Академический Документы

Профессиональный Документы

Культура Документы

4-14 HD Line Boring Machine and Accessories Catalogue: Portable - Powerful - Flexible - Easy To Use

Загружено:

Anonymous 5J81IWo1SИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

4-14 HD Line Boring Machine and Accessories Catalogue: Portable - Powerful - Flexible - Easy To Use

Загружено:

Anonymous 5J81IWo1SАвторское право:

Доступные форматы

4-14 HD Line Boring Machine

And

Accessories Catalogue

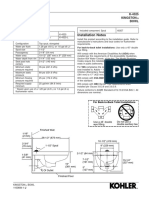

Manual Hydraulic Bar Drive

Used with 5HP power unit

Proportional Hydraulic Bar Drive

Used with 10HP power unit

Portable - Powerful - Flexible - Easy to Use

Line Boring | Bore Welding | Inline Turning | Rotary Milling

1641-17th Ave. Campbell River BC Canada V9W 4L5 1

1-888-783-9675

4-14 HD Line Boring Machine

The York 4-14HD hydraulic line boring machine is built for more power.

Our new 3 guide bar design makes a more rigid machine allowing higher

metal removal rates with less chatter. With up to 351 ft. lbs. of torque at the

bar and a feed motor that delivers 30 ft. lbs. of torque, heavy cuts are made

easy. York has two options available to suit every users need, the manual

control machine with a 5hp hydraulic power unit and the proportional control

machine with a 10hp hydraulic power unit.

Hydraulic

Boring Bar Drives

M—Manually Operated

P—Pendant Operated (Proportional

Version)

Maximum Bar Rotation Speeds of

90, 160, 280, and 460 RPM

3 Hydraulic Power supplies:

5HP Single Phase, 5HP Three Phase,

10HP Three Phase

10 HP Power supply

with pendant remote

Boring diameters from 3 –24” (76—609mm)

14” (355) cutting tool travel

Up to 351 ft. lbs. (475.89 Nm) of torque at the boring bar

Variable speeds up to 460 rpm

Universal mount for line boring and bore welding—allowing you to set up ahead

while you work. Works with all 4-14 options

Machine weight 72lbs. Bar drive weight 12lbs.

Factory trained dealer representatives provide demo's and training for line boring

and bore welding machines.

5HP single phase available in 220/230V 50 or 60 Hz

5HP / 10HP three phase available in 230, 380, 460 or 575V 50 or 60 Hz

Portable - Powerful - Flexible - Easy to Use

Line Boring | Bore Welding | Inline Turning | Rotary Milling 2

1641-17th Ave. Campbell River BC Canada V9W 4L5

1-888-783-9675

4-14 HD M

4-14 HD Manually Operated Bar Drive

Boring diameters from 3—24” (76-609mm)

14” (355mm) cutting tool travel

Up to 351 ft. lbs. (475.89Nm) of torque at the

boring bar

Available maximum speeds of 90, 160, 280,

and 490rpm

Works with all York 4-14 options

Borewelder interface

Part Number: 4-14HD-M

4-14 HD P

4-14 HD Proportional ( Pendant Operated)

Remote Pendant allows for convenient control

of rotation speed.

Boring diameters from 3—24” (76-609mm)

14” (355mm) cutting tool travel

Up to 351 ft. lbs. (475.89Nm) of torque at the

boring bar

Available maximum speeds of 90, 160, 280,

and 490rpm

Works with all York 4-14 options

Borewelder interface

Part Number: 4-14HD-P

Line Boring | Bore Welding | Inline Turning | Rotary Milling 3

1641-17th Ave. Campbell River BC Canada V9W 4L5

1-888-783-9675

5 HP Hydraulic Power Units

Available Units:

Features:

5 HP single or three phase electric

Reversible hydrostatic drive

Three Phase

Hydraulic Power Units

190 Volt, 50 Hz Part Number: HPU-05-319050

220~240 Volt, 50Hz Part Number: HPU-05-322050

380 Volt, 50 Hz Part Number: HPU-05-338050

440~460 Volt, 50 Hz Part Number: HPU-05-344050

230 Volt, 60 Hz Part Number: HPU-05-323060

440~460 Volt, 60 Hz Part Number: HPU-05-346060

575 Volt, 60 Hz Part Number: HPU-05-357560

Single Phase

Available Units:

220~240 Volt, 60Hz Part Number: HPU-05-123060

220~240 Volt, 50Hz Part Number: HPU-05-123050

Manual Control Bar Drives:

