Академический Документы

Профессиональный Документы

Культура Документы

Large-Scale Biofloc Tank Culture in Malawi - A Technical Success Story - June 2017 Issue of WA Magazine

Загружено:

Ramon Kourie0 оценок0% нашли этот документ полезным (0 голосов)

78 просмотров5 страницTilapia tank culture in Malawi using Biofloc Technology (BFT) authors copy

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документTilapia tank culture in Malawi using Biofloc Technology (BFT) authors copy

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

78 просмотров5 страницLarge-Scale Biofloc Tank Culture in Malawi - A Technical Success Story - June 2017 Issue of WA Magazine

Загружено:

Ramon KourieTilapia tank culture in Malawi using Biofloc Technology (BFT) authors copy

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 5

Large-Scale Biofloc Tank Culture

of Tilapia in Malawi –

a Technical Success Story

Ray Kourie

Malawi — a Fish assimilation into new

Eating Nation bacterial cell biomass.

Although Malawi BFT simultaneously

is endowed with the provides an abundant

ninth largest lake in source of “bacterial

the world and the third plankton” and a

largest and second rich source of good-

deepest lake in Africa, quality protein

overfishing resulted in and nutrients for

the collapse of the tilapia filter-feeding fish

fishery around 1990- and shrimp — BFT

1991. Tilapia, known is then rather like

locally as chambo, is the killing two birds with

country’s favorite fish one stone. Figure 2

and now costs from US$ provides a schematic

4.00-8.00/kg (R55-110/ FIGURE 1. Imhoff cones are used to measure biofloc volume in BFT tanks at Chambo Fisheries. of the process of

kg) for whole or live fish. Biofloc Technology

This is a result of market scarcity which is unfortunate considering (BFT) to promote nitrogen uptake by heterotrophic bacteria which

the massive demand for the fish and its abundant availability at very then becomes a food source for tilapia and shrimp.

affordable prices (< US$1.50/kg) prior to 1990. Population growth Experience raising tilapia in BFT, where feeding rates per unit

at nearly 3 percent per annum in Malawi since 1990 has put the area are at least 4 to 5 orders of magnitude greater than shrimp BFT

anticipated supply shortfall of fish in the country at around 80,000 t systems, is limited. Knowledge gaps remain about BFT engineering

for 2017 based on sustaining 1990 per capita supply levels. economics, tilapia feeding systems and bioenergetics, cost factors

Tilapias are the preferred fish and the national dish in the and the economics of this new technology relative to conventional

country. A substantial market exists for producers capable of tilapia aquaculture systems. Insightful experience gained at Chambo

providing whole fish more competitively than dressed broiler Fisheries fills many of these knowledge gaps.

chickens, less than a cost of US$2.40/kg (R33.00/kg) in Malawi.

Under favorable economies of scale and scope, tilapia production Chambo Fisheries

using biofloc technology represents an attractive investment Chambo Fisheries is purportedly the world’s largest tilapia

proposition if that selling price can be matched. biofloc technology (BFT) tank farm and the largest such tank farm

in Africa, located on the outskirts of Blantyre, Malawi (Fig. 3). The

Biofloc Technology farm became operational in 2013 based on the mandatory production

Biofloc Technology (BFT) is a relatively new and potentially of Mozambique tilapia Oreochromis mossambicus and Shiranus

revolutionary technology that is especially productive for tilapia tilapia O. shiranus due to restrictions that forbid the importation and

and shrimp aquaculture. BFT is a sustainable and environmentally- culture of farmed breeds of Nile tilapia O. niloticus in the country.

friendly method of aquaculture that controls water quality and Despite the slow growth of Mozambique and Shiranus tilapias,

harmful pathogens along with providing value-added production compared to the best farmed breeds of Nile tilapia, good flavor

of microbial protein feed for the aquatic farm system. Bioflocs quality without purging, low feed conversion ratios (FCRs), year-

are clustered aggregations of microbial communities such as round production potential (upon completion of a shallow solar

phytoplankton, bacteria, and living and dead particulate organic pond supplemental heating system) and favorable economic factors

matter (Fig. 1). Shrimp and tilapia especially benefit from BFT due has Chambo Fisheries poised for expansion regionally. The system

to their ability to filter-feed on floc in the water column, thereby design was developed by the author of this article in his capacity as

reducing feed costs by improving feed conversion. Chief Technical Officer of SustAqua Fish Farms (Pty) Ltd. (SAFF),

