Академический Документы

Профессиональный Документы

Культура Документы

Repair PDF

Загружено:

Hernan F GodoyОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Repair PDF

Загружено:

Hernan F GodoyАвторское право:

Доступные форматы

TEMPORARY WIRING HARNESS REPAIR

The following method to repair wiring harnesses is ● Wind a layer of vinyl insulation tape up to the cable

temporary. Do not attempt to repair wiring on any cover at each end of the repair section.

system sensors as these are sealed and should only

be replaced with a new component.

NOTE: When soldering a cable, use RESIN CORE

SOLDER only, other types of solder may result in

further damage.

● Locate damaged portion of the harness, cut away

outer protective cover on both sides of the

damaged area.

BC07H063

● Make a paper trough, apply silicon rubber

compound (non hardening sealant) over the

repaired section up to the outer protective cover.

BC07H061

● Using a suitable solvent, clean about 50 MM. (2

inches) from each cover end.

● Strip about 13 MM. (½ inch) of insulation from the

wires. Do not cut away any of the wire strands.

BC07H064

● Allow the compound to cure then cover the area

with insulation tape. Overlap the tape at least 50

MM. (2 inches) over each end of the protective

cover.

● Check the operation of the equipment.

IMPORTANT: Replace the damaged cable as soon

as possible, this is only a temporary repair and water

or chemical ingression can cause additional damage

to the equipment.

BC07H062

● Twist two bare leads together for each damaged

lead, be sure to match wire colors, then solder the

leads using resin core solder. Tape each repaired

lead with vinyl insulation tape.

Вам также может понравиться

- Weatherproofing: The DIY Guide to Keeping Your Home Warm in the Winter, Cool in the Summer, and Dry All Year AroundОт EverandWeatherproofing: The DIY Guide to Keeping Your Home Warm in the Winter, Cool in the Summer, and Dry All Year AroundОценок пока нет

- Catalogo Herramienta para Montar Correas de DistribucionДокумент152 страницыCatalogo Herramienta para Montar Correas de DistribucionJoan Angel Solanelles100% (3)

- Revised Design of Buttress WallДокумент15 страницRevised Design of Buttress WallVincent Gabrielle N. GallardoОценок пока нет

- Motor Jhon Deere 2 PDFДокумент190 страницMotor Jhon Deere 2 PDFHarold ReveloОценок пока нет

- Motor Jhon Deere 2 PDFДокумент190 страницMotor Jhon Deere 2 PDFHarold ReveloОценок пока нет

- s80001 PDFДокумент196 страницs80001 PDFHernan F Godoy100% (3)

- 9.9 Diaphragms-With-Interior-Shearwalls PDFДокумент4 страницы9.9 Diaphragms-With-Interior-Shearwalls PDFnickОценок пока нет

- Nitomortar TC2000 PDFДокумент3 страницыNitomortar TC2000 PDFtalatzahoor100% (2)

- EHV CableДокумент19 страницEHV Cablevikrant jainОценок пока нет

- Bosch Aftertreatment DEF Controller ConnectorДокумент4 страницыBosch Aftertreatment DEF Controller ConnectorO mecanicoОценок пока нет

- General Guidelines InsulationДокумент56 страницGeneral Guidelines InsulationPadmanaban SoundirarajanОценок пока нет

- Surface Repair Using Form-and-Pour Techniques: Reported by ACI Committee E 706Документ7 страницSurface Repair Using Form-and-Pour Techniques: Reported by ACI Committee E 706Carlos Gonzalez100% (1)

- HVAC Systems Duct DesignДокумент39 страницHVAC Systems Duct Designsardarmkhan100% (2)

- L4 BeamsДокумент10 страницL4 BeamsFairiey Izwan Azazi100% (1)

- LS Cable Power Cable GuideДокумент33 страницыLS Cable Power Cable Guideselaroth168Оценок пока нет

- Casting Defects LDДокумент17 страницCasting Defects LDSrinivas OhatkerОценок пока нет

- ASTM C1602-22 Standard Specification For Mixing Water Used in The Production of Hydraulic Cement ConcreteДокумент5 страницASTM C1602-22 Standard Specification For Mixing Water Used in The Production of Hydraulic Cement ConcreteOmid DeldarОценок пока нет

