness calculations shall, as a minimum, consider all pipeline loading

cases detailed in section 6.2 and expansion / flexural factors detailed in section 6.3. The pre-

installed riser at the EA RP-A has a corrosion allowance of 3mm.

6.5 River and Swamp Crossings

6.5.1 General

The gas pipelines shall be laid in swamp and offshore areas and as such will have a concrete

weight coating applied to the outer surface all lines. The weight coating required for the

pipeline shall be defined in Buoyancy calculations during the BDEP phase.

6.5.2 Major Watercourse Crossings

These are crossings over 200m wide and 3m deep. They are generally associated with large

water flows, navigable and subject to dredging. Pipeline installation techniques across these

rivers usually require special equipment such as Cutter-Suction Dredgers and/or Horizontal

Directional Drilling. Both techniques shall provide at least 3m cover over the pipe below the

river bed.

Typical details and cross sections shall be provided for the major watercourse crossings

during the BDEP phase. Specific crossing details for each major river crossing shall be

provided during the detail design phase when the pipeline topographical survey, alignment

sheets and geotechnical site investigation details would have been re-validated.

6.5.3 Minor Watercourse Crossings

These are defined as those where the river crossing installations may be achieved by normal

excavation, trenching, laying and backfilling. Typical crossing details shall be provided during

the BDEP phase to show the construction type required at the crossings.

6.6 Landfall and Shore Approach

The offshore pipeline landfall consists of a very shallow sloping seabed, assumed to be in the

order of 1:1000. Consideration should be given the Beach Pull construction method for the

installation of the offshore pipeline landfall. Landfall and shore approach drawings are to be

produced during BDEP phase.

Sheet pilling is required at the landfall to minimise the width of excavation. The trench depth is

selected such that the pipeline is under submerged condition during construction and is

subsequently provided with a 2m minimum soil cover after backfilling. Depending on the

construction scenario and the selected pipelay barge operating draft, additional dredging may

be required to bring the barge close to the shore.

SSG-TPEF-GEN-LA-5507-00001-A01 Page 19 of 29 Pipelines Design Philosophy

This document is controlled electronically and is uncontrolled when printed

Two factors that primarily influence the pulling capacity required for a bottom pull are the

length of pull and the concrete thickness, which determines the pipe weight. An additional

condition is that the maximum pull force shall not exceed the strength of the pipe during

installation. Beach pull calculations are to be determined during the BDEP phase.

6.7 Subsea Pipeline Crossing Design

The crossings shall be as near to a right angle as possible and the included angle shall not be

less than 30°. There shall be an adequate separation between the two pipelines at the

crossing so that they do not interfere with each other. The minimum recommended clearance

is 300mm.

Possible interference of the cathodic protection systems shall be avoided. The crossing

design shall consider allowable stress levels in the pipelines and allowable free-spans as well

as any potential interference with fishing activities or other potential accidental loading

conditions. The crossing shall be protected by mattresses, grout bags or other acceptable

alternatives and shall provide protection against ice gouging should it be located in a

susceptible area.

The pipeline crossing shall not restrict the operation of the pipeline system and should impose

minimum restriction on maintenance.

6.8 Pipeline Branches Connections

Where a tie-in is required on the pipeline, barred tees shall be installed on all branches larger

than 25% of the pipeline diameter. In all cases, branch connections shall comply with the

DEP for Pipeline Engineering.

6.9 ESD and Blowdown

Emergency shutdown valves shall be installed within the fenced areas after the pipe exits and

before entering the scraper traps at each ends of the Tunu export and NAG pipelines. The

ESD valves will close the pipelines at either end should an emergency shutdown be initiated

in the control room within on site plant facilities. In general, these shutdown valves will only

be activated automatically on a fire or high-level gas release within the plant, wellhead or riser

platform area.

Manual or controlled blowdown of the export and NAG pipelines will be carried out through

the Tunu flare system during pipeline emergency or repair. Blowdown capacities shall be

determined during the BDEP phase.

There shall be neither overpressure protection nor emergency blowdown on the AG pipelines

as these are low pressure gas gathering pipelines

6.10 Subsea Valves

A risk assessment was performed during the OGGS FEED to determine the need for the

installation of riser/subsea valves, (i.e. subsea isolation valves – SSIV‘s) which included this

pipeline. Subsea Isolation valves are not required (Ref 10). This shall considered during the

SSGAS pipelines Major Risk Assessment Studies.

6.11 Sectionalizing Valves

The Oil and Gas Pipelines Regulations, 1995, recommends adherence to ASME B31.8. This

code requires the installation of sectionalizing valves every 32km along gas pipelines. As all

SSAGS pipelines are less than 32km, pipeline sectionalizing valves are not recommended.