The beauty of BFT is in the mechanisms for ammonia removal a South African concern, who developed the farm blueprints,

from water. Using feeds with a carbon to nitrogen (C/N) ratio greater production schedules, management systems and executed start-up,

than 15 results in the dominance of heterotrophic bacteria as the monitoring and management training.

major pathway for the removal of toxic nitrogenous compounds via (CONTINUED ON PAGE 26)

W W W.WA S .O R G • W O R L D A Q UACU LT U R E • J U N E 2 017 25

Vertically Integrated Farm Design

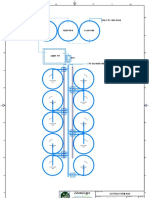

Chambo Fisheries operates a vertically integrated farming FIGURE 2.

operation that includes a quarantine facility, broodstock pairing A schematic of

tanks, an artificial incubation room for hatching eggs collected from the process of

female brooders, a dedicated nursery system, purging tanks, a moist biofloc technology

feed milling plant, an ice plant and cold-storage facilities apart from to promote

the Biofloc Technology (BFT) grow-out tanks. Figure 4 details the nitrogen uptake

farmed production cycle of Shiranus tilapia at Chambo Fisheries. via heterotrophic

The farm has eight large round-ended (R-ended) grow-out bacteria that

tanks, each holding 780 m3 of water and capable of producing up becomes a food

to 100 t of tilapia per tank in a year, or up to 130 kg/m3 of effective source for tilapia and

rearing volume per year via a multi-cohort sequential production shrimp.

schedule, although rearing densities average only around 20 kg/

m3. Because of the cool climate near Blantyre at 1130 m above sea

level, all production facilities require placement within greenhouse

enclosures. Supplemental heat is sourced from shallow solar ponds

(SSP) coupled to a hydronic heating system that includes stainless

steel heat exchangers built into the tank floor that are regulated by

thermostatically actuated heat exchange pumps.

The design of the R-ended BFT grow-out tanks by SAFF at

Chambo Fisheries is novel in many respects. The tanks include a

built-in lamella separator for solids capture and removal. Control over

floc concentration in the water column and the retention time of fecal

and organic material is achieved by regulating water flow through

the lamella separator from a full-width floor drain in the main tank.

Water is pulled through the lamella separator through development of

a water head differential at the far end of the central channel by using

a multiple-pod airlift pump that permits flexible control over water FIGURE 3. A battery of eight 766-m3 multi-cohort sequential SAFF-BFT

pumping rate. grow-out tanks at Chambo Fisheries near Blantyre, Malawi.

Every aspect of the BFT R-ended tank design aims to minimize

capital and operating costs, taking full advantage of the superior indicating the high rate of crop turnover relative to system carrying

hydraulic environment created by the integrated R-ended tank capacity.

design, creating a beneficial streaming effect while improving the The use of a multi-sequential, multi-cohort production system

driving concentration gradient for oxygen transfer by carefully in essence doubles output production and halves input power costs

selected and positioned aeration devices. in comparison to batch production, which yields an effective P:C

Forced moderate exercise has been shown to induce muscle ratio of only 2.4. Economic viability is greatly enhanced due to

hypertrophy, improve growth rates and reduce the energetic costs the doubling of production output based on the same investment

of protein accretion. Fish that are fed under continuous moderate in equipment and infrastructure compared to a batch production

exercise exhibit a shift in metabolism to derive energy for swimming system. This unique innovation by SAFF, called the SAFF One-Tank

activity largely from carbohydrates and lipids rather than protein, Husbandry Approach, was first pioneered by the company in the

a survival mechanism to spare protein loss from the muscle. This Middle East on two RAS farms and a third RAS farm in Malawi.

results in fish at harvest with a lower fat content while FCRs are Shiranus tilapia reach an average marketable weight of 218 g

reduced, growth is enhanced, flesh texture firmness is improved, and in 189 days from hatch at a temperature range of 27-29 C. Although

fillet yields are elevated marginally (more plump fish relative to their purging fish to improve flavor quality is practiced, it is unnecessary

body lengths). Horizontal water velocity control in the range 15-30 in well-managed BFT systems because the fish carry no off-flavors or

cm/sec is achieved by adjusting the submergence depth of the paddles flavor taints. Fish are sold whole on ice and no processing takes place

on paddlewheel aerators. on site.