Variable Rotational Bar Drive Motors Available

90 rpm, 183.5 ft lb Torque (249 Nm) Part Number: HBD-M-000-90

160 rpm, 145.9 ft lb Torque (198 Nm) Part Number: HBD-M-000-160

280 rpm, 73.6 ft lb Torque (100 Nm) Part Number: HBD-M-000-280

460 rpm, 56 ft lb Torque (76 Nm) Part Number: HBD-M-000-460

Bar rotation lock valve mounted on bar drive

9 gallon (40.3Lt) fluid tank

Bar drive weight 26 lbs (12kg)

Power supply weight 275 lbs (125kg)

Line Boring | Bore Welding | Inline Turning | Rotary Milling 4

1641-17th Ave. Campbell River BC Canada V9W 4L5

1-888-783-9675

10 HP Hydraulic Power Units

Features:

10HP three phase electric

Reversible hydrostatic drive

Available Units:

10HP Three Phase

Hydraulic Power Unit with Remote Pendant

230 Volt, 50 Hz Part Number: HPU-10-323050

230 Volt, 60 Hz Part Number: HPU-10-323060

380 Volt, 50 Hz Part Number: HPU-10-338050

400 Volt, 50 Hz Part Number: HPU-10-340050

415 Volt, 50 Hz Part Number: HPU-10-341550

460 Volt, 50 Hz Part Number: HPU-10-346050

460 Volt, 60 Hz Part Number: HPU-10-346060

575 Volt, 60 Hz Part Number: HPU-10-357560

Proportional Bar Drives:

Variable Rotational Bar Drive Motors Available

90 rpm, 183.5 ft lb Torque (249 Nm) Part Number: HBD-P-000-90

160 rpm, 145.9 ft lb Torque (198 Nm) Part Number: HBD-P-000-160

280 rpm, 73.6 ft lb Torque (100 Nm) Part Number: HBD-P-000-280

460 rpm, 56 ft lb Torque (76 Nm) Part Number: HBD-P-000-460

Bar rotation lock valve mounted on bar drive

19 us gallons ( 72 Lt) fluid tank

Bar drive weight 26 lbs (12kg)

Power supply weight 570 lbs ( 258 kg)

Line Boring | Bore Welding | Inline Turning | Rotary Milling 5

1641-17th Ave. Campbell River BC Canada V9W 4L5

1-888-783-9675

A) Premium Plus Package: 1.5 to 16”

(38 to 406mm) A B C D E Package Includes

Complete 5 bar package that covers the entire

1 1/4" Bar Package

operating range of the 4-14. This is a very

1 1 1 4 Foot Bar

dynamic package designed for those who work

1 1 1 1 6 Foot Bar

on a wide range of large and small bores. 2 2 2 2 3" Line-up Cones

Part Number: P-1 2 2 1 2 Mounting Head

2 2 1 2 Bore weld Interface

B) Premium Package: 1.5 to 10" (38 to 2 2 2 2 Tail Support

254mm) 2 2 2 2 Clamping Collars

Complete 5 bar package that is designed for 1 1 1 1 Calibration Tool

those in the heavy equipment industry that work 1 1 1 1 Accessories Tool Box

on bores up to 10 inches, this kit can be easily 2" Bar Package

upgraded at any time to 16” (406mm) 1 1 1 3 Foot Bar

diameters. 1 1 1 1 5 Foot Bar

1 1 1 7 Foot Bar

Part Number: P-2

2 2 2 2 2-4 " Line-up Cones

2 2 2 2 4-6" Line-up Cones

C) Standard Package: 2.5 to 6” (63.5 to 2 2 6-8" Line-up Cones

152mm) 2 8-10" Line-up Cones

3 bar package using our 2” (52mm) boring bars. 1 8-16" Line-up Spiders

Small bars can be added at any time if required. 2 2 2 1 Mounting Head

Part Number: P-3 2 2 2 1 Bore welder Interface

1 Adjustable X/Y Mounting Kit

D) Combo Package: 1.5 to 6" (38 to 2 2 2 2 Tail Support

152mm) 2 2 2 2 Clamping Collars

1 1 1 1 Calibration Tool

Kit is designed to meet the needs of most

equipment owners. This kit is upgradeable by 1 1 6-10" Big Bore Adaptor

adding components as needed. 1 10-13" Big Bore Adaptor

Part Number:P-4 1 13-16" Big Bore Adaptor

1 1 1 1 Accessories Tool Box

E) Small Bore Package: 1.5 to 3" (38 to 2 ¼” (58mm) Bars now available using our

76mm) Hydraulic drives – bore up to 24”(609mm)

2 bar package is designed for our 1-1/4”

(32mm) bars for small diameters, we have an Chrome Plated Bars Available as

upgrade kit that can be added to reach an Option

5” (127mm) using our 1 1/4” (32mm) bars.

Part Number: P-5

Custom packaging is also available. All our

bars can be supplied with either imperial or

metric tool ports.