Furthermore, Nigerian regulations require the installation of block valves at major watercourse

crossings. To this end, rivers will be surveyed during the BDEP phase to confirm this

SSG-TPEF-GEN-LA-5507-00001-A01 Page 20 of 29 Pipelines Design Philosophy

This document is controlled electronically and is uncontrolled when printed

requirement and the BDEP phase shall proceed on this basis. However, a waiver should be

sought from the Nigerian Department of Petroleum Resources with supporting QRA

proposing the removal of such valves for reasons of vandalism by third parties.

6.12 Corrosion Control

Details of the pipeline corrosion control are provided in the Corrosion Control Strategy (Ref

12). However, the following specific points should be noted:

6.12.1 General

The CP design and supply for the onshore section of the pipelines shall be in accordance with

section 27 of the SCS and DEP 30.10.73.31 while the offshore section shall be in accordance

with DEP 30.10.73.32.

6.12.2 Onshore CP System

Soil Resistivity surveys and an assessment of the existing Plant CP systems shall be

conducted to establish CP requirements for the onshore segment of the pipelines including

confirmation of the design premise, stand-alone or integrated. When these surveys have been

completed a design for the Impressed Current Cathodic protection of the pipelines should be

developed. A temporary cathodic protection system is required during construction.

Test stations shall be installed at spacings of typically of 1 – 2km, including pipeline and river

crossings as well as at isolating joint locations. Test stations shall include bare steel coupons

buried adjacent to the pipeline.

6.12.3 Offshore CP System

The offshore section of the Tunu export pipeline shall be protected by a cathodic protection

system based on bracelet-type sacrificial anodes. The cathodic protection system shall be

designed to maintain the exposed pipeline metal surfaces within an electrochemical potential

range, which controls corrosion within acceptable limits without causing material damage.

At the interfaces with onshore pipelines, platforms or crossings, particular attention should be

paid to the compatibility of the possibly different cathodic protection systems and isolation

joints specified where necessary.

A monitoring plan for the cathodic protection system shall be developed.

6.12.4 Isolation Joints

Isolating joints shall be installed at the following locations on the onshore pipelines:

Close to the interface with the export pipeline offshore section. Note that Isolation

joint at Tunu Beach will be buried to minimise third party interference.

Immediately downstream of the pig traps at the interface between buried and non-

buried pipeline sections.

The isolation joint specification will cater for potential interferences between the Tunu export

pipeline offshore and onshore CP systems.

6.12.5 Rectifiers

Transformer-rectifiers will be air-cooled units if located in an equipment/control room or oil

cooled units if located externally within flowstations / Tunu CPF. In the latter case, the

enclosures will be IP54 rated or better, and shall be rated for use in hazardous areas if

appropriate to their selected location.

SSG-TPEF-GEN-LA-5507-00001-A01 Page 21 of 29 Pipelines Design Philosophy

This document is controlled electronically and is uncontrolled when printed

6.12.6 Interfaces

The onshore section CP system interfaces with the systems installed Flowstations and the

Tunu CPF. The cathodic protection design report should evaluate interference hazards and

suggest measures that can be taken to minimize such effects. Test stations installed along

the parallel route sections should have cables to each of the pipelines to facilitate addition of

resistive interference bonds should these become necessary.

6.13 Hydrotest, Pre-Commissioning and Commissioning

For hydrotest, pre-commissioning and commissioning of the SSAGS pipelines, refer to the

Hydrostatic Testing and Pre-commissioning Philosophy (Ref 9)

6.14 Pipeline Leak Detection

There will be no online pipeline leak detection system on the SSAGS pipelines.

6.15 Drains

All pig launchers and receivers should be integrated within the common open and closed

(except NAG) drain facilities. Open and closed drains should be routed so as to minimize

pockets and sloped down to the existing collection pits / tanks. All drain systems will be

atmospheric systems and so there will be no continuous or regular discharge of pressurized

hydrocarbons to drain systems. Vessels will be depressurized before draining to sumps.

The existing pig trap on the EA RP-A platform is connected to the platform drain system.

Liquids generated by pigging the export pipeline at Tunu will be allowed to flow directly into

the EA RP-A to North Bank CCP pipeline.

6.16 Instrument Air

All host stations shall provide instrument air and/or hydraulic supplies to the pig launching and

receiving facilities. Instrument air shall for the NAG lines shall be provided from the NAG well

gas bottles.

6.17 Safeguarding Philosophy

6.17.1 AG and Export Lines

The EA RP-A Riser Platform forms a manifolding facility for the OGGS pipeline system, and

hence provides a central point for OGGS status monitoring. The platform is normally

unmanned, except during pigging operations and maintenance activities. Operators will

monitor the status of the platform from both the EA Production Facility CCR and the Central

Production Co-ordination Centre, using monitoring systems on the platform and telemetry

links. The Tunu CPF Process Automation System will control gas delivery into the export

pipeline at the Tunu CPF (Ref 13). Similarly, the PAS for the three Flowstations will control

delivery into the AG pipelines (Ref 14).