Multi-cohort Production Specialized Feeds Produced On Site

The farm design has been tailored to take advantage of the Feeds — including broodfish diets, starter feeds and specialized

benefits of continuous sequential production where each grow-out C/N ratio feeds — are produced on-site using a low-cost moist-pellet

tank is stocked and harvested every three weeks. This production milling plant that produces sinking pellets of medium to low water

strategy is enabled by using screened compartments (Fig. 5) where stability. The major components of the Chambo Fisheries feed plant

fish are moved in a conveyer fashion every three weeks to a larger include a hammer mill and a combination grinder, mixer and moist

compartment using simple crowding screens. This management feed pelletizer, and a horizontal dryer and grading sieves for starter

technique results in production output yields of 4.6-5.8 t every three feed production on-site.

weeks. This elevates the production to capacity (P:C) ratio to 5.5-6.2, Feeds for fish >5 g are all animal protein-free and are based

26 J U N E 2 017 • W O R L D A Q UACU LT U R E • W W W.WA S .O R G

such as copper, iron and manganese as these tend to accumulate and

are recycled through the biofloc. An iterative metal homeostasis model

has been constructed that allows for the optimization of customized

diets for BFT by SAFF given response data derived from actual

systems.

Bioenergetics and Feeding Strategy

Feed often makes up 55-65 percent of the final farm-gate

production cost in conventional tilapia culture systems, such as

greenwater ponds, lake-cage culture, and recirculating aquaculture

systems (RAS). Chambo Fisheries has been able to routinely achieve

FCRs that average around 1 feeding a 20.2 percent protein feed (equal

to a C/N ratio of 15.5) raising Mozambique and Shiranus tilapias.

Such huge shortfalls in the supply of protein in formulated feed means

that fish must obtain the balance of their needed protein — ranging

from 55-60 percent of total required protein intake — through filter

FIGURE 4. Farmed production cycle of Shiranus tilapia from a four-tank feeding on biofloc. This is not surprising considering the high carbon

biofloc technology module producing up to 400 t/yr of 218-g fish year-round. conversion efficiency via the “heterotrophic microbial loop” of around

40-60 percent into heterotrophic bacterial cell biomass and the very

short trophic pathway (lower trophic energy losses) of microbial

aquaculture systems. The basic pathway is dissolved C + N → C + N

in microbial biomass → C + N in farmed organisms.

Table 1 illustrates the advantage of biofloc-raised tilapia at

Chambo Fisheries, achieving impressive performance metrics of

36.6 percent Net Protein Retention (NPR) and 20.9 percent Net

Energy Retention (NER) on an edible meat yield basis. Based on

results achieved at Chambo Fisheries, bioenergetic feeding rate

models include the contribution of biofloc harvested by filter feeding

tilapia, ranging from 20 to 25 percent of the Digestible Energy (DE)

requirements of live-weight fish. Bioenergetic feeding rate models have

not been properly applied to biofloc tank culture of tilapia and process

optimization studies by the global research community are needed.

FIGURE 5. A single multi-cohort sequential 766-m3 SAFF-BFT grow-out The work at Chambo Fisheries by SAFF represents first attempts to

tank at Chambo Fisheries. optimize feeding rates, considering the contribution of biofloc grazing

towards meeting a portion of the daily DE requirements of the fish

solely on oilseed meals and maize plus vitamin and mineral pre- reared.

mixes. In addition to premixes, additives include choline chloride, For NPR, biofloc tilapia production is more than 100 percent

vitamin C, monocalcium phosphate, an organic acid, molasses used more efficient than tilapia production in a RAS system and 162 percent

as a nutritive binder and most importantly the use of mycotoxin more efficient than lake cage culture (Table 1). These results suggest

absorbent which is mandatory under BFT conditions in Malawi due that properly managed biofloc tank culture of tilapia is potentially the

to the high prevalence of aflatoxin and other mycotoxins in locally most efficient form of feedlot animal production, outperforming lamb,

sourced maize. broiler chickens, pigs and beef steers as well as feedlot aquaculture