- Checklist For LT Cabel JointingДокумент3 страницыChecklist For LT Cabel Jointingccsures100% (4)

- Electrical Systems - Harnesses and Connectors: ANIL12TR01310JAДокумент60 страницElectrical Systems - Harnesses and Connectors: ANIL12TR01310JAHernan F GodoyОценок пока нет

- Electrical Systems - Harnesses and Connectors: ANIL12TR01310JAДокумент60 страницElectrical Systems - Harnesses and Connectors: ANIL12TR01310JAHernan F GodoyОценок пока нет

- Electrical Systems - Harnesses and Connectors: ANIL12TR01310JAДокумент60 страницElectrical Systems - Harnesses and Connectors: ANIL12TR01310JAHernan F GodoyОценок пока нет

- Load Sensing2Документ6 страницLoad Sensing2Victor Acuña0% (1)

- Standard procedures for 11kV and 6.6kV cable preparationДокумент144 страницыStandard procedures for 11kV and 6.6kV cable preparationGuler RahimОценок пока нет

- Installation instructions for SEIK 14, 24, 34 plug-in cable terminationsДокумент5 страницInstallation instructions for SEIK 14, 24, 34 plug-in cable terminationsSonia Noval LlorianОценок пока нет

- INSTRUCTION Heat Shrink Termination Single Core Cables MV HV 6.6kV 11kV 33kVДокумент6 страницINSTRUCTION Heat Shrink Termination Single Core Cables MV HV 6.6kV 11kV 33kVNemitha LakshanОценок пока нет

- 18 30 KV 1-Core Cold Shrink Silicone Rubber Joint Kit Installation InstrumentДокумент8 страниц18 30 KV 1-Core Cold Shrink Silicone Rubber Joint Kit Installation InstrumentDkalestОценок пока нет

- 15kV PM Joints_Straight_KSU_500-500sq.mmДокумент8 страниц15kV PM Joints_Straight_KSU_500-500sq.mmabd elmohsen saedОценок пока нет

- Cable Installation InstructionsДокумент2 страницыCable Installation InstructionsZubab PanniОценок пока нет

- INSTRUCTION Heat Shrink Termination 3 Core Cables MV HV 6.6kV 11kV 33kVДокумент7 страницINSTRUCTION Heat Shrink Termination 3 Core Cables MV HV 6.6kV 11kV 33kVNemitha LakshanОценок пока нет

- Phase 2-Chassis Assembly (SM)Документ24 страницыPhase 2-Chassis Assembly (SM)myturtle gameОценок пока нет

- Cable Termination 11kV Heat Shrink TerminationДокумент8 страницCable Termination 11kV Heat Shrink TerminationmontadaaОценок пока нет

- Maintenance Coupling: Assembly Instructions For Butt-End Joints and RepairДокумент2 страницыMaintenance Coupling: Assembly Instructions For Butt-End Joints and RepairmusОценок пока нет

- DTS617/DTB617 Deadbreak Bolted Tee Connector: Power Systems Installation InstructionДокумент10 страницDTS617/DTB617 Deadbreak Bolted Tee Connector: Power Systems Installation InstructionMuhammad Lathieful HaqОценок пока нет

- Sikadur Injectokit LVДокумент3 страницыSikadur Injectokit LVRialno TambunanОценок пока нет

- Connectors: For 75-Ohm HELIAX and Radiax Coaxial Cable of Nominal Diameter 7/8" (22 MM)Документ2 страницыConnectors: For 75-Ohm HELIAX and Radiax Coaxial Cable of Nominal Diameter 7/8" (22 MM)ruizinho 1Оценок пока нет

- 15kV Indoor Termination_KSU_500sq.mmДокумент6 страниц15kV Indoor Termination_KSU_500sq.mmabd elmohsen saedОценок пока нет

- PROFILEДокумент6 страницPROFILEvalerynova86Оценок пока нет

- Wiring Diagram: Programmable Room ThermostatДокумент2 страницыWiring Diagram: Programmable Room ThermostatAndy CrissellОценок пока нет

- TDS Nitobond EP Saudi ArabiaДокумент3 страницыTDS Nitobond EP Saudi ArabiaSCCPL UKОценок пока нет