6.17.2 NAG Pipelines

The design pressure for the NAG lines shall be 263barg which is equal to the CITHP.

However, the possibility of designing to the FTHP of 150 barg in addition to a pressure

protection system should be investigated during BDEP phase.

6.18 Pipeline Risk Analysis

A comprehensive risk analysis for the SSAGS pipelines shall be carried throughout the BDEP

and followed up during the detailed design phase to identify and mitigate major risks

throughout the pipeline design life.

SSG-TPEF-GEN-LA-5507-00001-A01 Page 22 of 29 Pipelines Design Philosophy

This document is controlled electronically and is uncontrolled when printed

7.0 OPERATIONAL REQUIREMENTS

7.1 Start Up

The start-up philosophy for the export pipeline is dependent on the SSAGS start-up. Tunu will

require fuel gas for start-up and a preference may be to backpressure the export pipeline from

the EA RP-A to allow fuel gas import. The high pressure drop that would result from this

action may result in temperatures below the design temperature of the pipeline and /or the

formation of ice or hydrates.

The export pipeline will need to be dried prior to use and then inerted with nitrogen.

Procedures are to be developed to avoid hydrate formation during start up. This philosophy

and the impact on material selection, if any, will be further developed during the BDEP phase.

7.2 Maintenance and Inspection

Facilities for permanent pig launching and receiving are required at all SSAGS end facilities.

Access platforms shall be provided local to the receivers and launchers to ensure accessibility

of all valves, strainers, instrumentation and other in-line equipment. All pipelines launching

and receiving facilities shall be designed such that their associated doors can only be opened

on positive confirmation of depressurization. Riser and Pig receiving facilities are already

installed at the EA RP-A, the launching facility at the Tunu CPF should therefore be a similar

design to the receiver. An interlock system shall be installed on pig traps to prevent the

pipeline valves being opened when the end closure is open and to ensure that the trap is fully

vented before being opened.

Provision for flushing/purging facilities is required on the carbon steel launchers and receivers

to prevent ignition/combustion from possible accumulation of pyrophoric matter as traces of

H2S might be present in the process fluids.

Adequate pig handling equipment shall be provided at all launchers and receivers with

appropriate access, lay down areas, lifting, purging and flushing equipment.

Baseline intelligent pigging surveys shall be carried out as soon as possible after the pipeline

is commissioned to establish the ―as new‖ wall thickness readings throughout the pipeline for

future comparison with later surveys. The pipelines should therefore be designed to for

intelligent pigging in line with the DEP for Pig Trap Systems (Ref 3)

7.3 Isolation / Locked Valve Philosophy

Sufficient isolation points must be provided in the design throughout the plant to ensure safe

isolation of system, sub-system and each unit of pipeline equipment. Operating manuals shall

specify plant, equipment and pipeline system isolation requirements. A locked-open/locked-

close register shall be in place. Double block and bleed philosophy shall apply to all gas

transmission and drain connections requiring isolation. Integral double block and bleed valves

may be used for:

Equipment removal and/or in-situ maintenance jobs

Repairs and modification through appropriate change control procedure

Vessel/Tank entry for inspection and/or repairs.

7.4 Spares

A spare parts policy compatible with availability requirements of the end facilities shall be

established. Electronic Spare Parts Interchange ability Records (E-SPIR) will be provided by

the vendors. Specifications for pipeline valves shall take local inspection, maintenance and

replacement of valves into consideration.

In addition to the commissioning spares, two-year operational spares and special

maintenance tools will be provided as part of the initial equipment purchase. Specifications for

SSG-TPEF-GEN-LA-5507-00001-A01 Page 23 of 29 Pipelines Design Philosophy

This document is controlled electronically and is uncontrolled when printed

equipment requiring spares should be prepared with consideration for local in-stock

availability of the spares.

SSG-TPEF-GEN-LA-5507-00001-A01 Page 24 of 29 Pipelines Design Philosophy

This document is controlled electronically and is uncontrolled when printed

8.0 CONSTRUCTABILITY / CONSTRUCTION INTERFACES

A full constructability review shall be conducted during the BDEP and detail engineering

phase of the project. This shall consider the construction through the following areas.

Offshore, beach landings and EA RP-A areas

Flowstation and wellhead areas

Swamp and sand-filled areas subject to flooding.

River crossings

Areas close to communities

The constructability review will consider the pipeline material delivery schedule, QA inspection

access, construction access, roads, lay down areas, RoW width and construction spreads

required for installing the pipelines through the above area. Due to the critical nature of the

offshore section, vendor competency will be paramount in the contracting process.

The result of the constructability review shall be incorporated into the BDEP and detail

engineering.