Line Boring | Bore Welding | Inline Turning | Rotary Milling 6

1641-17th Ave. Campbell River BC Canada V9W 4L5

1-888-783-9675

2" (50.8mm) Boring Bars & Accessories

2” (50.8mm) Mounting Head

Two bearings for added support

One bore welder mounting plate included

Alignment adjusting screws

Part Number: 414-201

Replacement Inserts

Part Number: 414-201A

2" (50.8mm) Tail Support

4 bolt flange bearings on replaceable

mounting plates

Part Number: 414-202

Replacement Weld Plate

Part Number: 414-202A

Replacement Flange Bearing

Part Number: 414-202B

X/Y Adjustable Mounting Kit

Freedom to move - the X/Y mounting

head allows you to move the bar

5/8" (15.8mm) in any direction from

center. You also have a 6 degree spher-

ical adjustment. This feature is a huge as-

set for bores larger than 10" (254mm)

that might require an extra degree of pre-

cision alignment.

Part Number: 414-309 (Kit)

Adjustable X/Y Mounting Head only

Part Number: 414-310

Adjustable X/Y Tail Support only

Part Number: 414-330

Line Boring | Bore Welding | Inline Turning | Rotary Milling 7

1641-17th Ave. Campbell River BC Canada V9W 4L5

1-888-783-9675

4-14 ET 2" (50.8mm) Items

2" Diameter (50.8mm) Boring Bars

Staggered 1/2” tool ports every three

inches along the bar.

Tool ports are broached and threaded

Bars are made from C1045 precision

ground shafting

Available chrome plated and polished

3’ Bar

Part # 414-213-36 Polished Bar

Part # 414-213-36C Chrome Bar

5’ Bar

Part # 414-213-60 Polished Bar

Part # 414-213-60C Chrome Bar

7’ Bar

Part # 414-213-84 Polished Bar

Part # 414-213-84C Chrome Bar

Note: For Metric bars place an M at the

end of the part number

Custom bars and lengths available on

request

2" (50.8mm) Line-Up Cones

Steel cones

Precision alignment

Relieved in the back to reduce weight

2 to 4” (50.8 to 101.6mm)

Part Number: 414-203

4 to 6” (101.6 to 152.4mm)

Part Number: 414-204

6 to 8” (152.4 to 203.2mm)

Part Number: 414-215

8 to 10” (203.2 to 254mm)

Part Number: 414-214

Line Boring | Bore Welding | Inline Turning | Rotary Milling 8

1641-17th Ave. Campbell River BC Canada V9W 4L5

1-888-783-9675

4-14ET 2" (50.8mm) Items

2" (50.8mm) Adjustable Line-Up Tool

(Spider) for bores 8"- 16" (203mm -

406mm)

For aligning and centering the bar when

working with bores larger than

8” (203mm). The line up tool dials out to

the diameter that you need.

The kit comes in a custom carrying case,

with two centering tools and four sets of

extensions

Part Number: 414-501

2" (50.8mm) Clamping Collars

To secure the line up cones in place

during set up

Split collar with allen head screws

Part Number: 414-205

(sold in package of 2)

2" (50.8mm) Calibration Wrench

The calibration wrench allows accurate cutting

tool adjustment in increments of .001”. All of

our boring bars have broached and threaded

tool ports with a scribed line on center. We put

an adjusting screw at the base of the cutting

tool that the calibration wrench fits into. There

are 50 graduations on the wrench. With each

graduation past the scribed line the cutting tool

advances .001”

Part Number: 414-207 (c/w 5 cutting tool

adjusters)

Cutting Tool Adjusters

Part Number: 414-206 A York

(sold in package of 5) Exclusive!

Line Boring | Bore Welding | Inline Turning | Rotary Milling 9

1641-17th Ave. Campbell River BC Canada V9W 4L5

1-888-783-9675

4-14ET 2" (50.8mm) Items

2" (50.8mm) Accessories Tool Box

Includes:

Tool box (26”)

Set screws

Sample Micro 100 carbide tooling

Wrenches

Allen keys

Part Number: 414-250

2" (50.8mm) Large Bore Adapters

The York large bore adapters clamp securely

to our 2” (50.8mm) boring bar. The large

bore adapter supports the tool bit to

accommodate larger bores over 6” (152mm)

in diameter. The 6-10” (152-254mm) adapter

can be used with the York calibration wrench

and is our standard adapter. Custom large

bore adapters are also available for 10-

13” (254-330mm) and 13-16” (330-406mm)

6 to 10” (152.4 to 254mm)

Part Number: 414-303

10 to 13” (254mm to 330mm)

Part Number: 414-301

13 to 16” (330.2 to 406mm)