- Kit Empalme 3M Resina Mineria 8096-2Документ8 страницKit Empalme 3M Resina Mineria 8096-2Claudio Joaquin PérezОценок пока нет

- NLLK FLURESCENTE Ex Linear EmergencyДокумент4 страницыNLLK FLURESCENTE Ex Linear EmergencyJOSEОценок пока нет

- 15kV Outdoor Termination_KSU_500sq.mmДокумент5 страниц15kV Outdoor Termination_KSU_500sq.mmabd elmohsen saedОценок пока нет

- Level 2 Repair GuideДокумент8 страницLevel 2 Repair GuideRamíro ChocotecóОценок пока нет

- Fi - SCST Multimode Singlemode Connector - II PDFДокумент4 страницыFi - SCST Multimode Singlemode Connector - II PDFmirkofedorОценок пока нет

- ASS2005002801 D Roxtec RS Ex Seal Installation Instruction enДокумент4 страницыASS2005002801 D Roxtec RS Ex Seal Installation Instruction enRicardo RbОценок пока нет

- Nitomortar TC2000Документ3 страницыNitomortar TC2000Ahmed Imad Al-BdairiОценок пока нет

- Procedure For Wrapping & Coating Rev2Документ4 страницыProcedure For Wrapping & Coating Rev2Alpesh100% (5)

- Ig07 UserДокумент6 страницIg07 Userapi-3756260Оценок пока нет

- Monitor Signage: Service ManualДокумент12 страницMonitor Signage: Service ManualtaviОценок пока нет

- Yshield en GroundingДокумент1 страницаYshield en GroundingTonnie RostelliОценок пока нет

- Repairing Faulty EMV Backlight Inverter.: Table 1 Parts Required For RepairДокумент11 страницRepairing Faulty EMV Backlight Inverter.: Table 1 Parts Required For RepairJulian SchmitzОценок пока нет

- Nitomortar TC2000 Nitomortar TC2000: Constructive SolutionsДокумент3 страницыNitomortar TC2000 Nitomortar TC2000: Constructive SolutionsalbertooooooОценок пока нет

- LM M730aДокумент59 страницLM M730aapi-3711045100% (1)

- ACCESSORIES FOR ELECTRICAL CABLES INSTALLATIONДокумент8 страницACCESSORIES FOR ELECTRICAL CABLES INSTALLATIONZubab PanniОценок пока нет

- XT11S IT GB r1.0 18.06.2004Документ1 страницаXT11S IT GB r1.0 18.06.2004Jennifer Eszter SárközyОценок пока нет

- Repair of LG Rewriter 6721RFN021AДокумент13 страницRepair of LG Rewriter 6721RFN021Anoone42723Оценок пока нет

- Expanmortar SP PDFДокумент2 страницыExpanmortar SP PDFIrfan AkhtarОценок пока нет

- Boscoseal 16: Self Adhesive Sheet Waterproofing MembraneДокумент2 страницыBoscoseal 16: Self Adhesive Sheet Waterproofing MembraneShaun WongОценок пока нет

- Application Note AN 992: Beam Lead Attachment MethodsДокумент7 страницApplication Note AN 992: Beam Lead Attachment MethodsXavier G TeslaОценок пока нет

- RVR / Outlander Sport / Asx Floor Illumination (Blue) MZ360353EX Installation and Handling InstructionsДокумент12 страницRVR / Outlander Sport / Asx Floor Illumination (Blue) MZ360353EX Installation and Handling InstructionsKip ClayОценок пока нет

- Light Wave CommunicationДокумент105 страницLight Wave CommunicationVargheseMartinОценок пока нет

- CC3000 Adhesion Test Kit: SP1680, SP1681, SP1682, SP1683, SP1684 User ManualДокумент1 страницаCC3000 Adhesion Test Kit: SP1680, SP1681, SP1682, SP1683, SP1684 User Manualravi00098Оценок пока нет

- SOUTHERN CABLE 630mmsq Cu XLPEДокумент3 страницыSOUTHERN CABLE 630mmsq Cu XLPERozaimi GhazaliОценок пока нет

- Raychem Screened, Separable Connection System RSTI-68 800 A Up To 42 KVДокумент4 страницыRaychem Screened, Separable Connection System RSTI-68 800 A Up To 42 KVgiovany_vq91Оценок пока нет