SSG-TPEF-GEN-LA-5507-00001-A01 Page 25 of 29 Pipelines Design Philosophy

This document is controlled electronically and is uncontrolled when printed

9.0 REFERENCES

1. SSAGS Project Basis for Design, SSG-TPD-GEN-AA-7704-00001

2. SPDC Corporate Change Control Procedure, SPDC-2011-02-00000205

3. DEP 31.40.10.13, Design of Pipeline Pig Trap Systems, February 2011

4. Route Selection Study for Gathering Lines SF3-12.01.PPE.001

5. Dodo Flowlines Route Selection Report SDA-SSG-GEN-AA8212-00004

6. Tunu – OGGS RP-A Pipeline Route Survey Report

7. DEP 31.40.00.10, Pipeline Engineering, February 2011

8. ISO 13623:2009, Pipeline Transportation Systems

9. Hydrostatic Testing & Pre-commissioning Philosophy, SSG-TPEF-GEN-LA-5507-00001

10. OGGS Basis of design End of FEED update Report number OG-BFK-1001

11. Material Selection Report

12. Corrosion Control Strategy

13. Process Control Philosophy & Narrative (CPF)

14. Process Control Philosophy & Narrative (F/S)

15. Applicable codes and standards are detailed overleaf

SSG-TPEF-GEN-LA-5507-00001-A01 Page 26 of 29 Pipelines Design Philosophy

This document is controlled electronically and is uncontrolled when printed

Shell Design and Engineering Practice (DEPs)

Document Number Document Title

DEP 30.10.73.10-Gen Cathodic Protection

DEP 30.10.73.31-Gen Design of Cathodic Protection Systems for Onshore Buried Pipelines

DEP 30.48.00.31-Gen. Painting and Coating of New Equipment

DEP 31.36.00.30-Gen Pipeline transportation systems - pipeline valves (amendments/supplements to

ISO 14313)

DEP 31.38.01.29-Gen Pipe supports

DEP 31.40.00.10-Gen. Pipeline Engineering - November 1993

DEP 31.40.10.13-Gen Design of Pipeline Pig Trap Systems

DEP 31.40.10.14-Gen Pipeline Overpressure Protection

DEP 31.40.20.37-Gen Linepipe for critical service.

DEP 31.40.20.33-Gen Linepipe induction bends (amendments/supplements to ISO 15590-1)

DEP 31.40.21.30-Gen. Pipeline fittings (amendments/supplements to MSS SP-75)

DEP 31.40.21.31-Gen Pipeline Isolation Joints (amendments/supplements to MSS SP-75)

DEP 31.40.21.32-Gen. Pig trap end closures (amendments/supplements to MSS SP-75)

DEP 31.40.21.33-Gen. Pig signallers: Intrusive type

DEP 31.40.21.34-Gen. Carbon and low alloy steel pipeline flanges for use in oil and gas operations

(amendments/supplements to MSS SP-44)

DEP 31.40.30.30-Gen Concrete coating of linepipe

DEP 31.40.30.31-Gen External polyethylene and polypropylene coating for line pipe

DEP 31.40.40.38-Gen Hydrostatic pressure testing of new pipelines

DEP 31.40.50.30-Gen Pre-commissioning of pipelines

DEP 31.40.60.11-Gen. Pipeline leak detection

DEP 61.40.20.30-Gen. Welding of pipelines and related facilities (amendments/supplements to

ANSI/API STD 1104)

SPDC Pipeline Engineering Construction Specification

Descriptions Document Number

SPDC Standard Construction Specification – Pipeline Section 25 - Jan. 1985, Rev. 03

Construction

SSG-TPEF-GEN-LA-5507-00001-A01 Page 27 of 29 Pipelines Design Philosophy

This document is controlled electronically and is uncontrolled when printed

International Codes and Standards

American Society of Mechanical Engineers - ASME

Document Number Document Title

ASME B1.20.1 (Jan 2001) Pipe Threads, General Purpose

ASME B16.10 (Jan 2003) Face to Face and End to End Dimensions of Valves

ASME B16.10 Face to Face Dimensions for Flanged Globe Style Control

Valves

ASME B16.11 (Jan 2001) Forged Fitting Butt-Welding and Threaded

ASME B16.20 (Jan 1998) Metallic Gaskets for Pipe Flanges Ring-Joint, Spiral-Wound, and

Jacketed

ASME B16.21 (Jan 1992) Non-metallic Flat Gaskets for Pipe Flanges

ASME B16.25 (May 1997) Butt Welding Ends

ASME B16.28 (Jan 1994) Wrought Steel Butt-Welding Short Radius Elbows and Returns