Best results were achieved with a 20.2 percent protein feed systems raising Atlantic salmon in net-pens and tilapia under typical

that provides an input C/N ratio of about 15.5 based on the use of lake cage culture, greenwater pond farming and RAS conditions in

bioenergetic feeding rate models constructed by SAFF where FCRs terms of protein recovery on an edible yield basis (Table 1).

average about 1. Meal intervals were spaced four hours apart and the From an economic perspective, results at Chambo Fisheries

day’s first meal size was the largest at 50 percent of the daily Feed represents a 50 percent feed cost saving when compared to feeding

Allotment (dFA). Tests conducted using feeding trays indicated that fish on conventional 32 percent protein feeds raised in a RAS. The

all feed is consumed at the specified meal intervals, meal percentage merits of BFT include a significant reduction in the final farm-gate

of dFA and feed applied within five minutes. The ability to custom- production cost of raising tilapias to around US$1.30/kg (about R17.70/

formulate feeds on site allows for adjustments to the formulation kg) in Malawi in 2016. A comprehensive economic study based on

with ease. During the start-up of BFT, over the first 45-60 days, feeds data gathered at Chambo Fisheries shows BFT farms to potentially

require additional vitamin C fortification and sometimes the addition produce tilapia at about 60 percent lower cost than large-scale cage

of crushed garlic to improve the immune response in fish until the culture, 34 percent less than RAS and 8.5 percent less than greenwater

biofloc becomes mature. pond farming, assuming all farms are located in or near Lake Malawi.

After three months of continuous operation, it is necessary to

reduce mineral inclusion levels in BFT tanks, particularly metals (CONTINUED ON PAGE 28)

W W W.WA S .O R G • W O R L D A Q UACU LT U R E • J U N E 2 017 27

Water Use Efficiency emissions and solids loadings into sensitive lake ecosystems such as

Another big advantage of BFT is the massively reduced water Lake Malawi.

requirement compared to conventional tilapia aquaculture systems. Four selected tilapia grow-out technologies were compared

Currently Chambo Fisheries uses around 150 L of water to produce (Table 2) on the basis of the following sustainability indicators:

1 kg fish, which compares well against greenwater pond culture that • Feed conversion ratio (kg feed/kg edible weight),

requires 2500-5000 L/kg of fish. The high annual fish yields per unit • Whole carcass protein efficiency (%),

tank surface area and volume and reduced water use in BFT opens • Nitrogen emission (kg/t protein produced),

up great possibilities for applications in greenhouse enclosures on the • Phosphorus emission (kg/t protein produced),

highlands of Africa and on the periphery of major cities, reducing • Land use (t edible product/ha), and

transport logistics to urban markets. The results obtained by Chambo • Consumptive freshwater use (m3/t).

Fisheries clearly highlight the merits of BFT as a competitive and By these measures, the SAFF-BFT system performs best,

sustainable alternative low-cost intensive feedlot technology for followed by the SAFF-RAS. Greenwater pond farming has poor

tilapia aquaculture. input:output nitrogen and phosphorus efficiency ratios, likely

caused by high N losses through volatilization and denitrification

Environmental Sustainability to the atmosphere and P losses to the sediment, despite being a low-

BFT tilapia along with RAS farms, particularly when cost production technology. Clearly, the lake cage culture model

incorporating an aquaponics component, with or without duckweed represents a relatively less sustainable form of intensive tilapia

(Lemna spp.) nutrient recovery lagoons designed to achieve zero aquaculture (Table 2) where no opportunity exists to recover neither

effluent status, represents exemplary Best Management Practice dissolved and fecal-bound nutrients or organic matter that can

(BMP). Direct loading of organic solids and dissolved nitrogen and overload the nearby benthic environment of lake ecosystems.

phosphorus emissions to receiving surface water bodies can be

eliminated in BFT and RAS farms, thereby comparing favorably to The Future of SAFF and Chambo Fisheries

lake-cage culture operations that are characterized by high N and P BFT promises to revolutionize tilapia and shrimp aquaculture