- TDS Conbextra EP10 LV IndiaДокумент2 страницыTDS Conbextra EP10 LV IndiaAnanth KumarОценок пока нет

- TDS Nitofill EPLV BFLДокумент2 страницыTDS Nitofill EPLV BFLanandswarupОценок пока нет

- Installation instructions for cold-shrink termination on polymeric insulated cableДокумент6 страницInstallation instructions for cold-shrink termination on polymeric insulated cableQuang Kien NguyenОценок пока нет

- Grommet LED Task Light User Guide TorontoДокумент4 страницыGrommet LED Task Light User Guide TorontoĐức BùiОценок пока нет

- Quick Overview: Strengths The Most Flexible One: Technical Data SheetДокумент1 страницаQuick Overview: Strengths The Most Flexible One: Technical Data SheetJxyz QwОценок пока нет

- Beam Modification Devices in Radiotherapy 3Документ45 страницBeam Modification Devices in Radiotherapy 3Eskadmas BelayОценок пока нет

- Raychem Screened, Separable Connection System RSTI-58 800 A Up To 24 KVДокумент4 страницыRaychem Screened, Separable Connection System RSTI-58 800 A Up To 24 KVGiovany Vargas QuirozОценок пока нет

- Ê®Ú ºéä) Õ Éé Þ®Úòú Núù®Úºéæséé®Ú - É Ééämé Éé Éé B É (Éò - 7Документ7 страницÊ®Ú ºéä) Õ Éé Þ®Úòú Núù®Úºéæséé®Ú - É Ééämé Éé Éé B É (Éò - 7naveen_1507Оценок пока нет

- Esd 4873 Au 5 - 09 PDFДокумент13 страницEsd 4873 Au 5 - 09 PDFGeorge IstrateОценок пока нет

- Cat DeutschДокумент160 страницCat DeutschHernan F GodoyОценок пока нет

- TT4.55 Al TT4.75Документ38 страницTT4.55 Al TT4.75Hernan F GodoyОценок пока нет

- MWM Electronic Engine Circuit DiagramsДокумент44 страницыMWM Electronic Engine Circuit DiagramsHernan F GodoyОценок пока нет

- Get PDFAttachmentДокумент2 страницыGet PDFAttachmentHernan F Godoy100% (1)

- TT4.55 Al TT4.75Документ38 страницTT4.55 Al TT4.75Hernan F GodoyОценок пока нет

- PowerPole 153045 - 15A 30A 45AДокумент11 страницPowerPole 153045 - 15A 30A 45AHernan F GodoyОценок пока нет

- AMP SUPERSEAL 1.5 SERIES Connectors: Section Catalog 1654292-3 Main Catalog 1654400-1Документ8 страницAMP SUPERSEAL 1.5 SERIES Connectors: Section Catalog 1654292-3 Main Catalog 1654400-1Hernan F GodoyОценок пока нет

- Socapex - AmphenolДокумент8 страницSocapex - AmphenolHernan F GodoyОценок пока нет

- New Holland CR9060 Combine ConnectorsДокумент2 страницыNew Holland CR9060 Combine ConnectorsHernan F GodoyОценок пока нет

- AMP SUPERSEAL 1.5 SERIES Connectors: Section Catalog 1654292-3 Main Catalog 1654400-1Документ8 страницAMP SUPERSEAL 1.5 SERIES Connectors: Section Catalog 1654292-3 Main Catalog 1654400-1Hernan F GodoyОценок пока нет

- Socapex - ComponentesДокумент7 страницSocapex - ComponentesHernan F GodoyОценок пока нет

- SB 350 Connectors - Up To 450 AmpsДокумент5 страницSB 350 Connectors - Up To 450 AmpsHernan F GodoyОценок пока нет

- Section 55 - Electrical Systems Chapter 1 - General InformationДокумент34 страницыSection 55 - Electrical Systems Chapter 1 - General InformationHernan F GodoyОценок пока нет

- Temporary Wiring Harness Repair: SOLDER Only, Other Types of Solder May Result in Further DamageДокумент1 страницаTemporary Wiring Harness Repair: SOLDER Only, Other Types of Solder May Result in Further DamageHernan F GodoyОценок пока нет

- TT4.55 Al TT4.75Документ38 страницTT4.55 Al TT4.75Hernan F GodoyОценок пока нет