Part Number: 414-302

Line Boring | Bore Welding | Inline Turning | Rotary Milling 10

1641-17th Ave. Campbell River BC Canada V9W 4L5

1-888-783-9675

4-14ET 1-1/4" (32mm) Items

1 1/4" (32mm) Mounting Head

Two bearings for added support

One bore welder mount plate included

Alignment adjusting screws

Part Number: 414-101

Replacement Inserts

Part Number: 414-101A

1 1/4" (32mm) Tail Support

4 bolt flange bearing on a replaceable

mounting plate

Part Number: 414-102

Replacement Weld Plate

Part Number: 414-102A

Replacement Flange

Part Number: 414-102B

1 1/4" (32mm) Line-Up Cones

Steel cones 1 1/4 to 3” and 3 to 5”

Precision alignment

1 1/4 to 3”

3 to 5”

1 1/4” to 3” (32 to 76mm)

Part Number: 414-103 (set of 2)

3” to 5” (76 to 127mm)

Part Number: 414-104 (set of 2)

Line Boring | Bore Welding | Inline Turning | Rotary Milling 11

1641-17th Ave. Campbell River BC Canada V9W 4L5

1-888-783-9675

4-14ET 1-1/4" (32mm)Items

1 1/4" (32mm) Boring Bars

Staggered 3/8” (9.5mm) tool ports every

3” (76.2mm) along the bar

Tool ports are broached and threaded

Bars are made from C1045 precision

ground shafting

Available chrome plated and polished

4’ Bar (1219.2mm)

Part Number: 414-113-48 Polished bar

Part Number: 414-113-48C Chrome bar

6’ Bar (1828.8mm)

Part Number: 414-113-72 Polished bar

Part Number: 414-113-72C Chrome bar

Note: For Metric bars place an M at the

end of the part number

Custom bars and lengths available on

request

1 1/4" (32mm) 3-5" (76 to 127mm)

Large Bore Adaptor

This adapter is used to support tooling for

bores greater than 3”. It will help reduce

tool breakage and chatter. For maximum

success we recommend using our 2” bars

for bores greater than 3”

Part Number: 414-307

1 1/4" (32mm) Clamping Collars

Used to secure the line up cones in place

during set up

Spit collar with allen head screw

Part Number: 414-105

(sold in a package of 2)

Line Boring | Bore Welding | Inline Turning | Rotary Milling 12

1641-17th Ave. Campbell River BC Canada V9W 4L5

1-888-783-9675

4-14ET 1-1/4" (32mm) Items

1 1/4" Calibration Wrench

The calibration wrench allows accurate

cutting tool adjustment in increments

of .001”. All of our boring bars have

broached and threaded tool ports with a

scribed line on center. We put an adjusting

screw at the base of the cutting tool that the

calibration wrench fits into. There are 50

graduations on the wrench. With each grad-

uation past the scribed line the cutting tool

advances .001”.

Part Number: 414-107 (c/w 5 cutting tool

adjusters)

A York

Cutting Tool Adjusters

Part Number: 414-106

Exclusive!

(sold in package of 5)

1 1/4" (32mm) Accessories Tool Box

Includes:

Tool box (21”)

Set screws

Sample Micro 100 carbide tooling

Wrenches

Allen keys

Part Number: 414-150

Line Boring | Bore Welding | Inline Turning | Rotary Milling 13

1641-17th Ave. Campbell River BC Canada V9W 4L5

1-888-783-9675

4-14 ET 2-1/4" (57mm) Items

Recommended with our hydraulic bar drives

2 ¼” (57mm) Mounting Head (Standard)

Two bearings for added support

One bore welder mount plate included

Alignment adjusting screws

Part Number: 414-601

Replacement Inserts

Part Number: 414-601A

X/Y Adjustable Mounting Head & Tail

Support

Freedom to move - the X/Y mounting head

allows you to move the bar 5/8" (15.8mm)

in any direction from center. You also have

a 6 degree spherical adjustment. This fea-

ture is a huge asset for bores larger than

10" (254mm) that might require an extra

degree of precision alignment.

Part Number: 414-609 (Kit)

Mounting Head Only

Part Number: 414-610 Adjustable X/Y

Adjustable X/Y Tail Support Only

Part Number: 414-630

2 ¼” (57mm) Tail Support

4 bolt flange bearing on a replaceable

mounting plate

Part Number: 414–602

Replacement Weld Plate

Part Number: 414-602A

Replacement Flange

Part Number: 414-602B

Line Boring | Bore Welding | Inline Turning | Rotary Milling 14

1641-17th Ave. Campbell River BC Canada V9W 4L5

1-888-783-9675

4-14 ET 2-1/4" (57mm) Items

2 ¼” (57mm) Boring Bars

Staggered 1/2" (12.7mm) tool ports eve-

ry 3” (76mm) along the bar.

Tool ports are broached and threaded

Bars are made from C1045 precision

ground shafting.