ASME B16.34 (Jan 1996) Valves - Flanged, Threaded and Welding end

ASME B16.47 (Jan 1996) Large Diameter Steel Flanges

ASME B16.5 Steel Pipe Flanges and Flanged Fittings

ASME B16.9 (Jan 2003) Factor -Made Wrought steel Butt-Welding Fittings

ASME B31.3 (April 2002) Chemical Plant and Petroleum Refinery Piping

ASME B31.4 2000 (Jan 2002) Pipeline Transportation Systems for Liquid Hydrocarbons and

other Liquids

ASME B31.8 (2003) Gas Transmission and Distribution Piping Systems

American Society for Testing and Materials - ASTM

Document Number Document Title

ASTM A 105 (Oct 2003) Forgings, Carbon Steel, For Piping Components

ASTM A 134 (2001) Spec for electric fusion arc welded steel pipe

ASTM A-234 (Oct 2003) Spec for pipe fittings of wrought carbon steel and alloy steel for

moderate & high temperature service

ASTM A-370 (Oct 2003) Std. Test Methods & Definitions for Mech. Test of Steel Products

ASTM A-694 ( Oct 2003) Spec for Carbon & Alloy steel forgings for pipe flanges, fittings,

valves and parts for high pressure transmission service.

ASTM D1250 (2002) Manual of Petroleum Measurement Standards

ASTM E 92 (2003) Test Method for Vickers Hardness of Metallic Materials

American Petroleum Institute

Document Number Document Title

API 1102 (July 2002) Steel Pipelines Crossing Railroads and Highways

SSG-TPEF-GEN-LA-5507-00001-A01 Page 28 of 29 Pipelines Design Philosophy

This document is controlled electronically and is uncontrolled when printed

API 1104 (Sept 1999) Standard for Welding Pipelines and Related Facilities

API 598 (Oct 1996) Valve Inspection and Test

API 6D (Jan 2002) Pipeline Valves, (steel gate, plug ball and check valves)

API 6FA (April 1999) Specification for Fire Test for Valves

API RP 552 (Note 1) (Oct 1994) Transmission Systems

API RP 554 (Note 1) (Sept 1995) Process Instrumentation and Control

API RP521 (Mar 1997) Guide for Pressure Relieving and Depressuring Systems, 3rd

Edition, 1990.

ISO Standards

Document Number Document Title

Petroleum and natural gas industries — Steel pipe for pipeline

ISO 3183 transportation systems

ISO 13623 Petroleum and Natural Gas Industries – Pipeline transportation

systems

ISO 15590-1 Induction Bends for Pipeline Transportations Systems

ISO 15590-1 Induction Bends for Pipeline Transportations Systems

ISO 15590-1 Induction Bends for Pipeline Transportations Systems

SSG-TPEF-GEN-LA-5507-00001-A01 Page 29 of 29 Pipelines Design Philosophy

This document is controlled electronically and is uncontrolled when printed

Вам также может понравиться

- Platform and Pipeline Operating Philosophy Gaseous Phase OperationДокумент20 страницPlatform and Pipeline Operating Philosophy Gaseous Phase OperationDucViking100% (1)

- Pipeline Pigging Philosophy for Rumaila ProjectДокумент15 страницPipeline Pigging Philosophy for Rumaila ProjectfadhilОценок пока нет

- 6.9 Pigging Philosophy PDFДокумент10 страниц6.9 Pigging Philosophy PDFDonald.KОценок пока нет

- k2s-Ng01007551-Gen-ra7754-00004 Specification For Line Pipe Protective Coating RepairДокумент15 страницk2s-Ng01007551-Gen-ra7754-00004 Specification For Line Pipe Protective Coating Repairadeoye_okunoyeОценок пока нет

- 6.8 Pipeline Testing and Drying Philosophy PDFДокумент9 страниц6.8 Pipeline Testing and Drying Philosophy PDFDonald.KОценок пока нет

- SSG Ng01017365 Gen MP 7303 00001 - d01 - MR For Stud Bolts and NutsДокумент8 страницSSG Ng01017365 Gen MP 7303 00001 - d01 - MR For Stud Bolts and NutsDaniel DamboОценок пока нет

- 6.6 Onshore and Offshore Pipeline Design Philosophy PDFДокумент28 страниц6.6 Onshore and Offshore Pipeline Design Philosophy PDFDonald.K100% (1)

- GP 43-50 - Pigging Pig Launchers and ReceiversДокумент43 страницыGP 43-50 - Pigging Pig Launchers and Receiverseliealtawil100% (2)

- Spec SCAPSA PDFДокумент30 страницSpec SCAPSA PDFGustavo Fama100% (1)

- 0708-L-CC-002 Pipeline Stress Calculation From GRF Keramasan To AKE Rev BДокумент10 страниц0708-L-CC-002 Pipeline Stress Calculation From GRF Keramasan To AKE Rev BElias EliasОценок пока нет

- PIG TRAP SPECIFICATION FOR 16Документ18 страницPIG TRAP SPECIFICATION FOR 16AJ NugrohoОценок пока нет

- BBS SLT PLL RP 0002 0 RevA - Pipeline HydraulicДокумент33 страницыBBS SLT PLL RP 0002 0 RevA - Pipeline HydraulicAnonymous E3sSdt851X0% (1)