28 J U N E 2 017 • W O R L D A Q UACU LT U R E • W W W.WA S .O R G

industries globally. Some leading scientists believe that harnessing SAFF has moved operations from the Middle East and Sub-

the flow of microbes to fish represents the next revolution in food Sahara African countries to focus on South Africa in support of

production. Chambo Fisheries aims to expand operations into various initiatives, including BFT farms that include an aquaponics

warmer regions of Malawi and internationally using the same design component and multitrophic land-based marine RAS farming of

templates with minor improvements (a second generation BFT several high-value finfish species on the East Cape coast and Atlantic

system) to be supplied by SAFF, based on technical successes at the salmon farming on the West Cape coast.

less-than-ideal site on the outskirts of Blantyre, Malawi.

W W W.WA S .O R G • W O R L D A Q UACU LT U R E • J U N E 2 017 29

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- 14 Aquaculture Technologies Implemented by NFDBДокумент66 страниц14 Aquaculture Technologies Implemented by NFDBVenkyОценок пока нет

- Fisheries WK 10Документ47 страницFisheries WK 10Nick254Оценок пока нет

- Economics of Fish Hatcheries and Grow OutДокумент17 страницEconomics of Fish Hatcheries and Grow OutFoy FauziОценок пока нет

- Fish Diseases and Disorders, Volume 1 Protozoan and Metazoan Infections, 2nd Edition (VetBooks - Ir) PDFДокумент801 страницаFish Diseases and Disorders, Volume 1 Protozoan and Metazoan Infections, 2nd Edition (VetBooks - Ir) PDFAdel EL GD100% (1)

- Ahsan Agro RAS Catfish - High DensityДокумент1 страницаAhsan Agro RAS Catfish - High DensityFortaengineering FortaenviroОценок пока нет

- Fish Supply Chain Management - Upstream & Downstream IssuesДокумент25 страницFish Supply Chain Management - Upstream & Downstream IssuesASHISH RAJОценок пока нет

- IoT Smart Fish Farming SystemДокумент9 страницIoT Smart Fish Farming SystemMd Bulbul AhmedОценок пока нет

- IAF1801 Til2Документ5 страницIAF1801 Til2Ramon KourieОценок пока нет

- FW Article Feb 2004Документ2 страницыFW Article Feb 2004Ramon KourieОценок пока нет

- IAF1801 Til2Документ5 страницIAF1801 Til2Ramon KourieОценок пока нет

- Industrial Ecology Korhonen PDFДокумент15 страницIndustrial Ecology Korhonen PDFRamon KourieОценок пока нет

- Fish To 2030 The Role and Opportunity For AquacultureДокумент20 страницFish To 2030 The Role and Opportunity For AquacultureRamon KourieОценок пока нет

- Fishhatcherymana00pipe PDFДокумент544 страницыFishhatcherymana00pipe PDFRamon KourieОценок пока нет

- Review ArticleДокумент23 страницыReview ArticleRamon KourieОценок пока нет

- Fishhatcherymana00pipe PDFДокумент544 страницыFishhatcherymana00pipe PDFRamon KourieОценок пока нет

- Publication 497Документ22 страницыPublication 497Ramon KourieОценок пока нет

- Salmon Farming in SA Prospects and Potential - Press Coverage 1994 - 95 PDFДокумент3 страницыSalmon Farming in SA Prospects and Potential - Press Coverage 1994 - 95 PDFRamon KourieОценок пока нет

- Journal of Cleaner Production 10 (2002) 197–214Документ18 страницJournal of Cleaner Production 10 (2002) 197–214Ramon KourieОценок пока нет

- Periphyton Biofilm and BiofoulingДокумент8 страницPeriphyton Biofilm and BiofoulingRamon KourieОценок пока нет

- A Comparative Study of The Purification of Aquaculture Wastewater Using Water Hyacinth - Water Lettuce and Parrots FeatherДокумент14 страницA Comparative Study of The Purification of Aquaculture Wastewater Using Water Hyacinth - Water Lettuce and Parrots FeatherRamon KourieОценок пока нет

- Aquaculture Asia October 2012Документ44 страницыAquaculture Asia October 2012Ramon KourieОценок пока нет