Available chrome plated and polished

3' (914mm) Boring Bar

Part Number: 414-613-36 Polished Bar

Part Number: 414-613-36C Chrome Bar

5' (1524mm) Bar

Part Number: 414-613-60 Polished Bar

Part Number: 414-613-60C Chrome Bar

8' (2438mm) Bar

Part Number: 414-613-96 Polished Bar

Part Number: 414-613-96C Chrome Bar

Note: for Metric place an M at the end of

the part number

Custom bars and lengths available on

request

2 ¼” (57mm) Line-Up Cones

Steel cones

Precision alignment

Relieved in the back to reduce weight

2" to 4" (50.8 to 101.6mm)

Part Number: 414-603 (Set of 2)

4" to 6" (101.6 to 152.4mm)

Part Number: 414-604 (Set of 2)

6" to 8" (152.4 to 203.2mm)

Part Number: 414-615 (Set of 2)

Line Boring | Bore Welding | Inline Turning | Rotary Milling 15

1641-17th Ave. Campbell River BC Canada V9W 4L5

1-888-783-9675

4-14 ET 2-1/4" (57mm) Items

2 ¼” (57mm) Adjustable Line-Up Tool (Spider)

for bores 8" to 24"

For aligning and centering the bar when

working with bores larger than 8" (203mm). The

line up tool dials out to the diameter you need.

The kit comes in a custom carrying case, with

two centering tools and four sets of extensions.

Part Number: 414-600

2 ¼” (57mm) Clamping Collars

Used to secure the line up cones in place

during setup

Split collar with allen head screw

Part Number: 414-605

Accessories Tool Box

Includes:

Tool Box (26”)

Set Screws

Sample Micro 100 carbide tooling

Allen keys

Key Stock

Wrenches

Part Number: 414-250

Line Boring | Bore Welding | Inline Turning | Rotary Milling 16

1641-17th Ave. Campbell River BC Canada V9W 4L5

1-888-783-9675

Optional Accessories

Facing Tools

The York facing tools are designed to

machine surfaces 90 degrees to the bore.

The facing tool attaches to our

2" (50.8mm) boring bar. Two tool ports

are set in the facing tool; one at 45 de-

grees and the other at 90 degrees. Each

revolution of the bar actuates a gear driv-

en lead screw that advances the cutting

tool .005" (.127mm).

Part Number: FT-1000 Max 10” (254mm)

FT-1000 FT-9000

Part Number: FT 9000 Max 18” (457mm)

Off-Set Drive

(A unique feature no one else has)

Our offset drive feature allows more flex-

ibility than thru bar designs. The York line

-boring machine is an excellent choice for

working in constricted areas, as the

driveline allows 30 degrees offset in any

direction from the boring bar alignment.

Part Number: OFF-000

Carbide Insert Tool Package

1/2" (12mm)

The York insert tool places the carbide

cutting surface into the center of the

bore, substantially improving cutting tool

performance while extending tool holder

life. Our tool holders use standard inserts

that are readily available from most

cutting tool suppliers. Insert tooling takes

the guesswork out of tool geometry and

improves the overall performance of your

line boring machine.

Part Number: ITK-000

Line Boring | Bore Welding | Inline Turning | Rotary Milling 17

1641-17th Ave. Campbell River BC Canada V9W 4L5

1-888-783-9675

Optional Accessories

Thru Bar Measuring Kits

1.9 - 12" (48.26 - 304.8mm) or

1.9 - 16" (48.26—406.4mm) Diameters

Our thru bar measuring tool allows you to

accurately measure the bore without

removing the bar. The measuring tool is

placed into an adjacent tool port and

traversed into the bore. By loosening the

setscrew, the spring loaded measuring

tool snaps opens - capturing the size of

the bore. Tighten the setscrew and

traverse the tool from the bore. Pull the MT2-1000

measuring tool out of the bar. Using a

micrometer, measure the thru bar tool for

the diameter of the bore.

1.9" to 12" (48.26 to 304.8mm)

Part Number: MT2-1000

1.9" to 16" (48.26 to 406.4mm)

Part Number: MT2-2000

MT2-2000

Snap Ring Tool

3.8 to 7" (96.5 to 177.8mm)

5/8" stroke (15.8mm)

Hydraulic feed

Accurate adjustment

Part Number: SR- 000

Ripper Shank Repair Kit

A unique option that saves having to pull

the tracks to repair worn bores on D-9 to

D-10 Cat

(*Call us for kits to repair other models)

Part Number: RIP-000

Line Boring | Bore Welding | Inline Turning | Rotary Milling 18

1641-17th Ave. Campbell River BC Canada V9W 4L5

1-888-783-9675

Optional Accessories

Micro 100 Brazed Carbide Cutting Tools

Micro 100 is highly shock resistant, will not

chip or break under normal machining

conditions and is unexcelled in interrupted

cutting. Micro 100 carbide is a space age

carbide with superior rupture strength for

exceptional machining versatility.