- 6.41 Materials Selection and Integrity Protection Report For OffshoreДокумент22 страницы6.41 Materials Selection and Integrity Protection Report For OffshorePrasanta GhoshОценок пока нет

- 5 16 16 Signed Final Report To PST On ECAДокумент14 страниц5 16 16 Signed Final Report To PST On ECAnankingОценок пока нет

- Navigational Aids For Offshore StructuresДокумент35 страницNavigational Aids For Offshore Structuresdebjit2001100% (1)

- SSG-NG01017365-GEN-BA-6008-00118 - R02 - N2 Bypass Line Pressurization To ...Документ87 страницSSG-NG01017365-GEN-BA-6008-00118 - R02 - N2 Bypass Line Pressurization To ...Ubong P. EffiongОценок пока нет

- Otc 21575Документ7 страницOtc 21575Mintu ChoudhuryОценок пока нет

- Buried PipelinesДокумент93 страницыBuried Pipelineserik Romani chavezОценок пока нет

- 24in Pipeline Buoyancy CalculationДокумент1 страница24in Pipeline Buoyancy CalculationAdaghara67% (3)

- 321 AeДокумент72 страницы321 AeMauro MLR100% (1)

- Quest CCS Project Material Selection ReportДокумент23 страницыQuest CCS Project Material Selection ReportRoni Gerald100% (1)

- E-C.2.4-HQ-PRO-001 Process and Mechanical Valving and Isolation PhilosophyДокумент16 страницE-C.2.4-HQ-PRO-001 Process and Mechanical Valving and Isolation Philosophyagaricus100% (2)

- (Ihs) PEL - PL - CAL - 003 Pipeline Stability and Bouyancy Calculation Benoa - Pesanggaran (Rev 0)Документ11 страниц(Ihs) PEL - PL - CAL - 003 Pipeline Stability and Bouyancy Calculation Benoa - Pesanggaran (Rev 0)Indra HarapanОценок пока нет

- Pipeline Design BasisДокумент51 страницаPipeline Design Basisgv gowrav100% (2)

- Basic Subsea Pipeline Engineering TrainingДокумент6 страницBasic Subsea Pipeline Engineering TrainingGodwinОценок пока нет

- Sda Ng01006306b Odipl La 0510 00001 c04 Stability AnalysisДокумент20 страницSda Ng01006306b Odipl La 0510 00001 c04 Stability AnalysisDaniel Dambo100% (2)

- Pipeline Design BasisДокумент40 страницPipeline Design Basisasokk0% (1)

- 6.19 Process Isolation System Design Philosophy PDFДокумент6 страниц6.19 Process Isolation System Design Philosophy PDFdamanpb3633Оценок пока нет

- Eni S.p.A. Process Minimum Requirements Design CriteriaДокумент25 страницEni S.p.A. Process Minimum Requirements Design CriteriaFlorin Daniel AnghelОценок пока нет

- Material Selection For Flare TipsДокумент200 страницMaterial Selection For Flare Tipscanakyuz100% (2)

- 4.7 Construction PhilosophyДокумент13 страниц4.7 Construction PhilosophyPaidar Engineering and Energy Development Co.Оценок пока нет

- Droped ObjectДокумент19 страницDroped ObjectOgangwu BenjaminОценок пока нет

- 2007-6031-2J-0007 Rev H Re-AFD Pipeline Hydraulic Analysis - ApprovedДокумент166 страниц2007-6031-2J-0007 Rev H Re-AFD Pipeline Hydraulic Analysis - ApprovedManh Tien HoangОценок пока нет

- Pipeline Design Criteria 40RSN 00 BD PL DSC 2001 A0Документ15 страницPipeline Design Criteria 40RSN 00 BD PL DSC 2001 A0hgolestaniОценок пока нет

- 6.7 Pipeline Material Selection Corrosion Protection and Monitoring PhilosophyДокумент13 страниц6.7 Pipeline Material Selection Corrosion Protection and Monitoring Philosophyadenlan100% (3)

- GF-OGF4-P-CA-2001 - Pipeline Design Report - Rev 0 - AFC...Документ60 страницGF-OGF4-P-CA-2001 - Pipeline Design Report - Rev 0 - AFC...Rami KsidaОценок пока нет

- Lateral BucklingДокумент36 страницLateral Bucklingrsb72Оценок пока нет

- Introduction FreeSpanningPipelinesDNV RP F105Документ13 страницIntroduction FreeSpanningPipelinesDNV RP F105Nabil37Оценок пока нет

- Design of HP HT Pipelines Against Lateral BucklingДокумент20 страницDesign of HP HT Pipelines Against Lateral BucklingHarmoni Andreas100% (1)