- The Potential of Fish Production Based On PeriphytonДокумент32 страницыThe Potential of Fish Production Based On PeriphytonRamon KourieОценок пока нет

- Cage Culture Trials in Rwanda (09feb12) Word 2003Документ12 страницCage Culture Trials in Rwanda (09feb12) Word 2003Ramon KourieОценок пока нет

- Conservation of The African Great Lakes: A Limnological PerspectiveДокумент14 страницConservation of The African Great Lakes: A Limnological PerspectiveRamon KourieОценок пока нет

- Cage Culture Trials in Rwanda (09feb12) Word 2003Документ12 страницCage Culture Trials in Rwanda (09feb12) Word 2003Ramon KourieОценок пока нет

- Yi Et Al 2003 AquacultureДокумент14 страницYi Et Al 2003 AquacultureRamon KourieОценок пока нет

- Guidelines NFDB Schemes & Blue Revolution-Inland Fisheries SchemesДокумент15 страницGuidelines NFDB Schemes & Blue Revolution-Inland Fisheries SchemesKrishna DevavarapuОценок пока нет

- AlgicideДокумент16 страницAlgicideRISHIKAОценок пока нет

- Factors Affectingaquaculture Productioninuganda, Gulu DistrictДокумент52 страницыFactors Affectingaquaculture Productioninuganda, Gulu DistrictOLOYA LAWRENCE KABILAОценок пока нет

- Milkfish culture techniques for fishpondsДокумент17 страницMilkfish culture techniques for fishpondsNiño Jess Mar MechaОценок пока нет

- USAID - Report On Agribusiness SectorДокумент7 страницUSAID - Report On Agribusiness SectorFulbari EnterpriseОценок пока нет

- Fish Nutrition PPT Title Defense 1Документ17 страницFish Nutrition PPT Title Defense 1Cristel Mae De GuzmanОценок пока нет

- White Paper On The Role of IoT in The Fisheries Sector 190321Документ76 страницWhite Paper On The Role of IoT in The Fisheries Sector 190321Indrawan SuparanОценок пока нет

- FYP ProposalДокумент16 страницFYP ProposalMichelle KamОценок пока нет

- Srac 0260Документ4 страницыSrac 0260Wahyu SatriojatiОценок пока нет

- Package of Practices - Breeding & Culture - Freshwater Fish Species - October2018Документ88 страницPackage of Practices - Breeding & Culture - Freshwater Fish Species - October2018Vijayagopal PanikkerОценок пока нет

- FAO Project On Gillnet in Indonesia-2017Документ77 страницFAO Project On Gillnet in Indonesia-2017iyus_sariОценок пока нет

- Isabela Therese Dedel BSFi 2-3Документ3 страницыIsabela Therese Dedel BSFi 2-3Isabela Therese DedelОценок пока нет

- Small-Scale Fish Farming in RwandaEconomic CharacteristicsДокумент12 страницSmall-Scale Fish Farming in RwandaEconomic CharacteristicsLuc KoneОценок пока нет

- The Global Seafood Revolution: George Chamberlain President Global Aquaculture AllianceДокумент37 страницThe Global Seafood Revolution: George Chamberlain President Global Aquaculture AllianceLuisОценок пока нет

- Fish SeedДокумент100 страницFish Seedanu_sat100% (2)

- Indian Carp (Catla Catla)Документ17 страницIndian Carp (Catla Catla)anu_satОценок пока нет

- AquacultureДокумент74 страницыAquacultureFlorenda IguinОценок пока нет

- Marine Shrimp FarmingДокумент19 страницMarine Shrimp FarmingVikas SainiОценок пока нет

- Ashton 2008 ShrimpmangroveДокумент13 страницAshton 2008 ShrimpmangroveAjay PandeyОценок пока нет

- AHDF manual for transparencyДокумент42 страницыAHDF manual for transparencyRaghava GoudОценок пока нет

- Kondisi Gracilaria Di Kabupaten Bone Sulawesi SelatanДокумент11 страницKondisi Gracilaria Di Kabupaten Bone Sulawesi SelatanGhamal WahabОценок пока нет

- Tilapia Farming with Moringa-Based FeedДокумент6 страницTilapia Farming with Moringa-Based FeedRoan Eam TanОценок пока нет