#6 - 3/8"

Part Number: AR-6 or AL-6 MICRO 100 “A” Style

Part Number: BR-6 or BL-6 MICRO 100 “B” Style

#8 - 1/2"

Part Number: AR-8 or AL-8 MICRO 100 “A” Style

Part Number: BR-8 or BL-8 MICRO 100 “B” Style

Bore Welder Adapter Plates

Part Number: 414-212

(Sold in package of 2)

* NOTE: Will work with most brands of bore welders

Line Boring | Bore Welding | Inline Turning | Rotary Milling 19

1641-17th Ave. Campbell River BC Canada V9W 4L5

1-888-783-9675

Вам также может понравиться

- Multi-Function CNC Lathe: FCL-18/25 SERIESДокумент10 страницMulti-Function CNC Lathe: FCL-18/25 SERIESBhargav SaiОценок пока нет

- Barrenadora CatalogoДокумент18 страницBarrenadora CatalogoJhonny AlvarezОценок пока нет

- Phu Tung YokeДокумент19 страницPhu Tung YokeAnh TranОценок пока нет

- CADET Catalogue - 1Документ14 страницCADET Catalogue - 1Алмаз КенжетаевОценок пока нет

- Section DДокумент7 страницSection Dodqm_25Оценок пока нет

- Form For Site Visit BN-12 (25!03!2014)Документ28 страницForm For Site Visit BN-12 (25!03!2014)nadiraОценок пока нет

- Sandvik DP1100i: Surface Top Hammer DrillsДокумент3 страницыSandvik DP1100i: Surface Top Hammer DrillsTuan Pham AnhОценок пока нет

- York Brochure Cadet PDFДокумент2 страницыYork Brochure Cadet PDFDirectorio FotograficoОценок пока нет

- Boring Bar PackagesДокумент1 страницаBoring Bar PackagesOswaldo TolozaОценок пока нет

- L057R51 Economy Series DS 2019Документ3 страницыL057R51 Economy Series DS 2019Eero KosonenОценок пока нет

- Spec Pantera Dp1500i t4 2 WebДокумент3 страницыSpec Pantera Dp1500i t4 2 WeblenardoangeloОценок пока нет

- Bug OДокумент24 страницыBug ORogo CatalinОценок пока нет

- P1928F PerformerSeriesДокумент2 страницыP1928F PerformerSeriestlatoani77Оценок пока нет

- DocumentДокумент3 страницыDocumentTamirat DgtОценок пока нет

- Sandvik DU311 ITH - Descripción Técnica - EnglishДокумент4 страницыSandvik DU311 ITH - Descripción Técnica - EnglishErix Alcayaga GonzálezОценок пока нет

- Digital Paddlewheel Flow Meter: FeaturesДокумент4 страницыDigital Paddlewheel Flow Meter: FeaturesAfrizal PHBОценок пока нет

- Dp1500i t3 Specification Sheet EnglishДокумент3 страницыDp1500i t3 Specification Sheet EnglishSTANLEYОценок пока нет

- 8" Submersible Motors Standard: ApplicationsДокумент7 страниц8" Submersible Motors Standard: Applicationswpt_meОценок пока нет

- SOP (Drilling)Документ8 страницSOP (Drilling)sanjeet giriОценок пока нет

- North American Edition: Sensing Your NeedsДокумент114 страницNorth American Edition: Sensing Your NeedsMiguel CasasОценок пока нет

- LN 25 Pro PDFДокумент4 страницыLN 25 Pro PDFGalo Abad Huayta FernándezОценок пока нет

- F2000 Flow Meter Tech DatasheetДокумент4 страницыF2000 Flow Meter Tech DatasheetZulfeqar AliОценок пока нет

- PLL 1397 PDFДокумент63 страницыPLL 1397 PDFpamururamuОценок пока нет

- DX500Документ3 страницыDX500med_tataОценок пока нет

- PiperBug Bro 6 - 12 - 1350027891Документ8 страницPiperBug Bro 6 - 12 - 1350027891Goran BoskovicОценок пока нет

- Specification - MechanicalДокумент5 страницSpecification - MechanicalEDEN FALCONIОценок пока нет

- Gecko: Fillet Welding TractorДокумент8 страницGecko: Fillet Welding TractorMiki RandiОценок пока нет

- PAT Drilling Catalogue (ACF)Документ22 страницыPAT Drilling Catalogue (ACF)sunilchoppala100% (3)

- Sandvik DP1100: Surface Top Hammer DrillsДокумент3 страницыSandvik DP1100: Surface Top Hammer DrillsSMRUTIRANJAN DASHОценок пока нет