- 31401015Документ29 страниц31401015dakidofdaboomОценок пока нет

- 6.57 Onshore Pipeline Mechanical Design ReportДокумент17 страниц6.57 Onshore Pipeline Mechanical Design ReportSanjay Kumar100% (2)

- Repairs of Piping Components PDFДокумент54 страницыRepairs of Piping Components PDFIshtiaqueОценок пока нет

- GP 43-50 31 January 2009Документ52 страницыGP 43-50 31 January 2009Orlando RojasОценок пока нет

- 6.25 Transient Analysis Start Up (Pipeline) PDFДокумент71 страница6.25 Transient Analysis Start Up (Pipeline) PDFMuhammad Ibad AlamОценок пока нет

- Attachment - 7 - P158-150-PL-SPC-0003-00 - B01 Specifications For Pipeline Crossing Roads, Rail Roads and Minor Water WaysДокумент16 страницAttachment - 7 - P158-150-PL-SPC-0003-00 - B01 Specifications For Pipeline Crossing Roads, Rail Roads and Minor Water Wayshasan shahriar0% (1)

- PTGGP-00-PL-CAL-004 - 0 Pipeline Buoyancy and Stability Calculation Grissik-PusriДокумент16 страницPTGGP-00-PL-CAL-004 - 0 Pipeline Buoyancy and Stability Calculation Grissik-Pusrihamid sobirin100% (3)

- GP 62-01Документ125 страницGP 62-01mahamed medlamineОценок пока нет

- Flare Jide9Документ17 страницFlare Jide9samuel100% (3)

- Inputs For Piping Stress AnalysisДокумент1 страницаInputs For Piping Stress AnalysisswapnavattemОценок пока нет

- 028120-BDL-001 Basis of Design - Pipeline System Rev. FДокумент14 страниц028120-BDL-001 Basis of Design - Pipeline System Rev. FRokan PipelineОценок пока нет

- 6.6 Onshore and Offshore Pipeline Design PhilosophyДокумент28 страниц6.6 Onshore and Offshore Pipeline Design Philosophyifechuu100% (1)

- Technical Note - Insulation GasketsДокумент3 страницыTechnical Note - Insulation Gasketssdk1978100% (1)

- 4119-Sa-00315523 - A - 01 - Piping Design PremiseДокумент20 страниц4119-Sa-00315523 - A - 01 - Piping Design Premisesivaguruswamy thangaraj100% (1)

- S-LV-SWG-Outdoor Ds - 00Документ51 страницаS-LV-SWG-Outdoor Ds - 00Sachin PrakashОценок пока нет

- Wärtsilä Propac Project GuideДокумент186 страницWärtsilä Propac Project Guideannabogatyreva27Оценок пока нет

- DBD40024770Документ36 страницDBD40024770Safiz TutorОценок пока нет

- PIPING DESIGN & PLANT LAYOUT MANUAL SPECIFICATIONДокумент24 страницыPIPING DESIGN & PLANT LAYOUT MANUAL SPECIFICATIONzsmithОценок пока нет

- General Technical Requirements SpecificationДокумент44 страницыGeneral Technical Requirements Specificationdidi9696Оценок пока нет

- A6V10462640 - Actuators SAX.. SAY.. SAV.. SAL.. - en PDFДокумент87 страницA6V10462640 - Actuators SAX.. SAY.. SAV.. SAL.. - en PDFSaif KhanОценок пока нет

- EF2017-000-DC00-PHL-0001 Process Design Philosophy Rev A2Документ48 страницEF2017-000-DC00-PHL-0001 Process Design Philosophy Rev A2k yОценок пока нет

- SPE 113752 An Empirical Model For Estimating The Rock Lithology and The Cation Exchange Capacity From Dielectric Permittivity DataДокумент30 страницSPE 113752 An Empirical Model For Estimating The Rock Lithology and The Cation Exchange Capacity From Dielectric Permittivity DataDaniel DamboОценок пока нет

- SPE 113805 New Electro-Mechanical Perforating Technology Reduces Cost and Increases Safety in Workover OperationsДокумент9 страницSPE 113805 New Electro-Mechanical Perforating Technology Reduces Cost and Increases Safety in Workover OperationsDaniel DamboОценок пока нет

- Unriznntal /a/all and I Iftinn Mln-Hanieme TN Iltimzata: BackgroundДокумент7 страницUnriznntal /a/all and I Iftinn Mln-Hanieme TN Iltimzata: BackgroundDaniel DamboОценок пока нет

- Producing Ricc-Gas-Condensate Reservoirs (Case Study)Документ6 страницProducing Ricc-Gas-Condensate Reservoirs (Case Study)Daniel DamboОценок пока нет

- SPE 112028 Creating A Sustainable Step Change in Safety From An Innovative Self Evaluation ProgrammeДокумент5 страницSPE 112028 Creating A Sustainable Step Change in Safety From An Innovative Self Evaluation ProgrammeDaniel DamboОценок пока нет