- Temporary Wiring Harness Repair: SOLDER Only, Other Types of Solder May Result in Further DamageДокумент1 страницаTemporary Wiring Harness Repair: SOLDER Only, Other Types of Solder May Result in Further DamageHernan F GodoyОценок пока нет

- Get PDFAttachmentДокумент2 страницыGet PDFAttachmentHernan F GodoyОценок пока нет

- Section 55 - Electrical Systems Chapter 1 - General InformationДокумент34 страницыSection 55 - Electrical Systems Chapter 1 - General InformationHernan F GodoyОценок пока нет

- SB 50 Connectors - Up To 120 AmpsДокумент6 страницSB 50 Connectors - Up To 120 AmpsHernan F GodoyОценок пока нет

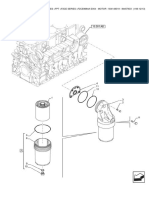

- New Holland F2CE Engine Oil FilterДокумент2 страницыNew Holland F2CE Engine Oil FilterHernan F GodoyОценок пока нет

- Sigma Marine Coatings Manual - Part8Документ2 страницыSigma Marine Coatings Manual - Part8EngTamerОценок пока нет

- Copper Pipe and Insulation 2009 Thailand or ChinaДокумент18 страницCopper Pipe and Insulation 2009 Thailand or ChinaLe Manh HieuОценок пока нет

- Waterloo RWV-plain-face-adjustable-circular-diffusersДокумент6 страницWaterloo RWV-plain-face-adjustable-circular-diffusersDan RotariОценок пока нет

- Alfa Laval Gphe Catalog 2022Документ20 страницAlfa Laval Gphe Catalog 2022JUAN ANTONIO HERNANDEZ SOSAОценок пока нет

- Fde 1Документ19 страницFde 1Ivan MarijanovićОценок пока нет

- Fuse in XpandercrossДокумент16 страницFuse in XpandercrossMUHAMMAD IKHWANUDINОценок пока нет

- Bridge Elastomeric Bearing PadsДокумент10 страницBridge Elastomeric Bearing PadsShwanОценок пока нет

- C-31 - Defence Colony - Terrace Garden ProposalДокумент7 страницC-31 - Defence Colony - Terrace Garden ProposalDevangie Shrivastava100% (1)

- Control Valve CV Calculation ManualДокумент86 страницControl Valve CV Calculation ManualDuong NguyenОценок пока нет

- Introduction To Bare Overhead ConductorsДокумент49 страницIntroduction To Bare Overhead ConductorsAlvin RamsaranОценок пока нет

- En GRP Vs PE CSДокумент19 страницEn GRP Vs PE CSbehzad sahandpourОценок пока нет

- F7az Em12kДокумент1 страницаF7az Em12kKara WhiteОценок пока нет

- MEN 321 Chapter 9 Flow Over Immersed BodiesДокумент81 страницаMEN 321 Chapter 9 Flow Over Immersed BodiesGeo AyoubОценок пока нет

- Amex Seals Product Data SheetsДокумент13 страницAmex Seals Product Data SheetscloantafОценок пока нет

- Arora BookДокумент18 страницArora BookGowtham SmartyОценок пока нет

- Pawling - Entrance MatsДокумент12 страницPawling - Entrance Matsmk779900mkОценок пока нет

- 1 - Introduction To AggregateДокумент22 страницы1 - Introduction To AggregateFatin HazwaniОценок пока нет

- DESIGN OF SHALLOW FOUNDATIONS FOR BUILDINGSДокумент19 страницDESIGN OF SHALLOW FOUNDATIONS FOR BUILDINGSJule LobresОценок пока нет

- TDS - Bronco Pre HDPE Membrane (S)Документ3 страницыTDS - Bronco Pre HDPE Membrane (S)Shreyansh UdaniОценок пока нет

- Corrosion-Guide 1 Stainless Steel CategoriesДокумент8 страницCorrosion-Guide 1 Stainless Steel CategoriesMarc L'abbéОценок пока нет

- ASI Rhinophalt Technical and SafteyДокумент2 страницыASI Rhinophalt Technical and SafteyIndrajeet UpadhyayОценок пока нет

- Principles of RCCДокумент28 страницPrinciples of RCCprashmce100% (1)