- Dp1500i t4 Specification Sheet EnglishДокумент3 страницыDp1500i t4 Specification Sheet EnglishMahamadou IssoufouОценок пока нет

- Well HandyДокумент6 страницWell HandymtonellyОценок пока нет

- L170R... Mega DS 2021Документ7 страницL170R... Mega DS 2021ชัชวาล เมตตาОценок пока нет

- WWW Lkgoodwin Com More Info WR Wire Rope Models 3 and 5 TonДокумент13 страницWWW Lkgoodwin Com More Info WR Wire Rope Models 3 and 5 TonmashudiОценок пока нет

- Gorlitz Sewer & DrainДокумент24 страницыGorlitz Sewer & DrainCleaner MagazineОценок пока нет

- Roughing-In: Product Information Installation NotesДокумент1 страницаRoughing-In: Product Information Installation Notesfopoku2k2Оценок пока нет

- HRD 42Pf - HRD 60Pf: High Productivity, Easy Handling - The Ideal Option For Series ProductionДокумент3 страницыHRD 42Pf - HRD 60Pf: High Productivity, Easy Handling - The Ideal Option For Series ProductionSergio OsorioОценок пока нет

- Tamrock Pantera 1500Документ3 страницыTamrock Pantera 1500Hafidha Dwi Putri AristienОценок пока нет

- Roper Serie 3600 PDFДокумент2 страницыRoper Serie 3600 PDFantonioОценок пока нет

- 6 LargethruholeДокумент2 страницы6 LargethruholeAnkurОценок пока нет

- Sandvik DP1500i: Surface Top Hammer DrillsДокумент3 страницыSandvik DP1500i: Surface Top Hammer DrillsTuan Pham AnhОценок пока нет

- INVALCO CatalogДокумент24 страницыINVALCO Catalogemuno008Оценок пока нет

- Dx800 s5 Specification Sheet EnglishДокумент3 страницыDx800 s5 Specification Sheet EnglishAntónio Pedro TavaresОценок пока нет

- Specifications:: 1. Traveling Block (YG-150)Документ6 страницSpecifications:: 1. Traveling Block (YG-150)Dewantoro HarisОценок пока нет

- Pipe Bending Machine ManufacturerДокумент13 страницPipe Bending Machine ManufacturerS.N. ENTERPRISES PIPE BENDING100% (1)

- Overcome Your Most Demanding Automation Challenges: Biffi Actuators and Control SystemsДокумент20 страницOvercome Your Most Demanding Automation Challenges: Biffi Actuators and Control SystemsIsmael García LopezОценок пока нет

- AGITADOR SUBMERSÍVEL ABS SULZER XRW - 210 - 60Hz - TDSДокумент1 страницаAGITADOR SUBMERSÍVEL ABS SULZER XRW - 210 - 60Hz - TDSVictor SouzaОценок пока нет

- Transpose Comfort Height: The Complete Solution Two-Piece Elongated ToiletДокумент2 страницыTranspose Comfort Height: The Complete Solution Two-Piece Elongated ToiletSimon LemireОценок пока нет

- MR615 Product GuideДокумент16 страницMR615 Product GuideDinesh RajaОценок пока нет

- Manual Do BOP IEДокумент18 страницManual Do BOP IEandre vidalОценок пока нет

- Sbin 001Документ24 страницыSbin 001Julián CamargoОценок пока нет

- D-Head W-80 5-06 LTRДокумент4 страницыD-Head W-80 5-06 LTRNguyen Tho VanОценок пока нет

- Intercable PreseДокумент32 страницыIntercable PreseIngaОценок пока нет

- Axminster 06 - Drilling Machines & Driil Bits - p185-p211Документ27 страницAxminster 06 - Drilling Machines & Driil Bits - p185-p211Pierre799esОценок пока нет

- Model 15T Thru-Bore Model 15H Hollow BoreДокумент3 страницыModel 15T Thru-Bore Model 15H Hollow BoreSergio RiveroОценок пока нет

- Spec Ranger Dx700 t4 4 en 16228 WebДокумент3 страницыSpec Ranger Dx700 t4 4 en 16228 WebManuelОценок пока нет

- AWT 1000 LeafletДокумент6 страницAWT 1000 Leafletphucgenji0% (1)

- Technical Specifications For Centrifugal Pumps PDFДокумент12 страницTechnical Specifications For Centrifugal Pumps PDFVicky GautamОценок пока нет

- Op Amps: Design, Application, and TroubleshootingОт EverandOp Amps: Design, Application, and TroubleshootingРейтинг: 5 из 5 звезд5/5 (2)

- Z7 Parts Manual - PreliminaryДокумент47 страницZ7 Parts Manual - PreliminaryMD.ebadul IslamОценок пока нет