- Stochastic Modeling For The Heterogenous Anisotropic ReservoДокумент8 страницStochastic Modeling For The Heterogenous Anisotropic ReservoDaniel DamboОценок пока нет

- Fast and Robust Algorithm For Compositional Modeling PT 2Документ16 страницFast and Robust Algorithm For Compositional Modeling PT 2Daniel DamboОценок пока нет

- SPE 113374 The Art of Mentoring As Told by Both Sides of The 3-Decade-Old Struggle in The Petroleum IndustryДокумент5 страницSPE 113374 The Art of Mentoring As Told by Both Sides of The 3-Decade-Old Struggle in The Petroleum IndustryDaniel DamboОценок пока нет

- ICA in GeophysicsДокумент7 страницICA in GeophysicsArashОценок пока нет

- Giilfi: SPE 36740 Pressure and Results Composition Effect On Wax Precipitation: Experimental Data and ModelДокумент14 страницGiilfi: SPE 36740 Pressure and Results Composition Effect On Wax Precipitation: Experimental Data and ModelDaniel DamboОценок пока нет

- Pore Scale Gravity Drainage Under Diffrent Wettabilities AnДокумент14 страницPore Scale Gravity Drainage Under Diffrent Wettabilities AnDaniel DamboОценок пока нет

- Spe29111 Coats Compositional and Black Oil Reservoir SimulationДокумент14 страницSpe29111 Coats Compositional and Black Oil Reservoir SimulationObinnaОценок пока нет

- Wettability Effects On Oil Recovery MechanismsДокумент14 страницWettability Effects On Oil Recovery MechanismsDaniel DamboОценок пока нет

- Theoritical and Experimental Investigation of Isothermal CoДокумент15 страницTheoritical and Experimental Investigation of Isothermal CoDaniel DamboОценок пока нет

- Achieving World Class Condensate Recovery Using Integrated Reservoir Management Practices - Oso 1-Y1 Case StudyДокумент8 страницAchieving World Class Condensate Recovery Using Integrated Reservoir Management Practices - Oso 1-Y1 Case StudyDaniel DamboОценок пока нет

- Production Logging Problem DescriptionДокумент15 страницProduction Logging Problem DescriptionDaniel DamboОценок пока нет

- Vertical Flow Barrier Characterisation in Amenam R4 Reservoir (Nigeria) and Impact On Field Development and Reservoir ManagementДокумент5 страницVertical Flow Barrier Characterisation in Amenam R4 Reservoir (Nigeria) and Impact On Field Development and Reservoir ManagementDaniel DamboОценок пока нет

- Role of Geology in Stochastic ModelingДокумент5 страницRole of Geology in Stochastic ModelingDaniel DamboОценок пока нет

- Spe 128609 PDFДокумент11 страницSpe 128609 PDFDaniel DamboОценок пока нет

- Spe 128609 PDFДокумент11 страницSpe 128609 PDFDaniel DamboОценок пока нет

- Important Considerations in Matrix Stimulation Candidate Selection in Niger DeltaДокумент11 страницImportant Considerations in Matrix Stimulation Candidate Selection in Niger DeltaAbduerhman KhaledОценок пока нет

- Research and Development: Utilization of Local Additive in The Cementation of HPHT Wells in NigeriaДокумент8 страницResearch and Development: Utilization of Local Additive in The Cementation of HPHT Wells in NigeriaDaniel DamboОценок пока нет

- Expandable Sand Screen Deployment in Cased Hole Completions: SPDC ExperienceДокумент8 страницExpandable Sand Screen Deployment in Cased Hole Completions: SPDC ExperienceDaniel DamboОценок пока нет

- Novel Through Tubing Sand Control Solution For Failed Gravel Pack-Alpha Well - 4L Case StudyДокумент6 страницNovel Through Tubing Sand Control Solution For Failed Gravel Pack-Alpha Well - 4L Case StudyDaniel DamboОценок пока нет

- First-Pass Screening of Reservoirs With Large Gas Caps For Oil Rim DevelopmentДокумент21 страницаFirst-Pass Screening of Reservoirs With Large Gas Caps For Oil Rim DevelopmentDaniel DamboОценок пока нет

- Spe 128600 PDFДокумент11 страницSpe 128600 PDFDaniel DamboОценок пока нет

- Improving Production Forecasts Through The Application of Design of Experiments and Probabilistic Analysis: A Case Study From Chevron, NigeriaДокумент10 страницImproving Production Forecasts Through The Application of Design of Experiments and Probabilistic Analysis: A Case Study From Chevron, NigeriaDaniel DamboОценок пока нет

- First-Pass Screening of Reservoirs With Large Gas Caps For Oil Rim DevelopmentДокумент21 страницаFirst-Pass Screening of Reservoirs With Large Gas Caps For Oil Rim DevelopmentDaniel DamboОценок пока нет