- Ibm Infoprint 1570 DatasheetДокумент3 страницыIbm Infoprint 1570 DatasheetxyzОценок пока нет

- MK Wiring Accessories 1Документ14 страницMK Wiring Accessories 1dega2556Оценок пока нет

- MAX-Blade ToolДокумент2 страницыMAX-Blade ToolErnest AmadiОценок пока нет

- Caranzo, Clarish Ann B. BSN-1105 Human Anatomy and Physiology LabДокумент2 страницыCaranzo, Clarish Ann B. BSN-1105 Human Anatomy and Physiology LabClarish Ann CaranzoОценок пока нет

- Spesifikasi Teknis Suku Cadang Pemurnian Dan Analisis Gas 2021Документ2 страницыSpesifikasi Teknis Suku Cadang Pemurnian Dan Analisis Gas 2021Hendar Tubagus IMОценок пока нет

- Electrical and Plumbing DrawingДокумент6 страницElectrical and Plumbing DrawingazniОценок пока нет

- SIP-ignition-performance Manual 240122 210229Документ12 страницSIP-ignition-performance Manual 240122 210229ahmad.abdolahi1402Оценок пока нет

- Series 27100 28000 Vertical Detect A Fire UnitsДокумент2 страницыSeries 27100 28000 Vertical Detect A Fire UnitsMarcelo LeguizamonОценок пока нет

- Controls, Start-Up, Operation, Service and Troubleshooting: 30XA080-500 Air-Cooled Liquid Chillers 60 HZДокумент126 страницControls, Start-Up, Operation, Service and Troubleshooting: 30XA080-500 Air-Cooled Liquid Chillers 60 HZHasib Khan100% (1)

- Armoring Protection StandardsДокумент7 страницArmoring Protection StandardsbasaricaОценок пока нет

- Trajan Sge SyringesДокумент4 страницыTrajan Sge SyringesCarolina GarciaОценок пока нет

- Sturdy Stick: Silstar Powertip Classic RodsДокумент1 страницаSturdy Stick: Silstar Powertip Classic RodsRoddy GonzalezОценок пока нет

- Grillo Walking TractorsДокумент28 страницGrillo Walking TractorsS JОценок пока нет

- Oilchange BMW F 650 GSДокумент2 страницыOilchange BMW F 650 GSDaniel De MulderОценок пока нет

- Heavy Lifting Permit VERY PERMIT - ContohДокумент1 страницаHeavy Lifting Permit VERY PERMIT - ContohOctaviary Bintan FamilyОценок пока нет

- Media-Based Arts and Designs in The Philippines (Photography)Документ25 страницMedia-Based Arts and Designs in The Philippines (Photography)ROMMEL LAGATIC100% (1)

- Quotation Sheet: Foro Industry Co.,LtdДокумент2 страницыQuotation Sheet: Foro Industry Co.,LtdWong JowoОценок пока нет

- What Is An SSD - Solid-State Drive Definition - AvastДокумент10 страницWhat Is An SSD - Solid-State Drive Definition - AvastThomasОценок пока нет

- Datasheet TFT Monitor Okuma ControlДокумент3 страницыDatasheet TFT Monitor Okuma ControlayeshajavedsahibaОценок пока нет

- Acti9 Disbo - DBX324MNS63FDДокумент2 страницыActi9 Disbo - DBX324MNS63FDbenghoe77Оценок пока нет

- Low Power AM Broadcast Radio Transmitter Kit: Assembly and Operating InstructionsДокумент34 страницыLow Power AM Broadcast Radio Transmitter Kit: Assembly and Operating InstructionsArchaeoAnalytics MeetingОценок пока нет

- 10 PrecautionДокумент2 страницы10 PrecautionkoletОценок пока нет

- Side Impact Sensor 8212 C Pillar Removal and InstallationДокумент2 страницыSide Impact Sensor 8212 C Pillar Removal and InstallationMichael HernandezОценок пока нет

- SGP 5Документ7 страницSGP 5Soumajit PoddarОценок пока нет

- HDS01Документ3 страницыHDS01Sylvain AguedaОценок пока нет

- EP-51658-P-CAE-0201 (00) Phase A TG CEДокумент3 страницыEP-51658-P-CAE-0201 (00) Phase A TG CEG Bill AlphaОценок пока нет

- Valve Assy, Control, P - N Yy30v00036f1Документ3 страницыValve Assy, Control, P - N Yy30v00036f1刘奇雄Оценок пока нет

- Fire Protection System Comprises of The FollowingДокумент6 страницFire Protection System Comprises of The FollowingMukesh KumarОценок пока нет

- Tunneling & Rock Drilling EquipmentДокумент5 страницTunneling & Rock Drilling EquipmentRasu Rawat100% (1)